4

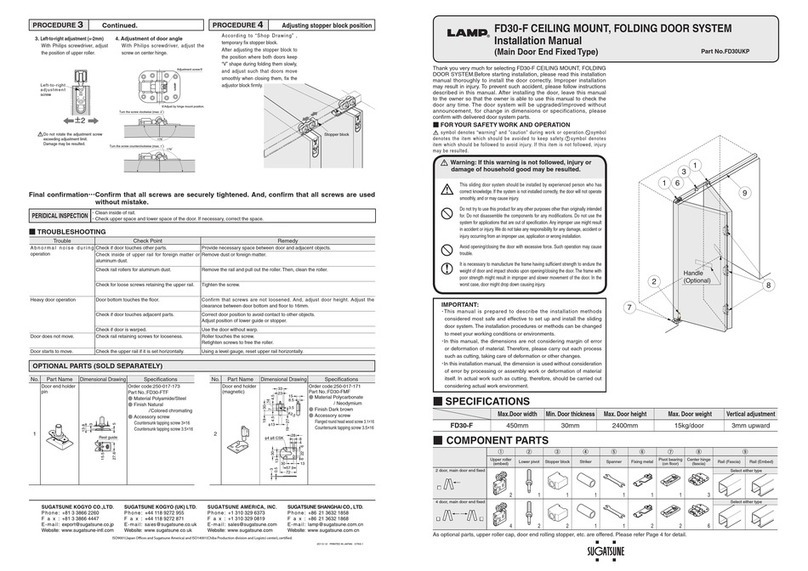

Hanging the Door and Adjustment

2

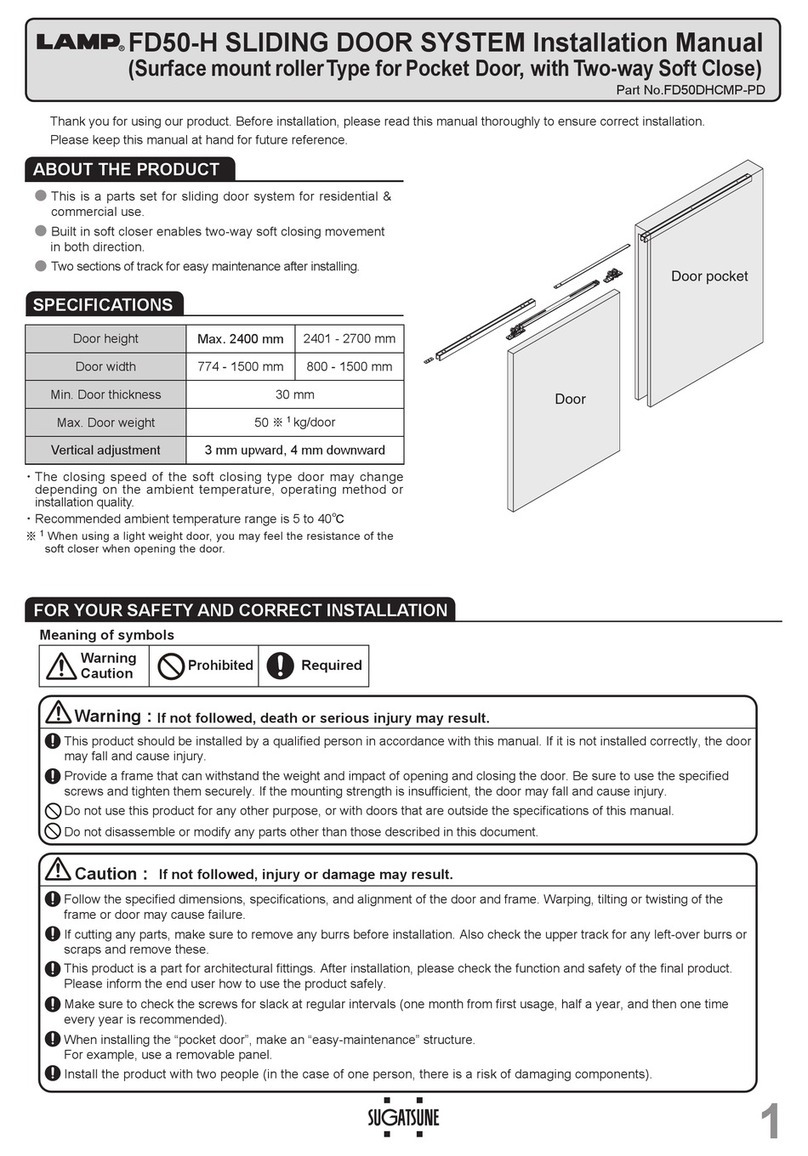

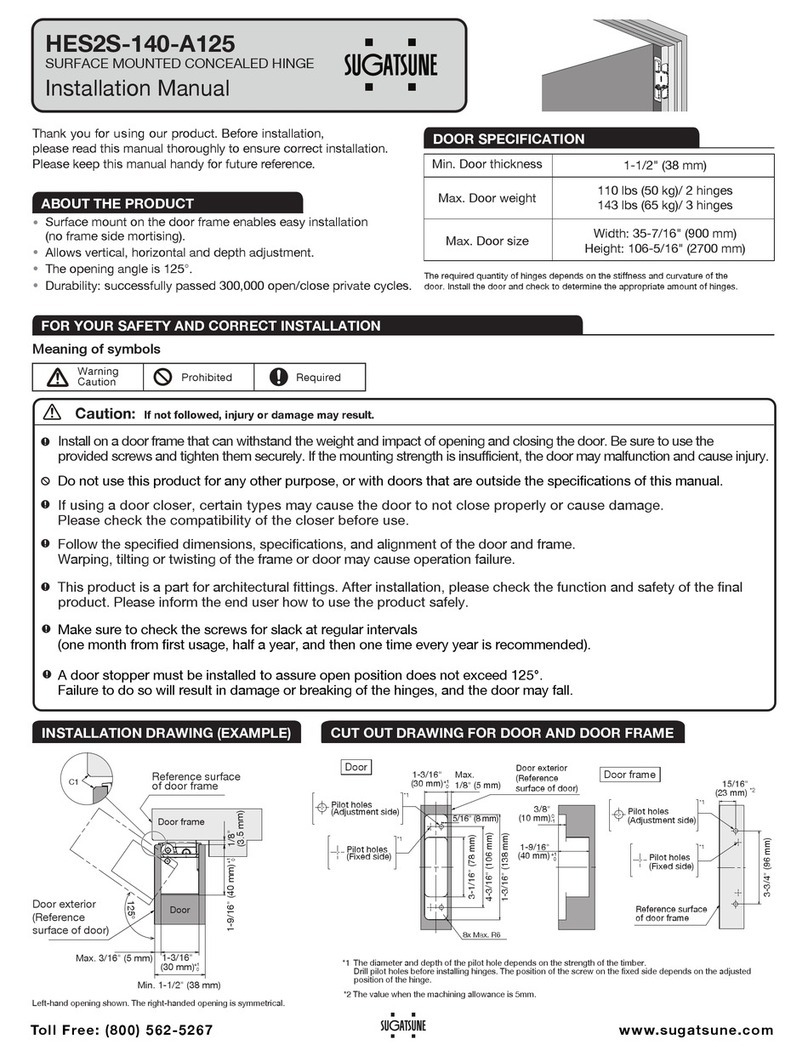

2Hanging (Top part)

Insert the upper roller into the bracket as shown in the drawing below.

1Hanging (Bottom part)

Put a 10 mm support under the door.

While holding the door, place the groove under the door

on the protruding part of the floor guide.

