Toro Cab Kit User manual

FormNo.3432-927RevA

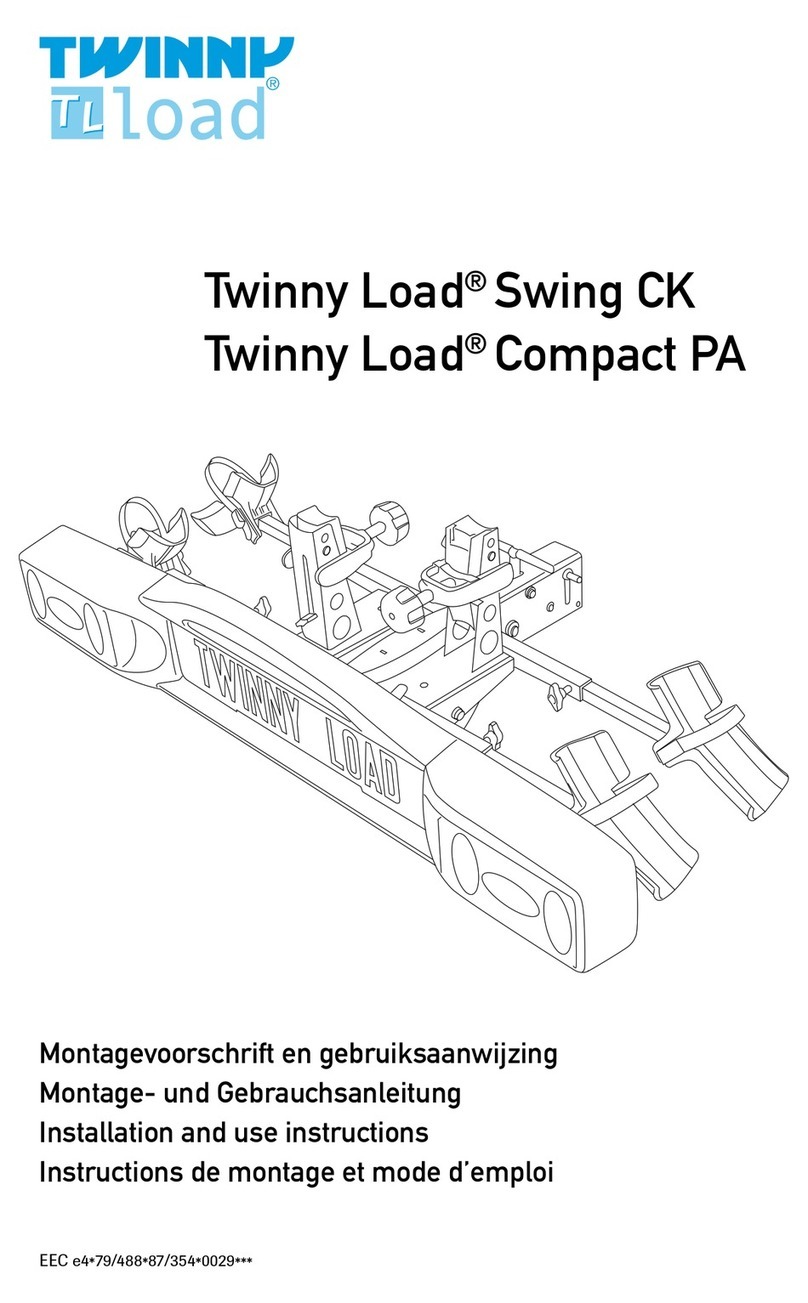

CabKit

Workman®GTXUtilityVehicle

ModelNo.07142—SerialNo.316000001andUp

ModelNo.07142—SerialNo.400000000andUp

Operator'sManual

Important:ThePowerConverterKitisrequired

tousethecabonaWorkmanGTXElectricutility

vehicle.ContactyourauthorizedTorodistributor

formoreinformation.

Important:TheSpringKitisrequiredtouse

thecabonaWorkmanGTXutilityvehicle.The

SpringKitshouldbeinstalledonlybyqualied

ToroServiceTechniciansusingapprovedtools.

Improperremoval,disassembly,orinstallationof

thespringassemblyposesadangertoyouand

bystanders.PleasecontactyourauthorizedToro

distributorfortheappropriatetoolsandproper

installationofthiskit.

Safety

WARNING

Thecompressedspringinthespringand

shockassemblyrepresentsastored-energy

hazard.Ifthespringisnotproperlyretained

duringcompressionorremoval,itcaninjure

youand/orbystanders.

•AlwaysusetheapprovedToro

spring-compressiontooltocompressthe

springinasecurepositionwhenremoving

theretentioncollar.

•Alwaysusecarewhenremovingpressure

fromthecompressedspring.

SafetyandInstructional

DecalsSafetydecalsandinstructionsare

easilyvisibletotheoperatorandare

locatednearanyareaofpotential

danger.Replaceanydecalthatis

damagedormissing.

decal133-1016

133-1016

1.Warning—readthe

Operator'sManual;wear

theseatbelt,andavoid

tippingthemachine.

2.Warning—wearhearing

protection.

©2019—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved*3432-927*A

decal133-1017

133-1017

1.Donotrepairorrevise—readtheOperator'sManual.

decal130-5964

130-5964

1.Warning—intheeventofanemergency1)Pullthelocking

pinoutofeachhinge;2)Pushthefrontwindowouttoexit.

decal131-8410

131-8410

1.Firehazard—shutofftheenginebeforefueling.

decal120-9570

120-9570

1.Warning—stayawayfrommovingparts,keepallguards

andshieldsinplace.

