Stratus SAE-C9P Guide

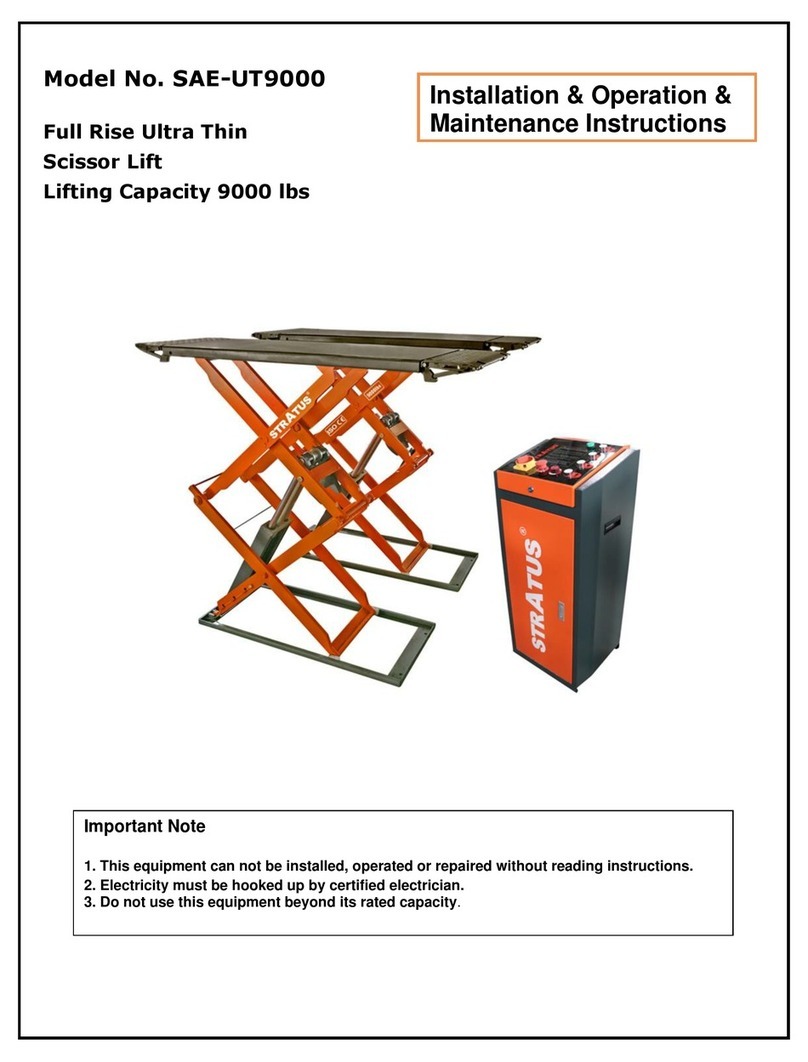

Model No. SAE-C9P

Two Post Lift,

Manual Release

Lifting Capacity 9000 lbs.

Installation, Operation

and Parts Manual

Important Note

1. This equipment cannot be installed, operated or repaired without reading instructions.

2. Electricity must be hooked up by certified electrician.

3. Do not use this equipment beyond its rated capacity.

Installation, Operation and Parts Manual

SAE-C9P

2

SAFETY NOTES................................................................................................................................................ 3

1.1 Operation of lifting platforms ................................................................................................................................3

1.2 Checking of the lifting platforms............................................................................................................................3

1.3 Important safety notices ........................................................................................................................................4

1.4 Warning labels .......................................................................................................................................................5

1.5 Potential safety risks ..............................................................................................................................................6

1.6 Noise level..............................................................................................................................................................6

PACKING, STORAGE AND TRANSPORTATION ................................................................................................... 7

2.1 The lift was dismantled into the following 2 parts for transportation ..................................................................7

2.2 Storage ...................................................................................................................................................................7

2.3 Opening the packs .................................................................................................................................................7

PRODUCTS DESCRIPTIONS .............................................................................................................................. 8

3.1 General descriptions ..............................................................................................................................................8

3.2 Construction of the lift...........................................................................................................................................8

3.3 Technical data ........................................................................................................................................................8

3.4 Dimensions.............................................................................................................................................................9

3.5 Safety devices descriptions..................................................................................................................................10

INSTALLATION INSTRUCTIONS ...................................................................................................................... 11

4.1 Preparations before installation ..........................................................................................................................11

4.2 Installation attentions..........................................................................................................................................11

4.3 General installation steps ....................................................................................................................................12

4.4 Items to be checked after installation .................................................................................................................21

OPERATION INSTRUCTIONS .......................................................................................................................... 21

5.1 Precautions ..........................................................................................................................................................21

5.2 Operation instructions .........................................................................................................................................22

TROUBLE SHOOTING .................................................................................................................................... 23

INSPECTION AND MAINTENANCE.................................................................................................................. 24

Annex 1, Floor plan ....................................................................................................................................................26

Annex 2, Electrical schemes and parts list .................................................................................................................27

Annex 3, Hydraulic schemes and parts list ................................................................................................................29

Annex 4, Mechanical exploded drawings and parts list.............................................................................................31

Installation, Operation and Parts Manual

SAE-C9P

3

SAFETY NOTES

1.1 Operation of lifting platforms

This lift is specially designed for lifting motor vehicles. Users are not allowed to use it for any other purposes. The applicable national

regulations, laws and directives must be observed.