pper roller

Bracket

Support

Bottom guide S

3Adjustment of Door Height

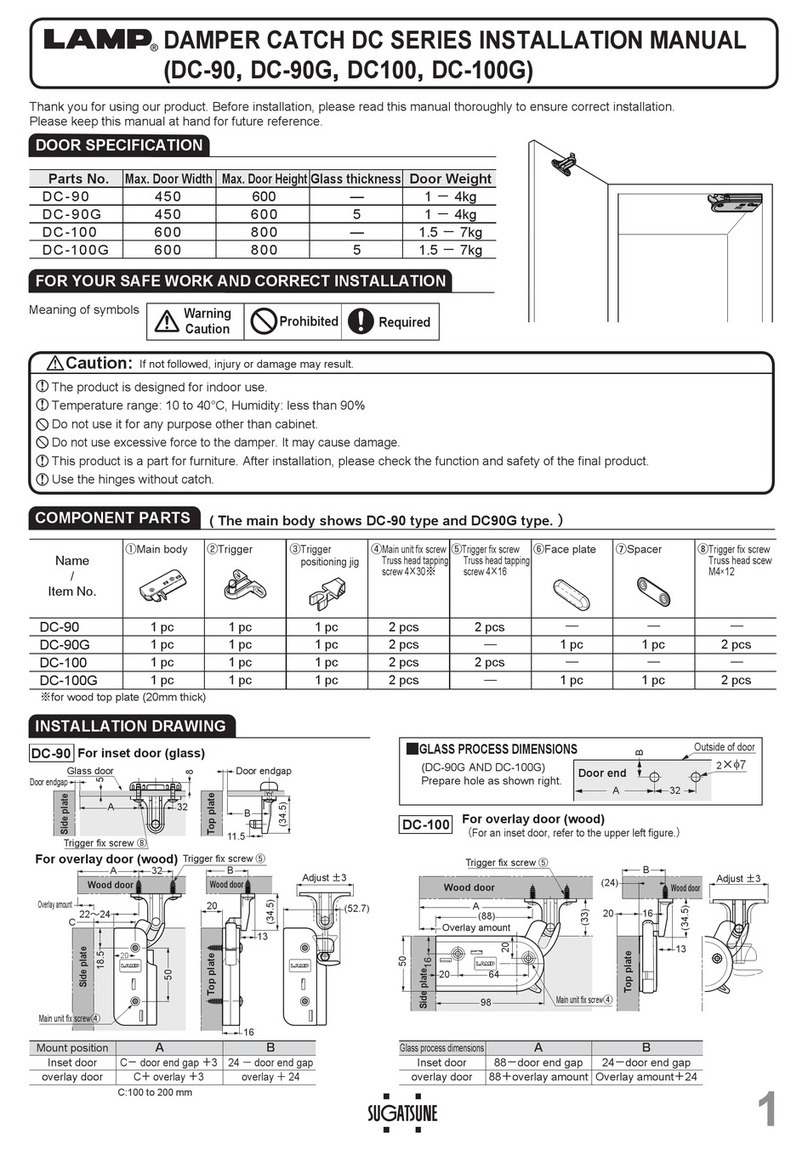

4Fixing end stopper

Fix the end stopper to the right position. Set the end stopper in place

as shown below. Then, fasten with the provided screw.

