Stratus MS9000XT User manual

Save these instructions!

This equipment should not be installed, operated or repaired without first reading instructions.

Failure to follow the instructions and safety can result in serious injury or death.

Electricity should be hooked up by a certified electrician.

Do NOT use equipment beyond its rated capacity.

Keep manual near lift for reference

By proceeding with installation and operation, you agree that you fully understand the contents of

this manual and assume full responsibility for product use.

Only Operate this lift if it can be done so safely.

IMPORTANT NOTE:

1.

2.

3.

4.

5.

6.

7.

8413 Calibration Ct.

College Station, Tx USA

Telephone:(512)640-9896

stratusautoequip.com

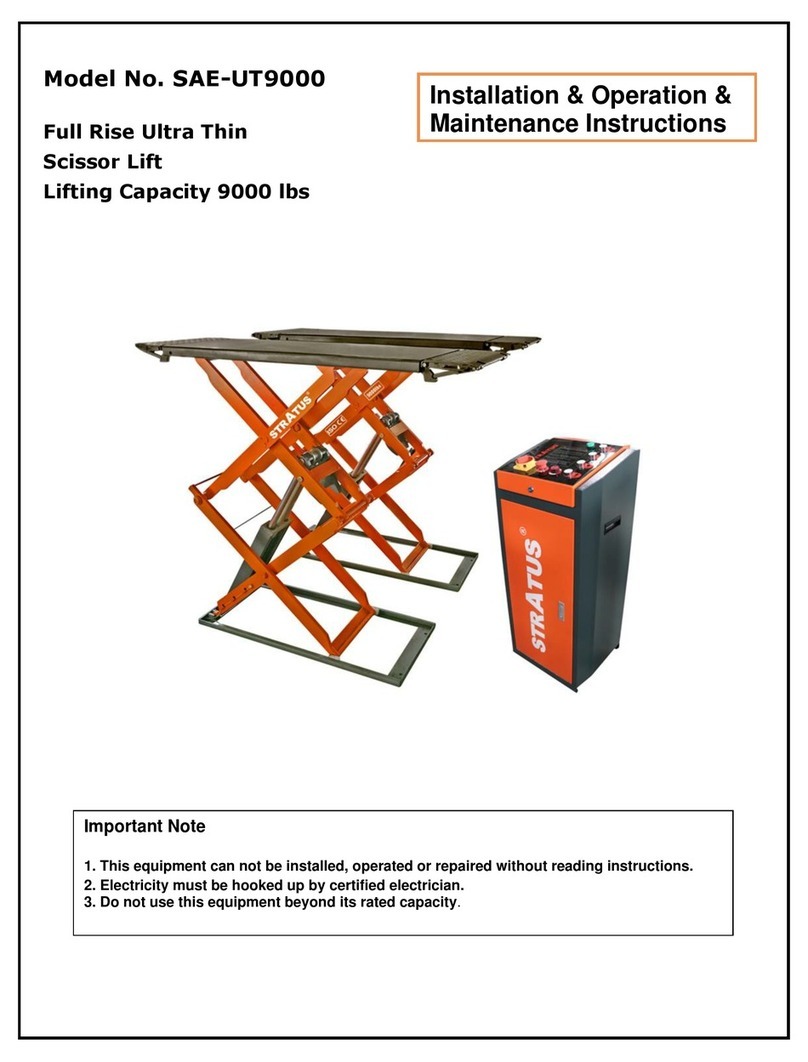

: MS9000XT

Manual SAEMSSERIES— Revision A1 — July2023

Models

SHOWN: MS9000X

Safety - Installation - Operation - Maintenance

Extra Wide Commercial Grade Open Center Mobile Mid Rise

Electric Safety Lock Release Scissor Vehicle Lift

Manual - MS9000XT- Extra Wide Commercial Grade Open Center Mobile Mid Rise Electric Safety

Lock Release Scissor Vehicle Lift - Safety - Installation - Operation - Maintenance -MSSERIES—

Revision A1 — July 2023

Copyright - Copyright © 2023 by Stratus Metals, Inc. dba Stratus Auto Equipment reserves all rights.

Copies may be made of this document if you agree full attribution to Stratus Metals Inc. Changes and

Copies for commercial purposes to this document are prohibited.

Trademarks- Stratus Auto Equipment and logo are registered trademarks of Stratus Metals, Inc. All

other company, product, and service names are used for identification only. All trademarks and

registered trademarks mentioned in this manual are the property of their respective owners.

Limitations- Whereas every effort has been made to ensure this manual has complete and accurate

information; Product updates, revisions, and/or changes could have occurred since this manual was

written and published. Stratus Auto Equipment reserves the right to change any information in this

manual without incurring any obligation for equipment previously or subsequently sold. Stratus Auto

Equipment is not responsible for typographical errors in this manual.

Safety- Your product was designed and manufactured with safety in mind. However, your safety also

depends on proper training and thoughtful operation. Do not install, operate, maintain, or repair the

unit without reading and understanding this manual and the labels on the unit; do not use your Lift

unless you can do so safely!

