Toro PA-17 WM Instruction Manual

1

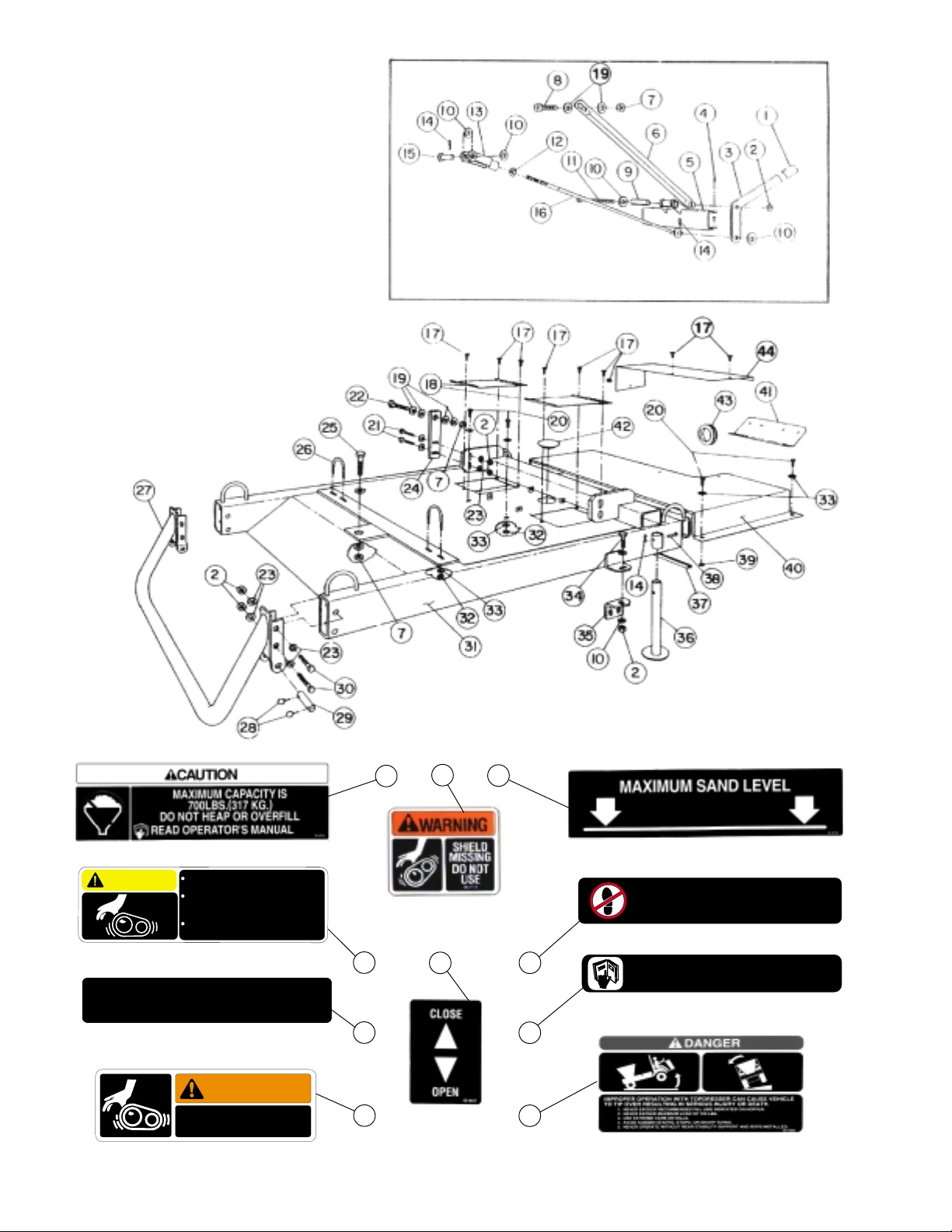

Refer to the illustrated Parts Catalog for the de-

tails of parts used in assembling the Workman

Spreader Frame Kit.

NOTE: Right, Left, Front and Rear are

reference while seated in the operators posi-

tion.

. Install the T R APU Electric Clutch Kit as

per the instructions provided with that kit.

2. Remove top and sides of crate. Remove the

lag screw at the Frame Mounting Bracket to re-

move the Crate skid.

NOTE: The optional Flow Control Kit (Model

No. 4 403) should be installed on the PA- 7

Spreader BEFORE the Spreader is attached

to the mounting frame. (FIG. ) See the Set-

Up and Parts Catalog furnished with the Flow

Control Kit for the installation instructions.

3. Remove the Drive Shaft Cover and position

the Spreader onto the Mounting Frame.