Fasten the opposite end stopper in a similar manner

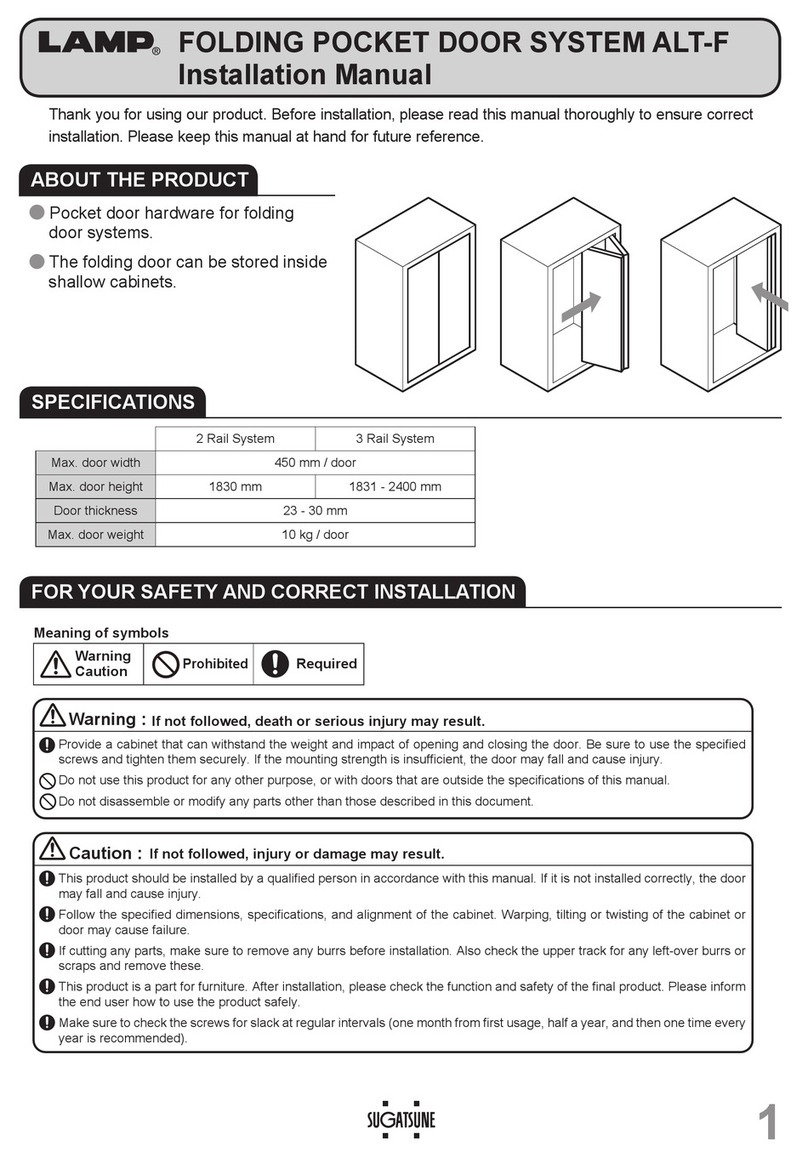

■HOW TO REMOVE DOOR

(1)Put a support under the door.

(2)Pull out the Holder.

(4)Remove the door from the Bottom guide.

(3)Pull out the Upper roller

from the Bracket.

Holder

Bracket

Upper roller

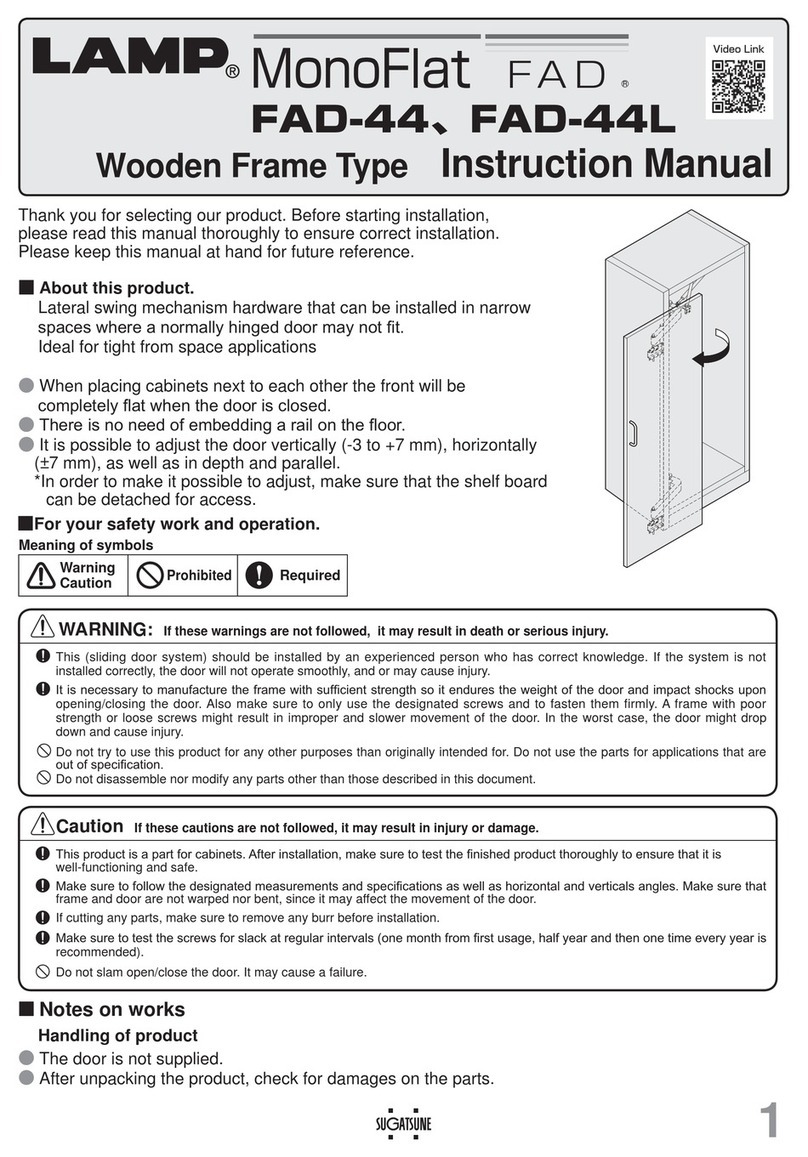

Trouble Check Point Solution

Abnormal noise during operation Check track rollers for ealuminum dust. Remove the track, then pull out and clean the roller.