decal130-5439

130-5439

1.ReadtheOperator’sManualforinformationonfuses.4.Windshieldspray

2.Windshieldwiper—15A5.Windshieldwiper

3.Lights—15A

2

Setup

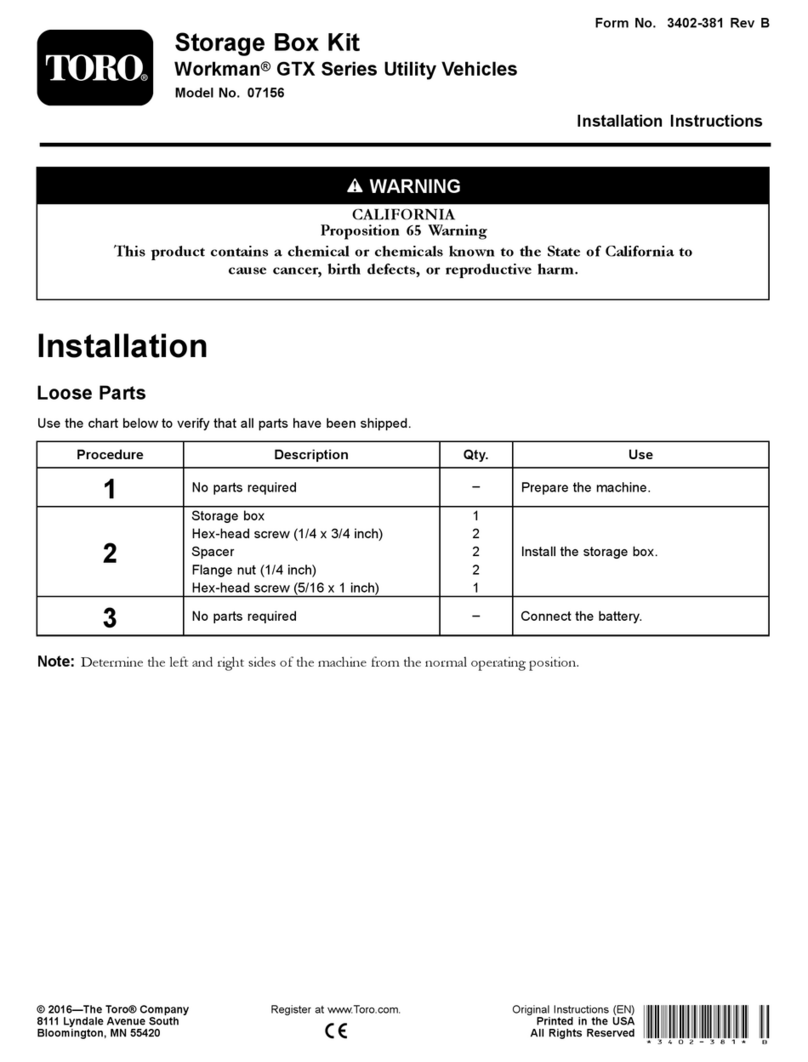

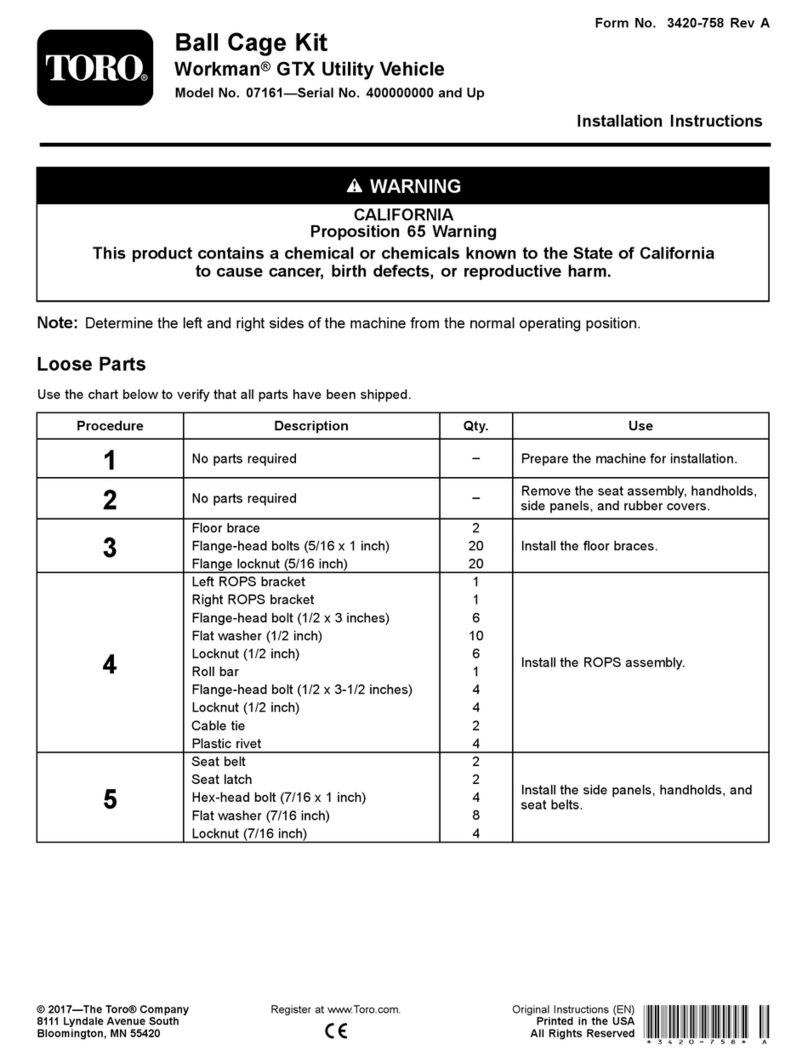

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescriptionQty.Use

1Nopartsrequired–Preparethemachine.

2Nopartsrequired–Removethestrutassembly(for2018

andbeforemachinesonly).

3Spring2Installthesprings(for2018andbefore

machinesonly).

4Nopartsrequired–Installthestrutassembly(for2018and

beforemachinesonly).

Floor-platesupport2

Flange-headbolt(5/16x1-1/4inches)16

Flangenut(5/16inch)16

Leftcabsupport1

Rightcabsupport1

Hex-headbolt(3/8x1-1/4inch)4

Flangenut(3/8inch)4

5

Washer(3/8inch)4

Installthesupports.

Cabframe1

Backfoamseal1

Backfoamsealcarpet1

Flange-headbolt(5/16x1-1/4inches)4

Flangenut(5/16inch)4

Flatwasher(5/16inch)4

Supportplate2

Right,frontfoamseal1

Left,frontfoamseal1

Upper,rearfoamseal1

Foamseal2

Hex-headbolt(3/8x1-1/4inches)6

Flangenut(3/8inch)6

6

Washer(3/8inch)6

Installthecab.

Fuseblock1

Hex-washerheadscrew(#10x3/4

inch)—for2019andafterelectric

machinesonly

2

Serratednut(#10)—for2019andafter

electricmachinesonly2

Self-tappingscrew—for2019andafter

gasolinemachinesonly2

7

Fuse(15A)1

Routethewireharness.

3

1

PreparingtheMachine

NoPartsRequired

Procedure

1.Parkthemachineonalevelsurface,settheparkingbrake,shutofftheengine,andremovethekey.

2.Raisethebeduntilthebedproprodisfullyengaged;refertotheOperator’sManualforthemachine.

3.Removetheseatbase.

4.Disconnectthenegativebatterycable;refertoyourOperator’sManual.

2

RemovingtheStrutAssembly

For2018andBeforeMachinesOnly

NoPartsRequired

Procedure

1.Removethefrontwheel.