Only users aged 18 or above who have been instructed on how to operate the lifting platform and have proven their ability to do so to the

owner are to be entrusted with unsupervised operation of lifting platforms. The task of operating the lifting platforms must be granted in

writing.

Before loading a vehicle onto the lift, users should study the original operation instructions and familiarize themselves with the operating

procedures in several trial runs.

Lift vehicle within the rated load. Don’t attempt to raise vehicles with excessive weight.

1.2 Checking of the lifting platforms

Checks are to be based on the following directives and regulations:

Basic principles for testing lifting platforms

The basic health and safety requirement

The applicable accident prevention regulations

The checks are to be organized by the user of the lifting platform. The user is responsible for appointing an expert or qualified person to

perform checking. It must be ensure that the person chosen satisfies the requirements.

The user bears special responsibility if employees of the company are appointed as experts or qualified persons.

1.2.1 Scope of checking

Regular checking essentially involves performing a visual inspection and a functional test. This includes checking the condition of the

components and equipment, checking that the safety systems are complete and functioning properly and that the inspection log book is

completely filled in. The scope of exceptional checking depends on the nature and extent of any structural modification or repair work.

1.2.2 Regular checking

After initial commissioning, lifting platforms are to be checked by a qualified person at intervals of not longer than one year.

A qualified person is somebody with the training and experience required to possess sufficient knowledge of lifting platforms and who is

sufficiently familiar with the pertinent national regulations, accident prevention regulations and generally acknowledged rules of

engineering to be able to assess the safe operating condition of lifting platforms.

1.2.3 Exceptional checking

Lifting platforms with a lift height of more than 2 meters and lifting platforms intended for use with people standing under the load bearing

elements of the load are to be checked by an expert prior or reuse following structural modifications and major repairs to load bearing

components.

An expert is somebody with the training and experience required to possess specialist knowledge of lifting platforms and who is sufficiently

familiar with the pertinent national work safety regulations, accident prevention regulations and generally acknowledged rules of

Installation, Operation and Parts Manual

SAE-C9P

4

engineering to be able to check and give an expert option on lifting platforms.

1.3 Important safety notices

1.3.1 Recommend for indoor use only. DO not expose the lift to rain, snow or excessive moisture.

1.3.2 Only use this lift on a surface that is stable and capable of sustaining the load. Do not install the lift on any asphalt surface.

1.3.3 Read and understand all safety warnings before operating the lift.

1.3.4 Do not leave the controls while the lift is still in motion.

1.3.5 Keep hands and feet away from any moving parts. Keep feet clear of the lift when lowering.

1.3.6 Only these properly trained personnel can operate the lift.

1.3.7 Do not wear unfit clothes such as large clothes with flounces, tires, etc., which could be caught by moving parts of the lift.

1.3.8 To prevent evitable incidents, surrounding areas of the lift must be tidy and with nothing unconcerned.

1.3.9 The lift is simply designed to lift the entire body of vehicles, with its maximum weight within the lifting capacity.

1.3.10 Always insure the safety locks are engaged before any attempt to work near or under the vehicle. Never remove safety related

components from the lift. Do not use if safety related components are damaged or missing.

1.3.11 Do not rock the vehicle while on the lift or remove any heavy component from vehicle that may cause excessive weight shift.

1.3.12 Check at any time the parts of the lift to ensure the agility of moving parts and the performance of synchronization. Ensure regular

maintenance and if anything abnormal occurs, stop using the lift immediately and contact our dealers for help.

1.3.13 Lower the lift to its lowest position and do remember to cut off the power source when service finishes.

1.3.14 Do not modify any parts of the lift without manufacturer’s advice.

1.3.15 If the lift is going to be left unused for a long time, users are required to:

a. Disconnect the power;

b. Empty the oil tank;

c. Lubricate the moving parts with hydraulic oil.

WARNING:The warnings, cautions and instructions discussed in this instruction manual cannot cover all possible conditions and

situations that may occur. It must be understood by the operator that common sense and caution are factors which cannot be built into

this product, but must be supplied by the operator.