Owner Responsibility- In order to ensure operator safety and maintain your product properly, it is

the responsibility of the product owner to read and follow these instructions:

• Follow all setup, operation, and maintenance instructions.

• Make sure product setup and use conforms to all applicable local, state, and federal codes, rules,

and regulations, such as state and federal OSHA regulations and electrical codes.

• Read and follow all safety instructions. Keep them readily available for operators.

• Make sure all operators are properly trained, know how to safely operate the unit, and are properly

supervised.

• Do not operate the product until you are certain all parts are in place and operating correctly.

• Carefully inspect the product on a regular basis and perform all maintenance as specified.

• Service and maintain the unit only with approved replacement parts.

• Keep all instructions permanently with the product and make sure all labels are clean and visible.

Stratus Auto Equipment makes no promises, guarantees or assurances that our products meet any state, county, federal or

international mandated permit, license, code, standard, certification, or any other mandate other than what is listed or shown

on Stratus Auto Equipment's website. Not all of Stratus Auto Equipment lift models meet the standards as prescribed by

ANSI/ALI ALCTV-(current edition) or ANSI/UL 201. Consult www.autolift.org for a complete list of lift models that meet

ANSI/ALI ALCTV-(current edition) or ANSI/UL 201 or contact support@stratusautoequip.com

Buyer assumes full responsibility for any state, county, federal or international mandated permit, license, code, standard,

certification, or any other mandate required related to the installation and/or operation of any Stratus Equipment. Stratus will

not be responsible for any charges, fines, liens, or other levies imposed on the Buyer related to any special or regional

structural, seismic or any other building code and/or codes such as the Uniform Building Code (UBC), International Building

Code (IBC), or any other state, county, federal or international mandated permit, license, code, standard, certification, or

other mandate, law, rule, regulation or directive by any other agency, government, administrations, or corporations whether

state, county, federal, or international mandated.

Unit Information

Be sure to document

the Model Number,

Serial Number, and

Date of Manufacture

from the label on your

unit. This information

is required for part or

warranty issues.

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Chapter 5

Chapter 6

Chapter 7

Chapter 8

Chapter 9

Chapter 10

Contents

Introduction

Symbols

Liability

Safety Instruction

Labels

FAQ

Warranty

Shipping

Returns

Parameters

Features

Components

Electrical

Checklist

Preparation

Installation

Operation

Troubleshooting

ALI

Exploded View

Chapter 11

Chapter 12

Chapter 13

Chapter 14

Chapter 15

Chapter 16

Chapter 17

Chapter 18

Chapter 19

Chapter 20

Introduction

This manual is designed to help customers use Stratus MS series scissor lifts.

These are mid rise, with an open center that provides full under vehicle access.

These lifts can be installed at ground level or flush mounted (in ground).

These lifts come with a capacity of 9000 Lbs.

Stratus does recommend keeping this manual within reach of the lift for anyone

who is to use or service the machine. Frequently asked questions and

Troubleshooting have been included within this manual. If you question and/or

issue which is not answered here, please contact us at 512-640-9896 or email

4

5

5

6

9

11

14

14

14

15

15

16

18

19

20

22

32

36

37

38

Calls attention to information that can help you use your product

better.

Following are the symbols used in this manual:

⚠

DANGER Calls attention to an immediate hazard that will result in injury or

death.

⚠

WARNING Calls attention to a hazard or unsafe practice that could result in

injury or death.

⚠

CAUTION Calls attention to a hazard or unsafe practice that could result in

minor personal injury, product, or property damage.

NOTICE Calls attention to a situation that, if not avoided, could result in

product or property damage.

Tip

Symbols

Stratus Auto Equipment assumes no liability for damages resulting from:

•Use of the product for purposes other than those described in this manual.

•Modifications to the equipment without prior, written permission from Stratus

•Injury or death caused by modifying, disabling, overriding, or removing safety

features.

•Damage to the equipment from external influences.

•Incorrect operation of the equipment.

Liability

Make sure that you have read the User’s Manual completely including relevant

instructions on installation, operation and safety before operating the lift.

This lift is designed for lifting vehicles. Any other use may result in damage of the

lift or injury to personnel.

Only those who have been properly trained should operate the lift. The vehicle

customer or inexperienced persons are prohibited from operating the lift at will.

Keep children and untrained personnel away from the Lift.

Do not overload the lift beyond its rated capacity. To reduce the risk of injury,

never attempt to lift more than the rated capacity. Refer to loading instructions.

The lift is designed to lift the entire body of vehicles with weight within the lifting

capacity.

If lift designed for indoor use only. Outdoor use is prohibited

Do not install lift on any surface other than concrete that is at least 6" thick and

has set for at least 30 days.

Do not move away from controls while lift is in motion.

Keep hands and feet away from any moving parts, Do not put hands at any

dangerous place, such as the space between tool arms.

Do not wear any loose clothing that could be caught in moving parts. Keep hair,

fingers, and all parts of body away from moving parts. Always wear appropriate

safety equipment during operation.

Keep area around lift clean to avoid incidents. Any oil stain or obstacle may pose

a safety risk.

