FormNo.3420-758RevA

BallCageKit

Workman®GTXUtilityVehicle

ModelNo.07161—SerialNo.400000000andUp

InstallationInstructions

WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orreproductiveharm.

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

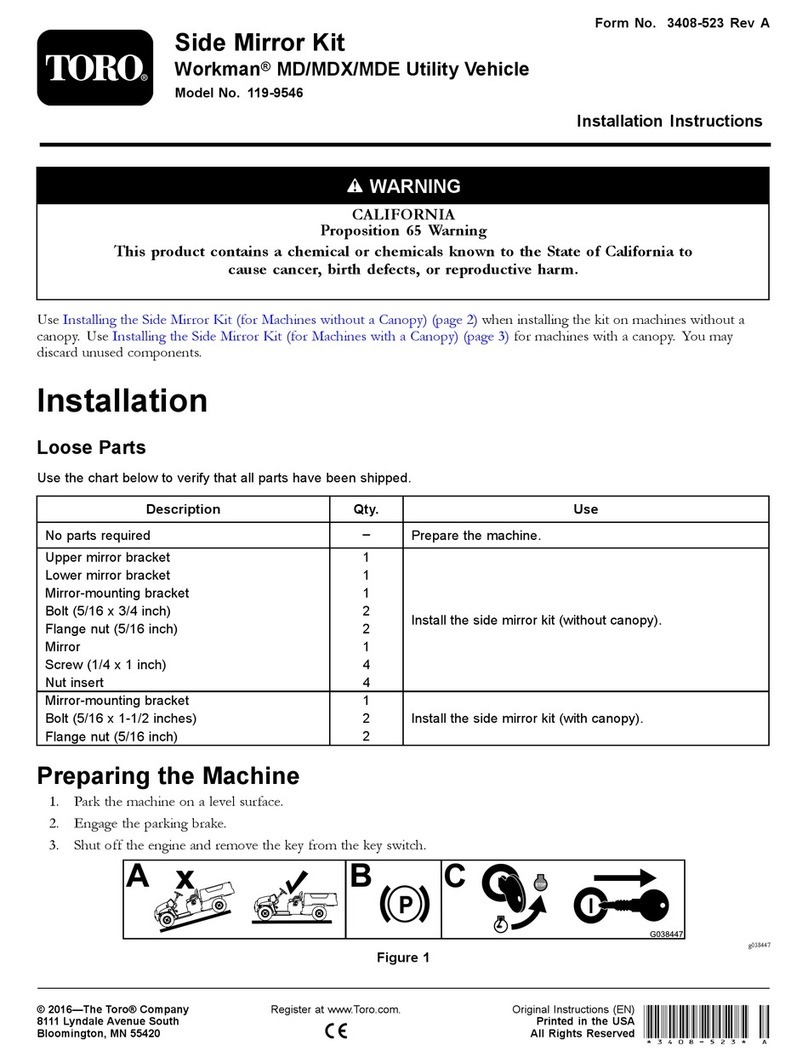

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescriptionQty.Use

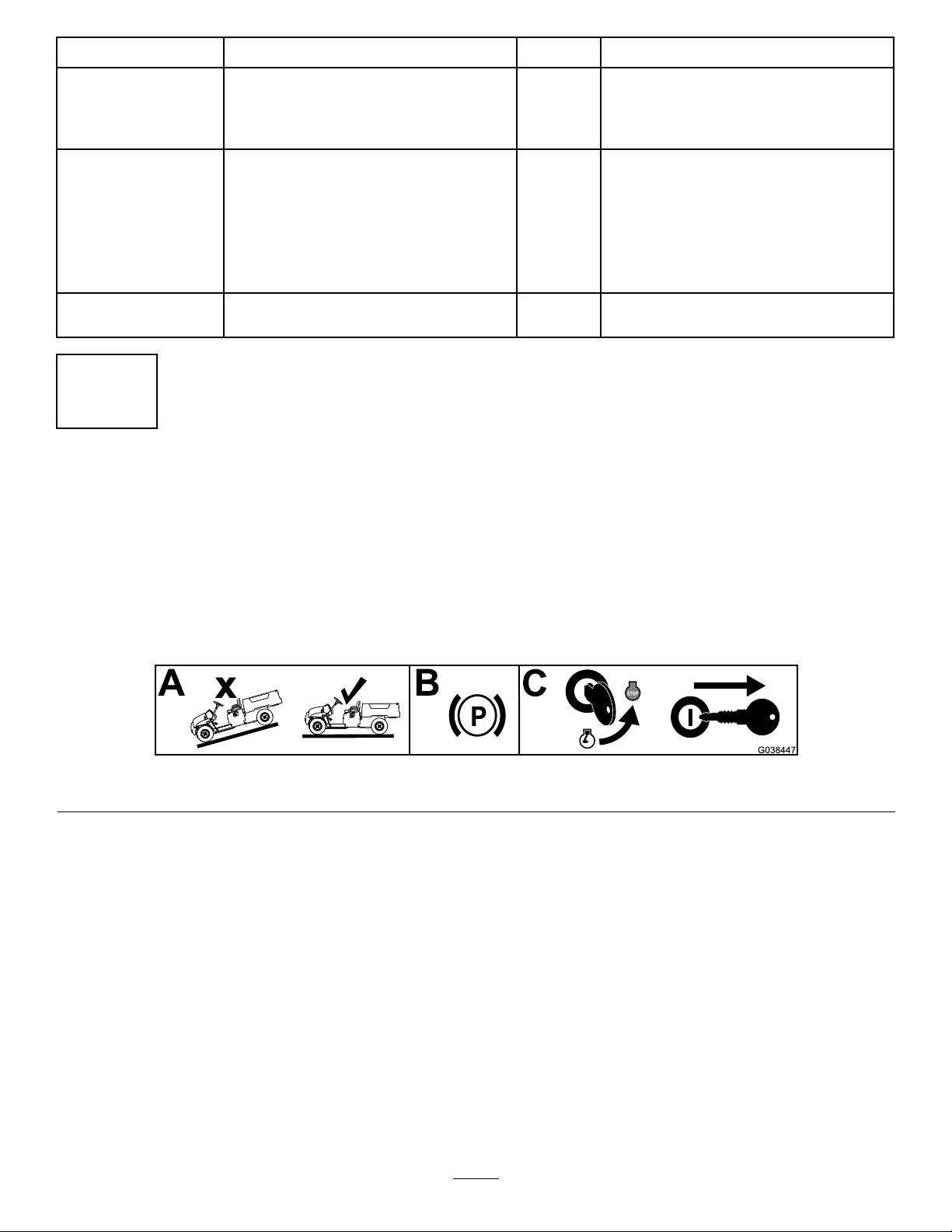

1Nopartsrequired–Preparethemachineforinstallation.

2Nopartsrequired–Removetheseatassembly,handholds,

sidepanels,andrubbercovers.

Floorbrace2