Installation, Operation and Parts Manual

SAE-C9P

5

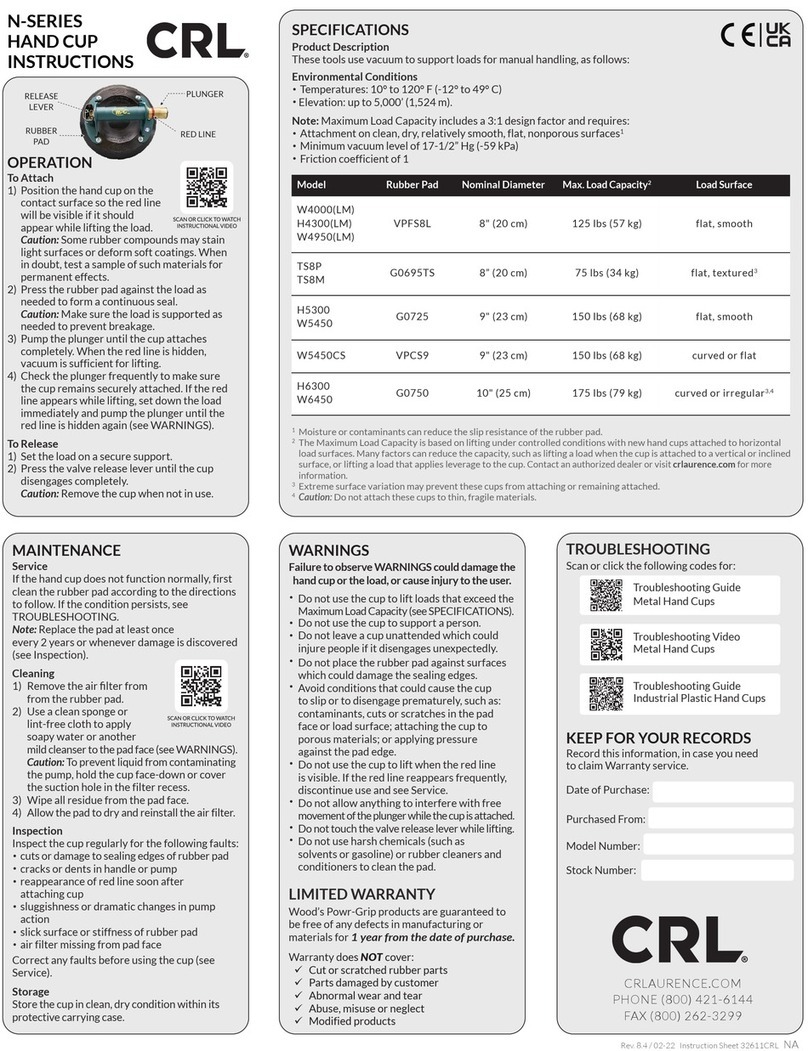

1.4 Warning labels

All safety warning labels are clearly depicted on the lift to ensure that the operator is aware of and avoid the dangers of using the lift in an

incorrect manner. The labels must be kept clean and they have to be replaced if detached or damaged. Please read carefully the meaning

of each label and memories them for future operation.

Installation, Operation and Parts Manual

SAE-C9P

6

1.5 Potential safety risks

1.5.1 Mains voltage

Insulation damage and other faults may result in accessible components being live

Safety measures:

Only ever use the power cord provided or a tested power cord.

Replace wires with damaged insulation.

Do not open the operating unit.

1.5.2 Risk of injury, danger of crushing

In the event of excessive vehicle weight, incorrect mounting of the vehicle or on removing heavy object, there is a risk

of the vehicle falling off or tipping up.

Safety measures:

The lift is only ever to be employed for the intended purpose.

Carefully study and heed all the information given in Section 1.4.

Observe the warning notices for operation.

1.6 Noise level

Noise emitted during operating the lift should be less than 70dB (A). For your health consideration, it is suggested to place a noise detector

in your working area.

Installation, Operation and Parts Manual

SAE-C9P

7

PACKING, STORAGE AND TRANSPORTATION

Packing, lifting, handling, transporting operations must be performed only by experienced personnel with

appropriate knowledge of the lift and after reading this manual.

2.1 The lift was dismantled into the following 2 parts for transportation

Name

Packed by

Quantity

Lift

Steel brackets

1

Power unit

Carton

1

2.2 Storage

The packs must be kept in a covered and protected area in a temperature range 0f -10℃to +40℃. They must not be exposed to direct

sunlight, rain or water.

Stacking the packs

We advise against stacking because the packs are not designed for this type of storage. The narrow base, heavy weight and large size of the

packs make stacking difficult and potentially dangerous.

If stacking is unavoidable, use all appropriate precautions:

-never stack to more than 2 meters in height.

-never make stacks of single packs. Always stack pairs of packs in a cross pattern so that the base is bigger and the resulting stack is more

stable. Once the stack is complete, restrain it using straps, ropes or other suitable methods.

A maximum of two packs can be stacked on lorries, in containers, and in railway wagons, on condition that the packs are strapped together

and restrained to stop them falling.