Always ensure the safety latches are operational before any attempt to work

near or under the vehicle. Be sure to perform mechanical locking after the

vehicle is lifted. It is prohibited to work under the vehicle before mechanical

locking is performed.

Ensure regular maintenance is completed. If anything, abnormal occurs, stop

using lift and immediately contact us for help. Do not use the lift if any

abnormality is found.

Do not rock vehicle while on lift or remove heavy components that may cause

weight shift as vehicle could fall.

Safety Instructions

The warning, cautions and instructions discussed in this manual cannot cover

all possible conditions and situations that may occur. It must be understood by

the operator that common sense and caution are factors which cannot be built

into this product, but must be supplied by operator.

ALWAYS ensure the mechanical safety locks are engaged. Never remove safety

related components from the lift. Do not use if safety related components are

damaged or missing.

Failure to correctly install, operate, or any improper modifications could result

in injury or death of operators.

WARNING:

1.

2.

3.

Do not modify any part of the lift without manufacturers advice. Do not make

any modifications to the Lift; this voids the warranty and increases the chances

of injury or property damage.

If lift is not in use, lower to the lowest position and disconnect power. Be sure to

cut off the power supply after the use of lift.

It is prohibited to lift the vehicle when someone is in the vehicle.

When a vehicle is being loaded onto or unloaded from the lift, no person is

allowed to stand in the vehicle passage.

Do not use the Lift while tired or under the influence of drugs, alcohol, or

medication.

Keep areas well lit.

Keep loads balanced on the Lift Platforms. Clear the area immediately if a

Vehicle is in danger of falling off the Lift. DO NOT ATTEMPT TO CATCH!

The rubber pad of the small scissor lift must have contact with the support point

of the vehicle, otherwise the vehicle chassis may be damaged. (It is

recommended to consult the vehicle manufacturer by telephone if the location

of the support point is not clear.)

Make sure there is no obstacle under the vehicle before lowering it

If the lift will be left unused for a long period of time, it is recommended that the

user disconnects power, empty the oil tank, and lubricate any moving parts with

hydraulic oil.

Attention: For environment protection, please dispose the disused oil in a proper way.

Safety Signs

Caution

Never stand, work or be

under the lift while it is

being operated

Caution

Operator should not

stand too close to lift but

in a safe position away

from moving parts

Warning

When the lift is lowered,

no auxiliary stand or

other blocking objects

should be near the lift

Warning

Do not shake or push

vehicle while it is on the lift

Warning

Only trained technicians

are permitted to operate

lift

Caution

Ensure feet and other

body parts are clear of lift

when lifting or lowering

Caution

Never try to lift or lower

only 1 platform

Warning

Do not change, tamper or

interfere with the safety

mechanisms of this lift

Warning

Ensure that the lifting

weight of the vehicle is

balanced on both

platforms to avoid tilting

or sliding

Warning

High voltage in control box,

use extreme caution

All safety warning labels are clearly depicted on the lift to ensure that the operator is

aware of and avoids the dangers of using the lift in an incorrect manner. The labels

must be kept clean and they have to be replaced if detached or damaged. Please

read carefully the meaning of each label and memorize them for future operation.

Labels

A

Keep feet clear of the lift

when lowering

B

Make sure the mechanical safety

has been locked before working

under the car

C

D

E

CAUTION

Only trained personnel is allowed to use the

lift.

Read the entire manual before operating

Never try to raize the vehicle exceding lift

capacity

Make sure you meet all safety requirements

before you start working under the vehicle

Surrounding of lift will remain clear when

raising or lowering

The manufacturer and distributor will not take

any responsibility if user does not follow the

operation manual that comes with the lift

Measurements

Frequently Asked Questions

What thickness of concrete do you recommend?

We recommend 6-12 inches reinforced concrete that has cured for at

least 28 days.

What is the recommended PSI for the concrete?

We recommend a psi of 3,000

Does the lift come with anchor bolts and how many?

Yes the lift comes with Anchor Bolts. There will be 16 in total

What are the specs of the Anchor Bolts?

The Anchor bolts are 3/4 diameter 6” long anchors bolts

What are the torque specifications?

We recommend 90 foot-pounds, never less than 80 or more than 110

foot-pounds.

What is the recommended breaker for this lift?

We recommend a 30A breaker

Does this lift come with a plug?

The lift does not come with a plug, you will need to get a 220v-250v,

30A plug

How do I hook up the electrical?

Yellow/green is ground, the other 2 are hot

How long does the power cord reach?

The cord is 11 feet

Is there a way to change the speed of the lift?

Yes, with the oil flow valve, you can tighten (clockwise) which will slow

the lift, or loosen (counter clockwise) which will speed up the lift.

How do I lower the lift that is stuck in the air?

Release the safety locks and then release pressure of the hydraulic

system.