4. Use lacquer thinner to remove the rust pre-

ventative coating from the Spreaders in-put shaft

and keyway. Insert the 1/4" square key into the

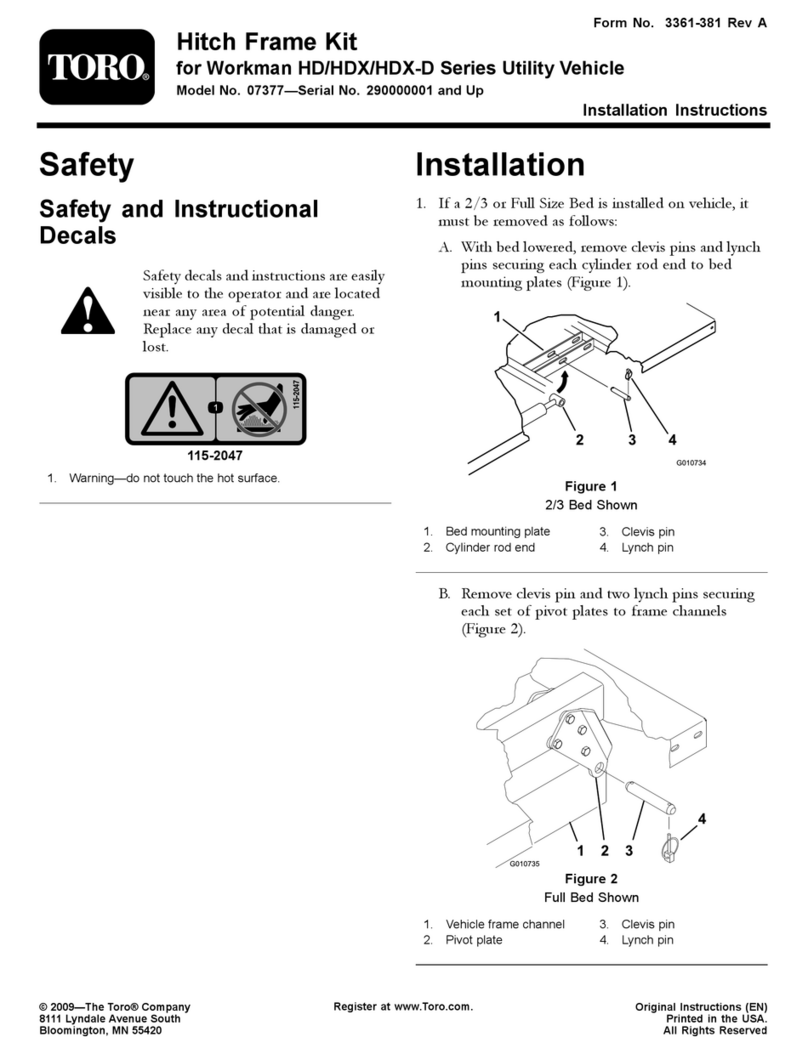

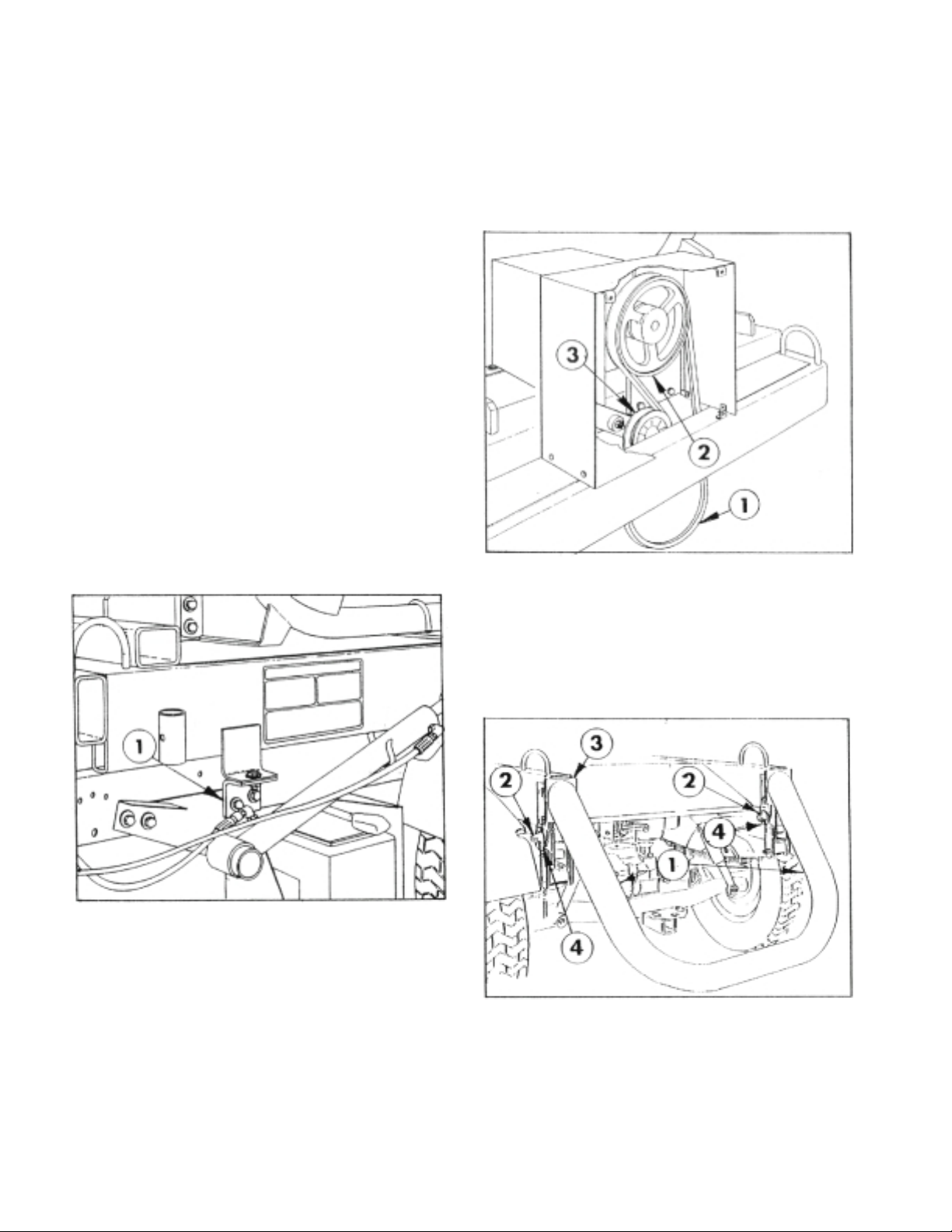

in-put shaft. See FIG. 1.

FIG.

1. Spreader In-Put Shaft 3. ptional Flow

2. End Yoke Control

5. Align the Spreader in-put shaft with the End

Yoke and slide the Spreader forward until the End

Yoke is fully engaged on the in-put shaft. D

N T TIGHTEN the set screw at this time.