2.3 Opening the packs

The packs can be lifted and transported only by using lift trucks. Never attempt to hoist or transport the unit using lifting slings.

When the lift is delivered make sure that it has not been damaged during transportation and that all the parts specified on the packing list

are present.

Packs must be opened adopting all the precautions required to avoid injury to persons (keep at a safe distance when cutting the straps) or

damage to parts of the machine (be careful that no parts are dropped while you are opening the packing).

Take special care with the hydraulic power unit, the control panel and the cylinder.

Installation, Operation and Parts Manual

SAE-C9P

8

PRODUCTS DESCRIPTIONS

3.1 General descriptions

This is chassis supporting vehicle lift for road vehicles.

It is mainly composed by two posts, two carriages, four swing arms and a power and control unit.

It is driven by an electro-hydraulic system. The gear pump delivers hydraulic oil to oil cylinders and pushes upwards its piston. The cylinder

piston drives to raise the carriage and swing arms. It is equipped with mechanical safety locking unit which ensures no risks of slipping off in

case of hydraulic failure.

3.2 Construction of the lift

3.3 Technical data

Lifting capacity

9000 lbs.

Full rise

1900mm (74 3/4”)

Min height

95mm (3 3/4”)

Full rise time (with rated load)

Approx.60s

Full descent time (with rated load)

Approx.50s

Power Supply

220V/1Ph/60Hz

Oil tank volume

10L

1. Overhead crossbeam

2. Extending post

3. Mechanical safety latch

4. Carriage

5. Hydraulic power unit

6. Lifting arm

7. Hydraulic cylinder

8. Post

Installation, Operation and Parts Manual

SAE-C9P

9

3.4 Dimensions

Installation, Operation and Parts Manual

SAE-C9P

10

3.5 Safety devices descriptions

POS.

Description

Function

1

Roof protective limit switch

Stop rising in case the overhead bar is touched.

2

Max rise limit switch

Stop rising at max height.

3

Mechanical safety locking unit

Catch the carriages in case of hydraulic failure.

4

Arm lock

Ensure the lifting arms are locked and avoid being swinging during lifting process.

Installation, Operation and Parts Manual

SAE-C9P

11

INSTALLATION INSTRUCTIONS

4.1 Preparations before installation

4.1.1 Space requirements.

Refer to 3.4 for the dimensions of the lift. There must also be a clearance of at least 1 meter between the lifting platform and fixed

elements (e.g. wall) in all lifting positions. There must be sufficient space for driving vehicles on and off.

4.1.2 Foundations and connections

The user must have the following work performed before erecting the lift.

Construction of the foundation following consultation with the manufacturer’s customer service or an authorized service agent. Routing of

the wiring to the installation location. The user must provide fuse protection for the connection. Electrical system connection must be

done by licensed technicians. Requirements for power supply cable of the installation site: at least 2.5mm2 wire core for 3Ph power and

4.0mm2 wire core for 1Ph power.

Refer also to the corresponding information on the name plate and in the operation instructions.

Before doing electrical connection, make sure the lift is electrically adapt to the local power supply.

4.1.3 Foundations preparations

Refer to Annex 1 for footing.

C25 concrete foundation with a minimum thickness of 200mm (continuous footing).

Surface: Horizontal and even (Gradients max. 0.5 %)

Newly built concrete ground must be older than 20days.

4.1.4 Tools and equipment needed for installation

Tool name

Specification

Quantity

Electrical drill(C10)

D18 drill bit

1

Open spanner

D17-19

2

Adjustable spanner

bigger than D30

1

Cross socket screw driver

PH2

1

Quick spanner handle adapter/ Ratchet

REB-310

1

Socket spanner

D24

1

Levelling device

Accuracy: 1mm

1

Hammer

10 pounds

1

Truck lift

Capacity,1000kg

1

Lifting string

Capacity, 1000kg

2

Torque spanner

MD400

1

4.2 Installation attentions

4.2.1 Joints of oil hose and wiring must be firmly connected in order to avoid leakage of oil hose and looseness of electrical wires.

4.2.2 All bolts should be firmly screwed up.

4.2.3 Do not place any vehicle on the lift in the case of trial running.

Installation, Operation and Parts Manual

SAE-C9P

12

4.3 General installation steps

ONLY TRAINED AND QUALIFIED INSTALLERS CAN PERFORM LIFT INSTALLATION DUTIES.

Step 1: Remove the packaging and take out the accessories attached.

Attention

:

The packs must be opened adopting all the precautions required to avoid injury to persons (keep at a safe distance when cutting

the straps) or damage to parts of the machine (be careful that no parts are dropped while you are opening the packing).

Use proper means (put something supporting under the post or suspend the post by a crane) to suspend the post, unscrew and remove

the bolts fixed on the iron rack.

