1. GENERAL INFORMATION

1-3

Service Precautions

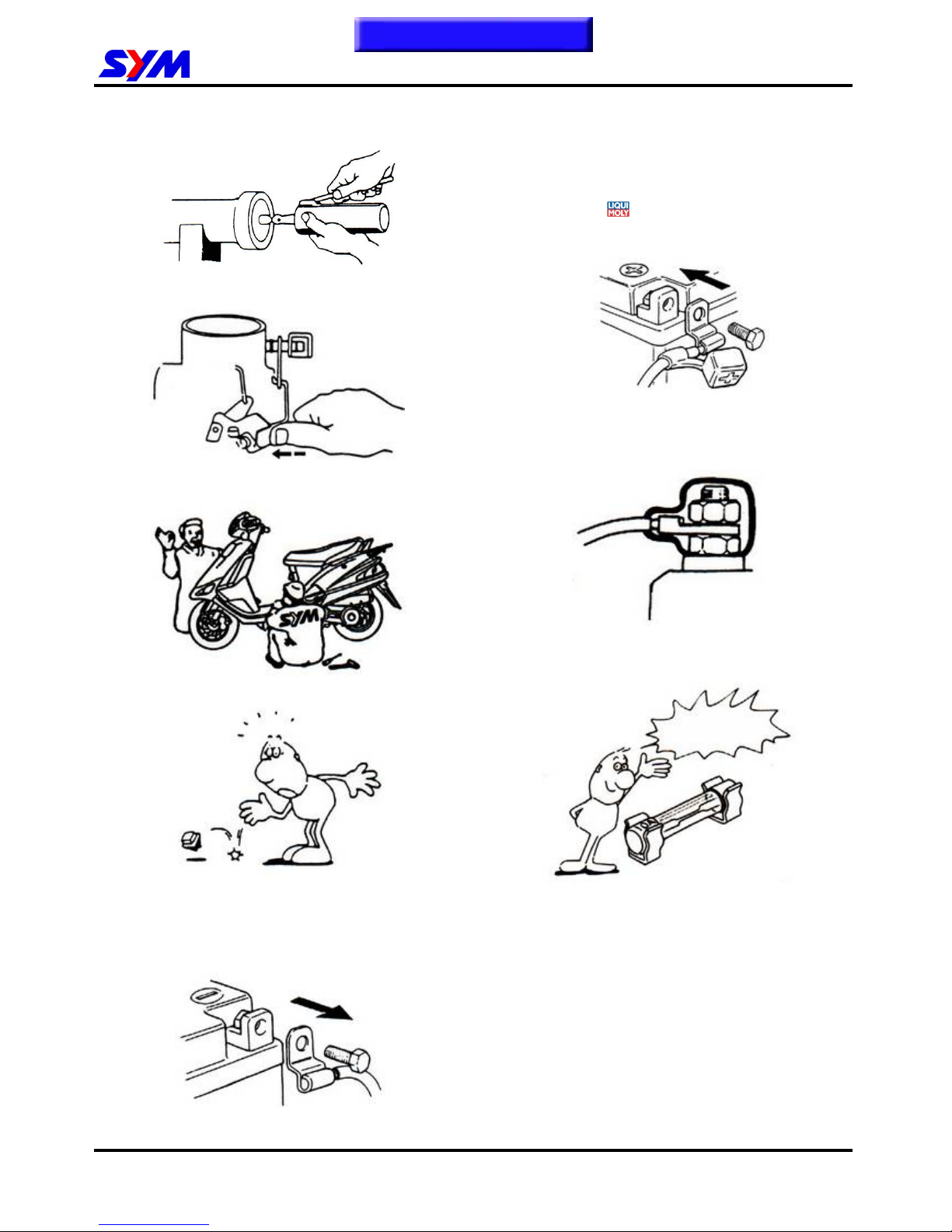

Always use with Sanyang genuine parts and

recommended oils. Using non-designed parts for

Sanyang motorcycle may damage the motorcycle.

Special tools are designed for remove and install

of components without damaging the parts being

work ed on. Using wrong tools may result in parts

damaged.

When servicing this motorcycle, use only metric

tools. Metric bolts, nuts, and screws are not

interchangeable with the English system, using

wrong tools and fasteners may damage this

vehicle.

Clean the outside of the parts or the cover

before removing it from the motorcycle.

Otherwise, dirt and deposit accumulated on the

part's surface may fall into the engine, chassis,

or brake system to cause a damage.

Wash and clean parts with high ignition point

solvent, and blow dry with compressed air. Pay

special attention to O-rings or oil seals because

most cleaning agents have an adverse effect on

them.