FORM NO. 92-8237 REV. A

MODEL NO. 4 252-9000 & UP

PA- 7 WM FRAME KIT & SPREADER

FOR THE WORKMAN R VEHICLE

SET-UP AND

PARTS CATALOG

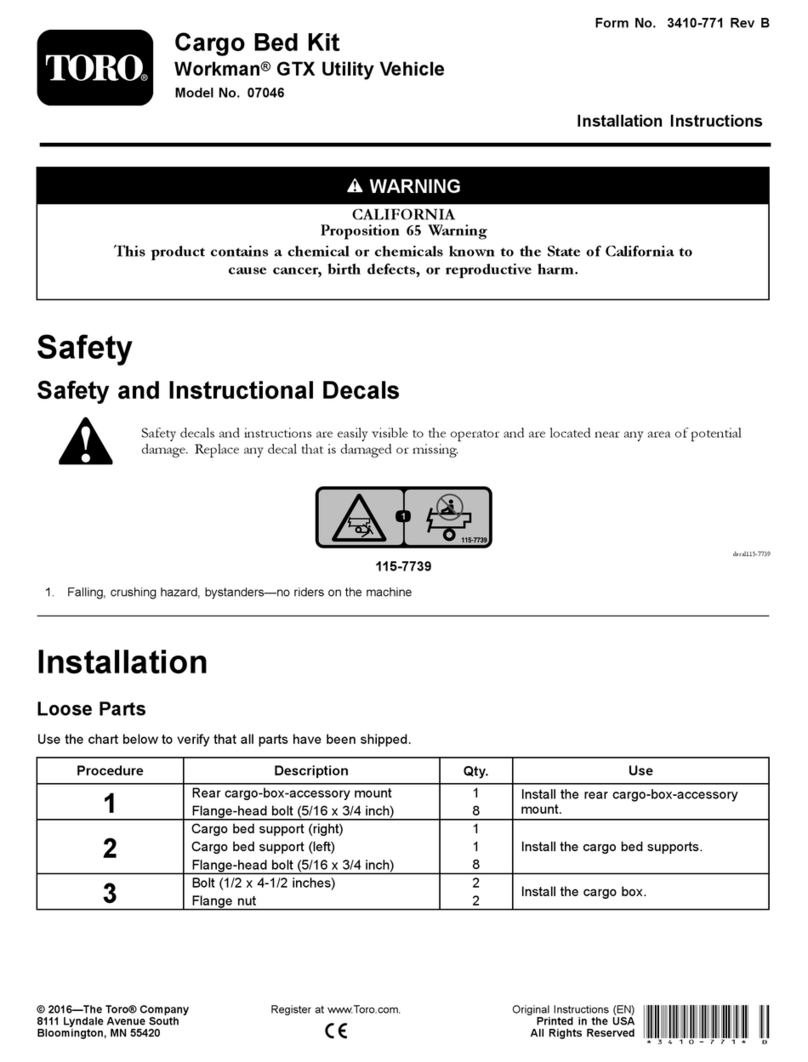

6. Loosen the fasteners on the Frames mount-

ing straps and align the hole in the Spreaders

rear mounting plate with the hole in the Mount-

ing Frame as shown in FIG. 2. Insert a 5/8" x 2"

bolt with washer through the holes to maintain

the alignment of the Spreader in-put shaft and

End Yoke.

FIG. 2

1. Rear Mounting Plate 2. U-Bolts

7. Align Frames mounting mounting straps with

the mounting lugs on the front of the Spreader.

Secure the Spreader to the straps with two 5/8" x

2-1/2" bolts, eight washers and two hex nuts. See

FIG. 3. Re-tighten mounting straps fasteners.

1. Mounting Straps 3. Cross Member

2. Mounting Lugs

FIG. 3

1398

1399

©The TORO Company - 999

All Rights Reserved

1397

2

8. Lift and secure the Mounting Frame and

Spreader approximately 12 inches above ground

level for easier access to fasteners used in secur-

ing the Spreader to the Mounting Frame.

9. Install hex nut and washer to 5/8" x 2" bolt at

rear mounting plate. See FIG. 2.

0. Insert two U-bolts over the tubular frame

of the Spreader and secure with four 3/8" flat

washers and lock nuts (FIG. 2).

. Secure the cross member of the Spreader

to the Mounting Frame with two 3/8" x 1" bolts,

four washers, and lock nut. See FIG. 3.

2. Tighten all fasteners securely. Apply thread

locking adhesive and tighten the set screw in the

End Yoke. Re-install the Drive Shaft Cover.

3. Install the Edge Trim on the Radiator Cover.

Mount the Radiator Cover on the Vehicle Frame

and secure with four 3/8" x 1" bolts and flat wash-

ers. n some models, it may be necessary to use

two nuts at rear holes.

4. Locate and remove two 1/2" bolts on each

side of the Workman frame and install the Attach-

ment Mounting Brackets, using the bolts and nuts

removed earlier. See FIG 4. Tighten the nuts

and bolts securely.

1. Attachment Mounting Bracket

NOTE: If the Workman vehicle is equipped

with the optional PTO Kit, remove the bottom

fasteners, loosen the top fasteners and tilt the

PTO Shield downward. This is necessary BE-

FORE the Mounting Frame can be assembled

to the Workman Frame.

5. Position the assembled Spreader and

Mounting Frame onto the Workman.

7. Remove the Knobs to release the hinged

door on the Belt Cover and install the Spreader

Spring as shown in FIG. 5. Install the Drive Belt

between the Gear Reducer Pulley and the

Workmans Electric Clutch Pulley. Close the cover

and re-install Knobs.

1. Drive Belt 3. Idler Pulley

2. Gear Reducer Pulley 4. Idler Spring

8. Mount the Rear Support to the Mounting

Frame and secure with two 1/2" x 3-1/4" bolts,

four flat washers, and two lock nuts on each side

of the Mounting Frame. Do not tighten bolts. See

FIG. 6.

1. Rear Support 3. Support Tube Plates

2. Mounting Pin 4. Lynch Pin

9. Slide the two 3/4" x 4-3/8" Mounting Pins

through the Support Tube Plates and the

Workmans frame. Secure with two Lynch Pins

on each Mounting Pin. Torque fasteners for Rear

Support to 75 ft. lbs.

FIG. 4

FIG. 5

FIG. 6

6. Secure the Mounting Frame to the Attach-

ment Mounting Brackets with two 1/2" x 1-1/2"

bolts four washers and lock nuts. See FIG. 4.

