Toro 07419 User manual

FormNo.3457-578RevA

RearPTOKit

Heavy-DutyWorkman®Vehicles

ModelNo.07419

InstallationInstructions

Formachineswithserialnumbers239999999andbefore,decal93-9861isnotincludedinthekit.Youmust

purchasedecal93-9861separatelyandapplyit.

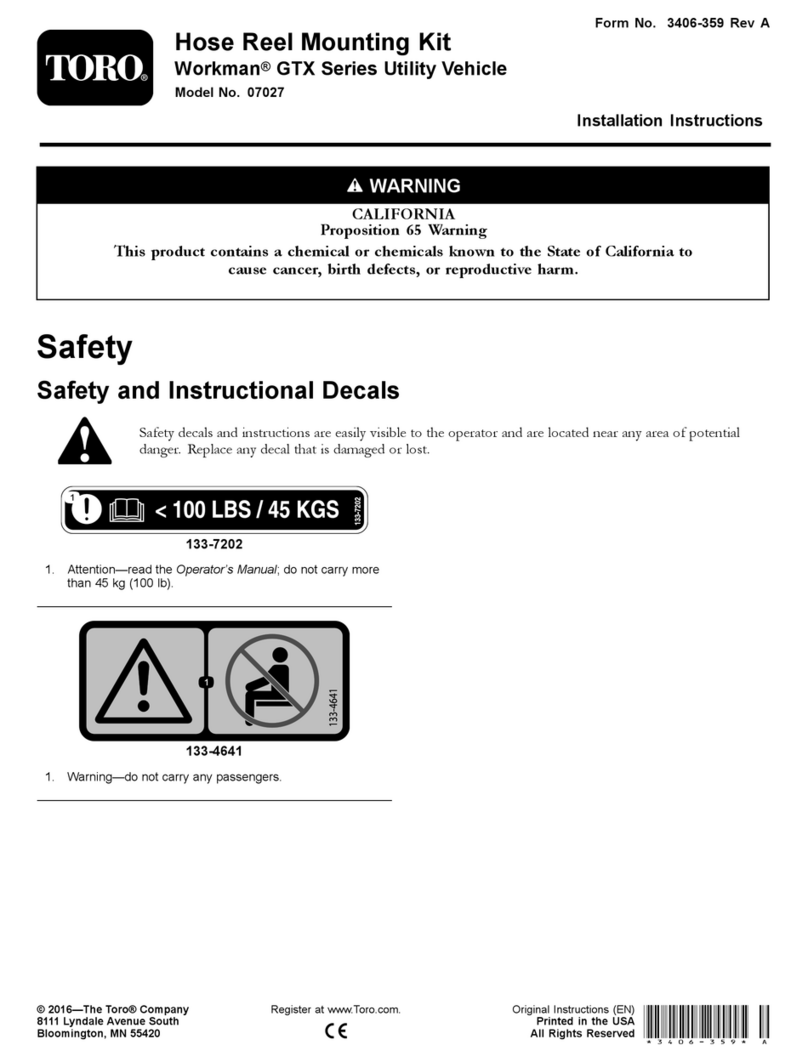

Safety

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

decal93-9861

93-9861

1.EngagePTO5.Entanglementhazard,

shaft

2.DisengagePTO6.ReadtheOperator's

Manual.

3.RearPTO7.Keepbystandersaway

fromthemachine.

4.Warning

decal93-9862

93–9862

1.Entanglementhazard—keepawayfrommovingparts;keep

allguardsandshieldsinplace.