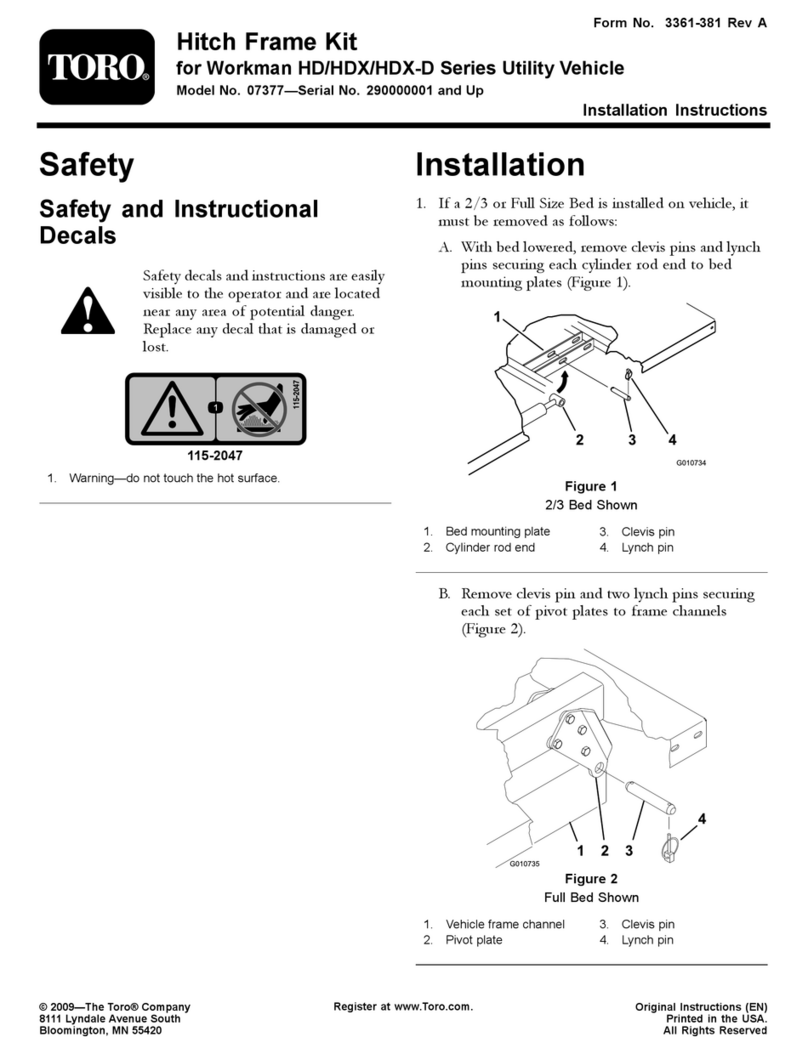

2.Removethehex-headbolt(3/8x4-3/4inches)andangenut(3/8inch)fromthespindle(Figure1).

3.Removethehex-headbolt(3/8x3-1/2inches)andangenut(3/8inch)fromthecontrolarm(Figure1).

4.Removethehex-headbolt(1/2x2-1/4inches)andlocknut(1/2inch)securingthestrutassemblyto

theupperframe(Figure1).

5.Removethestrutassembly(Figure1).

Note:Repeatthisprocedurefortheothersideofthemachine.

4

g038284

Figure1

Hoodandfendernotshowntoshowtheshock-mountbracket

1.Hex-headbolt(1/2x2-1/4inches)6.Flangenut(3/8inch)—fromthecontrolarm

2.Locknut(1/2inch)7.Flangenut(3/8inch)—fromthespindle

3.Collar8.Hex-headbolt(3/8x3-1/2inches)—fromthecontrolarm

4.Spring9.Hex-headbolt(3/8x4-3/4inches)—fromthespindle

5.Strutassembly

5

3

InstallingtheSprings

For2018andBeforeMachines

Only

Partsneededforthisprocedure:

2Spring

Procedure

UseanapprovedT orospring-compressiontoolto

removeandinstallspringsofthestrutassembly.

ContactyourauthorizedTorodistributor.

1.Placethestrutassemblyintothecompression

toolandusethetooltocompressthespring.

2.Whilethespringiscompressed,removethe

collar.

3.Removethespringfromthestrutassembly

(Figure1).

4.Installthenewspringovertheexistingstrut

assembly(Figure1).

5.UsingtheT orospring-compressiontool,

compressthespring.

6.Whilethespringiscompressed,installthecollar.

7.Carefullyreleasepressureonthespring,

allowingittoseatonthecollar.

8.Removethestrutassemblyfromthe

compressiontool.

Note:Repeatthisprocedurefortheothersideofthe

machine.

4

InstallingtheStrut

Assembly

For2018andBeforeMachines

Only

NoPartsRequired

Procedure

1.Installstrutassemblytothemachine.

2.Securetheupperportionofthestrutassembly

totheframeusingtheupper,hex-headbolt(1/2

x2-1/4inches)andlocknut(1/2inch)asshown

inFigure1.

3.Torquethehex-headbolt(1/2x2-1/4inches)to

91to113N∙m(67to83ft-lb).

4.Installthehex-headbolt(3/8x4-3/4inches)and

angenut(3/8inch)tothespindle(Figure1).

5.Torquethehex-headbolt(3/8x4-3/4inches)to

37to45N∙m(27to33ft-lb).

6.Securethelowerportionofthestrutassembly

tothecontrolarmusingthehex-headbolt(3/8x

3-1/2inches)andangenut(3/8inch)asshown

inFigure1.

7.Torquethehex-headbolt(3/8x3-1/2inches)to

37to45N∙m(27to33ft-lb).

8.Installthefrontwheel.

Note:Repeatthisprocedurefortheothersideofthe

machine.

6

5

InstallingtheSupports

Partsneededforthisprocedure:

2Floor-platesupport

16Flange-headbolt(5/16x1-1/4inches)

16Flangenut(5/16inch)

1Leftcabsupport

1Rightcabsupport

4Hex-headbolt(3/8x1-1/4inch)

4Flangenut(3/8inch)

4Washer(3/8inch)