1400

1401

1402

3

If the Spreader is NOT EQUIPPED with the

optional Flow Control Kit, proceed as follows:

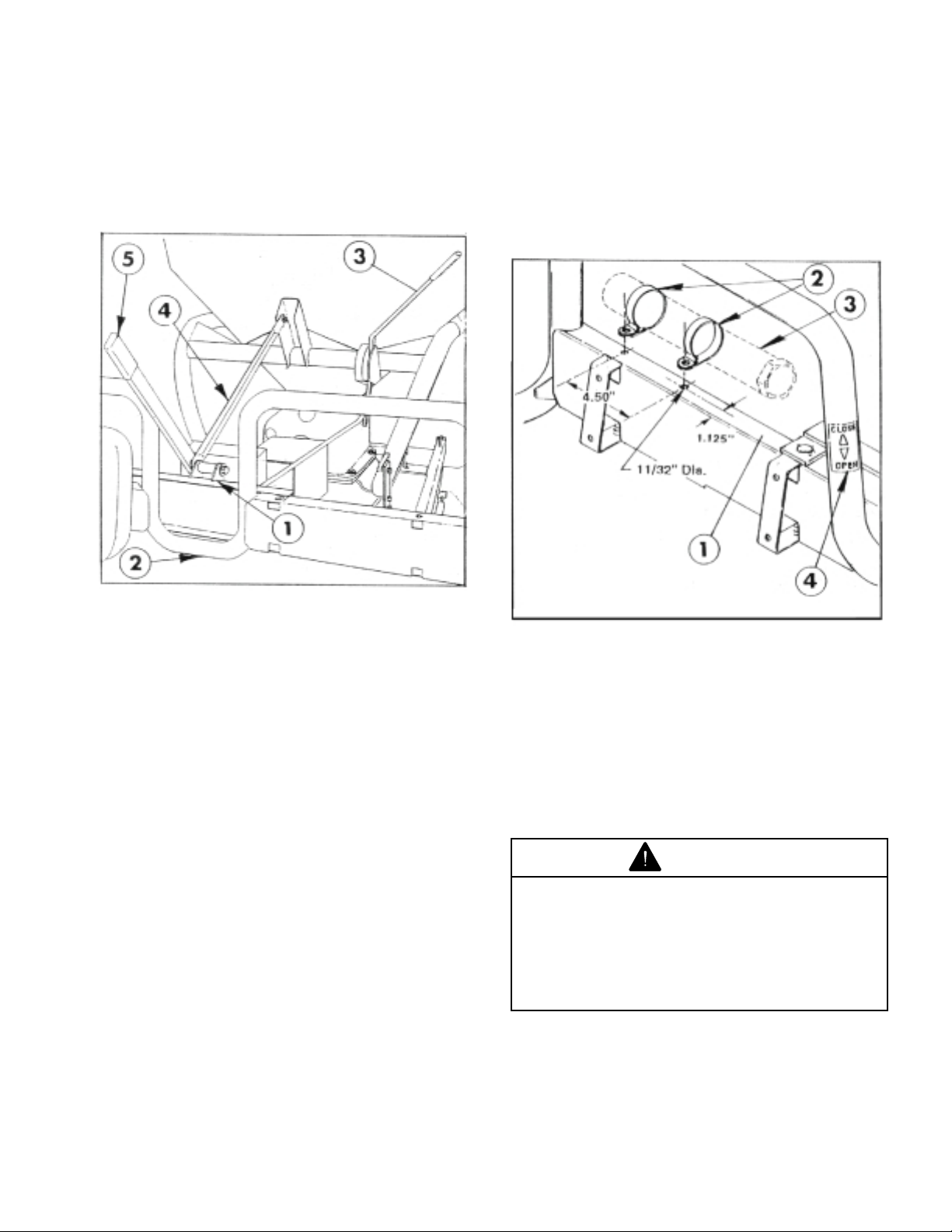

. Install the Lever Bracket Assembly on the

Workmans Seat Frame as shown in FIG. 7. Se-

cure with four 5/16" x 3/4" carriage bolts and nuts.

1. Lever Bracket Assy 4. Lever Bracket Brace

2. Seat Frame 5. Flow Control Handle

3 Flow Regulator Handle (in Close position)

(in Close Position)

2. Apply rust preventive oil to the Pivot Sleeve

and slide it inside the pivot tube on the Lever

Bracket Assembly, position a 1/2" flat washer and

insert the 1/2" x 4" bolt through the washer, the

pivot tube, the Lever Bracket Brace and the Con-

trol Lever. Secure with a lock nut.

3. Install the Lever Bracket Brace to the hole in

the Spreaders frame, using a 5/8" x 1-1/2" screw,

two washers and a lock nut.

4. Position the Flow Regulator and Flow Control

Handles in their CLOSE position as shown in FIG.

7.

5. Insert the Linkage Rod into the lower hole of

the Control Lever and secure with two 1/2" flat

washers and cotter pin.

6. Attach the adjustable clevis on the other end

of the Linkage Rod to the Spreaders Flow Regu-

lator Handle with a 1/2" x 1-1/2" clevis pin, two

washers and hairpin cotter. NOTE: The effec-

tive length of the Linkage can be shortened

or lengthened by loosening the jam nut and

turning the Adjustable Clevis. When length is

correct, re-tighten the jam nut.

Shown With R.H. Seat Back Removed

7. Position the Muaual Tube the passenger hand

side of the Seat Back Rest Channel, it will have to

be moved to the right hand side, with R-Clamps

posiotioned as shown in FIG. 8. If the existing hole

in that locatoin proceed as follows:

8. Using dimensions shown, locate, mark and

drill an 11/32" dia. hole in top of the right hand

Seat Back Rest Channel. Use a file to make a

square hole of the 11/32" dia. hole (for the car-

riage bolt head.)

NOTE: If the Spreader IS EQUIPPED with the

optional Flow Control Kit, skip Steps thru 6

and proceed to Step 7.