©2022—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved*3457-578*

Installation

1

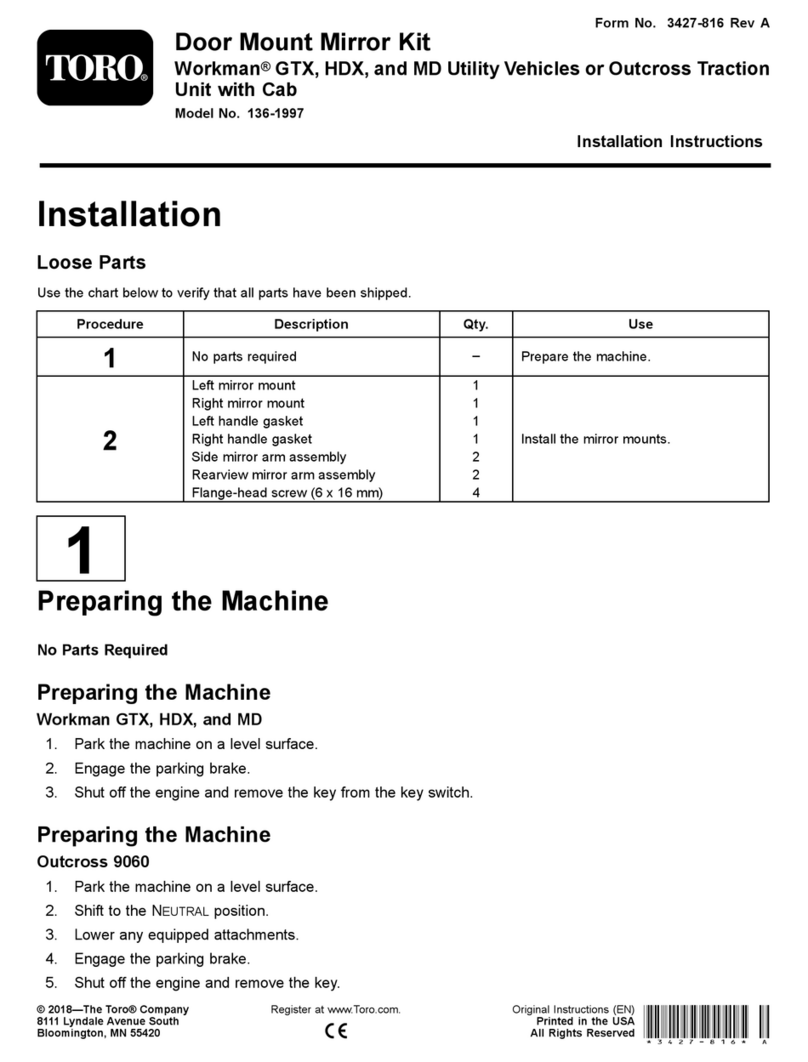

PreparingtheMachine

NoPartsRequired

Procedure

1.Parkthemachineonalevelsurface.

2.Formachinemodelswithautilitybed,perform

thefollowing:

A.Raisethebeduntiltheliftcylindersarefully

extended;refertotheOperator’sManual

forthemachine.

B.Removethebedsupportfromthestorage

bracketsonbackoftheROPSpanel(Figure

1).

g002397

Figure1

1.BedSupport

C.Pushthebedsupportontothecylinder

rod,makingsurethesupportendtabsrest

ontheendofcylinderbarrelandonthe

cylinderrodend(Figure2).

g009164

Figure2

1.Bedsupport3.Bed

2.Cylinderbarrel

3.Engagetheparkingbrake.

4.Shutofftheengineandremovethekey.

5.Disconnectthebatteryasfollows:

A.Squeezethebatterycovertoreleasethe

tabsfrombatterybase(Figure3).

g010326

Figure3

B.Removethebatterycoverfromthebattery

base(Figure3).

C.Removetheterminalofthepositivebattery

cablefromthebatterypost(Figure4).

Note:Ensurethattheterminalpositive

batterycabledoesnottouchthebattery

post.

2

g022071

Figure4

1.Terminalcover3.Batterypost

2.Positiveterminal4.Battery

2

InstallingthePTOControls

NoPartsRequired

InstallingtheLevers

Important:Usetheinstructionsinsteps1thru15

wheninstallingthekitonavehiclewithaserial

numbergreaterthan240000001;otherwiseskipto

ConnectingthePTOCable(page5).

1.Unscrewandremovealloftheknobsfromthe

consoleleversandfromthegearshiftlever

(Figure5).

g028744

Figure5

1.Consolelevers2.Gear-shiftlever

2.Removethe6screwsthatsecureoutsideedge

ofthecenterconsolecoverplatetotheframe

andremovethecoverplate(Figure6).

g028745

Figure6

1.Consolecoverplate3.Seat

2.Reservoirhose4.Shroud

3.Disconnectthereservoirhosefromtheradiator

andplugorclampthehosetoretainthecoolant

(Figure6).

4.Removethe8capscrewssecuringtheseats

andshroudtothemountingbrackets(Figure6).

Removeseatsandshroud.

5.Removethecotterpinsandclevispinsthat

securethecablestotheconsolelevers

(DifferentialLock,Hi–LowandHydraulicLift).

Retaincotterpinsandclevispins.

Note:Retainthecotterpinsandclevispins.

6.Removethenutandboltsecuringtheconsole

leverstoleverthesupportbracket(Figure7)

andtheremoveconsoleleverassemblyfrom

thelever-supportbracket.