Warranty

5 Years Structure - Platform, Safety Lock System

3 Years Hydraulic - Cylinder, Seal Kits, Gear Pump

2 Years Electrical - Motor, AC Contactor, PLC, Solenoid, Limiter Switches,

Power Light, Buttons, Capacitors

1 Year Functional Components - Safety Covers, Hydraulic Hoses, Fittings,

Reservoir, Oil/Water Regulator, Slider Blocks

No Warranty Odds and Ends - Rubber Pads

Shipping

Returns/Cancellations/Refunds

Returns are only accepted within 14 days from the delivery date, buyer pays

return shipping which is non-refundable unless the item sent is incorrect or

faulty.

Merchandise must be unused and packed with the original packages.

Proof of payment must accompany the return.

All returned merchandise are subject to inspection. If you are entitled to a

refund then we will refund the price of your item.

We CHARGE 30% HANDLING & RESTOCKING FEE if you want to return or

cancel the order after we ship out the item. If you choose to cancel your

order before we ship it out, your money will be refunded minus a $250

processing fee.

Refunds are usually processed within 7 working days of receipt. However,

during busy periods this may take longer. We will contact you via email as

soon as we have processed your return. Please make sure that your inbox

can receive emails from [email protected], as this is the email

address that we will use to contact you.

We only offer refunds onto the original payment method used to make the

order.

CHECK SHIPMENT UPON ARRIVAL

Whereas, we do take precautions to make sure your product gets to you in one

piece. There are rare instances where a product may get damaged in transit. You

should thoroughly inspect the shipment to make sure all pieces and parts have

arrived and document on the bill of lading before accepting. If you are missing

any part or damage has occured, contact us so we can help correct the issue.

Please document pictures for records.

Packaging

1 basic unit packed in a large wooden box, including all accessories, with base.

1 power unit packed in a small wooden box with base.

Model

MS9000XT

Rated Lifting Capacity

9,000 lbs

Driving Mode

Electro Hydraulic Drive

Lifting Height

47 1/4" (1200 mm)

Overall Length

85 1/4" (2182 mm)

Overall Width

77 3/16" (1930 mm)

Platform Length

62 5/8" (1590 mm)

Platform Width

20 1/2" (520 mm)

Motor Parameters

220V / 110V, 202 KW

Hydraulic Oil

46 # / 68 #

Equipment Weight

1,631 LBS (740KG)

Parameters

Features

Moveable Ramp which can be used as extension board

Monolithic base-plate without splice

Stable and reliable control system

Aluminum alloy motor with low noise and fast heat dissipation

Installation

Only skilled technicians, appointed by the manufacturer or authorized

dealers are to be allowed to carry our installation. Serious damage to

people and to the lift can be caused if installations are made by unskilled

personnel

Always refer to the exploded views attached during installation

Rotary Hammer Drill D.20

Carpenter’s Chalk

Hammer

Screw Sets

Level Bar

Tape Measure (7.5m)

English Spanner (12")

Lock Wrench

Wrench set

(10#, 13#, 14#, 15#, 17#,

19#, 24#, 27#, 30#)

Pliers

Ratchet Spanner With

Socket (28#)

Socket Head Wrench

(3#, 5#, 8#)

Tools Required

Notice

The lift has been designed to be used in a covered and sheltered place, free of

overhead obstructions. The place of installation must not be next to washing areas,

painting workbenches, solvent or varnish deposits. The installation near to rooms,

where a dangerous situation of explosion can occur, is strictly forbidden. The

relevant standards of the local Health and Safety at Work regulations, for instance,

with respect to minimum distance to wall or other equipment, escapes and the like,

must be observed. All areas next to the lift must be well and uniformly lit.

Floor Requirements

The lift should be fixed on a smooth and solid concrete ground with its strength

more than 3000psi, tolerance of flatness less than 5mm and minimum thickness

of 6 inches (153 mm). New concrete must be adequately cured by at least 28

days minimum.

Specifications of concrete must be adhered to. Failure to do so could cause lift

failure resulting in personal injury or death.

A level floor is suggested for proper installation. Small differences in floor slope

may be compensated for by proper shimming. Any major slope change will affect

the level lifting performance. If a floor is of questionable slope considering to

pour the new concrete slab.

Now locate the lift according to the floor plan (Figure 3), use a carpenters chalk

line to layout a grid for the column locations.

After the column locations are properly marked, use a chalk or crayon to make an

outline of the columns on the floor at each location using the column base plate

as a template.

Double check all dimensions and make sure that the bases of each column are

square and aligned with the chalk line.

Site Layout

Precautions for installation

Joints of oil hose must be

firmly connected in order to

avoid leakage.

All bolts should be firmly

screwed up.

Do not place any vehicle on

the lift in the case of trial

running.

Remove the packaging and take the mechanical and hydraulic assembly

to the designated installing place.

Connect the oil hose to the pump assembly with a proper wrench. (Make

sure the hose end is clean).

Connect the wires of limit switch to the wiring terminals in the control

box. Make sure to connect NO.1 wire with NO.1 terminal, NO.2 wire with

NO.2 terminal and so forth.

Link the air hose to compressed air source. (This step is only for the type

with pneumatic safety lock)

Fix the base frame. (Optional)

This MSL is portable. In other words, users may use it without having

it placed and fixed on the ground. Nevertheless, if you want to have

it fixed, fix it on a smooth and solid concrete surface.