Flange-headbolts(5/16x1inch)20

3Flangelocknut(5/16inch)20

Installtheoorbraces.

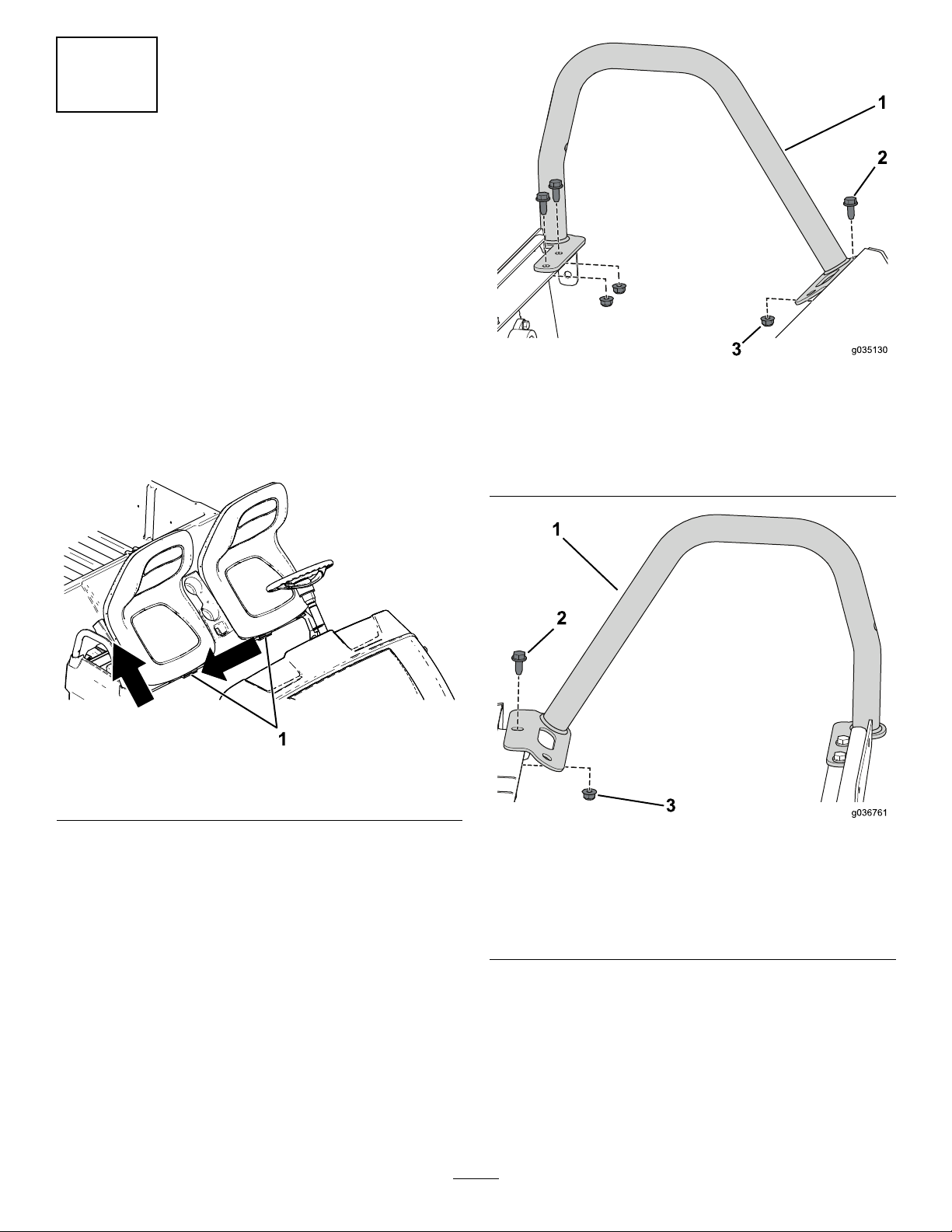

LeftROPSbracket1

RightROPSbracket1

Flange-headbolt(1/2x3inches)6

Flatwasher(1/2inch)10

Locknut(1/2inch)6

Rollbar1

Flange-headbolt(1/2x3-1/2inches)4

Locknut(1/2inch)4

Cabletie2

4

Plasticrivet4

InstalltheROPSassembly.

Seatbelt2

Seatlatch2

Hex-headbolt(7/16x1inch)4

Flatwasher(7/16inch)8

5

Locknut(7/16inch)4

Installthesidepanels,handholds,and

seatbelts.

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved*3420-758*A