Never bend or twist a control cable to prevent

unsmooth control and premature worn out.

Rubber parts may become deteriorated when

old, and prone to be damaged by solvent and

oil. Check these parts before installation to

make sure that they are in good condition,

replace if necessary.

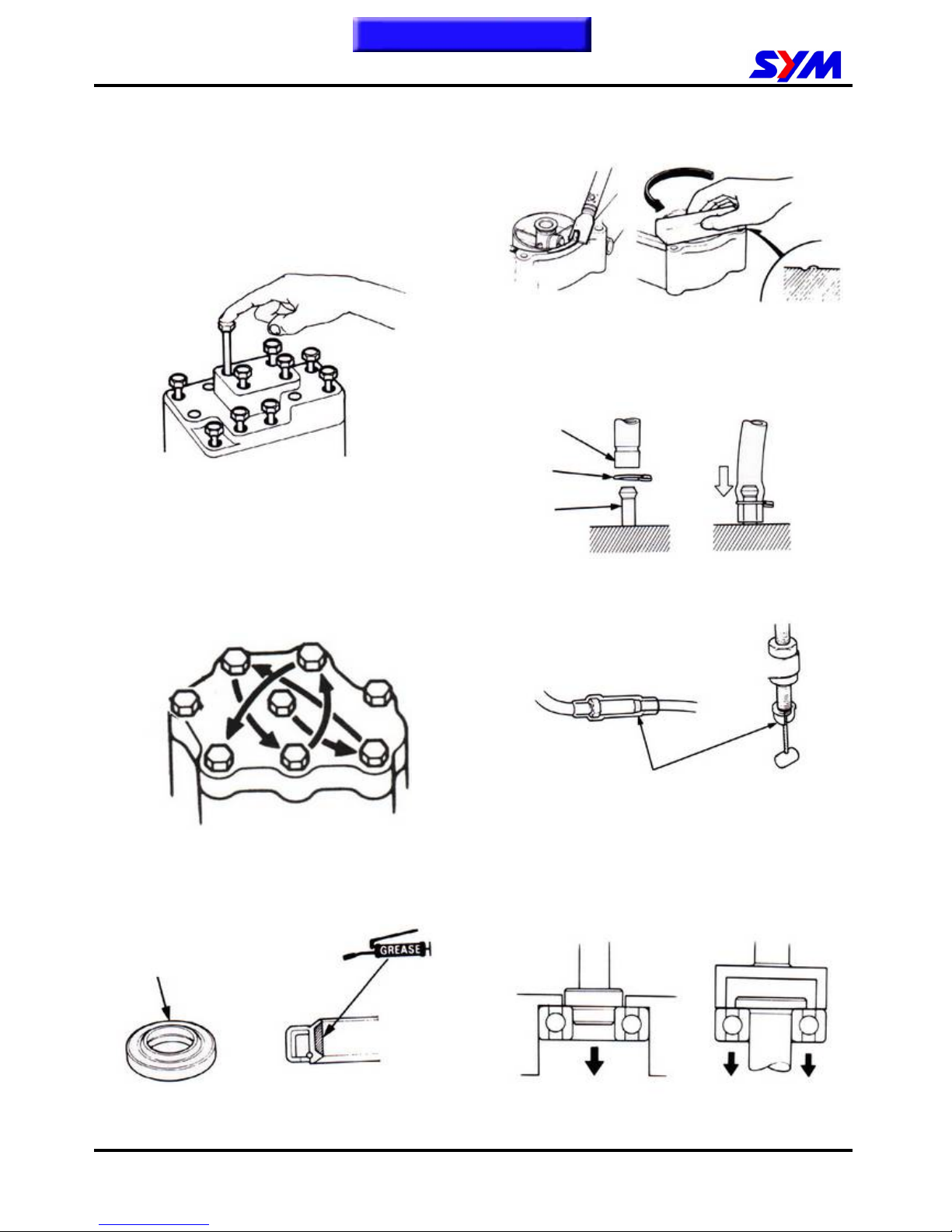

When loosening a component which has

different sized fasteners, operate with a

diagonal pattern and work from inside out.

Loosen the small fasteners first. If the bigger

ones are loosen first, small fasteners may

receive too much stress.

Store complex components such as transmission

parts in the proper assemble order and tie them

together with a wire for ease of installation later.

Note the reassemble position of the important

components before disassembling them to

ensure they wil l be reassembled in correct

dimensions (depth, distance or position).

Components not to be reused should be replaced

when disassembled including gaskets metal seal

rings, O-rings, oil seals, snap rings, and split pins.

To this chapter contents