Trial testing with load. (Do not use cars for trial testing). Load applied

shall not exceed 9,000 LBS / 2,500KG.

This step is of particular importance for it can check if the oil hose

and air hose are well connected. Connections are qualified when

there is no abnormal sound or leakage after having been tested for 2

or 3 times.

Please do read and understand this manual thoroughly before

completing

1.

2.

3.

4.

5.

a.

6.

a.

S/N Check Items

Yes

No

Are both platforms on the same level?

Are Oil Hoses well connected?

Are Electrical Connection correct?

Do Valves on the pump assembly leak?

Equipment Installation

Check After Installation

Precautions

Control Box

Check all the joints of oil hose. Only when there is no leakage, the lift can start

work.

Do NOT Operate lift is safety device malfunctions

The machine shall not lift or lower an automobile if its center of gravity is not

positioned midway of the rising platforms Otherwise, the manufacturer as well as

our dealers will not bear any responsibility for any consequence resulted

thereby.

Operators and other personnel concerned should stand in a safety area during

lifting and lowering process.

When platforms rise to the desired height, switch off the power at once to

prevent any wrong operation done by unauthorized people.

Make sure the safety lock of the lift is engaged before start working under the

vehicle and no people under the vehicle during lifting and lowering process.

Switch on (press the “emergency stop button” until the power indicator is on).

Press the DOWN button to lower the lift. (For the model with pneumatic safety

lock, firstly platforms of the lift will rise about 5cm which is to release the safety

lock; for the model without pneumatic safety lock, platforms will go down

directly.)

Drive away the vehicle.

Lower the lift

1.

2.

3.

Start

The lift is raised

Press the UP button

Turn on the power switch

Motor drives the gear pump work

Operation

Make sure that you have read and understood the operation manual before

operation.

Drive and park the vehicle midway between two platforms.

Place the four rubber pads under the prop-points of the vehicle and ensure car’s

gravity has been placed on the rubber pads.

Press the UP button on the control box until rubber pads have touched the

prop-points of vehicle.

Keep on pressing the UP button to lift the vehicle a bit higher from the ground

and check again if the vehicle is in a safe position.

Having raised the vehicle to the required height, press the “Emergency stop”

button before performing maintenance or repair work.

Raise the lift

1.

2.

3.

4.

5.

6.

Cylinder piston drives the

platform move up

Start

Press the DOWN button

Turn on the power switch

The lift is lowered

Emergency Lowing In Case of No Power

Safety Lock Not Engaged:

Tie up the safety teeth on both sides with rope; pull upward the rope making

the safety teeth unlocked.

Having the safety teeth unlocked, manually loose the core of electro-

magnetic valve on the pump assembly.

Safety Lock Engaged:

Screw off the fitting (opposite to the oil out-let) to connect a hand pump.

(Optional)

Connect the hydraulic assembly with the optional hand pump. Press down

the handle of the pump to raise the platforms to have the safety teeth

unlocked.

Tie up the safety teeth with rope and pull up the safety teeth.

Use a wrench to loose the core of the electro-magnetic valve to lower the

platforms.

Motor does

not run and

will not

raise

The wire connection is loose.

The Motor is burnt

The limit switch is damaged or

the wire connection is loose.

1.

2.

3.

Check and make a

good connection

Replace it

Connect it or replace

the limit switch

1.

2.

3.

Motor runs

but will not

raise

The motor run reversely

Overflow valve is loose or

jammed

The gear pump is damaged

Oil level is too low

The oil hose became loose

1.

2.

3.

4.

5.

Check the wire

connection

Clean or adjust it

Replace it

Add Oil

Tighten it

1.

2.

3.

4.

5.

Platforms

go down

slowly after

being raised

The oil hose leaks

The oil cylinder is not

tightened

The single valve leaks

The overflow valve leaks

Electrical unloading valve

leaks

1.

2.

3.

4.

5.

Check or replace it

Replace the seal

Clean or replace it

Clean or replace it

Clean or replace it

1.

2.

3.

4.

5.

Raising too

slow

The oil filter is jammed

Oil level is too low

The overflow valve is not

adjusted to the right

The hydraulic oil is too hot

The seal of the cylinder is

abraded

1.

2.

3.

4.

5.

Clean or Replace

Add Oil

Adjust it

Change the Oil

Replace the seal

1.

2.

3.

4.

5.

Lowering

too slow

The throttle valve jammed

The hydraulic oil is dirty

The Anti-Surge valve jammed

The oil hose jammed

1.

2.

3.

4.

Clean or Replace

Change the Oil

Clean it

Replace it

1.

2.

3.

4.

ATTENTION: If the trouble cannot be fixed by yourself, please do not hesitate to

contact us for help. We will offer our service at the earliest time we can. By the way,

troubles can be judged and solved much faster if more details or pictures are be

provided.