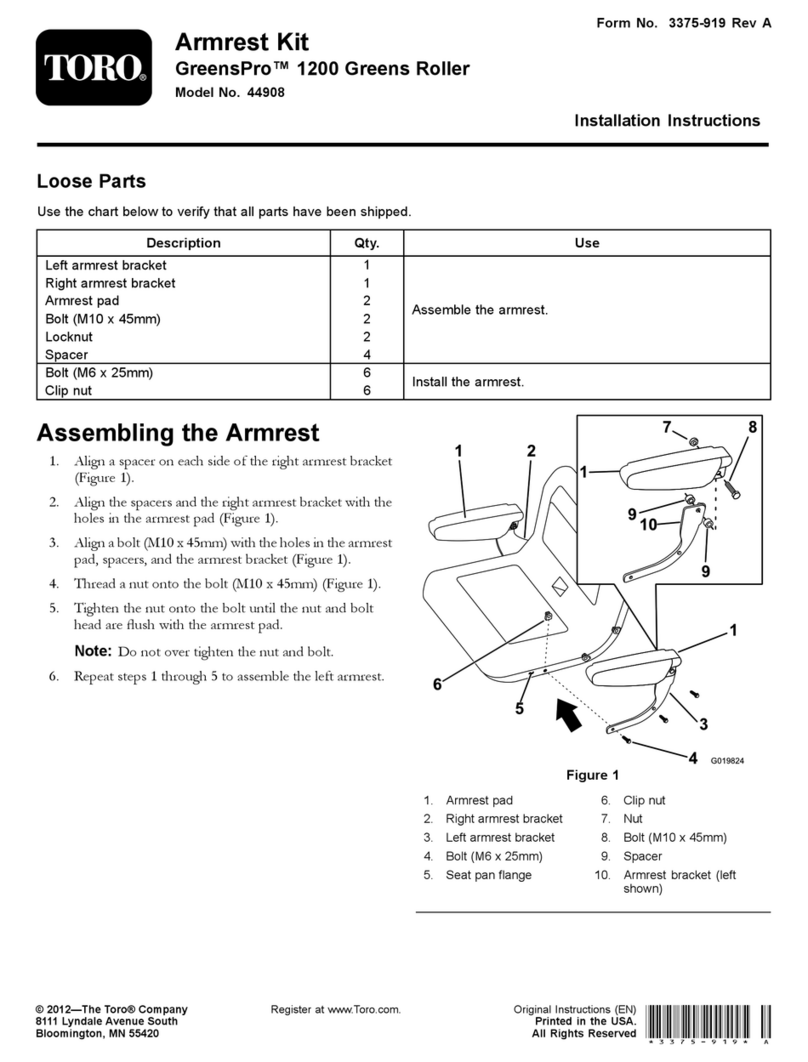

Procedure

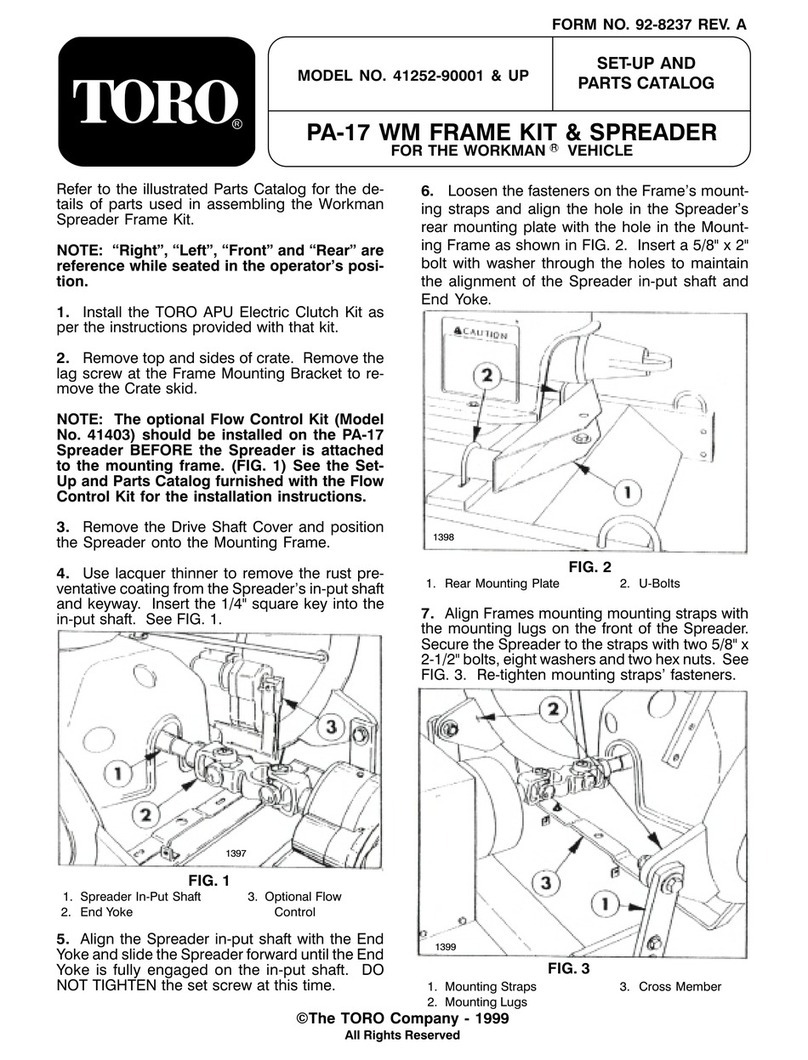

1.Removethe4screws(1/4x1-1/4inches)and4

nuts(1/4inch)fromtheoorplate(Figure2).

g038333

Figure2

1.Nut(1/4inch)3.Floorplate

2.Screw(1/4x1-1/4inches)

2.Useaoorjackundertheframetosupportthe

frontofthemachine(Figure3).

g038334

Figure3

1.Frame

3.Remove1oftheexistingoor-platesupports

(Figure4).

Important:Donotremovebothofthe

existingoor-platesupportssimultaneously.

g035246

Figure4

1.Existingoor-platesupports

7

4.Installanewoor-platesupportusing8

ange-headbolts(5/16x1-1/4inches)and8

angenuts(5/16inch)asshowninFigure5.

Note:Torquetheange-headbolts(5/16x

1-1/4inches)to34N∙m(25ft-lb).

g035247

Figure5

1.Flangenut(5/16inch)3.Floor-platesupport

2.Flange-headbolt(5/16x

1-1/4inches)

5.Removetheotherexistingoor-platesupport

(Figure4).

6.Installtheothernewoor-platesupportusing8

ange-headbolts(5/16x1-1/4inches)and8

angenuts(5/16inch)asshowninFigure5.

7.Installthepreviouslyremoved4screws(1/4x

1-1/4inches)and4nuts(1/4inch)intotheoor

plate(Figure2).

8.Usingthenewoor-platesupportsasaguide,

drill3holes(3/8-inchdiameter)intoeachoor

plate(Figure6).

Important:Drillonlythefront2holesonthe

newoor-platesupportsandthefarthest,

rearhole;asshowninFigure6.

g038352

Figure6

1.Donotdrillthishole.2.Frontofthemachine

9.Looselyattachtheleftandrightcabsupports

tothemachineusingthehex-headbolts(3/8x

1-1/4inch),washers(3/8inch),andangenuts

(3/8inch)asshowninFigure7.

