Operation

OperatingTips

1.TheTranspro80isintendedforusewith

Greensmaster800,1000,1600,2000,2600,

Flex18,21,1800,1820,2100,2120andeFlex

1800,1820,2100,2120WalkGreensmasters.

Thetowingofotherproductsmaydamagethe

axlesandtransmissionsthatcontinuetorotate

whentowed.

2.Useonlyavehiclewiththepropertowrating.

TheTranspro80and1greensmowerweigh

approximately400lb(182kg).Ensurethatthe

towvehiclehasadequatebrakingandhandling

capacitybycheckingtherecommendationsof

thevehiclemanufacturer.

3.Ensurethatthetrailerisproperlyconnectedto

thetowvehiclebeforeloadingorunloadingthe

greensmowertopreventsuddenunintended

tonguemovementoripup.Usearetention

deviceonthehitchpintosecuretheconnection.

Important:Thetrailertongueshouldbe

paralleltothegroundwhenyoualignitwith

thetowvehiclehitch.

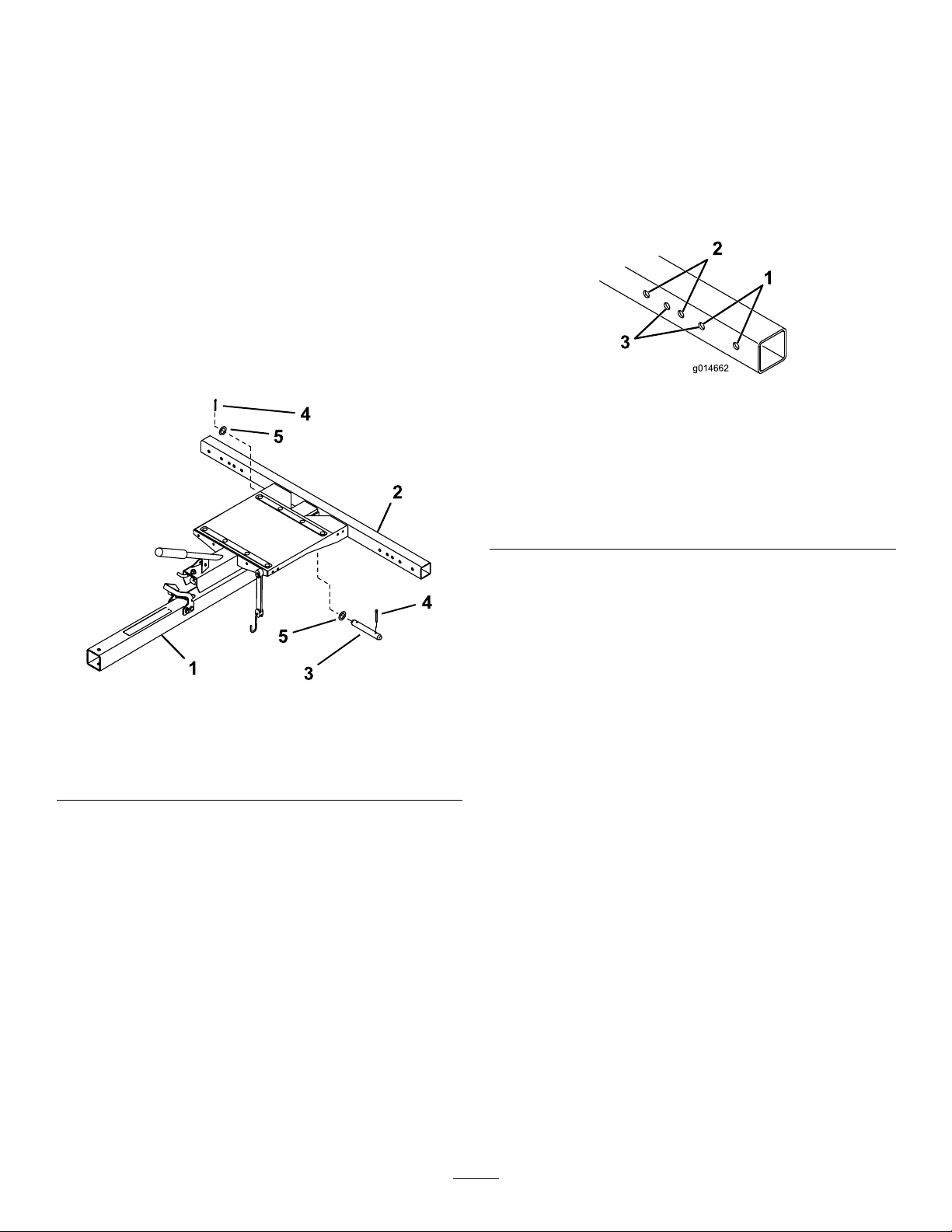

4.Duringtransport,usethebungeestraptosecure

thegreensmowertothetrailer(Figure15).You

canmovethebungeestraptodifferentmounting

holestoaccommodatedifferentmowers.

Note:Securethebungeestraptothegrass

baskethornsortothegrassbasketlooponthe

eFlex/Flex1800/2100models.

g014673

Figure15

1.Bungeestrap

5.TheTranspro80addsextratowingweighttothe

vehicle.Drivethevehiclesafely.

•Donotdriveonhighwayorpublicroads.

•Alwaysslowthetowvehiclewhen

approachingandwhilemakingaturn.

•Alwaysslowthetowvehiclewhendrivingin

unfamiliarareasoroverroughterrain.

•Alwaysslowthetowvehiclegraduallywhen

changingdirectionoftravelorpreparingto

stop.

•Whenturningordrivingonslopes,always

slowthetowvehicle,thenturntoprevent

lossofcontrolandpossibleupset.

•Donotmakesuddenorsharpturns.Donot

suddenlychangedirectionoftravelonan

incline,ramp,grade,slopeorsimilarsurface.

•Themaximumtowingspeedis15mph(24

kmh).Alwaysadjustthetowvehiclespeed

toallowforexistinggroundconditions,such

aswetslicksurfaces,loosesandorgravel

and/orlowvisibilityconditions,suchasdim

orbrightlighting,fog,mistorrain.

•Beespeciallycarefulwhendrivingaheavily

loadedvehicledownaninclineorslope.

Drivethevehicleupanddownthefaceof

theslopes,inclinesorgradeswhenever

possible.Donotdriveacrossthefaceifat

allpossible.Thereisariskofupsettingthe

vehicle,whichcanresultinseriousinjuryor

death.

6.Beforebackingup,looktotherearandensure

thatnooneisbehindyou.Backupslowlyand

watchthetrailermovementclosely.

7.Useextremecautionandslowspeedwhen

backingupthetrailerandtowvehicle.

8.Watchoutfortrafcwhennearorcrossingroads.

Alwaysyieldtherightofwaytopedestriansand

othervehicles

9.Ifthetrailerbeginstovibrateabnormally,stop

immediately.Shutoffthetowvehicleengine.

Repairalldamagebeforetowing.

10.Beforeservicingormakinganyadjustmentsto

thetrailer

•Stopthetowvehicleandsettheparking

brake.

•Shutoffthetowvehicleengineandremove

thekey.

11.Keepallnuts,boltsandotherfastenerstightened

securely.Replaceanypartsremovedduring

servicingoradjustments.

12.Toensureoptimumperformanceandcontinued

safetyofthisproduct,alwaysusegenuineToro

replacementparts.Replacementpartsand

accessoriesmadebyothermanufacturersmay

affecttheproduct’soperation,performanceor

durability.Suchusecouldalsovoidthewarranty

ofTheToroCompany.

7