1 Contents

4

1Contents

1Contents .................................................................................................. 4

2Safety and the environment ................................................................... 5

2.1. About this document ....................................................................... 5

2.2. Ensure safety .................................................................................. 6

2.3. Protecting the environment ............................................................. 6

3Specifications.......................................................................................... 7

3.1. Use ................................................................................................. 7

3.2. Technical data................................................................................. 8

4Product description ................................................................................ 9

4.1. Overview......................................................................................... 9

4.2. Basic properties ............................................................................ 11

5First steps.............................................................................................. 12

5.1. Commissioning ............................................................................. 12

5.2. Getting to know the product .......................................................... 13

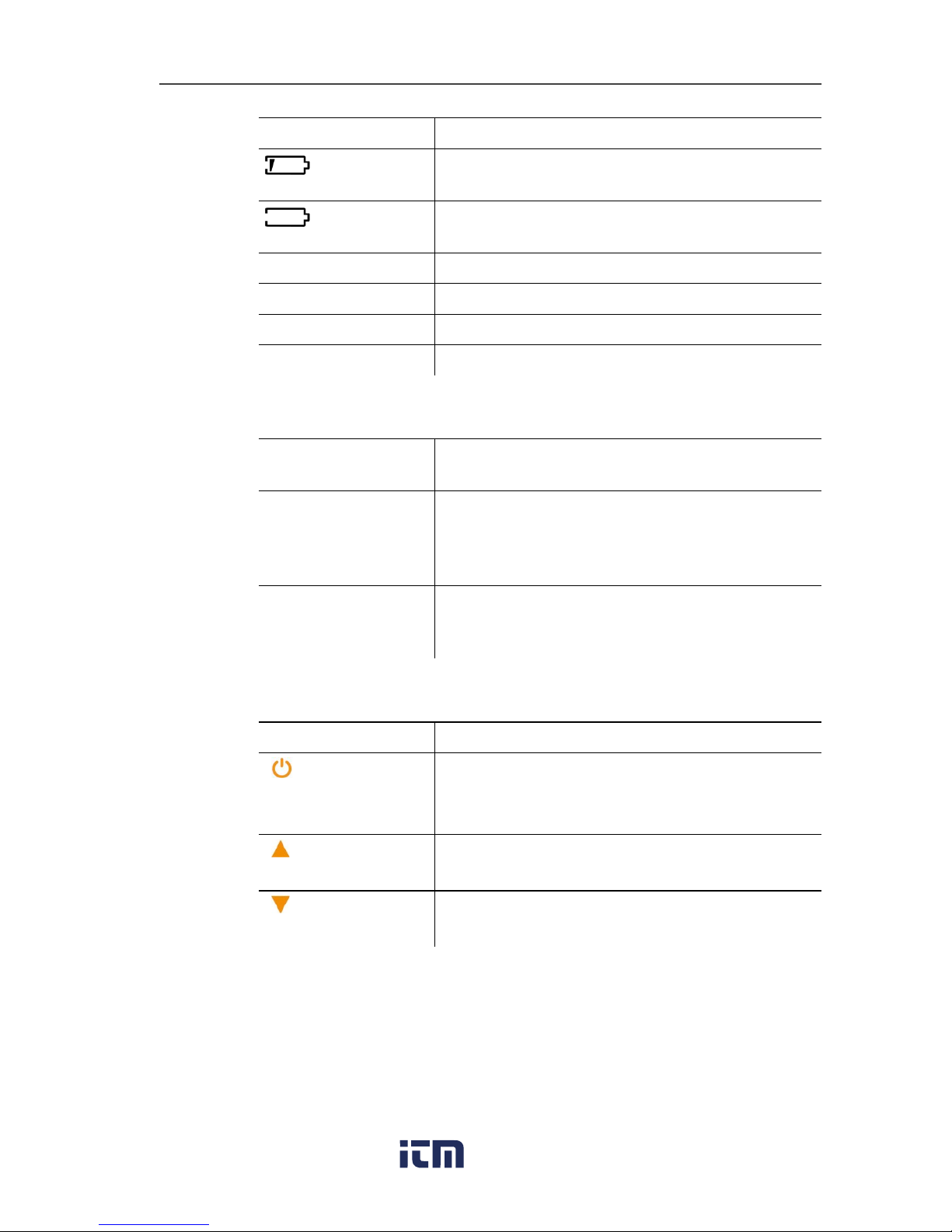

5.2.1. Switching the instrument on/off...................................................................... 13

5.2.2. Alarm LED ..................................................................................................... 14

5.2.3. Battery capacity ............................................................................................. 14

5.2.4. Hold function.................................................................................................. 14

5.2.5. Auto Hold function ......................................................................................... 15

5.2.6. Auto off function............................................................................................. 15

5.2.7. Setting the TPM limit values .......................................................................... 15

5.2.8. Locking/unlocking the TPM limit values ......................................................... 16

5.2.9. Configuring the instrument............................................................................. 16

5.2.10. Locking/unlocking the configurations ............................................................. 18

6Using the product ................................................................................. 19

6.1. General measuring notes.............................................................. 19

6.2. Performing measurements............................................................ 20

6.3. Function test ................................................................................. 22

7Maintaining the product ....................................................................... 23

7.1. Changing the batteries.................................................................. 23

7.2. Cleaning the sensor ...................................................................... 23

7.3. Cleaning the housing/TopSafe/wrist strap .................................... 24

7.4. Calibrating/adjusting the instrument.............................................. 25

8Tips and assistance .............................................................................. 28

8.1. Questions and answers ................................................................ 28

8.2. Accessories and spare parts......................................................... 29