Note:Donottightentheboltsatthistime.

g037135

Figure7

1.Hex-headbolt(3/8x1-1/4

inch)

3.Flangenut(3/8inch)

2.Cabsupport4.Washer(3/8inch)

8

6

InstallingtheCab

Partsneededforthisprocedure:

1Cabframe

1Backfoamseal

1Backfoamsealcarpet

4Flange-headbolt(5/16x1-1/4inches)

4Flangenut(5/16inch)

4Flatwasher(5/16inch)

2Supportplate

1Right,frontfoamseal

1Left,frontfoamseal

1Upper,rearfoamseal

2Foamseal

6Hex-headbolt(3/8x1-1/4inches)

6Flangenut(3/8inch)

6Washer(3/8inch)

Procedure

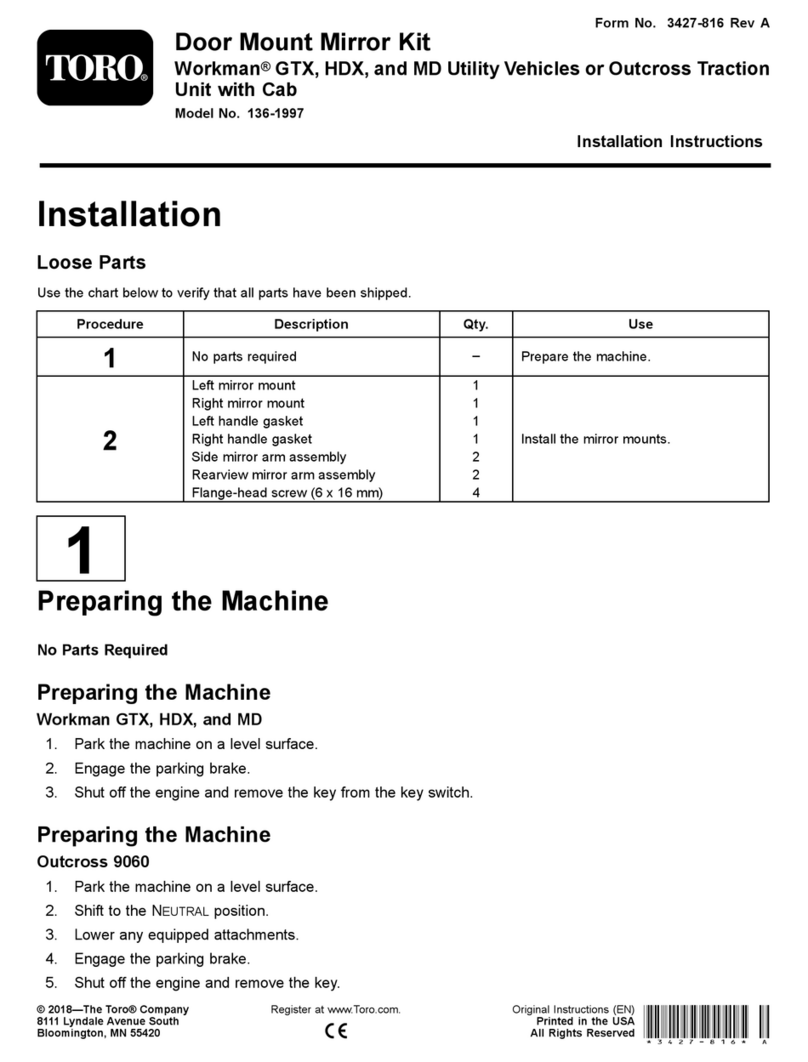

1.Removethebackingfromthebackfoamseal

andattachthesealtothemachineasshown

inFigure8.

Important:Ensurethattheundersideofthe

backfoamsealwiththeadhesivefacesthe

topoftherailsurface.

g035251

Figure8

1.Backfoamseal

2.Removetheseatbase.

3.Removethe3screwsand3nutssecuringthe

lefthandhold,andremoveit(Figure9).

g037177

Figure9

1.Handhold

4.Installthefrontsealingfoamifitisnotalready

installed(Figure10).

Note:Ensurethatyouinstallthefrontsealing

foamontothecabbeforeyouinstallthecab

ontothemachine.

g038337

Figure10

1.Frontsealingfoam

9

5.Liftthecabframeusingtheliftpointsandplace

itonthemachine(Figure11).

g037103

Figure11

1.Liftpoints

6.Securethesidesofthecabframetothemachine

using6hex-headbolts(3/8x1-1/4inches),6

washers(3/8inch),and6angenuts(3/8inch)

asshowninFigure12.

Note:T orquethehex-headbolts(3/8x1-1/4

inches)to58N∙m(43ft-lb).

g037137

Figure12

1.Hex-headbolt(3/8x1-1/4

inches)

3.Flangenut(3/8inch)

2.Washer(3/8inch)

7.Securethebackofthecabframetotheleftand

rightsupportsusing4ange-headbolts(5/16x

1-1/4inches),2supportplates,4atwashers,

and4angenuts(5/16inch)asshowninFigure

13.

Note:Torquetheboltsto34N∙m(25ft-lb).

g035253

Figure13

1.Flange-headbolt(5/16x

1-1/4inches)

3.Flatwasher

2.Supportplate4.Flangenut(5/16inch)

8.Tightentheleftandrightsupports,andtorque

theboltsto58N∙m(43ft-lb)asshowninFigure

7.

9.Installthepreviouslyremovedlefthandhold

usingthe3screwsand3nuts(Figure9).

10.Installtheupper,rearfoamseal(Figure14).

g038338

Figure14

1.Upper,rearfoamseal

10

11.Installtheseatbase.

Note:Youmayneedtopositionthe2center

seat-beltanchorstoallowtheseattodropinto

place.Loosenthe2locknuts(7/16inch)onthe

2centerseat-beltanchors,andtightenthe2

locknuts(7/16inch)to72to88N∙m(53to65

ft-lb)afteradjustingtheposition.

12.Removethebackingfromtheright,frontand

left,frontfoamsealsandattachthesealstothe

machine(Figure15).

g035254

Figure15

1.Left,frontfoamseal

13.Removethebackingfromthefoamsealand

attachthesealtotherightsideofthemachine

(Figure16).

g037104

Figure16

RightSideShown

1.Foamseal

11

7

RoutingtheWireHarness

Partsneededforthisprocedure:

1Fuseblock

2Hex-washerheadscrew(#10x3/4inch)—for2019

andafterelectricmachinesonly

2Serratednut(#10)—for2019andafterelectric

machinesonly

2Self-tappingscrew—for2019andaftergasoline

machinesonly

1Fuse(15A)

ForElectricMachines

Important:ThePowerConverterKitisrequired

tousethecabonaWorkmanGTXElectricutility

vehicle.ContactyourauthorizedTorodistributor

formoreinformation.