Troubleshooting

Table of contents

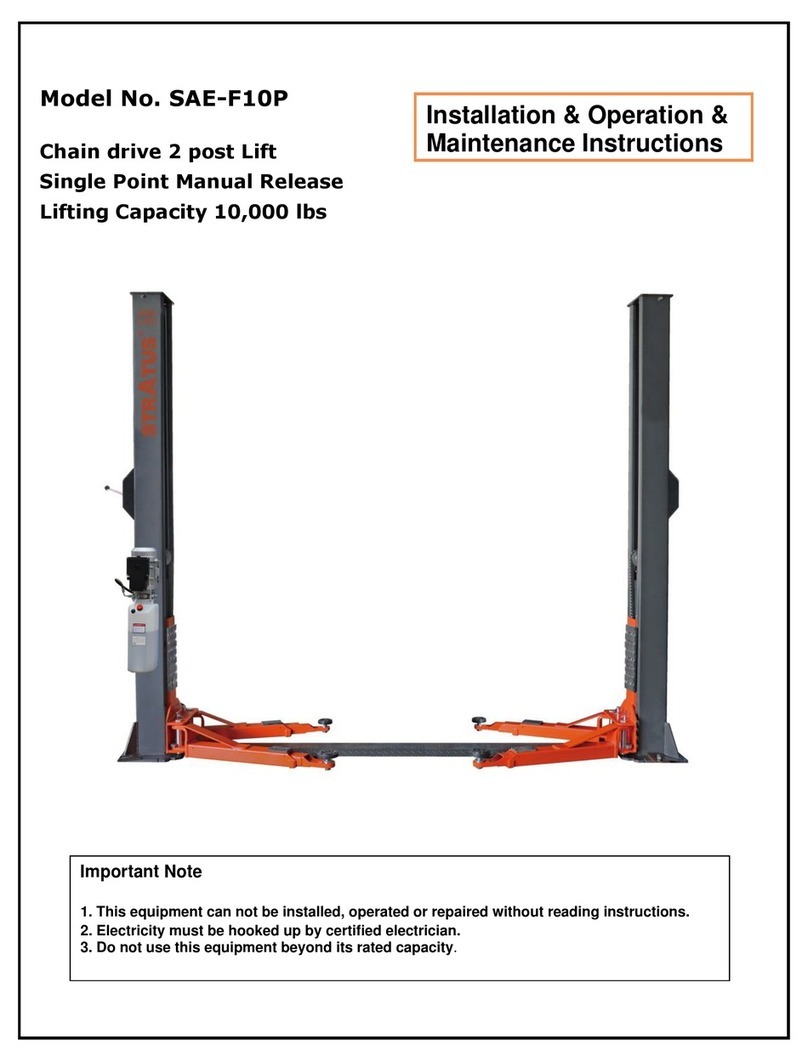

Other Stratus Lifting System manuals

Stratus

Stratus SAE-UT8000 Guide

Stratus

Stratus SAE-C10P Guide

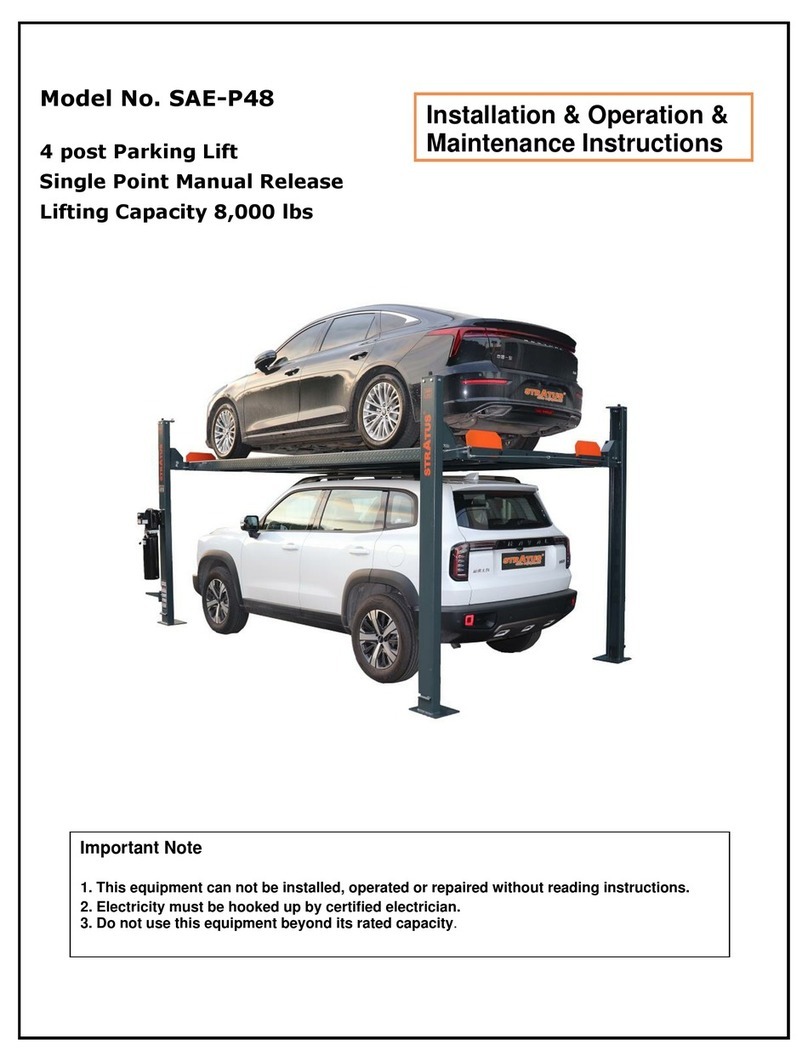