Check the track mounting screws for looseness. Retighten the screws to free the roller.

Heavy door operation &KHFNLIGRRUERWWRPFRQWDFWVWKHÀRRURUÀRRUJXLGH

9HULI\WKDWWKHWUDFN ¿[LQJ VFUHZVDUHQRWORRVHQHG7KHQDGMXVWWKHGRRUKHLJKW

VXFKWKDWWKHFOHDUDQFHEHWZHHQWKHGRRUERWWRPDQGÀRRULVPP

Door does not move.

Check the track mounting screws for looseness.

Retighten the screws to free the roller.

Door starts to move. Check if the upper track is set horizontally. Using a level gauge, reset the upper track horizontally.

TROUBLESHOOTING

123

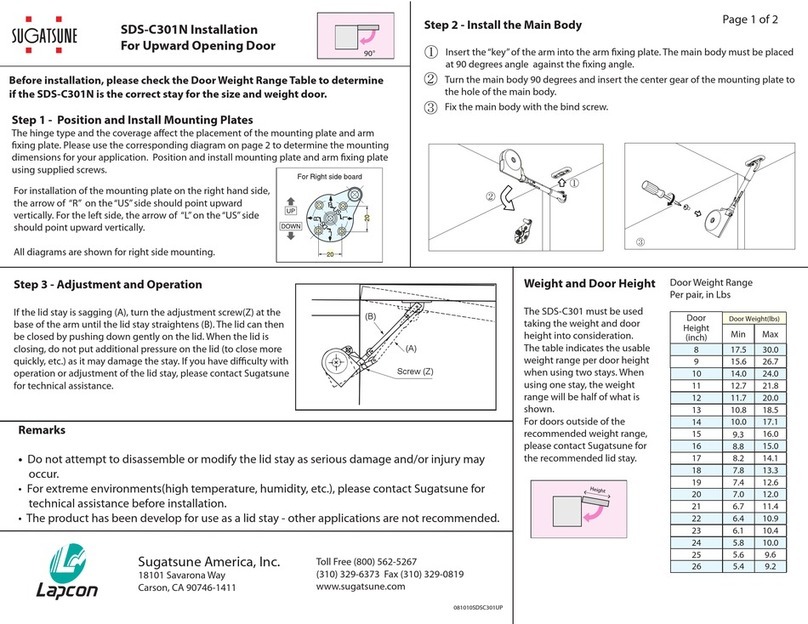

Inserting holder Verification of holder

Do not turn adjustment screw

more than adjustment range.

Bracket

Upper roller ②

Holder

Ensure that hanger bolt head

is in straight as shown for

proper fastening of the holder.

Vertical adjustment

range: 8mm

Adjustment of door height

1Adjusting the Door PositionRemove

the 10 mm support under the door.

2Adjust the door parallel to the upper

track with6 - 14 mm of clearance

between the door and floor.

Bracket

Hanger bolt M8

Down Raise

6 - 14 mm

CAUTION

SUGATSUNE KOGYO CO.,LTD

Tokyo, JAPAN

SUGATSUNE KOGYO (UK) LTD

Reading, UK

Phone: +44 118 9272 955

SUGATSUNE EUROPE GmbH

Dusseldorf, GERMANY

Phone: +49 211 53812900

SUGATSUNE SHANGHAI Co., LTD

Shanghai, CHINA

Guangzhou, CHINA

SUGATSUNE KOGYO INDIA PRIVATE LIMITED

Mumbai, INDIA

SUGATSUNE AMERICA, INC

California, USA

Chicago, USA

Phone: +1 630 317 7072

SUGATSUNE CANADA, INC.

Phone: +1 514 312 5267

2022.08 0595-6

Stopper position adjust screw

35

)LQDOYHUL¿FDWLRQ

Verify that all screws are securely tightened, and verify that all screws have been used.

PERIODICAL INSPECTION

・Clean the inside of the track.

・Check the upper and lower space of the door.,IQHFHVVDU\FRUUHFWWKHVSDFH