TEXI TRONIC 7 NF operation manual

CONTENTS

Before operation ……………………………………………….……………………………………….………………………. 2

1. Specifications …………………………………………….……………………………………………….………………... 2

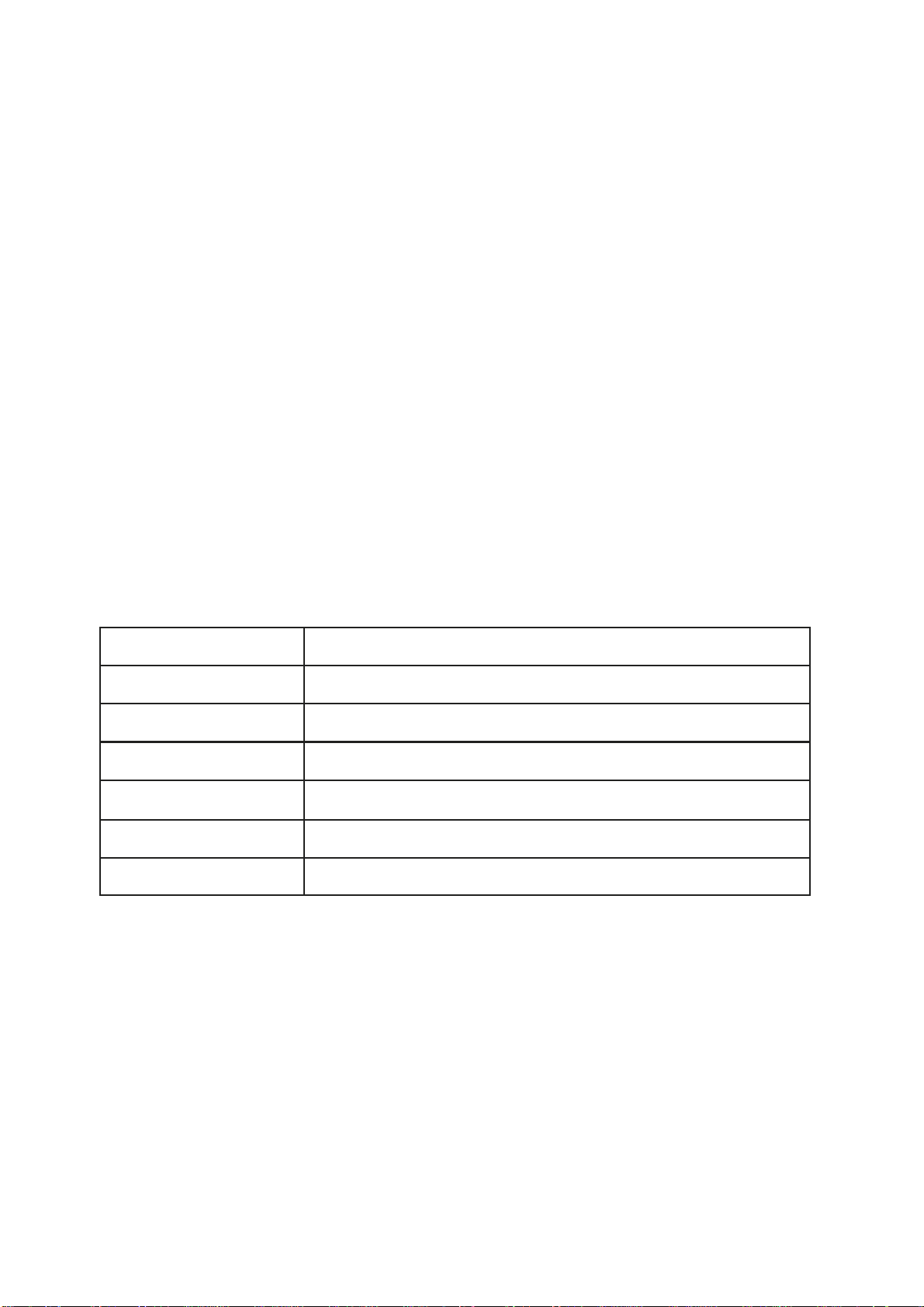

2. Installation ……………………………………………….………………………………………………………..………. 3

3. Adjusting the height of the knee lifter ………………………………………………………………………….………. 4

4. Installing the thread stand ……………………………………………………………………………………….……… 4

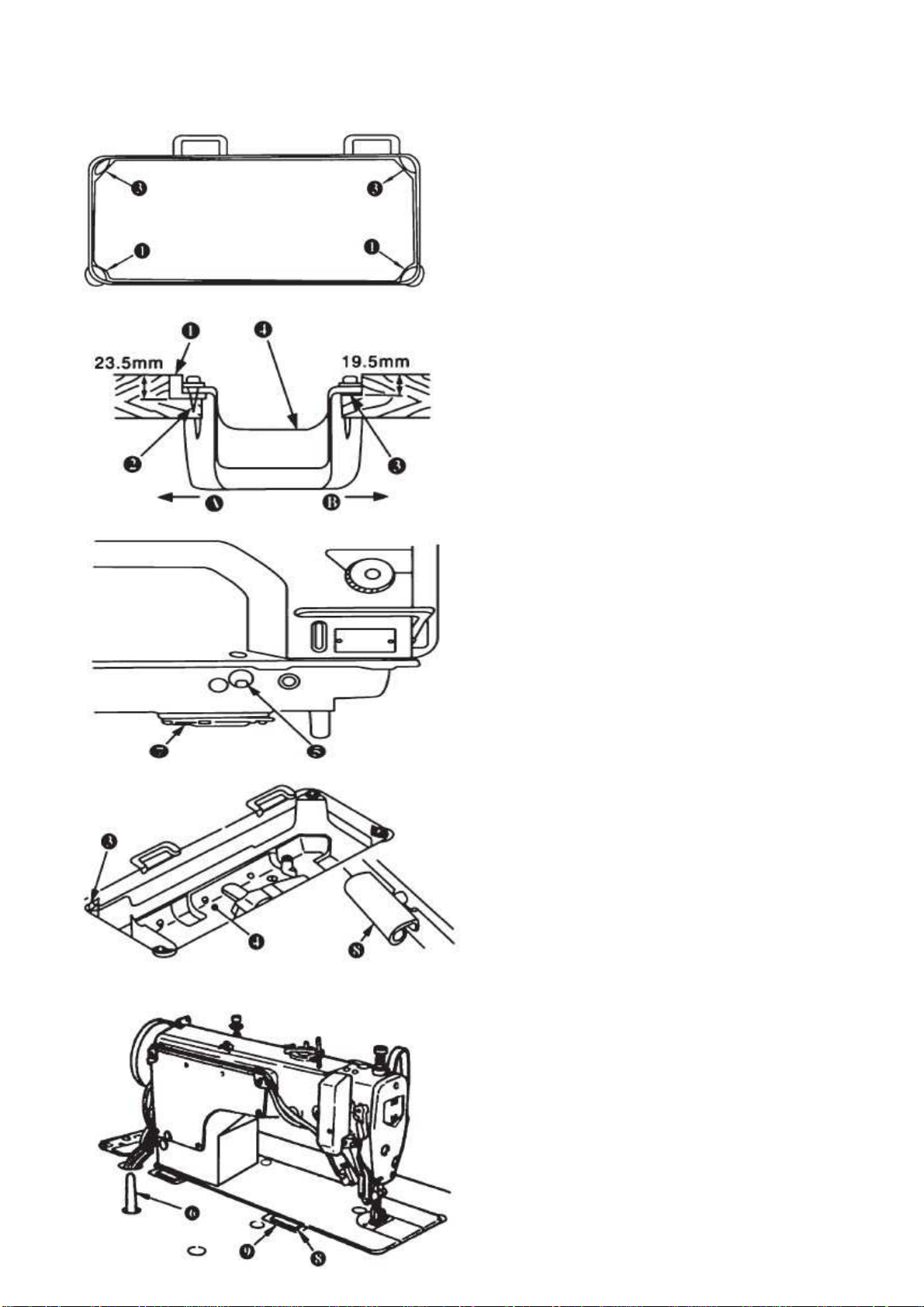

5. Lubrication ……………………………………………………………………………………………..…………………. 5

6. Adjusting the amount of oil in the hook ………………………………………………………………………..……… 5

