Contents

4

Contents

Preface ......................................................................2

General information ..................................................3

Contents....................................................................4

1. Basic safety information ............................................5

2. Intended use ............................................................6

3. Product description ..................................................7

3.1 System components ................................................7

3.2 Operating elements ..................................................7

3.3 Settings ..................................................................8

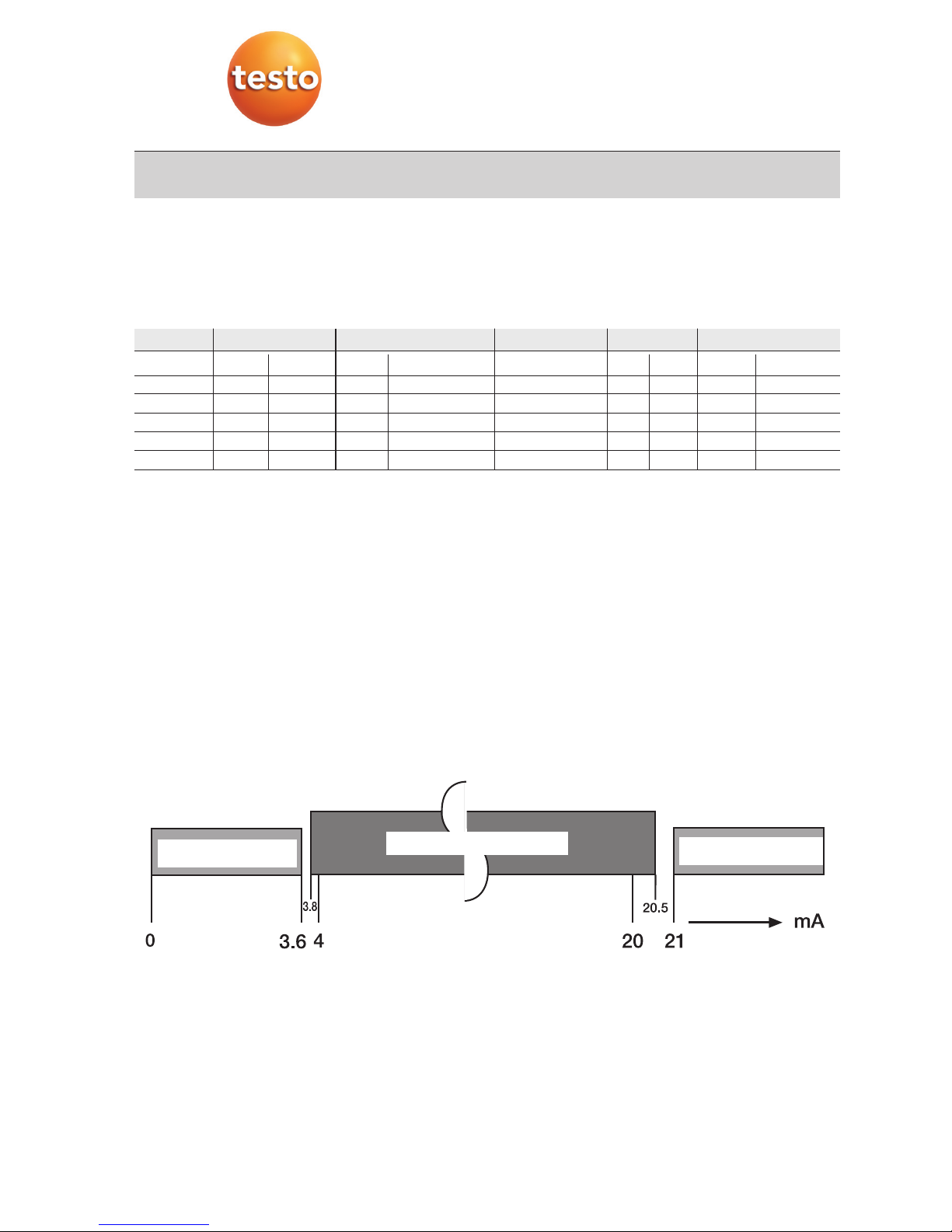

3.4 Current output intervals ............................................8

4. Initial operation ..........................................................9