Attention

:

Please pay special attention not to let the post fall down for it may cause casualty or bring damages to the accessories fixed in the

post.

Step 2: Fix the standing position for the two posts. (See Annex 1, floor plan)

1. Decide on which post the power unit is going to be mounted.

2. Draw an outline of the base plate on the installation ground with chalk and ascertain the position for the two posts.

Step 3: Assemble the two posts.

1. Hex nut M14

2. Flat washer M 14

3. Spring washer M14

4. Hex head full swivel screw M14x30

5. Extending post

1. Hex bolt

2. Iron rack

Installation, Operation and Parts Manual

SAE-C9P

13

Step 4: Erect and secure the post.

1. Make the posts face to each other and the distance between the posts equals to the length of the crossbeam. Use proper means to erect

the post.

2. Use suitable means to raise the lifting carriage to the first latching position. All the mounting holes in the base plate are then accessible.

Make sure the locking pawl is engaged.

3. Check and align the position of the base plates again.

4. Drill the mounting holes. Remove the drilling dust from the hole.

5. Use a spirit level to check the vertical alignment of the posts. If necessary, place equalizing plates under the base plates.

6. Tighten the nuts. Torque: (63-74b.ft) 80-100Nm

Anchoring bolt

A1

(foundation thickness )

A2

(drilling depth)

A3

(anchoring depth)

B

C

M18x160

≥200mm

130mm

105mm

240mm

≤55mm

Step 5: Connect and install the crossbeam.

A.

Nut

B.

Expansion anchoring bolt

C.

Equalizing plate

1. Hex nut M14

2.Flat washer M14

3.Spring washer M14

4.Hex head full swivel screw M14x30

Installation, Operation and Parts Manual

SAE-C9P

14

Step 6: Connect the synchronization steel cable.

1. Route and fix according to the following scheme.

2. Before attempting to route the cables, raise the lifting carriage at both sides to the first latching position making sure that the mechanical

safety locking units in each post are fully engaged.

3. After fixed the cables, adjust and make the cables at both sides be under the same tension which could be judged by the sound emitted

during lifting process.

4. Grease the cable after being fixed. (It is a must.)

1. Hex nut M14

6.Hex socket cylinder head screw M6x30

2.Flat washer M14

7.Hex nut M6

3.Spring washer M14

8.Protective rod

4.Hex head full swivel screw M14x30

9.Extending post

5.Crossbeam

1. Steel cable A

2. Steel cable B

Installation, Operation and Parts Manual

SAE-C9P

15

Step 7: Connect the hydraulic system.

1. Install hydraulic power unit onto the power side post.

2. Connect oil hoses to the three way connector in the power side post.

It must be taken adequate care that all fittings are securely tightened and no solid substance go into the hydraulic line, otherwise severe

leakage will occur.

1.Hex head flange screw M8x30

2.Anti-vibration pad

3.Hex head flange nut M8

4.Hydraulic power unit

1.Oil hose A

2.Hydraulic cylinder

3.Three way connector

4.Oil hose B

5.Oil hose C

6.Composite connector

7.Power unit

Installation, Operation and Parts Manual

SAE-C9P

16

Step 8: Make the electrical connection.

ONLY qualified electricians are permitted doing the electrical connection.

Read the name plate and check that the supply voltage is adapted to the voltage of the lift.

Refer to Annex 2 before doing the connection.

1. Fix max height limit switch onto the inside surface of the power side post and connect its wire to the terminals reserved at the motor.

2. Fix roof protection limit switch onto the overhead crossbeam and connect its wire.

3. Refer to the wire connection schemes and connect wires to the corresponding terminals in the control box.

1. Max height limit switch

2. Cross socket flat head screw M5x10

3. Cross socket flat head screw M5x10

4. Wire

1. Limit switch

2. Hex socket screw M4x25

3. Wire

Installation, Operation and Parts Manual

SAE-C9P

17

Step 9: Assemble and fix the mechanical safety locking unit.

a. Assemble the locking device.

Locking assembly at the power-side post

Locking assembly at the other post

1.circlip

2.washer

3.spring 1

4.spring 2

5.shaft

6.handle bar

7.hook

8.nylon spacer

9.release plate

Installation, Operation and Parts Manual

SAE-C9P

18

2. Route and fix the release rope for mechanical safety locking assembly.

2.1 Make release rope goes through pulleys on top of the two posts and fix the release rope at both sides of the post.

2.2 Install the protective cover

Step 10: Install lifting arms.

The arm pin shafts (No. 2) must be greased at the installation.

Install the lifting arms onto the carriages and ensure the arm lock could work.

Attention: Install Lifting arms ONLY after the complete assembly has been erected and anchored.

1.Hex socket cylinder head screw M6x8

1.Carriage

2.Pin shaft

3.Long arm

4.Pulling rod

5.Arm lock

Installation, Operation and Parts Manual

SAE-C9P

19

Step 11: Fill with hydraulic oil.

