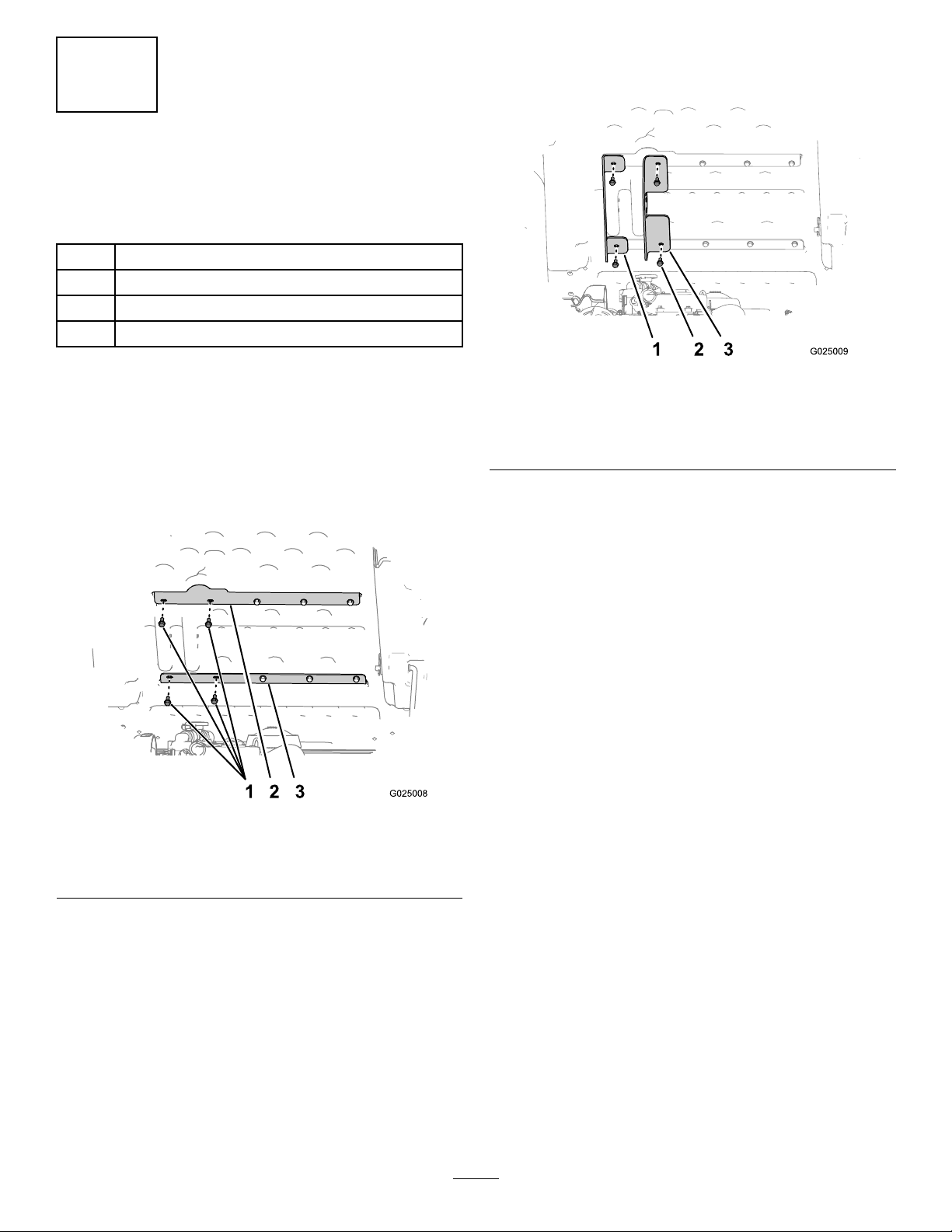

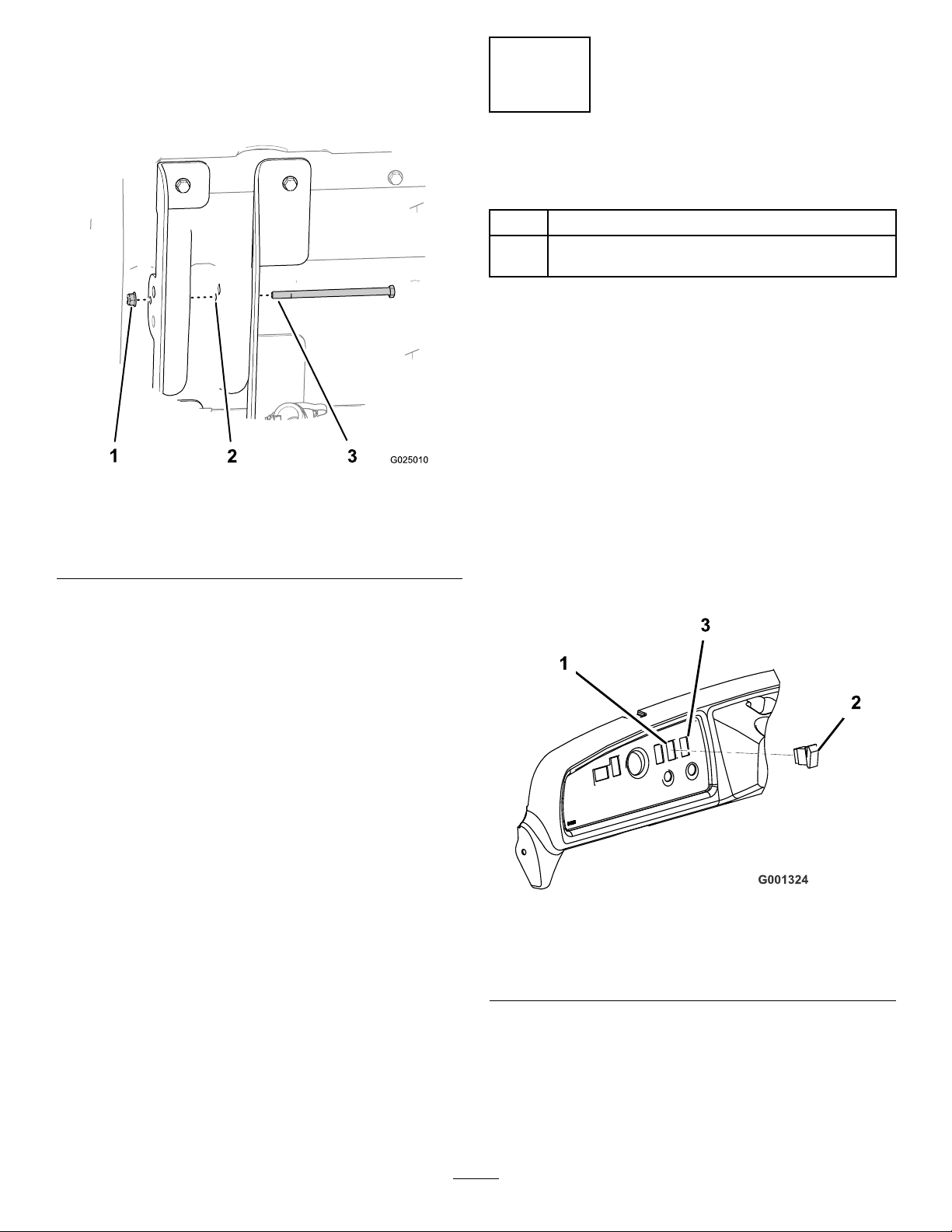

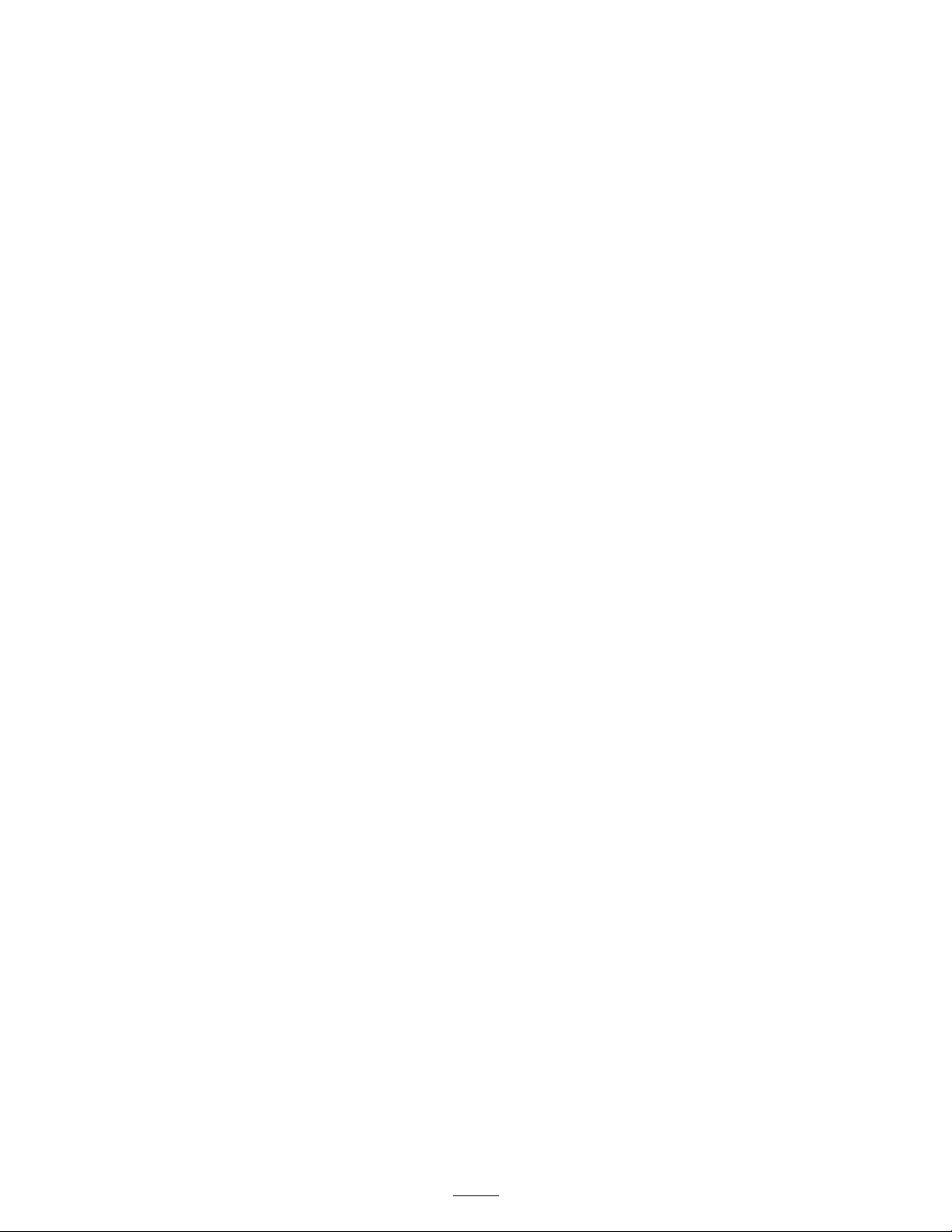

7.Presstheuppaddlethebed-liftswitchtoextend

therodoftheliftactuatorroduntiltheholeinthe

rodisalignswiththeholesintheinboardand

outboard-liftbrackets(Figure11).

Note:Selectthesetofholesinthebracket

forthegasolineanddieselmachines;referto

SafetyandInstructionalDecals(page1)forthe

holelocationsforthismachine.

g025012

Figure11

1.Locknut(1/2inch)5.Lift-actuatorrod

2.12.7mm(1/2inch)hole

forthehex-headbolt

6.12.7mm(1/2inch)hole

fortheclevispin

3.Hex-headbolt(1/2x5-1/2

inches)

7.Clevispin(3-1/2inches)

4.Hairpin

8.Securethelift-actuatorrodtotheliftbrackets

withtheclevispin(3-1/2inches)andhairpin

(Figure11).

Note:Tightenthelocknutandangenutuntil

theyaresnug.

9.Tightenthe4bolts(5/16x3/4inch)thatsecure

theinboardandoutboard-liftbracketstothebed

(Figure5)to15to16.6N-m(133to147in-lb).