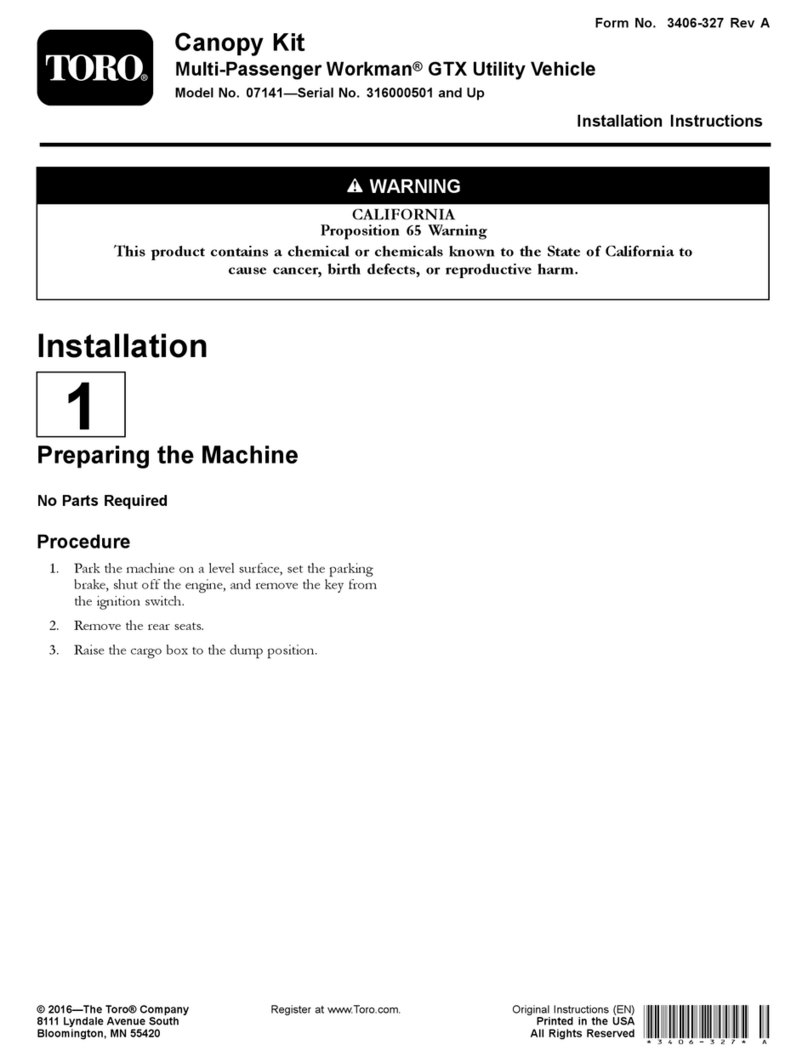

1.Installthenewfuseblockasfollows:

•For2018andbeforemachines,snapthe

newfuseblockontotheexistingfuseblock

onthemachine(Figure17).

g035257

Figure17

1.Toground3.Totheoptionalwasher

pumpkit

2.Tothefusedwire4.Newfuseblock

•For2019andaftermachines,securethe

newfuseblockusingthe2hex-washerhead

screws(#10x3/4inch)and2serratednuts

(#10)asshowninFigure18.

g290937

Figure18

1.Newfuseblock3.Serratednut(#10)

2.Hex-washerheadscrew

(#10x3/4inch)

4.Femaleconnector

2.For2019andaftermachines,connectthe

femaleconnectorontheharnesstothenew

fuseblock(Figure18).

3.Connectthelargeconnectoronthenewfuse

blocktotheoptionalpowercableontheexisting

fuseblock(Figure17).

12

4.Routethewireharnessbehindthecaband

undertheseat,andsecurethecliponthewire

harnesstothesidepanel(Figure19).

g035260

Figure19

1.Wireharness

5.Installtheblackgroundwiretothegroundwire

onthePowerConverterKitwireharness(Figure

20).

Note:Theblackterminalringisnotused.

6.Installtheredpowerwiretothepowerwireon

thePowerConverterKitwireharness(Figure

20).

g278776

Figure20

1.Cabwireharness3.Blackgroundwirewith

spadeterminal

2.Blackgroundwirewith

terminalring(notused)

4.Redpowerwirewithspade

terminal

7.Connecttheremainingwiretothefusedwireon

thenewfuseblock(Figure17).

8.Lowerthebedandconnectthebattery;referto

theOperator’sManual.

9.Installthepreviouslyremovedseatbase.

13

ForGasoline/PetrolorEFI

Machines

1.Installthenewfuseblockasfollows:

•For2018andbeforemachines,snapthe

newfuseblockontotheexistingfuseblock

onthemachine(Figure17).

•For2019andaftermachines,securethe

newfuseblockusingthe2self-tapping

screwsasshowninFigure21.

g290831

Figure21

1.Self-tappingscrew2.Newfuseblock

2.Connectthelargeconnectoronthenewfuse

blocktotheoptionalpowercableontheexisting

fuseblock(Figure17).

3.Routethewireharnessbehindthecaband

undertheseat,andsecurethecliponthewire

harnesstothesidepanel(Figure19).

4.Installtheblackterminalringtothegroundblock

onthemachine(Figure22).

5.Installtheredpowerwireintoanemptysloton

themachinefuseblock(Figure22).

Note:Installanadditionalfuseblockifthere

arenoremainingslotsopeninafuseblock.

g278776

Figure22

1.Cabwireharness3.Blackgroundwirewith

spadeterminal

2.Blackgroundwirewith

terminalring

4.Redpowerwirewithspade

terminal

6.Connecttheremainingwiretothefusedwireon

thenewfuseblock(Figure17).

7.Lowerthebedandconnectthebattery;referto

theOperator’sManual.

8.Installthepreviouslyremovedseatbase.

14

ProductOverview

Controls

ControlPanel

Windshield-WiperSwitch

Clicktheswitchforwardtoactivatethewindshield

wipers(Figure23).

g026274

Figure23

1.Windshield-wipercontrol2.Lightswitch

LightSwitch

Pushtheleftorrightsideofthelightplatetoturnon

thecablight(Figure23).

WindshieldLatch

Liftuponthelatchestoopenthewindshield(Figure

24).Pressdownonthelatchtolockthewindshieldin

theopenposition.Pulloutanddownonthelatchto

closeandsecurethewindshield.

g026672

Figure24

1.Windshieldlatch

15

TheToroWarranty

Two-Yearor1,500HoursLimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,ToroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourToroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

for2yearsor1,500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

8111LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:[email protected]

OwnerResponsibilities

Astheproductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Repairsforproductissues

causedbyfailuretoperformrequiredmaintenanceandadjustmentsarenot

coveredunderthiswarranty.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-T oro

brandedaccessoriesandproducts.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partsconsumedthroughusethatarenotdefective.Examplesofparts

whichareconsumed,orusedup,duringnormalProductoperation

include,butarenotlimitedto,brakepadsandlinings,clutchlinings,

blades,reels,rollersandbearings(sealedorgreasable),bedknives,

sparkplugs,castorwheelsandbearings,tires,lters,belts,andcertain

sprayercomponentssuchasdiaphragms,nozzles,andcheckvalves.

•Failurescausedbyoutsideinuence,including,butnotlimitedto,

weather,storagepractices,contamination,useofunapprovedfuels,

coolants,lubricants,additives,fertilizers,water,orchemicals.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear,anddeterioration.Normal

“wearandtear”includes,butisnotlimitedto,damagetoseatsdueto

wearorabrasion,wornpaintedsurfaces,scratcheddecalsorwindows.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.Torowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.T oromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumber

ofkilowatt-hourstheycandeliverduringtheirlifetime.Operating,

recharging,andmaintenancetechniquescanextendorreducetotal

batterylife.Asthebatteriesinthisproductareconsumed,theamount

ofusefulworkbetweenchargingintervalswillslowlydecreaseuntilthe

batteryiscompletelywornout.Replacementofwornoutbatteries,

duetonormalconsumption,istheresponsibilityoftheproductowner.