ONLY CLEAN AND FRESH OIL ONLY

Lift must be fully lowered before changing or adding hydraulic oil.

Prepare 12 liters anti-abrasion hydraulic oil. Fill about 10 liters into the oil tank to run the lift up and down for 2 or 3times after the electrical

system is connected.

Add more oil after running the lift for several cycles until the lift can rise to the maximum lifting height.

Note: It is suggested to use HM NO.46 hydraulic oil when average temperature of the location is above 18 degree Celsius and using HM

NO.32 hydraulic oil when temperature is below 10 degree Celsius.

Change the oil 6 months after initial use and once per year thereafter.

Step 12: Trial running.

Get familiar with lift controls by running the lift through a few cycles before loading vehicle on lift.

This step is of particular

importance as it can check if the oil hose is correctly connected. The connection is qualified when there is no abnormal sound or leakage

after having been tested for 5-6 times.

If the lift doesn't raise, the motor may turn in the wrong direction. In such event, interchange wires U, V in the connection box.

Bleeding the hydraulic system

Unscrew but don't remove the nut on top of the oil cylinder and slightly press the UP button until oil gets out. Screw the nut tight

thereafter.

After bleeding system, fluid level in power unit reservoir may be down. Add more fluid if necessary to raise lift to full height. It is only

necessary to add fluid to raise lift to full height.

Check the synchronization of both lifting carriages.

Ensure the synchronization by adjusting the balance steel cables at both sides. Make both cables be of the same tightness.

This could be judged by the sound emitted by the safety locking unit during lifting process.

Check the mechanical safety locking unit.

Check and ensure both safety locking hooks can be effectively engaged or released.

Vent air remained in the cylinder

Installation, Operation and Parts Manual

SAE-C9P

20

Step 13: Fix the protective column curtain.

Step 14: Install the height adapter holder. (Optional)