Stratus

Stratus SAE-P48 Guide

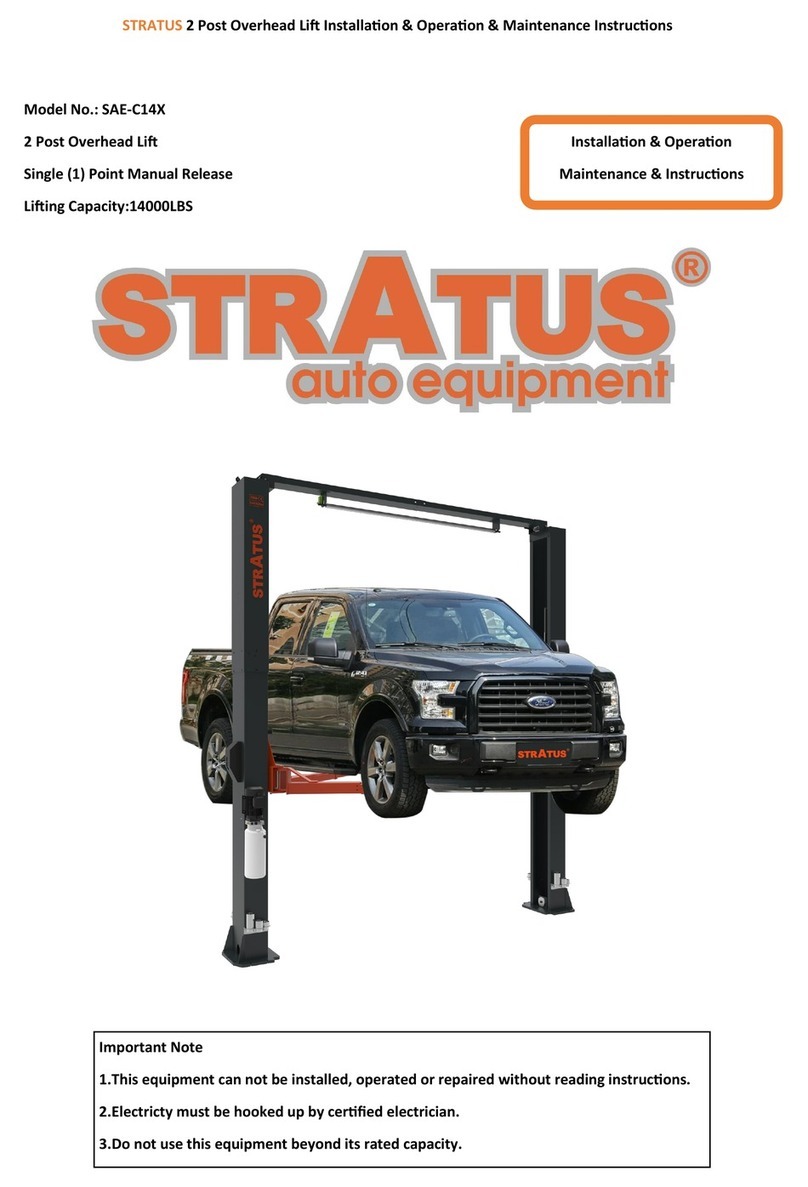

Stratus

Stratus SAE-C14X Guide

Stratus

Stratus SAE-C12X Guide

Stratus

Stratus SAE-F14X Guide

Stratus