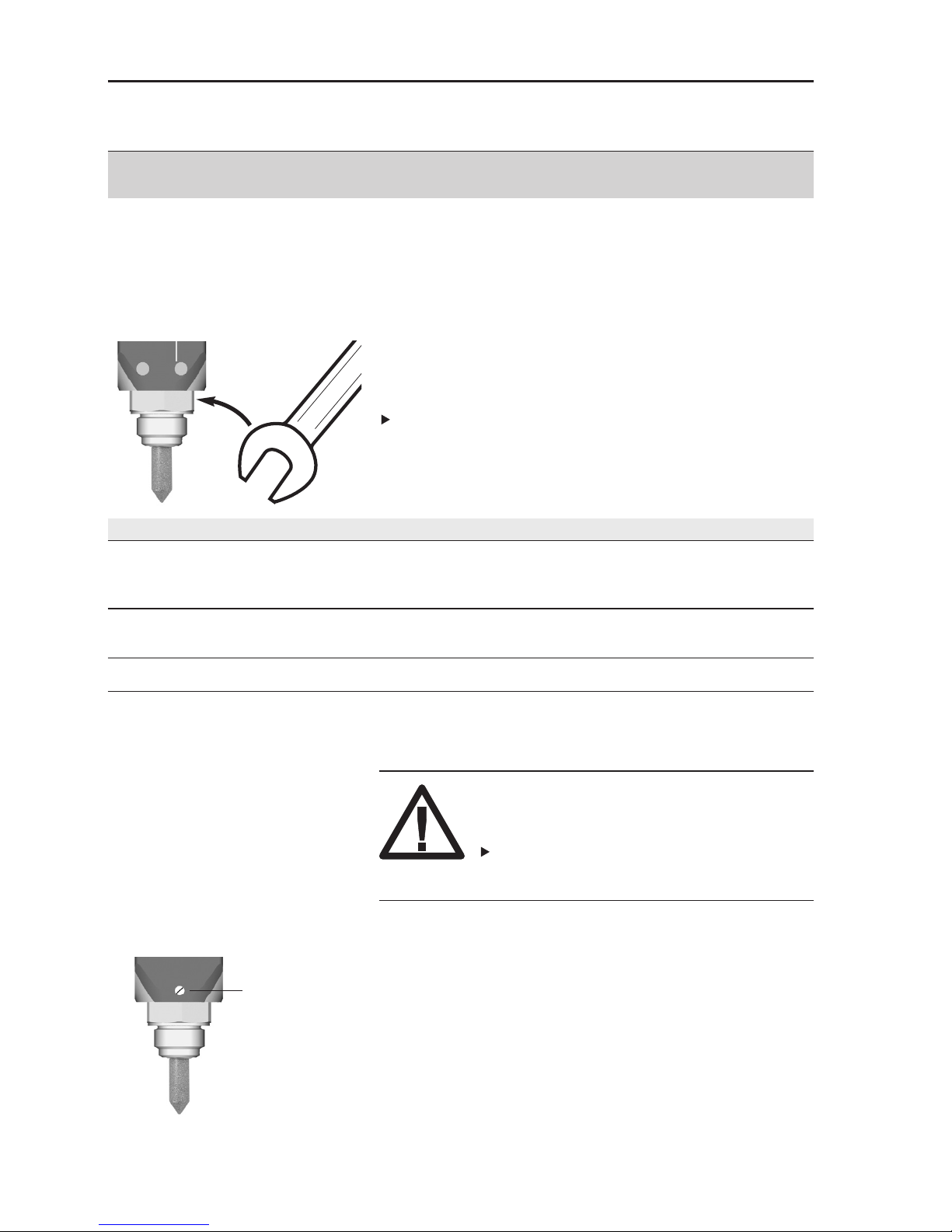

4.1 Mechanical assembly ..............................................9

4.2 Electric connection ..............................................11

4.3 Analog output/Limit signal outputs ........................14

5. Menu guide (0555.6743 /0555.6744 only) ..............16

6. Adjustment on site ..................................................19

7. Care and maintenance ............................................23

8. Troubleshooting ......................................................24

9. Technical data ........................................................25

9.1 Measurement ranges and accuracies ....................25

9.2 Additional instrument data ....................................25

9.3 Uncertainty pressure dewpoint temperature............26

10. Accessories /Spare parts ........................................27