3

TEXI Twin MS operation manual

CAUTION

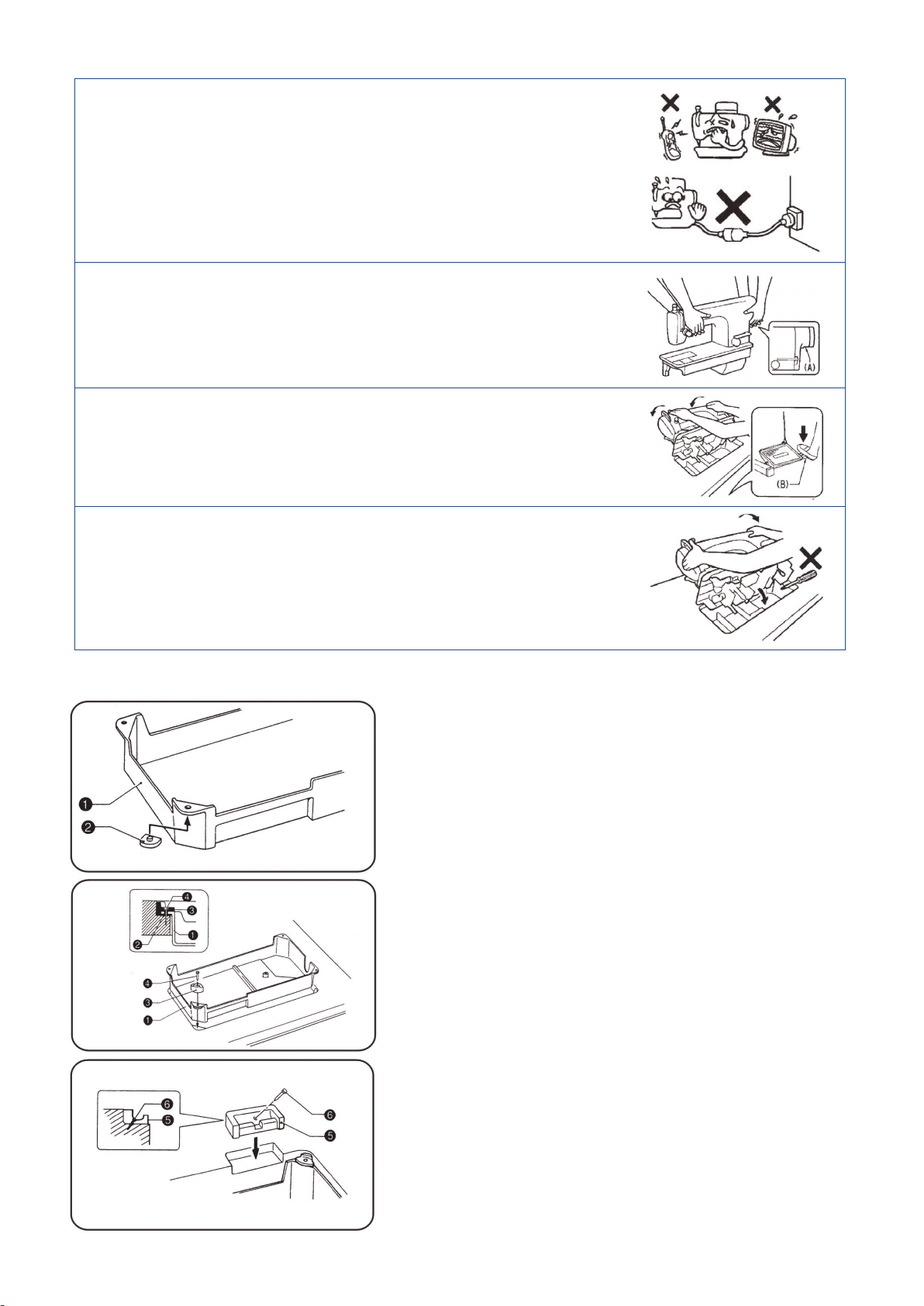

Installation

Sewing

Cleaning

Maintenance and inspection

Machine installation should only be carried our by

a qualified technician.

Contact your dealer or a qualified electrician for any

electrical work that may need to de done.

The sewing machine weights more than 65 kg.

The installation should be carried out by two or more

people.

Do not connect the power cord until installation is

complete. Otherwise the machine may operate if

the treadle is pressed by mistake, which could result

injury.

Be sure to connect the ground. If the ground

connection is not secure, you run the risk of receiving

a serious electric shock.

All cords should be secured at least 25 mm away

from any moving parts. Furthermore do not

excessively bend the cords or secure too firmly with

staples, otherwise shocks could occur.

Be sure to wear protective goggles and gloves when

handling the lubricating oil, so that no oil gets into

your eyes or onto your skin, otherwise inflammation

can result.

Furthermore do not drink the oil under any

circumstances as it can cause vomiting and

diarrhoea. Keep the oil out of the reach of children.

The sewing machine should only be used by

operators who have received the necessary training

in safe use beforehand.

The sewing machine should not be used for any

applications other than sewing.

Turn off the power switch at the following. The motor

will keep turning even after the power is switched off

as a result of the motor’s inertia. Wait until the motor

stops fully before starting work.

- When threading the needle

- When replacing the needle and bobbin

- When not using the machine and when leaving the

machine unattended.

Turn off the power switch before carrying out

cleaning. The motor will keep turning even after

the power is switched off as a result of the motor’s

inertia. Wait until the motor stops fully before starting

work. The machine may operate if the treadle is

pressed by mistake

Attach all safety devices before using the sewing

machine. If the machine is used without these

devices attached, injury may result.

Do not touch any of the moving parts or press any

objects against the machine while sewing as this may

result in personal injury or damage of the machine.

In an error occurs in machine or if abnormal noises

or smells are noticed mmediatelly turn off the power

switch. Then contact your nearest sealer or

a qualified technicain.

If the machine develops a problem contact your

nearest dealer or qualified technician.

Be sure to wear protective goggles and gloves when

handling the lubricating oil so that no oil gets into

your eyes or onto your skin. Otherwise inflammation

can result. Furthermore do not drink oil under any

sircumstances as it can cause vomiting and

diarrhoea. Keep the oil of hte reach of children.

Maintenance and inspection of machine should only

be carried out by a qualified technician.

Ask your dealer or a qualified electrician to carry any

maintenance and inspection o felectrical system.

Turn off the power switch and disconnect the power

cord from the wall outlet at the following times.

Otherwise the machine may operate if the threadle is

pressed by mistake. The motor will keep turning after

the power is switched off as a result of motor’s iner-

tia. Wait until motor stops fully before starting work.

When checking the rotary hook lubrication do not

touch moving parts such as the rotary hook, needle

and needle bar with your finger or paper. Otherwise

injury or damage of machine may result.

In any safety devices have been removed be absolu-

tely sure to re-install them to their original positions

and check if they operate correctly.

Any problems in machine operation which result from

unauthorized modifications to the machine will not be

covered by the warranty.