FIG. 7

FIG. 8

1403 1404

1. Back Rest Channel 3. Manual Tube

2. R-Clamps 4. pen/Close Decal

9. Re-install the R-Clamps and Manual Tube on

the right hand side of the channel, using the fas-

teners previously removed and hex nut provided.

See FIG. 8.

0. Remove backing and affix pen/Close De-

cal on Seat Frame. See FIG. 8.

DANGER

AN OVERLOADED SPREADER HOP-

PER CAN CAUSE A TIP OVER RESULT-

ING IN SERIOUS INJURY OR DEATH.

l Install the Level Limit and Capacity

700 LBS. Decals as instructed.

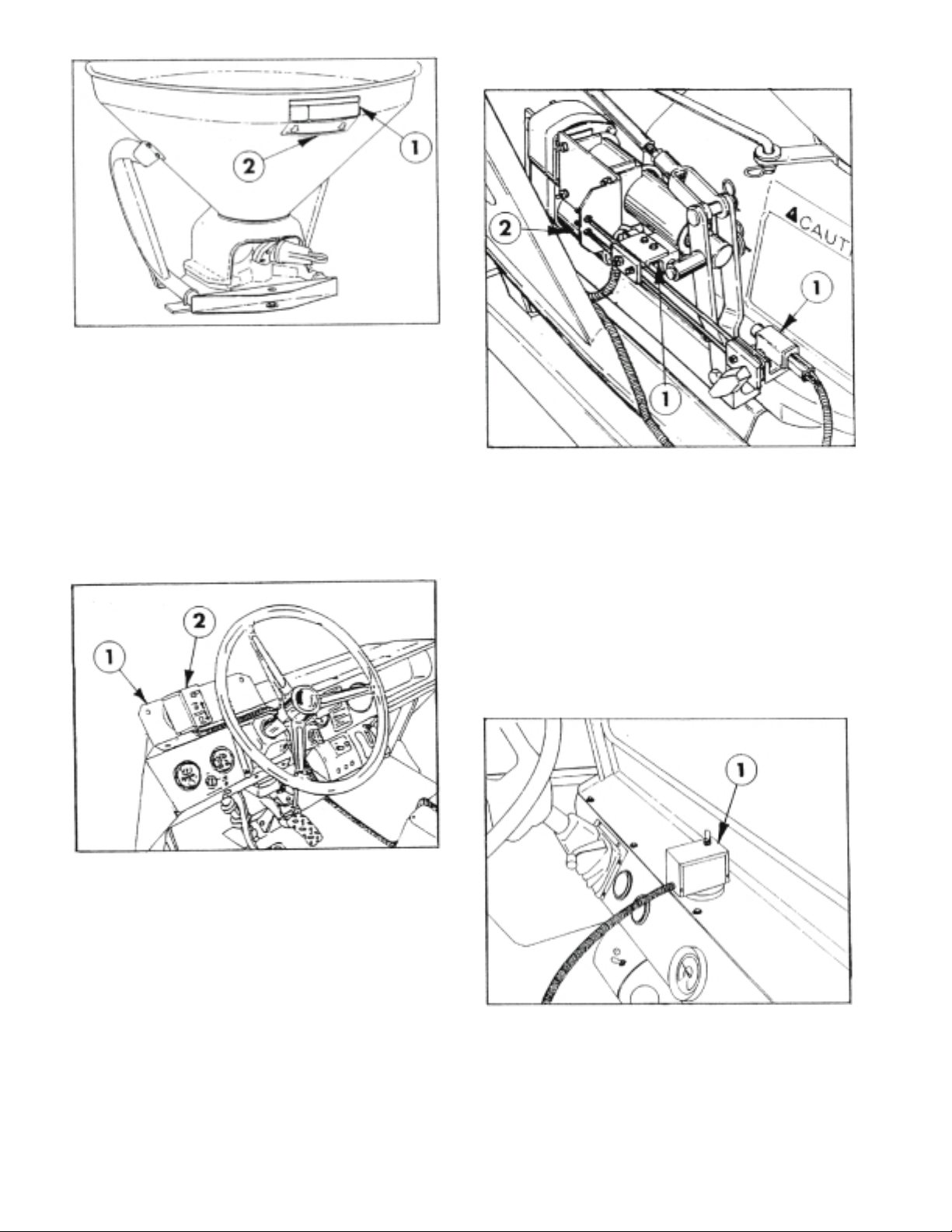

. Remove the backing and affix the Maximum

Sand Level Decal directly below the existing Ca-

pacity 1000 LBS. Decal, on the back of the

Spreader Hopper. See FIG. 9.

4

top of the Workman frame. Install Grommet in

hole.

7. Attach the Magnet and Control Box to the front

of the Enclosure as shown in FIG. 10.

1408

FIG. 2

1. Control Box

8. Re-connect the Wiring Harness to the Actua-

tor and Limit Switches.

9. Connect battery wires from the Wiring Har-

ness to the Workman Vehicles battery as de-

scribed in the Flow Control Kit instructions.

1. Limit Switch 2. Actuator

5. Slide the Grommet over the connectors.

6. Measure and mark the location, to drill a 2"

dia. hole in the rear of the Enclosure. Locate the

hole in a convenient location near the center of

the Enclosure, approximately 24 inches from the

1. Capacity 700 LBS. 2. Maximum Sand Level

Decal Decal

2. Remove the backing and affix the Capac-

ity 700 LBS. Decal over the Capacity 1000 LBS.

Decal, so it is completely covered.

INSTRUCTIONS FOR SPREADER EQUIPPED

WITH THE OPTIONAL FLOW CONTROL KIT:

. Remove two screws on the Workman dash

panel and use them to attach the Control Con-

sole Bracket to dash as shown in FIG. 10.

1. Console Mounting Brkt 2. Control Box

2. Route the Wiring Harness and Control Box

forward along the left side of the Workman frame

and connect the two battery wires to the Battery,

as described in the Flow Control Instructions.