7. Adjusting the amount of oil (oil splashes) in the hook ……………………………………………………...………… 6

8. Attaching the needle ……………………………………….……………………………………………..……………… 7

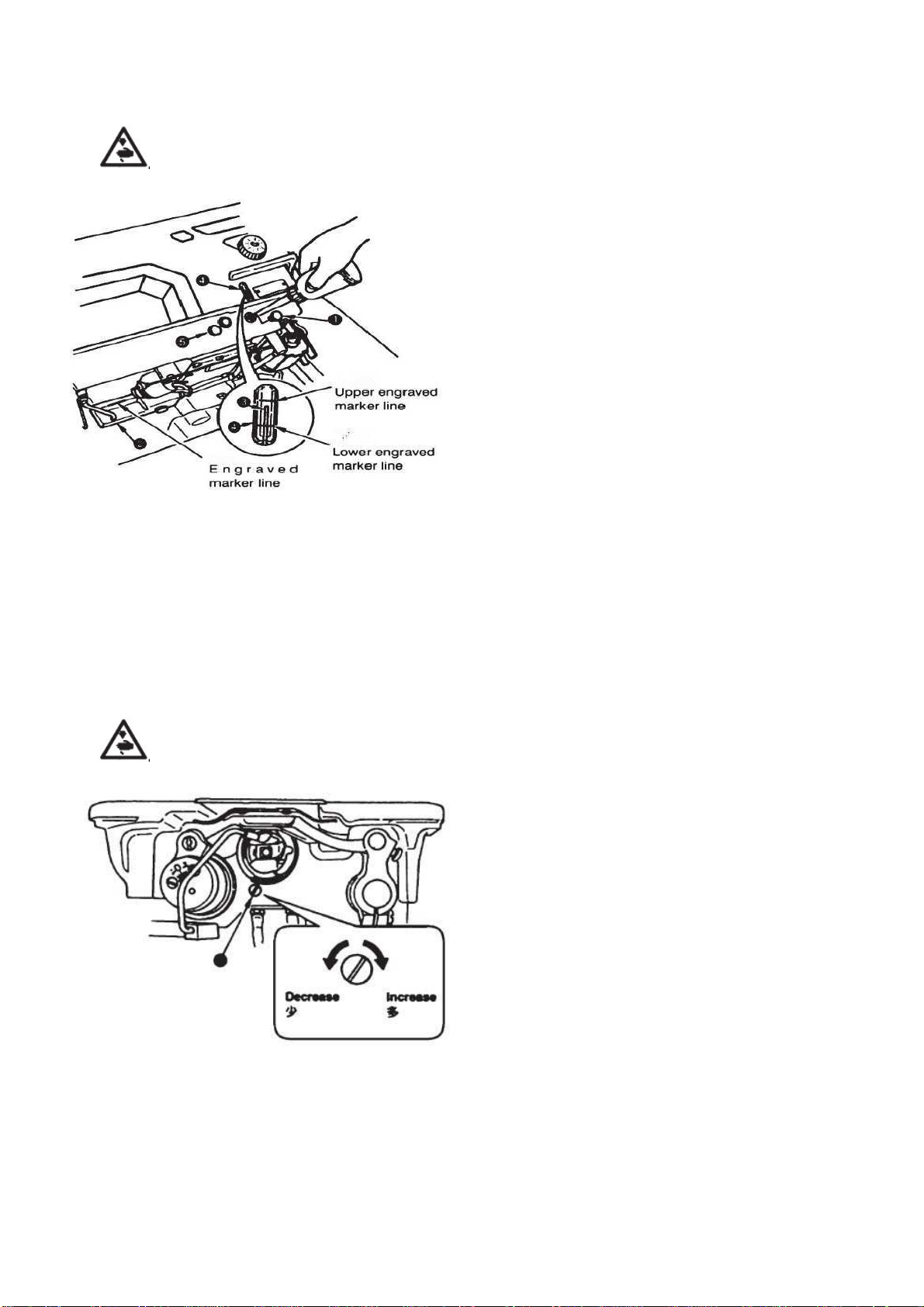

9. Setting the bobbin into the bobbin case …………………….……………………………………………….………… 7

10. Adjusting the stitch length ……………………………………………………………………………………….………. 7

11. Presser foot pressure ……………………………………………………………………………………………...……… 8

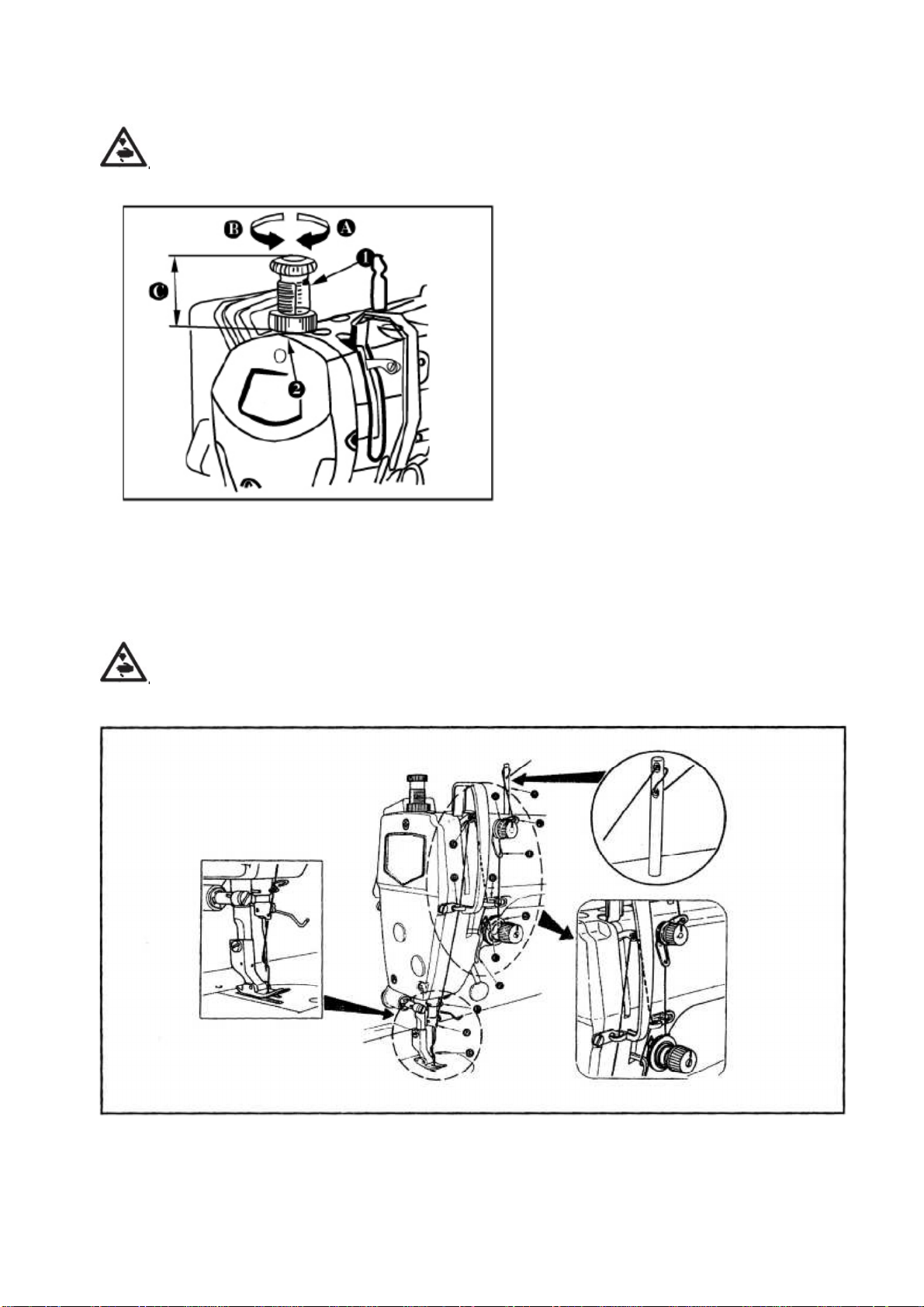

12. Threading the machine head …………………………………………………………………………………………….. 8

13. Winding the bobbin thread ………………………………………………………………………………………..……… 9

14. Thread tension ………………………………………………………………………………………………………..…… 10

15. Thread take-up spring …………………………………………………………………………………………………..… 10

16. Adjusting the thread take-up stroke …………………………………………………………………………………...… 11

17. Adjusting the needle stop position …………………………………………………………………………….………… 11

18. Adjusting of the pedal …………………………………………………………………………………………..………… 12

19. Pedal operation ……………………………………………………………………………………….…………………… 12

20. Wiper ………………………………………………………………………………………………………….……………. 13

21. One-touch reverse stitching mechanism …………………………………………………………………..…………… 13

22. Needle bar and hook regulation……………………………….………………………………………………………… 14

23. Replacing counter knife and moving knife………………………...……………………………………………………. 15

24. Thread cutting regulation………………………..……………….………………………………………………..……… 16

25. The change of feed cloth………………………………………………………………………………………………….. 17

26. Height and tilt of the feed dog …………………………………….……………………………………………….……… 17

27. Adjusting the feed timing …………………………………………..……………………………………….……………… 19

28. Thread tension release releasing mechanism ……………………..………………………………….………………… 19

29. Micro-lifting mechanism of the presser foot …………………………..…………………………………..……………… 20

30. Caution when carrying or placing the sewing machine ……………………………………………………..………… 20

Ask your supplier about

CE Declaration of Conformity

1