3

g028746

Figure7

1.Nut3.Lever-supportbracket

2.Bolt4.Spacer

7.Removethespacer(Figure7)fromtheassembly

andinstallthenewPTOleverinit’splaceonthe

pivottube.

Note:PositiontheleverasshowninFigure8.

g028747

Figure8

1.PTOlever4.Pivottube

2.Flatwasher5.Spacer

3.Wavewasher

8.Installthepreviouslyremovedcomponentsonto

bolt,positioningeachasshowninFigure8.

9.Securethebolttotheleversupportbracketwith

thenutthatyouremovedpreviously(Figure8).

3

InstallingthePTOCable

NoPartsRequired

RoutingthePTOCable

1.RoutethePTOcableundertherearofthelever

supportbracket.

2.ConnectthePTOcableclevistotheholeinPTO

leverwithaclevispinandacotterpin(Figure9).

g028748

Figure9

1.PTOlever3.Clevispin

2.PTOcableclevis4.Cotterpin

3.SecurethePTOcabletoundersideofthelever

supportbracketwithaclampand2hex-socket

headself-tappingscrews(Figure10).

Note:ThePTOlevershouldbepositioned

soitisinlinewiththeHi–Lowlever(Engaged

position)whenthetransaxleisshiftedintothe

Lowposition.

4

g028749

Figure10

1.PTOcable3.Clamp

2.Leversupportbracket

4.Routethecable,alongtheexistingcables,and

tothecablebracketmountedatfrontleftcorner

ofthetransaxle(Figure11).

g028750

Figure11

1.PTOCable3.Jamnut

2.Cablebracket

5.LoosentherearjamnutsonthePTOcableand

inserttheendofcableintotheopeninginthe

bracket.LooselysecurethePTOcabletothe

bracketwiththejamnuts.

6.Installtheshroud,seats,consolecoverplate,

andleverknobsontothemachine;refertostep

2in2InstallingthePTOControls(page3).

Note:WhenthePTOisengaged,thelever

mustnotcontactthecenterconsoleplate.

ConnectingthePTOCable

Important:Accomplishtheinstallationstepsin

ConnectingthePTOCable(page5)onlywhen

installingthekitonamachinewithaserialnumber

priorto239999999;otherwiseskipto4Installing

thePTOtotheTransaxle(page6).

Note:Someofthepartsrequiredtoinstallthiskit

onmachineswithserialnumberspriorto239999999

arenotincludedinthekit,butarelistedintheparts

catalog.

1.Removealloftheknobsfromthecenterconsole

levers(Figure12).

g028751

Figure12

1.Centerconsolecover2.PTOlever(shown

installed)

2.Removethe6screwsthatsecuretheoutside

edgeofcenterconsolecoverplatetotheframe

andremovecoverplate(Figure12).

3.ConnectthePTOcableclevistothebottom

holeinPTOleverwithaclevispinandcotter

pin(Figure13)

5

g028752

Figure13

1.PTOlever4.PTOleversupport

2.PTOcable5.Self-tappingscrews

3.Clamp

4.SecurethePTOcabletothePTOleversupport

withaclampand2selftappingscrews(Figure

13).

5.InsertotherendofthePTOlevercablethrough

theopeninginrightsideoftheconsoleand

throughthecableholderintherearofthe

console(Figure14).

Note:Routethecable,alongtheexisting

cablestothecablebracketmountedatfrontleft

cornerofthetransaxle.

g028750

Figure14

1.PTOCable3.Jamnut

2.Cablebracket

6.Loosentherearjamnutsoncableandinsert

theendofcableintotheopeninginthebracket.

LooselysecurethePTOcabletothebracket

withthejamnuts.

7.Usingthe3selftappingscrewssuppliedinthe

kit,mountthePTOleversupporttotherightside

ofconsole.

Note:Theleverlocationisshowningure8.

8.Cleanconsoleplateandinstalltheoperation

decaltotheconsolenexttoPTOlever,locating

thedecalasshowninFigure15.

g028754

Figure15

1.Console2.Operationdecal

9.Installtheconsolecoverplateandthelever

knobstomachine.

Note:WhenthePTOisengaged,thelever

mustnotcontactthecenterconsoleplate.

4

InstallingthePTOtothe

Transaxle

NoPartsRequired

RemovingtheTransaxleCover

Plate

Note:Theremainingstepspertaintoinstalling

thekitonallvehiclesunlessotherwisespecied.

1.Disconnectthehydraulichosefromthettingon

transaxlecoverplate(Figure16).