3. Attach the Magnet and Control Box to the

Bracket attached to the Workman dash panel in

Step 22.

INSTRUCTIONS FOR SPREADER EQUIPPED

WITH THE OPTIONAL FLOW CONTROL, TO

BE USED ON WORKMAN EQUIPPED WITH

OPTIONAL ENCLOSURE.

4. Disconnect the Wiring Harness at the Actua-

tor and the two Limit Switches.

FIG. 9

FIG. 0

FIG.

1405

1407

1406

5

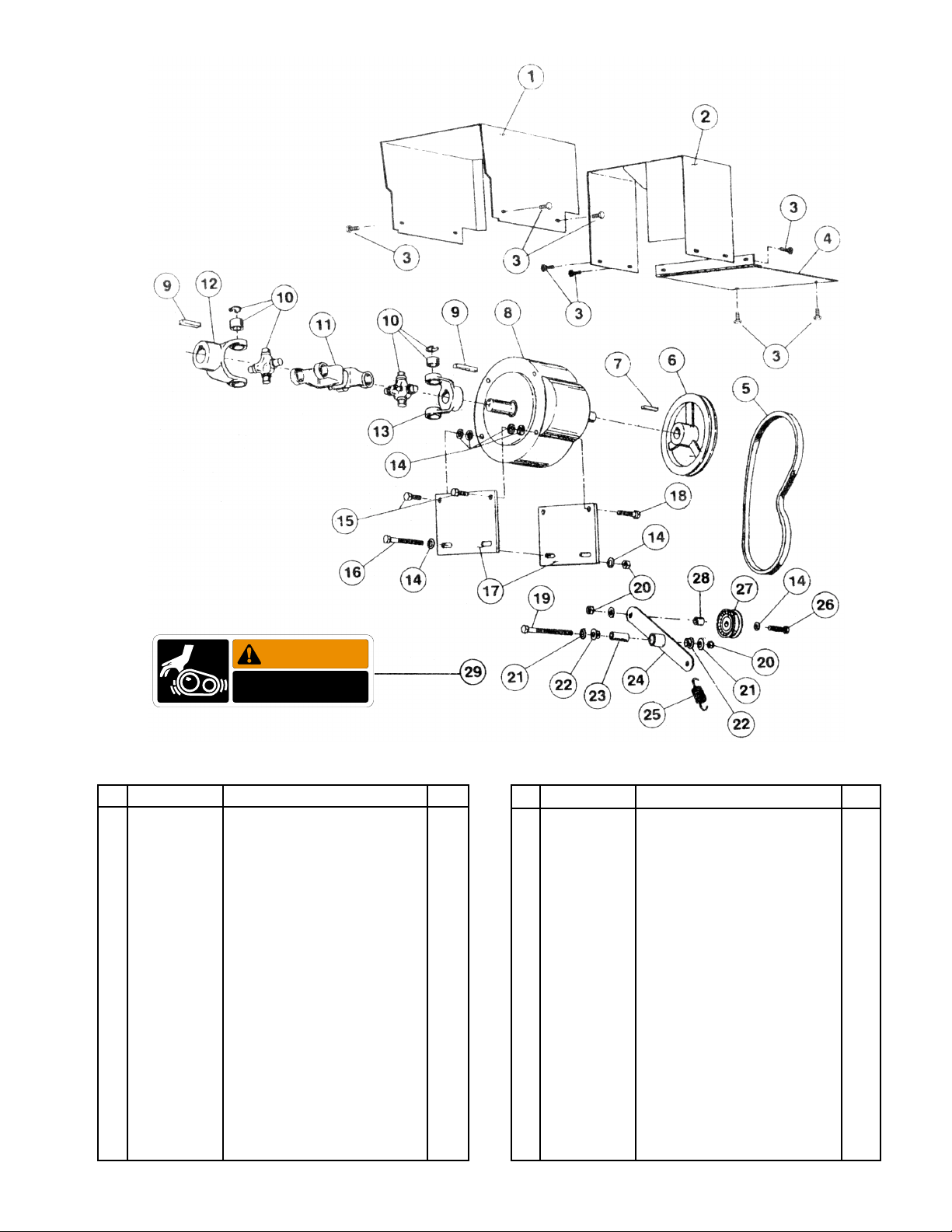

Ref Part No. Description Qty

1 93-6431 Drive Shaft Cover 1

2 92-8270 Belt Cover 1

3 32104-95 HWH - Self Tapping Screw 12

1/4 x 5/8"

4 92-8219 Belt Cover Door 1

5 92-8249 Drive Belt 1

6 92-8204 Speader Pulley 1

7 314110 Square Key, 3/16 x 1" 1

8 043003 Gear Multiplier 5:1 1

9 314233 Square Key, 1/4 x 1-1/2" 2

10 42554 Journal & Bearing 2

3247-3 Set Screw, 3/8 NC x 1/2" 4

11 43004 Double Center Yoke 1

12 42552 End Yoke, 1-3/16" Dia. 1

13 42553 End Yoke, 1" Dia. 1

14 3256-24 Flat Washer, 3/8" S.A.E. 10

Ref Part No. Description Qty

15 323-6 HHCS, 3/8 NC x 1" 2

16 323-38 HHCS , 3/8 NC x 4-3/4" 2

17 92-8205 Gearbox Plate 2

18 323-10 HCS, 3/8 NC x 5-1/2" 2

19 323-25 HHCS, 3/8 NC x 5-1/2" 1

20 32153-2 Lock Nut 4

21 3256-4 Flat Washer, 3/8" 2

22 256-258 Nylon Flange Bushing 2

23 92-8202 Idler Pivot Sleeve 1

24 92-8199 Idler Arm Ass'y 1

25 54-2730 Idler Spring 1

26 323-9 HHCS, 3/8 x 1-3/4" 1

27 041353 Idler Pulley 1

28 41488 Idler Spacer 1

29 80-8040 Decal - Rotating Members 1

SPREADER DRIVE

1409

WARNING

ROTATING MEMBERS

80-8040

6

NO RIDERS

75-5190

WARNING

ROTATING MEMBERS

80-8040

CAUTION

TO AVOID PERSONAL INJURY KEEP

ALL SHIELDS IN PLACE.

DISENGAGE AND SHUT OFF

ENGINE BEFORE SERVICING OR

UNCLOGGING MACHINE.

KEEP HANDS, FEET AND CLOTHING

AWAY FROM POWER-DRIVEN PARTS.

87-0450

NO STEP

36-3400

READ YOUR OPERATOR’S MANUAL FOR OPERATING AND

SAFETY INSTRUCTIONS. TO GET A REPLACEMENT MANUAL,

SEND MODEL AND SERIAL NUMBERS TO : THE TORO CO., 8111

LYNDALE AVE. S., MPLS., MN 55420

65-3090

Part No. 75-5190: Located on rear Rear Cover

2 - Located on sides of Rear Support Tube.

2 Located on Radiator Cver.

Part No. 80-8040: 2 - Locatied on Radiator Cover.

1 - Located on Belt Cover.

Part No. 65-3090: Located on top of Front Tube

Crossmember.

Part No. 36-3400: Located on Radiator Cover.

Part No. 87-0450: Located on top of Front Tube

Crossmember.

Part No. 92-4366: Located on R. H. and

L.H. side of Frame.

Part No. 88-8950: 1- Located

on Frame under Belt Cover.

1 - Located under PT .

Part No. 92-2741: Located on rear of Spreader Hopper. Part No.92-2742: Located on Hopper below

Decal No. 92-2741

Part No. 92-4447:

Located on Seat

Bar next to

Spreader Lever.

1410

THESE PARTS ARE N T USED WITH PTI NAL FL W

C NTR L KIT.

45 47 46

53 51

49

50

48

52

54

7

Ref Part No. Description Qty Ref Part No. Description Qty

SPREADER DRIVE

Lever Grip

Lock Nut, 1/2 NC

Lever

Carriage Bolt, 5/16 NC x 3/4"

Lever Pivot Bracket

Lever Bracket Brace

Lock Nut, 5/8 NC

HHCS, 5/8 NC x 1-1/2

Pivot Sleeve

Flat Washer, 1/2 USS

HHCS, 1/2 NC x 4"

Hex Jam Nut, 1/2" NF

Adjustable Clevis 1/2"

Hair Pin

Clevis Pin, 1/2 x 1-1/2"

Linkage Bar

HWH - Self Tapping Screw

1/4 x 5/8"

Service Door

Flat Washer, 5/8 USS

HHCS, 3/8 NC x 1"

HHCS, 1/2 NC x 2"

HHCS, 5/8 NC x 2-1/2"

Flat Washer, 1/2 SAE

Spreader Mount Plate

HHCS, 5/8 NC x 2

U-Bolt

Rear Support Tube (With decals)

Lynch Pin

Mounting Pin

92-8229

32153-5

92-8228

3230-1

92-8223

92-8230

32153-15

327-4

92-8235

3256-6

325-17

3220-5

92-0302

328967

283-68

92-8231

32104-57

92-8211

3256-7

323-6

325-8

327-7

3256-26

92-8210

327-6

92-2752

92-8269

92-1298

92-1233

1

11

1

4

1

1

4

1

1

10

1

1

1

4

1

1

9

2

12

6

4

2

16

2

1

2

1

4

2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

HHCS, 1/2 NC x 3-1/4

Frame Ass'y. (With decals)

Lock Nut, 3/8 NC

Flat Washer, 3/8 USS

HHCS, 1/2 NC x 1-1/2"

Attachment Mounting Bracket

Jack Stand

Cover Trim

Clevis Pin, 1/2 x 2"

Hex Nut, 3/8 NC

Radiator Cover (With decals)

Trim 5-5/8" Long

Trim 26" Long

Control Console Bracket

(Flow Control w/o Enclosure)

Hole Plug, 3-1/2"

Grommet

(Flow Control w/ Enclosure)

Radiator Panel

(Air-cooled WM only)

Decal - Capacity 700 lbs.

Decal - Sand Level

Decal - Warning

Decal - No Sept

Decal - No Riders

Decal - Rotating Members

Decal - pen/Close

Decal - Read Manual

Decal - Personal Injury

Decal - Danger Tip

325-13

92-8291

32153-2

3256-4

325-6

92-2667

92-8250

92-8233

42195

3217-7

93-6199

9203627

42657

92-3679

42591

40764

93-6427

92-2741

92-2742

88-8950

36-3400

75-5190

80-8040

92-4447

65-3090

87-0450

92-4366

4

1

6

8

2

2

2

1

2

2

1

1

1

1

1

1

1

1

1

2

2

5

2

1

1

2

2

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

8

REF PART NO. DESCRIPTION QTY

GEAR MULTIPIER, 5:

1411

250 Housing Half

250 Housing Half

250 Gear, INTG HEL LH, 15T

250 Gear, HEL RH , 75T

250 Shim, .002 Red

250 Shim, .005 Blue

Spec. Shaft - utput

Ball Bearing

Cup Bearing

Cone Bearing

HHCS 3/8 NC x 1-3/4 (Grade 5)