1.Hex nut M6

2.Class C flat washer M6

3.Hook

4. Column curtain.

5. Cross socket cap head screw M6x8

1.Height adapter

2.Holder

3.Hex socket button head screw M8x12

Table of contents

Other Stratus Lifting System manuals

Stratus

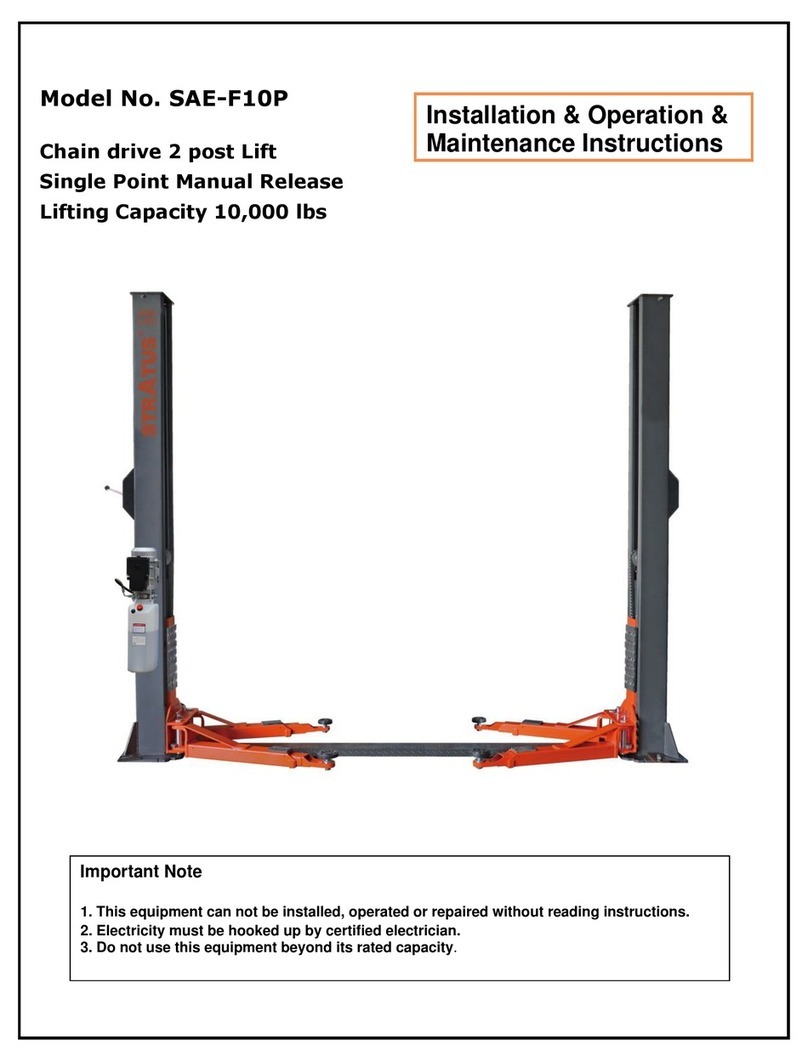

Stratus SAE-F10P Guide

Stratus

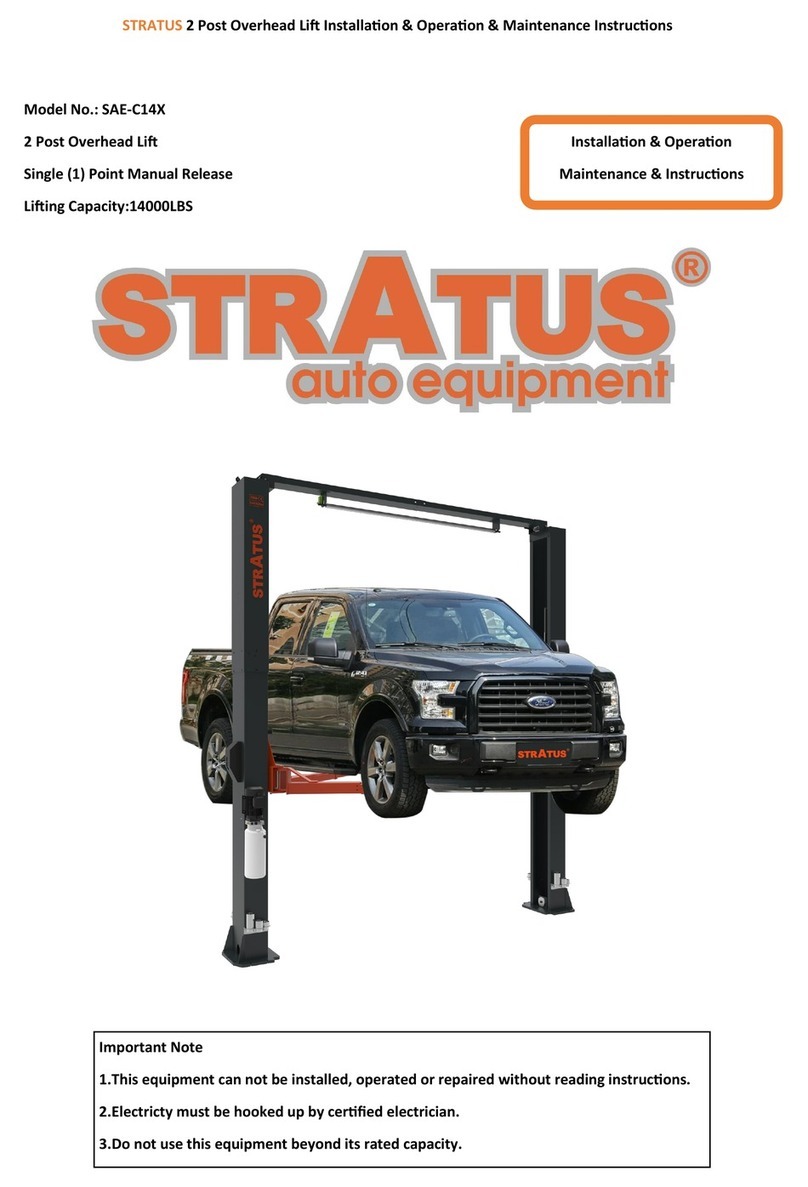

Stratus SAE-C14X Guide