10.Alignthehex-headbolt(1/2x5-1/2inches)

throughtheremaining12.7mm(1/2inch)holes

intheinboardandoutboard-liftbrackets(Figure

11)andsecureitwithalocknut(1/2inch)until

thenutissnug.

11.Tightentheangenutthatsecuresthebolt(5/16

inch)untilitissnug(Figure6).

5

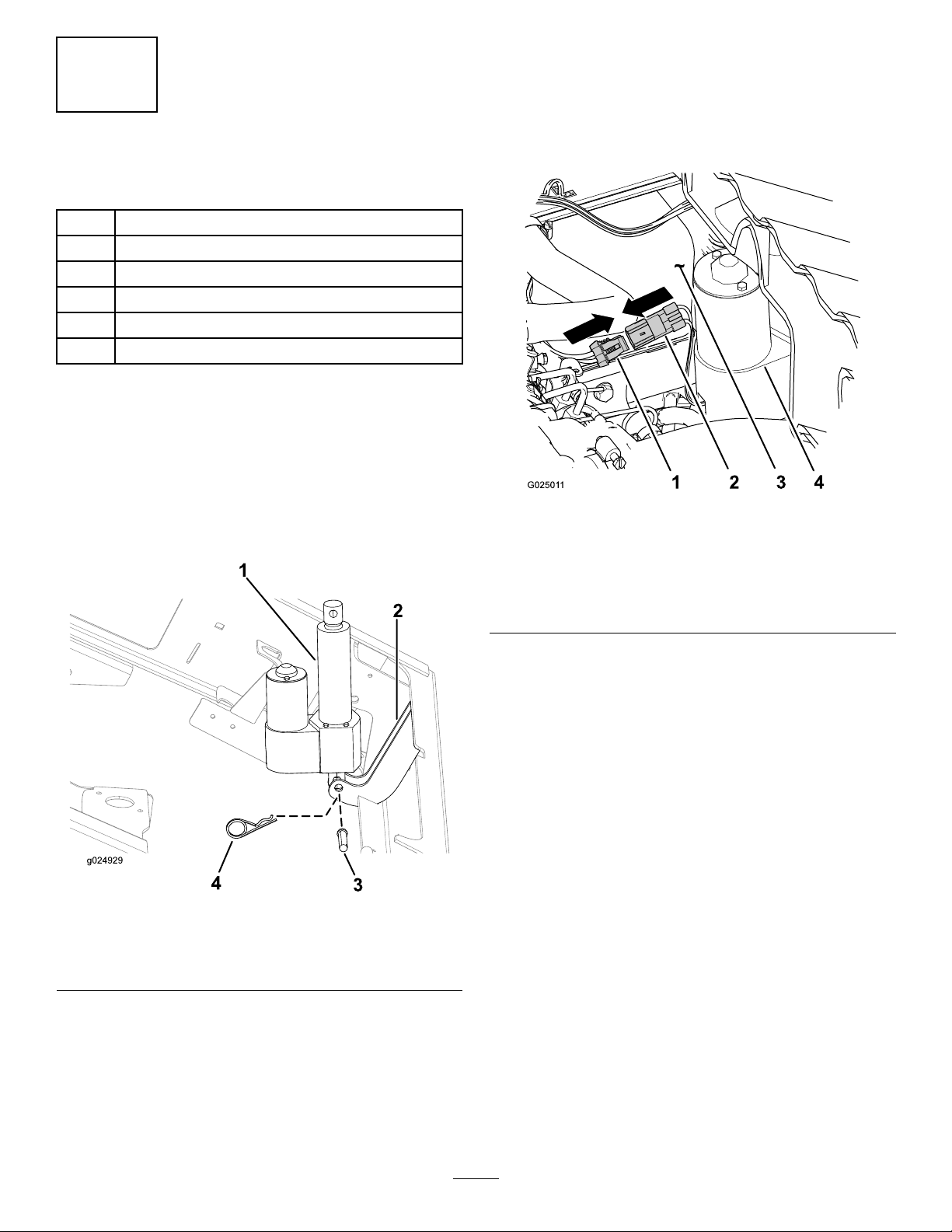

RemovingthePropRod

NoPartsRequired

Procedure

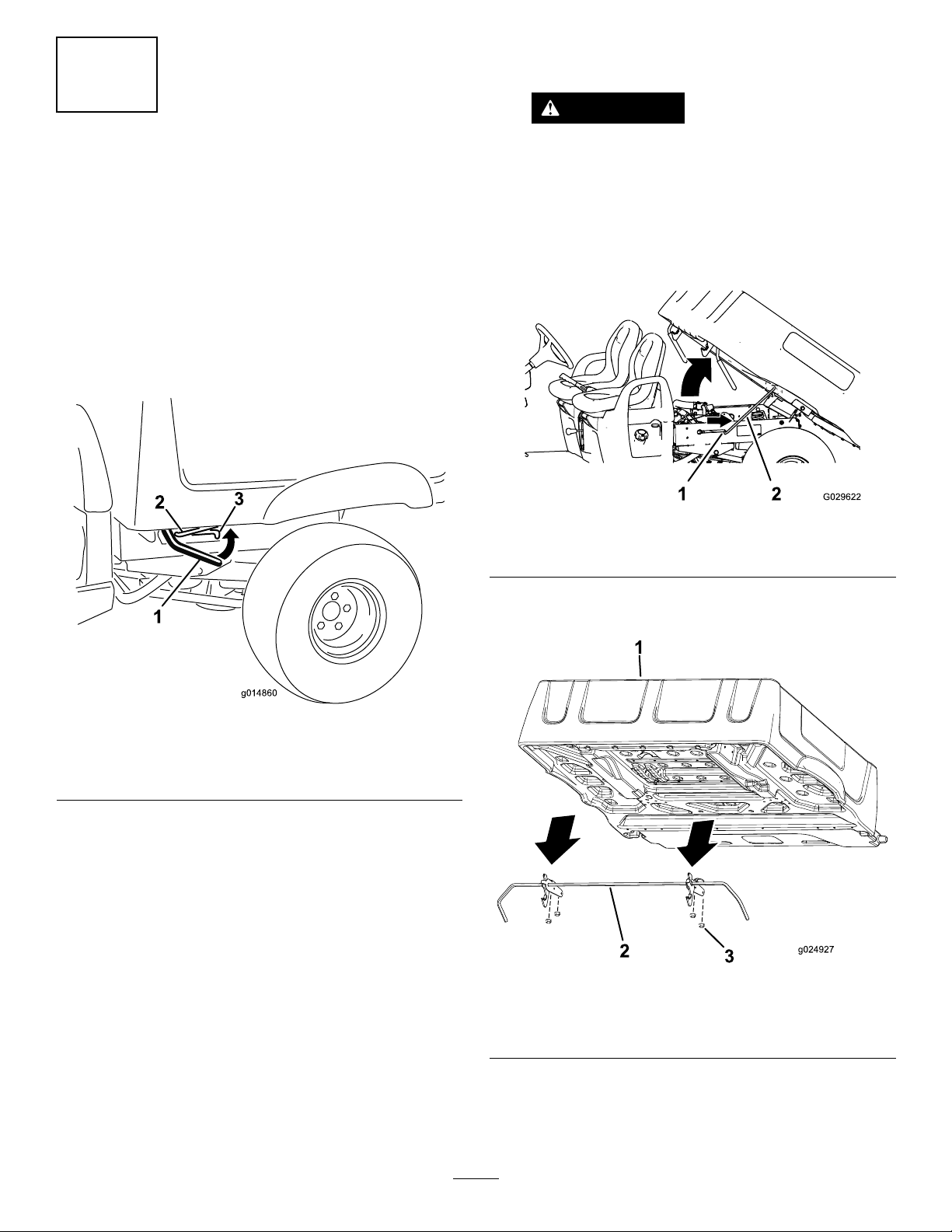

1.Removethehairpinandwasherthatsecurethe

proprodtothebottomofthebed(Figure12).

g025013

Figure12

1.Washer4.Bedhole

2.Hairpin5.Proprod

3.Slot(frame)

2.Slidetheproprodforwardtoremoveitfromthe

bracketontheframe(Figure12).

Note:Retaintheproprodcomponentsfor

futureuse.

Note:Iftheelectricboxliftiseverremoved,

installtheproprodandlatchrodagain,using

theexistingfastenersandtheprop-rodbracket.

8