Note:(Lithium-Ionbatteryonly):Pro-ratedafter2years.Refertothe

batterywarrantyforadditionalinformation.

LifetimeCrankshaftWarranty(ProStripe02657Model

Only)

TheProstripewhichisttedwithagenuineT oroFrictionDiscand

Crank-SafeBladeBrakeClutch(integratedBladeBrakeClutch(BBC)+

FrictionDiscassembly)asoriginalequipmentandusedbytheoriginal

purchaserinaccordancewithrecommendedoperatingandmaintenance

procedures,arecoveredbyaLifetimeWarrantyagainstenginecrankshaft

bending.Machinesttedwithfrictionwashers,BladeBrakeClutch(BBC)

unitsandothersuchdevicesarenotcoveredbytheLifetimeCrankshaft

Warranty.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

NoteRegardingEmissionsWarranty

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EPA)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentation.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contactyourAuthorizedT oroServiceCenter.

374-0253RevF

This manual suits for next models

1

Table of contents

Other Toro Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

Thule

Thule DOUBLETRACK 990XT installation instructions

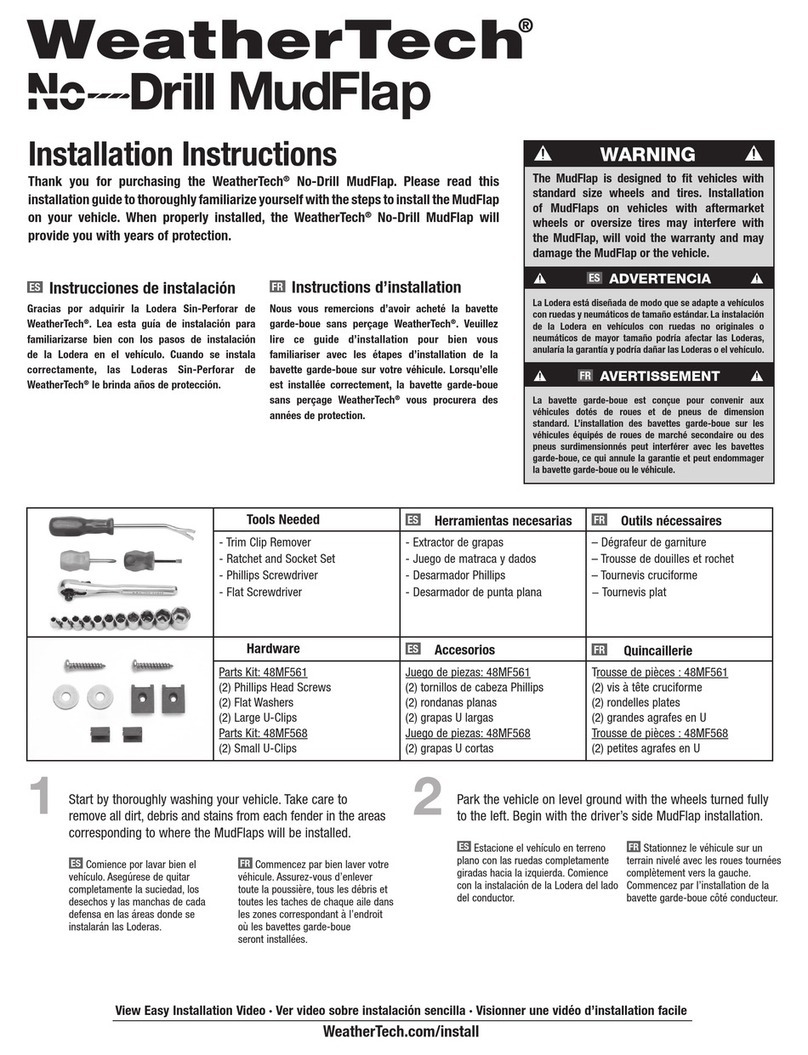

WeatherTech

WeatherTech No-Drill MudFlap installation instructions

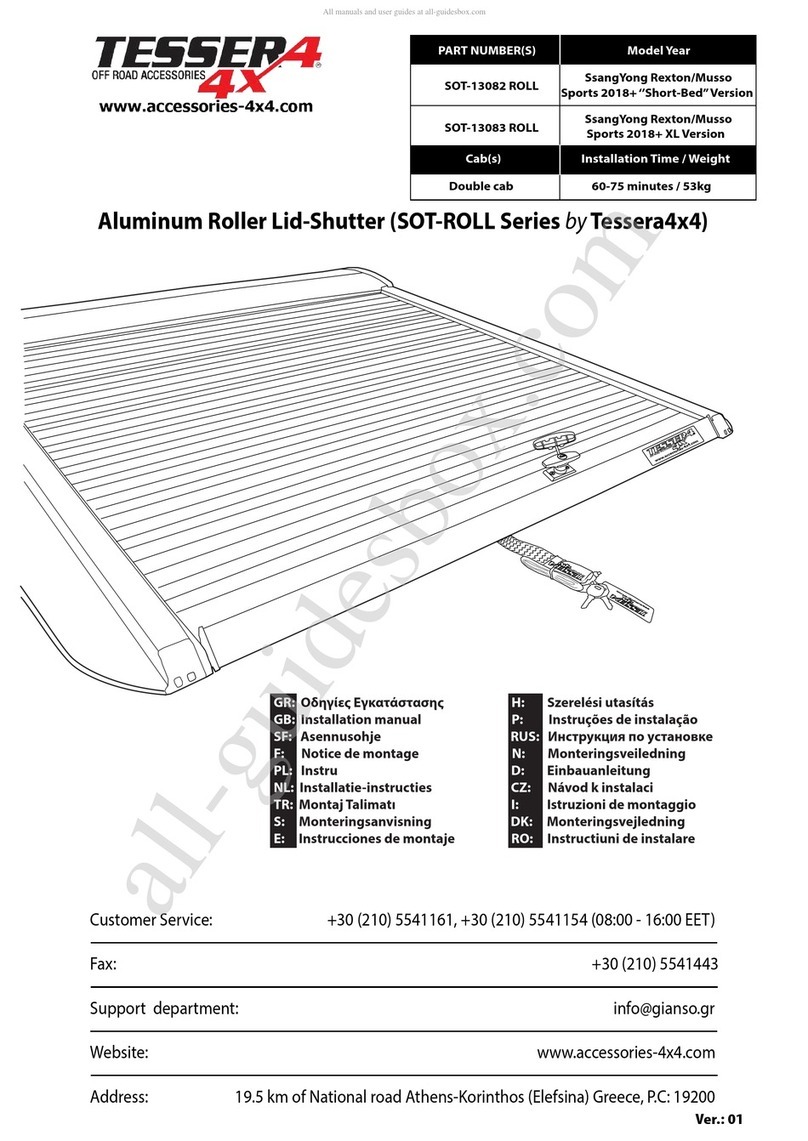

Tessera4x4

Tessera4x4 SOT-ROLL Series installation manual

Innogy

Innogy ePole installation instructions

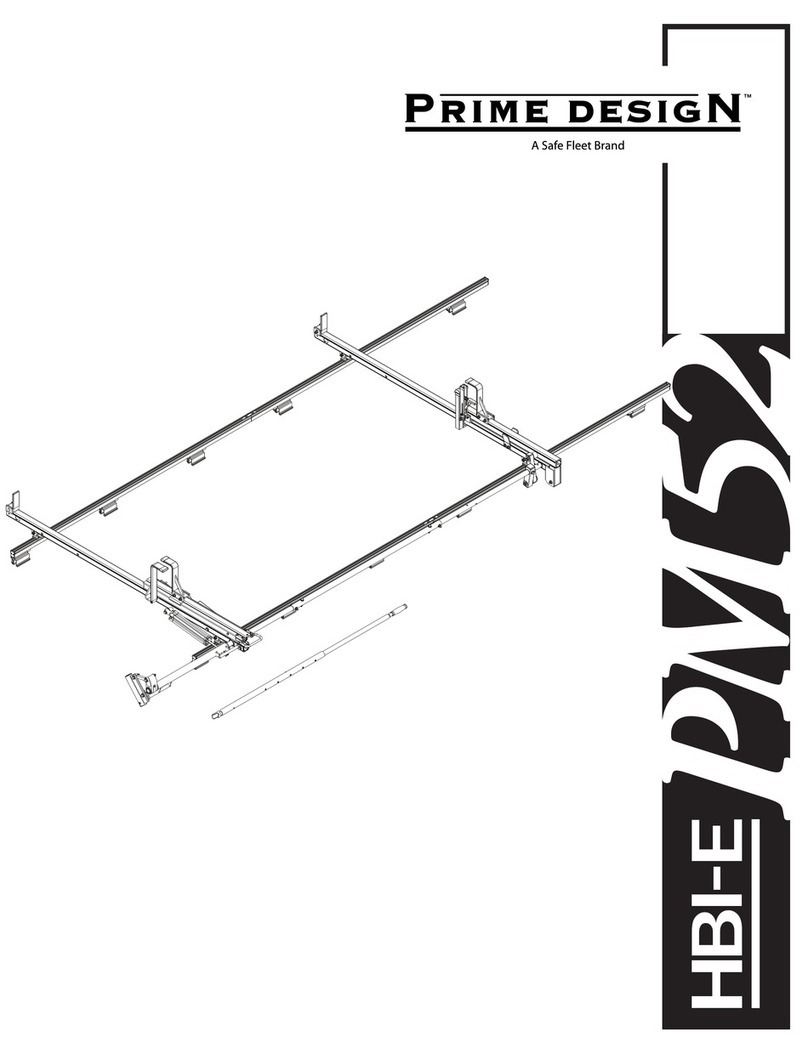

Safe Fleet

Safe Fleet PRIME DESIGN HBI-E-PM52 manual

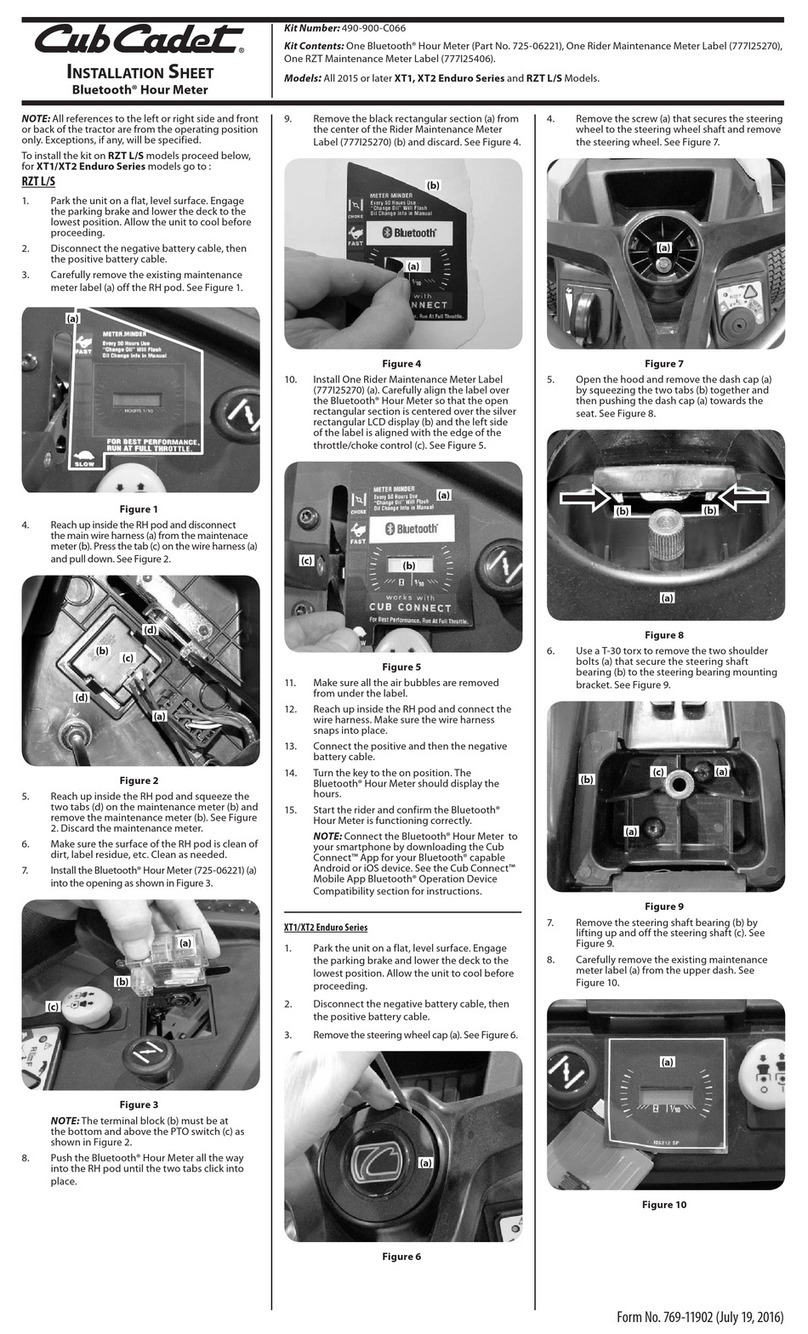

Cub Cadet

Cub Cadet 490-900-C066 Installation sheet