Note:Capendofhosetopreventcontaminants

fromenteringhose.

6

g028755

Figure16

1.Transaxlecoverplate3.Fitting

2.Hydraulichose

2.Removethettingfromcoverplate.

3.InstallthettingintothefrontofthenewPTO

andpositionttingasshowninFigure17.

g028756

Figure17

1.PTO2.Fitting

4.Removethe5bolts,lockwashersandnut

thatsecurethecoverplatetothetransaxle

andcarefullyremovecoverplatetoprevent

damagingtheO–ringseal(Figure17).

Note:Retainfastenersforinstallationlater.

InstallingthePTO

1.Installthe2alignmentpinsintotheholesinthe

transaxle,atlocationsshowningure14.

2.Usingthemountingbolts,lockwashersandnut,

thatyouremovedfromthetransaxlecoverplate,

mountthePTOassemblyontotransaxle(Figure

18).

Note:WhenmountingthePTOassembly,make

surethatO-ringispositionedproperlyingroove

ontransaxle.IfO–ringisdamaged,replaceit.

g028757

Figure18

3.Removethecapfromthedisconnectedhydraulic

hoseandinstallthehosetottingonthePTO

withclampthatyoupreviouslyremoved.

Note:Makesurehoseandttingareclean

beforeconnectionismade.

4.MovethePTOleveratthecenterconsoleallthe

wayback(towardstherearoftheconsole)and

thePTOleverarm(Figure19)onthetransaxle

totherightside(passengerside).

g028758

Figure19

1.PTOleverarm3.PTOSwitchconnector

2.Cableclevis

5.Adjustthecableclevisorjamnutsorboththat

securethecabletothebracket,untiltheclevis

7

pinwilldropfreelythroughthealignedmounting

holesintheclevisandleverarm(Figure19).

6.Securetheclevispinwiththecotterpin,tighten

jamnutthatsecuresthecabletocableclevis,

andtightenthejamnutsthatsecurethecable

tothebracket.

7.Removethejumpercablefromthewireharness

locatedinfrontofPTO.

8.Routethewireharnessunderthepositive

batterycableandconnecttheconnectorofthe

wiringharnessintothePTOswitchconnector.

9.MountthePTOshieldtorearframetubewith4

capscrews,2spacers,and4locknuts(Figure

20).

g028759

Figure20

1.PTOShield

10.Applythewarningdecaltolower-rearcrosstube

nexttoexistingdecal,justabovehitchpoint

(Figure21).

g028760

Figure21

1.Rearcrosstube2.Warningdecal

11.Usingthe5cabletiessuppliedinkit,securethe

PTOcabletotheexistingwiring.

5

CompletingthePTO

Installation

NoPartsRequired

Procedure

1.Connectthebatterycablestothebatteryand

installthebatterycover;referto1Preparingthe

Machine(page2).

2.Testtheinterlocksystem;refertoCheckingthe

InterlockSystemintheOperator’sManual.

3.Shutofftheengineandinspectthemachinefor

hydraulicuidleakswherethePTOhousing

mountsontothetransaxle.

Note:Repairalluidleaks.

4.StarttheengineandoperatethePTO.

5.Removethecylinderlockfromthebed-lift

cylinderandstowitinthebracketsattheback

oftheROPSpanel;referto1Preparingthe

Machine(page2).

6.Lowerthebedandshutofftheengine.

8

Operation

WARNING

Thevehiclemaymoveunexpectedlyifthe

PTOisengagedandthevehicleisshiftedinto

gear,whichcouldresultinseriousinjuryto

abystander.

•Donotshiftthetransmissionintogearuntil

thePTOattachmenthasstoppedrotating,

eveniftheclutchisdepressed.

•Ensurethatnobystandersarenearthe

PTOoutputshaftorthefrontorrearof

vehicle.

DANGER

Anuncoveredrotatingsplinecancatch

clothingandresultinseriousinjuryordeath.

•Whenanattachmentisnotconnectedto

thePTOshaft,disengagethedrivetothe

PTObypullingbackonPTOlever.

•ThePTOincludesashield.Thisshield

mustremaininstalledonthevehicleandin

goodcondition.

•AlwaysdisengagethePTOandshutoffthe

enginebeforecouplinganyattachmentto

thePTOshaft.

CAUTION

Usingattachmentswithhighinertia(i.e.

mowersorblowers)willincreasetheamount

offorcerequiredtoshiftthevehicleandwill

damagethetransaxleiffrequentlyshifted.