Key, 3/16 sq x 3/4

Dowell Pin, 1/4 x 3/4

Seal

Seal

Skt. Pipe Plug, 1/4 NPT

43047

43048

43049

43050

43051

43052

43053

43054

43055

43056

323-9

43057

43058

43061

43060

43059

1

1

1

1

2

2

1

2

2

2

4

1

2

1

1

4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

This manual suits for next models

1

Other Toro Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

Conceptronic

Conceptronic CCARHOLDTAB Multi Language Quick Guide

travall

travall TDG 1604 Fitting instructions

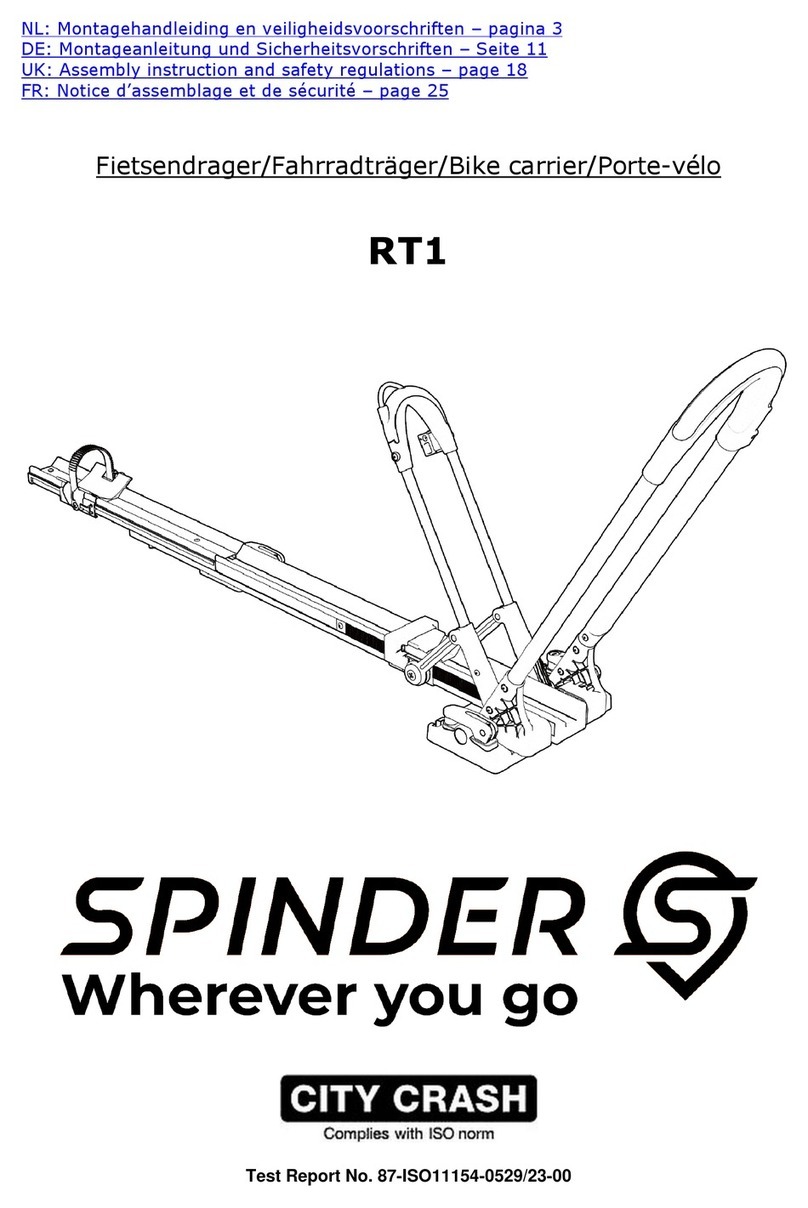

Spinder

Spinder RT1 Assembly instruction and safety regulations

Costway

Costway AT5565 user manual

Havis-Shields

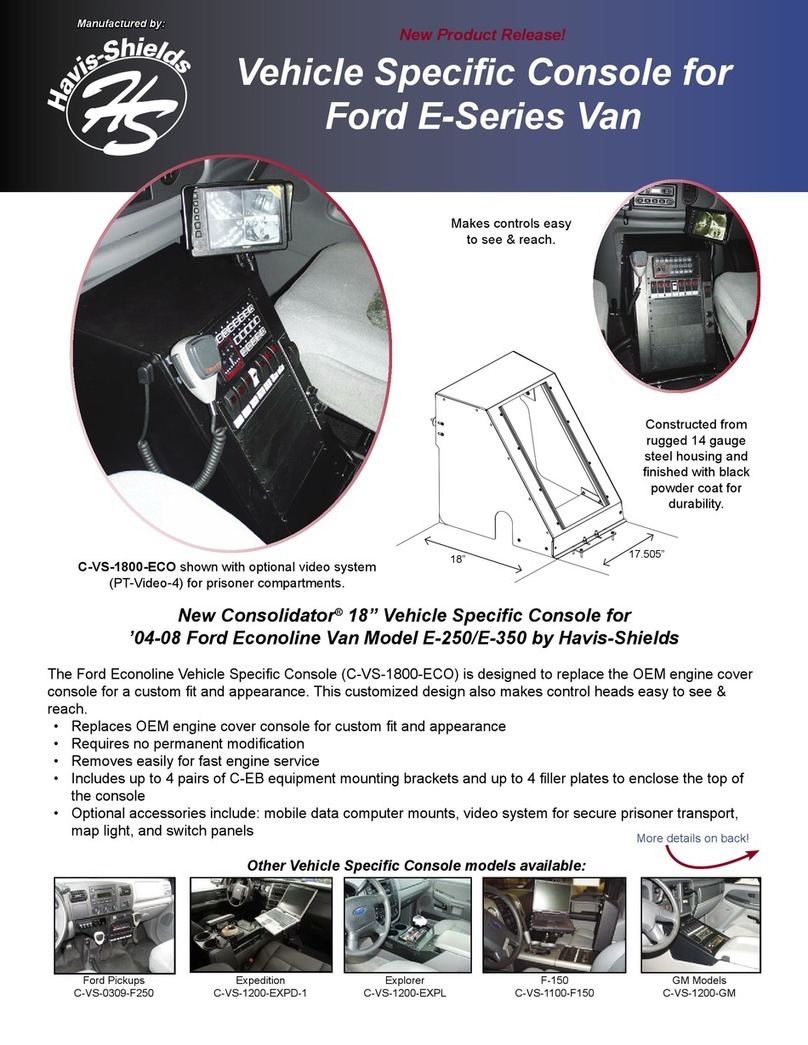

Havis-Shields 18" Vehicle Specific Console for '04-08 Ford Econoline Van... Brochure & specs

Michelin

Michelin Wheely-Safe FITMENT PROCEDURE