Stratus SAE-P410 User manual

Stratus

Stratus SAE-C10C Guide

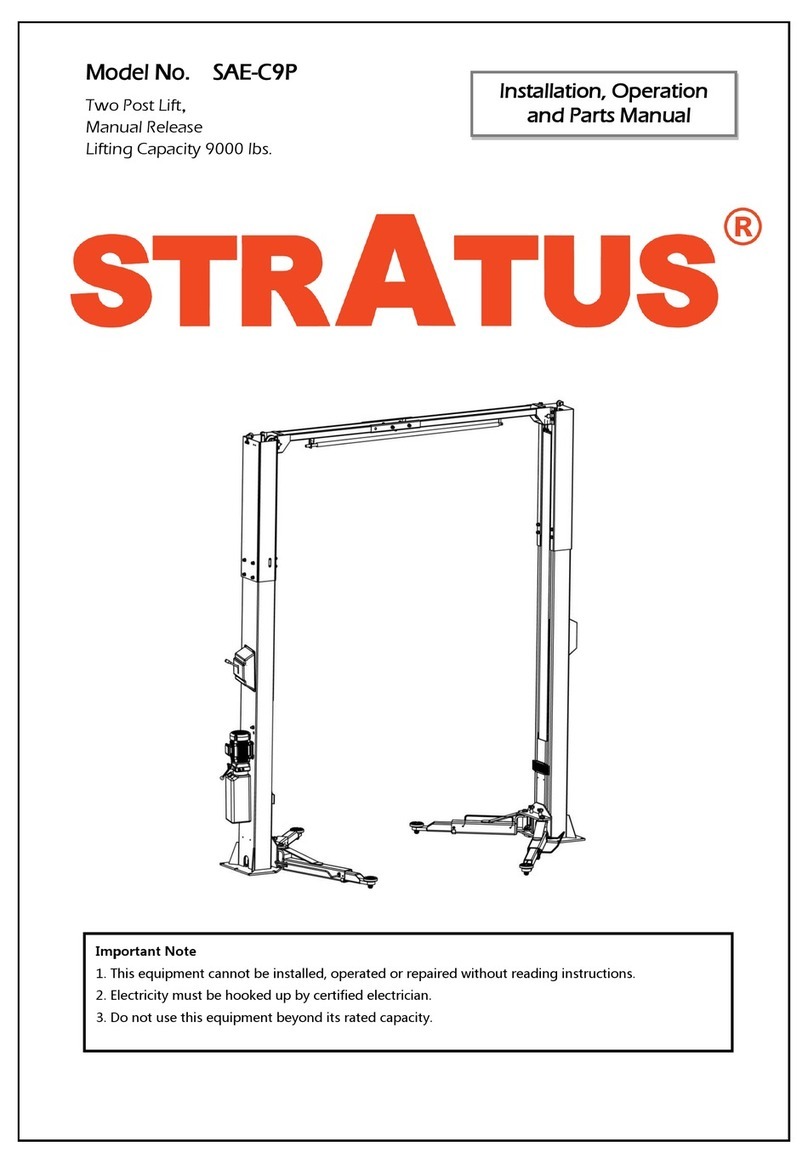

Stratus

Stratus SAE-C9P Guide

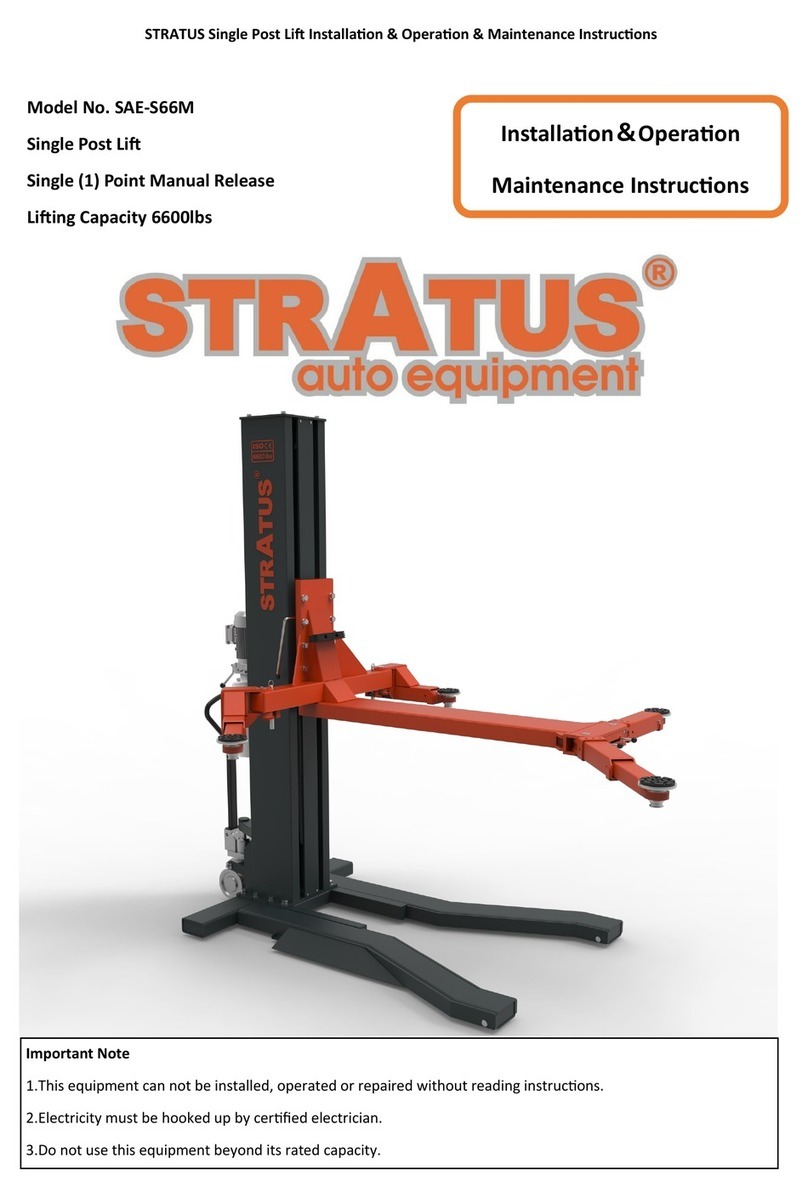

Stratus

Stratus SAE-S66M User manual