•Donotshiftthevehiclewhilethevehicleis

movingifthePTOisengaged.

•Alwaysusetheoptionaloverrunningclutch

whenpoweringahigh-inertiaattachment

withthePTO.

DescriptionofOperation

ThePTOtakespowerfromtheengine,throughthe

transaxle,andsuppliespowerthroughastandard

540rpm-splinedshaftattherearofthevehicle.PTO

powercanbeusedforbothmobileandstationary

attachments.

Note:RefertoattachmentOperator’sManualforrpm

recommendations.

9

MobilePTOOperation

Important:WhenoperatingthePTO,themachine

mustnotbemovingwhenPTOisstarted.

1.Engagetheparkingbrake.

2.ShiftthetransmissionintotheNEUTRALposition.

3.Fullydepresstheclutchpedalandstartthe

engine.

Note:TheenginewillnotcrankunlessthePTO

leverisintheOFFposition.

4.ShiftthePTOleverasfollows:

Important:Donotengageordisengage

PTOwhilemovingotherwisedamagetothe

PTOwilloccur.Alwaysstopvehiclebefore

shiftingPTO.

•Formachineswithserialnumbers

239999999andbefore,movePTOlever

fullyforwardtotheENGAGEposition.

•Formachineswithserialnumbers

240000000andafter,movePTOleverfully

rearwardtotheENGAGEposition.

5.Shiftthetransmissionintothedesiredgear.

6.Disengagetheparkingbrake.

7.Slowlyreleasetheclutchpedal.

TostopthePTOoperation,fullydepresstheclutch

pedalandmovePTOlevertotheDISENGAGEposition.

Note:YoumaystopthePTOmomentarilybyfully

depressingtheclutchpedalandallowingmachineto

cometoacompletestop.

StationaryPTOOperation

Important:WhenoperatingthePTO,themachine

mustnotbemovingwhenPTOisstarted.

1.Engagetheparkingbrake.

2.ShiftthetransmissionintotheNEUTRALposition.

3.Fullydepresstheclutchpedalandstartthe

engine.

Note:TheenginewillnotcrankunlessthePTO

leverisintheDisengageposition.

4.ShiftthePTOleverasfollows:

Important:Donotengageordisengage

PTOwhilemovingotherwisedamagetothe

PTOwilloccur.Alwaysstopvehiclebefore

shiftingPTO.

•Formachineswithserialnumbers

239999999andbefore,movePTOlever

fullyforwardtotheENGAGEposition.

•Formachineswithserialnumbers

240000000andafter,movePTOleverfully

rearwardtotheENGAGEposition.

5.Slowlyreleasetheclutchpedal.

TostopthePTOoperation,fullydepressclutchpedal

andshiftPTOlevertotheDISENGAGEposition.

Note:YoumaystopthePTOmomentarilybyfully

depressingtheclutchpedalandallowingtransaxle

andPTOtocometoacompletestop.

10

DeclarationofIncorporation

ModelNo.SerialNo.ProductDescriptionInvoiceDescriptionGeneralDescriptionDirective

07419—RearPTOKit,Heavy-Duty

WorkmanVehiclesREARPTOKITUtilityVehicle2006/42/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedT oromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:AuthorizedRepresentative:

MarcelDutrieux

ManagerEuropeanProductIntegrity

ToroEuropeNV

Nijverheidsstraat5

2260Oevel

Belgium

TomLangworthy

EngineeringDirector

8111LyndaleAve.South

Bloomington,MN55420,USA

October25,2022

UKDeclarationofIncorporation

ModelNo.SerialNo.ProductDescriptionInvoiceDescriptionGeneralDescriptionRegulation

07419—RearPTOKit,Heavy-Duty

WorkmanVehiclesREARPTOKITUtilityVehicleS.I.2008No.1597

RelevanttechnicaldocumentationhasbeencompiledasrequiredperSchedule10ofS.I.2008No.1597.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedT oromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Thisdeclarationhasbeenissuedunderthesoleresponsibilityofthemanufacturer.

TheobjectofthedeclarationisinconformitywithrelevantUKlegislation.

AuthorizedRepresentative:

MarcelDutrieux

ManagerEuropeanProductIntegrity

ToroU.K.Limited

SpellbrookLaneWest

Bishop'sStortford

CM234BU

UnitedKingdom

TomLangworthy

EngineeringDirector

8111LyndaleAve.South

Bloomington,MN55420,USA

October25,2022

Table of contents

Other Toro Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction