SAFETY ........................................................................................................................................................................3

1.1 Operation of lifting platforms.............................................................................................................................................. 3

1.2 Checking of the lifting platforms ......................................................................................................................................... 3

1.3 Important safety notices...................................................................................................................................................... 4

1.4 Risks and safety instructions................................................................................................................................................ 5

PACKING AND TRANSPORTATION.................................................................................................................................6

2.1 Packing ................................................................................................................................................................................ 6

2.2 Lifting and handling............................................................................................................................................................. 6

2.3 Storage ................................................................................................................................................................................ 6

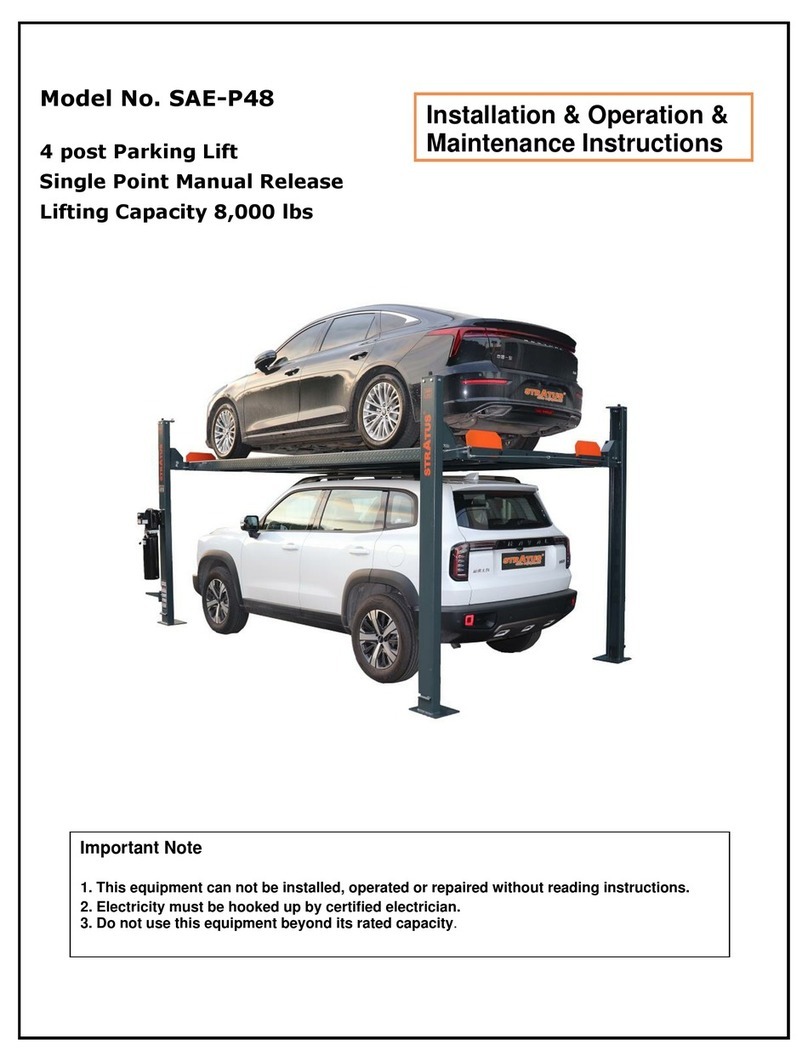

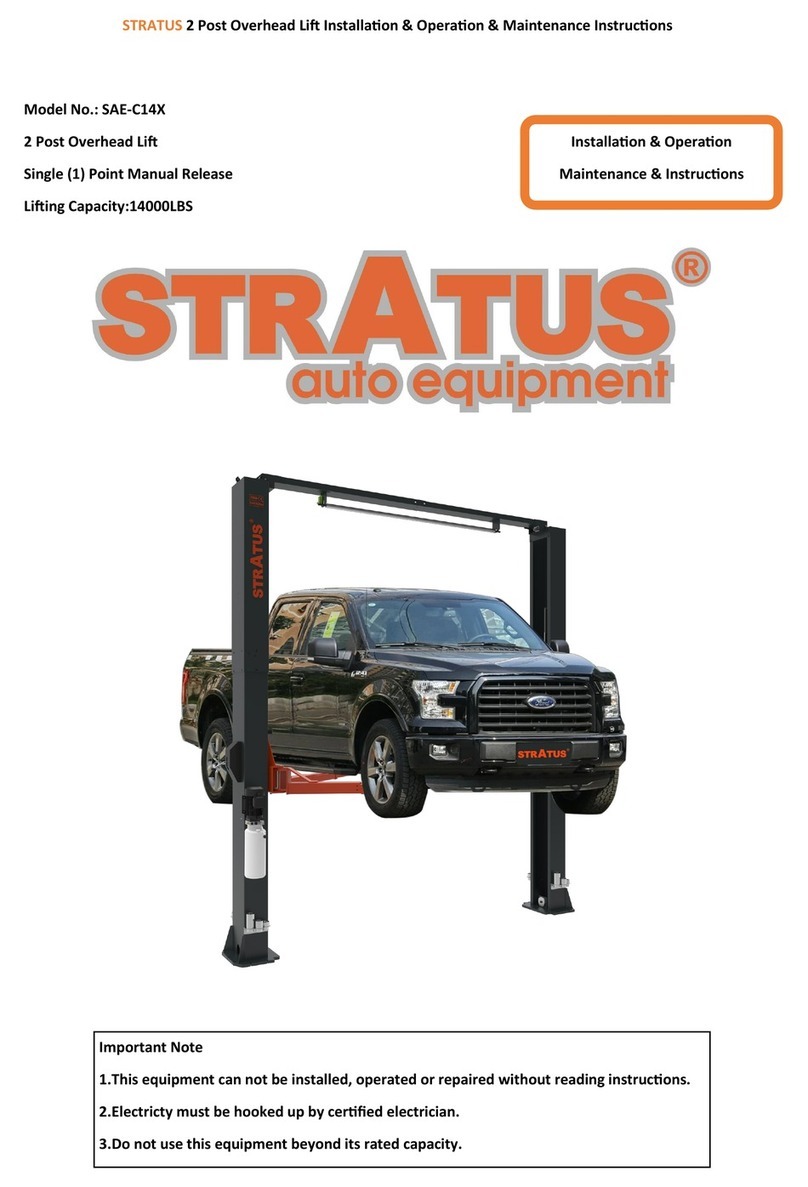

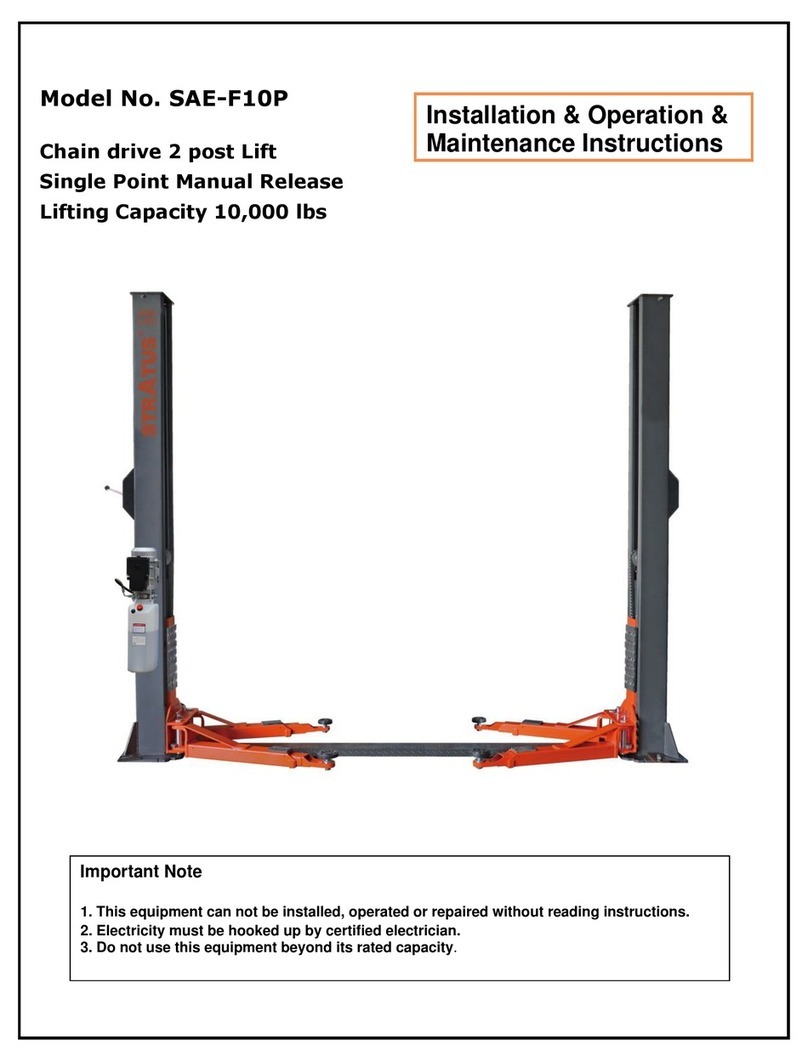

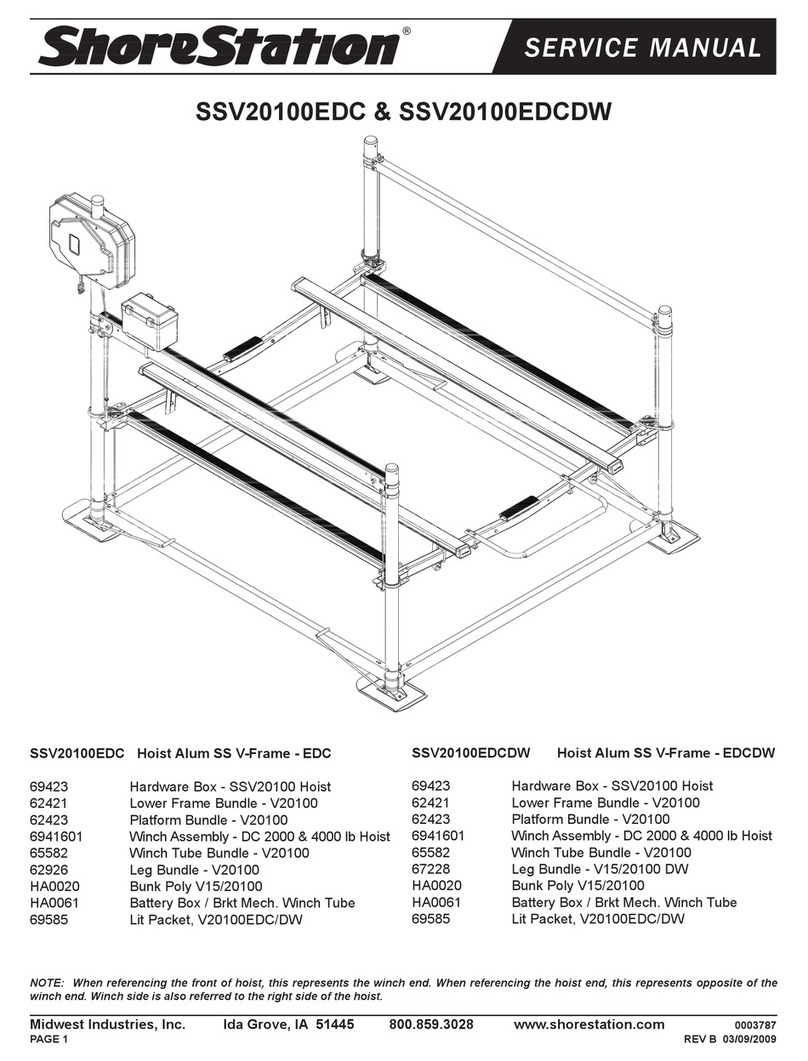

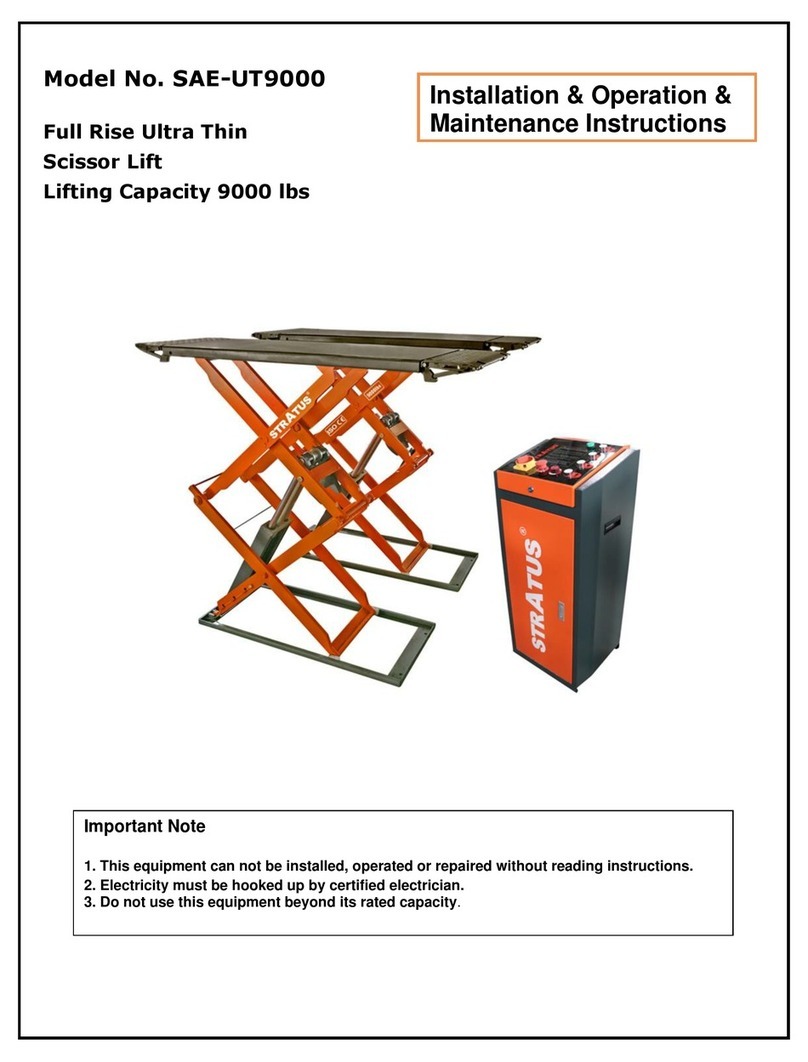

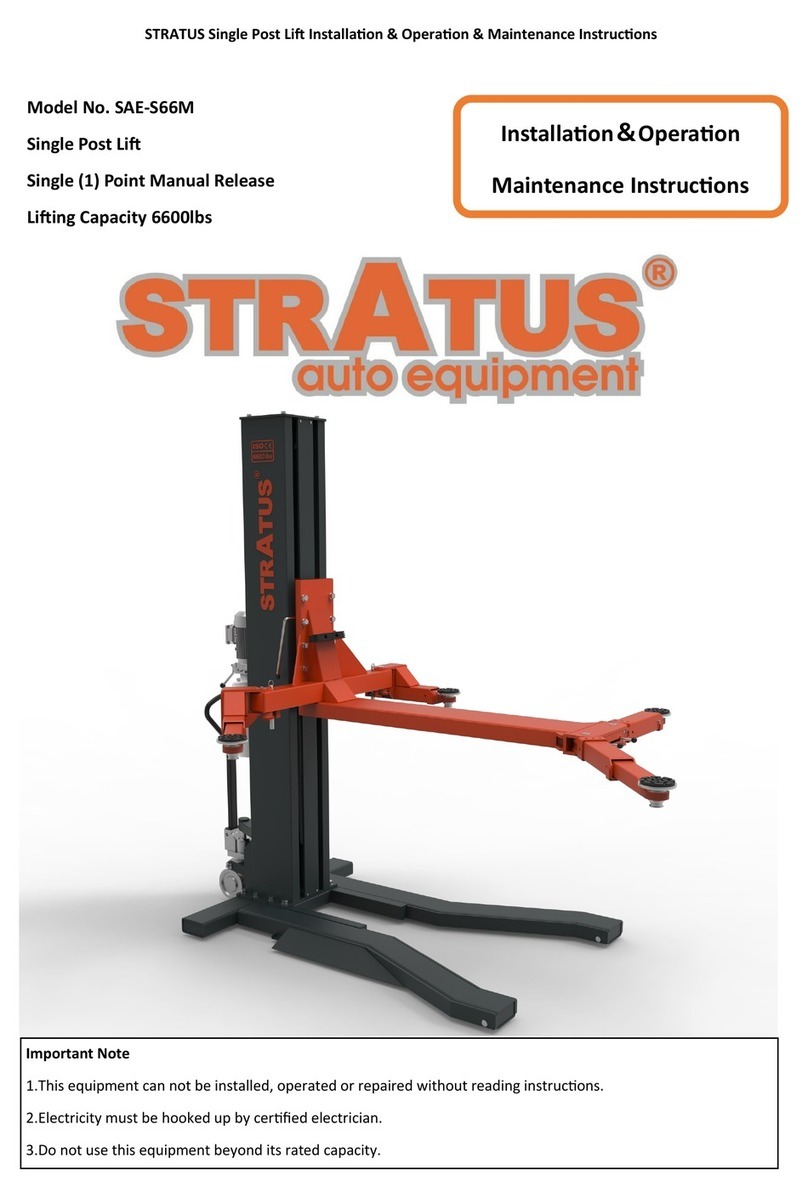

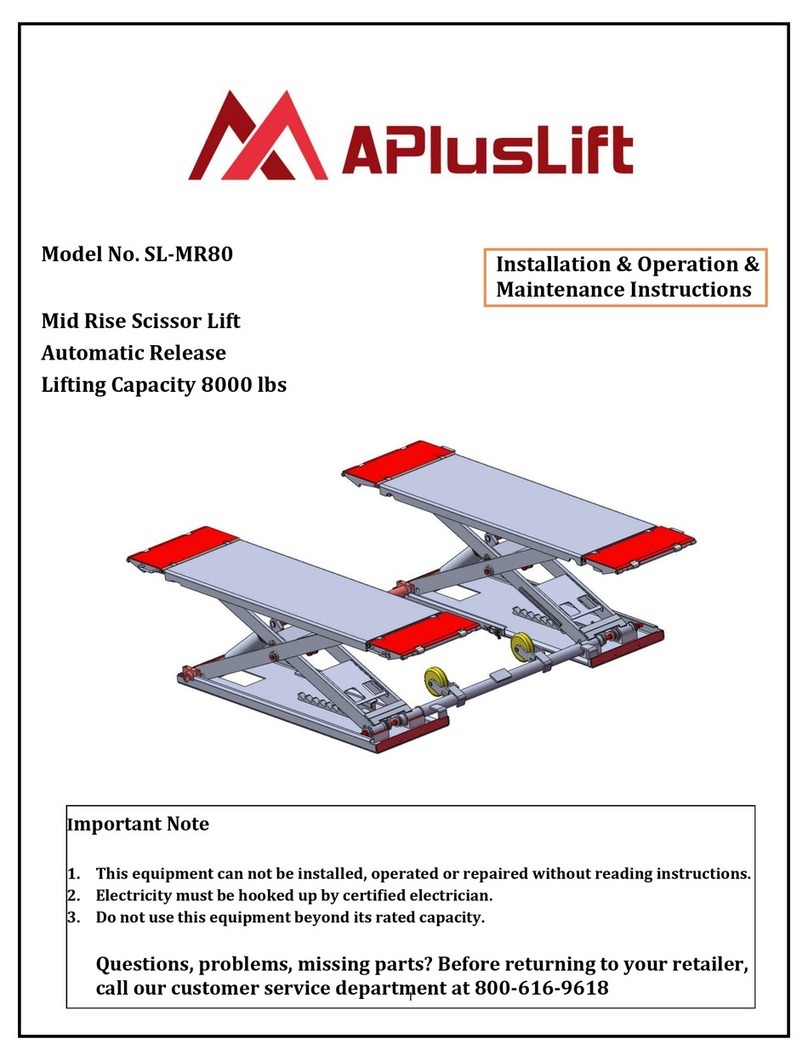

PRODUCTS DESCRIPTIONS............................................................................................................................................7

3.1 General descriptions............................................................................................................................................................ 7

3.2 General construction of the lift............................................................................................................................................ 7

3.3 Dimensions .......................................................................................................................................................................... 8

3.4 Technical data ..................................................................................................................................................................... 9

INSTALLATION INSTRUCTIONS......................................................................................................................................9

4.1 Preparations before installation.......................................................................................................................................... 9

4.2 Installation attentions ....................................................................................................................................................... 11

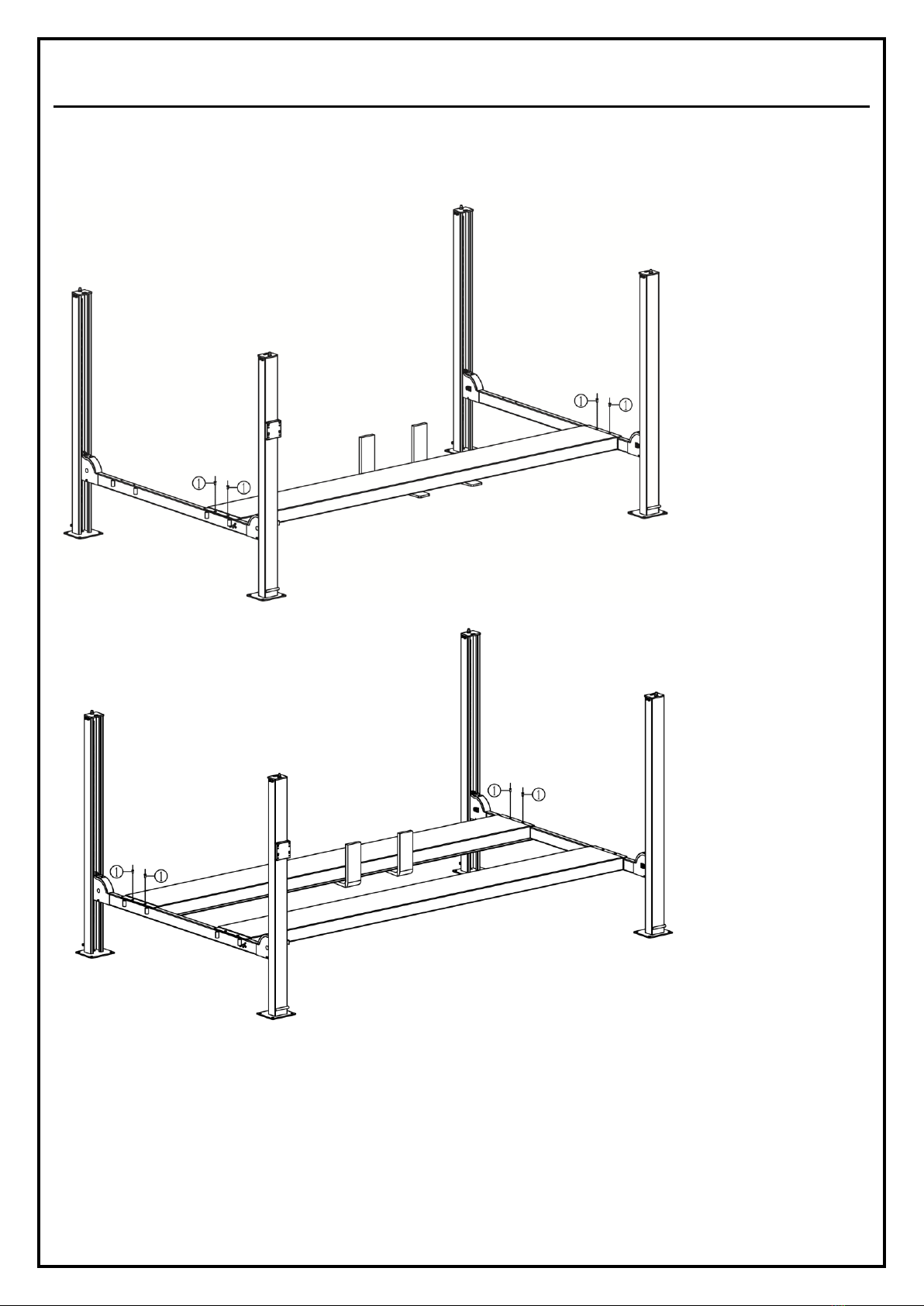

4.3 General Installation instructions........................................................................................................................................ 11

4.4. Items to be checked after installation .................................................................................................

错误

!

未定义书签。

OPERATION INSTRUCTIONS........................................................................................................................................19

5.1 Precautions........................................................................................................................................................................ 19

5.2 Operation instructions....................................................................................................................................................... 19

Annex 1, Hydraulic schemes and parts list .............................................................................................................................. 20

Annex 2, Electrical schemes and parts list............................................................................................................................... 23

Annex 3, Mechanical exploded drawings and parts list .............................................................................

错误

!

未定义书签。