Stratus

Stratus SAE-C10P Guide

Stratus

Stratus SAE-F14X Guide

Stratus

Stratus SAE-UT9000 Guide

Stratus

Stratus SAE-F10S Installation instructions

Stratus

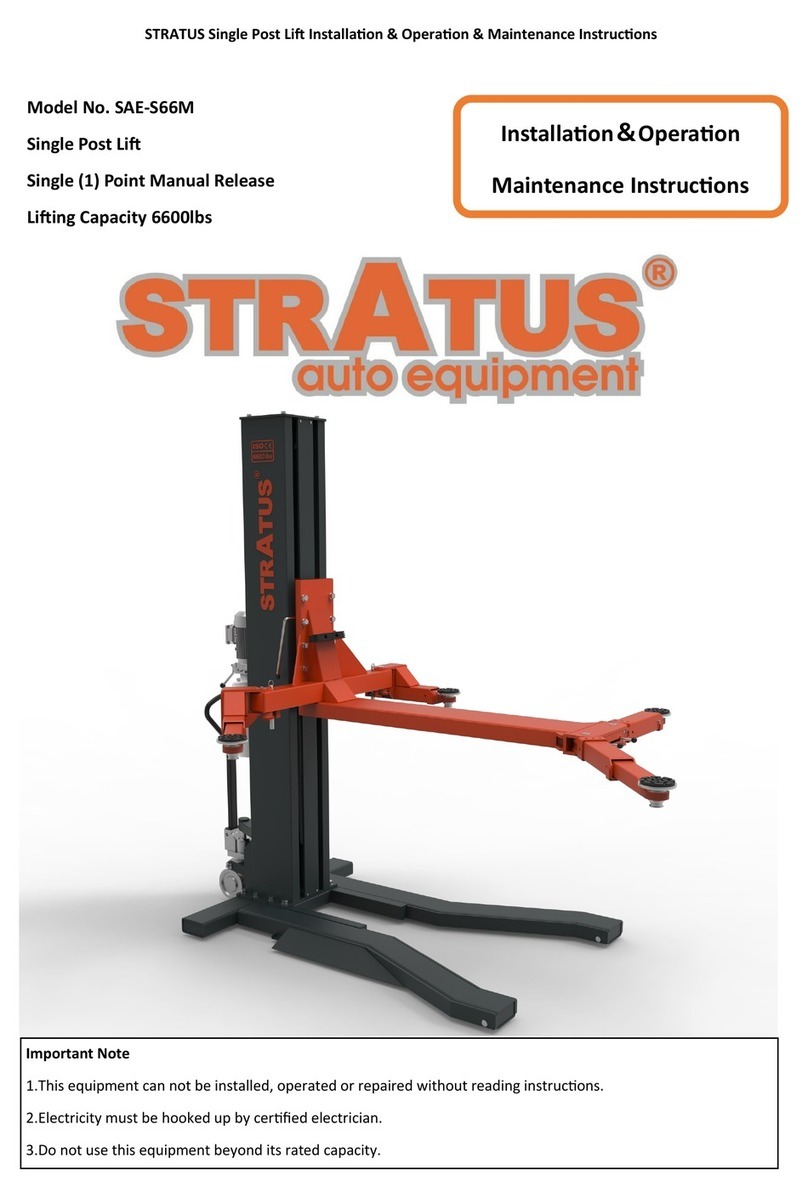

Stratus SAE-S66M User manual

Stratus

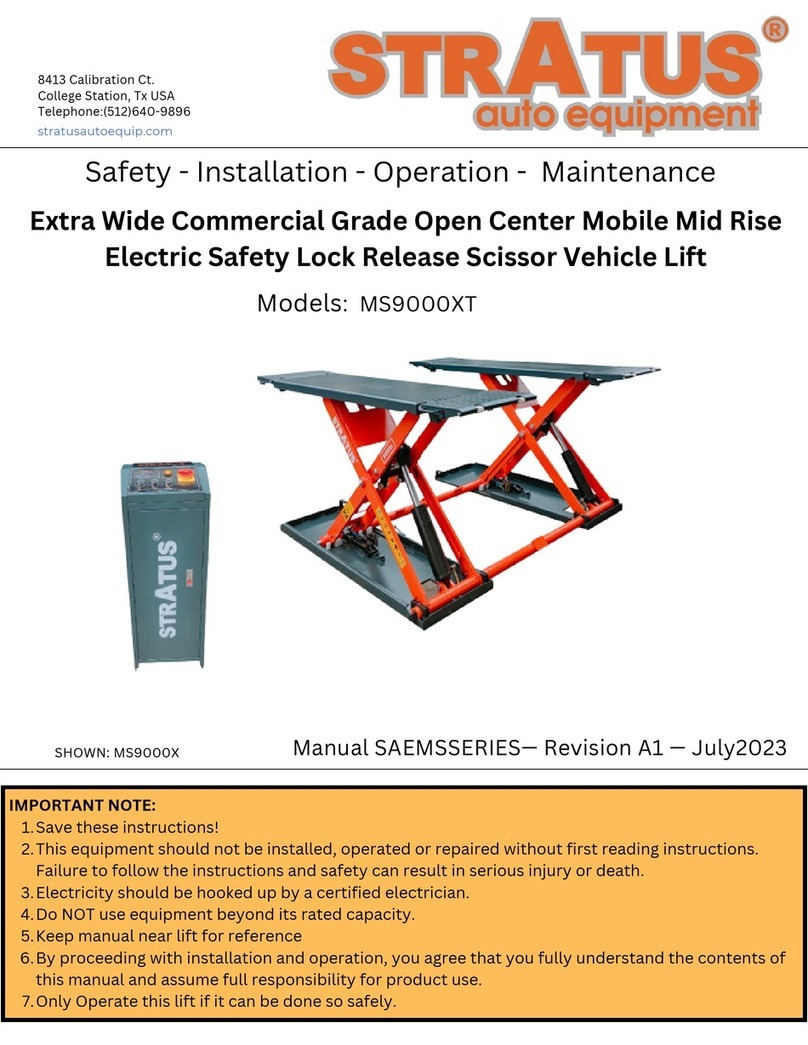

Stratus MS9000XT User manual

Stratus

Stratus SAE-C12XE Guide

Stratus

Stratus SAE-C10C Guide