1

PreparingtheMachine

NoPartsRequired

Procedure

Note:Youcanuseahoistforbetteraccessunder

themachine.

Important:Caporpluganydisconnected

hydraulichoses,tubes,orcomponentportsto

preventcontaminatingthesystem.

1.Parkonalevelsurface,engagetheparking

brake,ensurethatthetractionpedalisinthe

neutralposition.

2.EnsurethatthePTObuttonisintheOFF

position.

3.Shutofftheengine,removethekey,andallow

themachinetocool.

CAUTION

Ifyouleavethekeyintheignition

switch,someonecouldaccidentlystart

theengineandseriouslyinjureyouor

bystanders.

Removethekeyfromtheswitchbefore

youdoanymaintenance.

4.Bleedthepressurefromthehydraulicsystem

byturningthehydraulicpumpbypassvalve;

refertotheinstructionsforpushingortowingthe

machineintheOperator’sManual.

5.Ifyouarenotinstallingthe4WDswitch,skip

to2RemovingtheHydraulicLines(page4).If

youareinstallingthe4WDswitch,continuethis

procedure.

6.Opentherighttoolboxcoveranddisconnectthe

negativecablefromthebatterypost;refertothe

Operator’sManualforyourmachine.

WARNING

Incorrectbattery-cableroutingcould

damagethemachineandcablescausing

sparks.Sparkscancausethebattery

gassestoexplode,resultinginpersonal

injury.

•Alwaysdisconnectthenegative

(black)batterycablebefore

disconnectingthepositive(red)

cable.

•Alwaysconnectthepositive(red)

batterycablebeforeconnectingthe

negative(black)cable.

7.Disconnectthepositivebatterycablefromthe

battery;refertotheOperator’sManualforyour

machine.

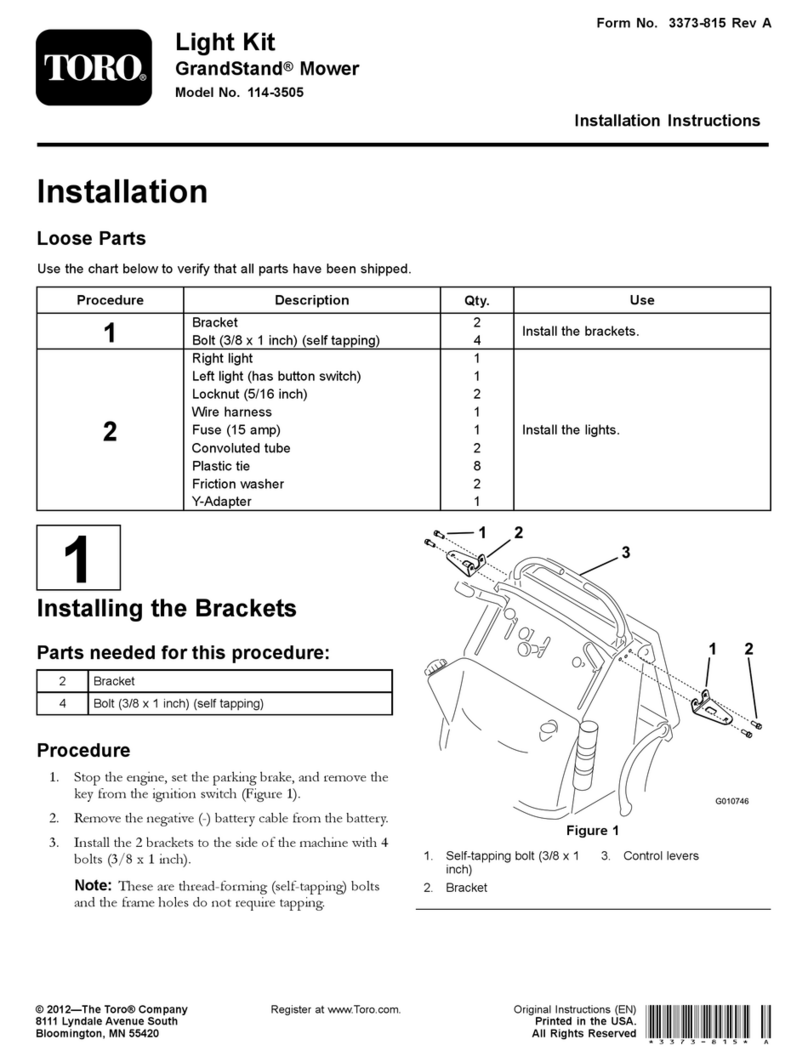

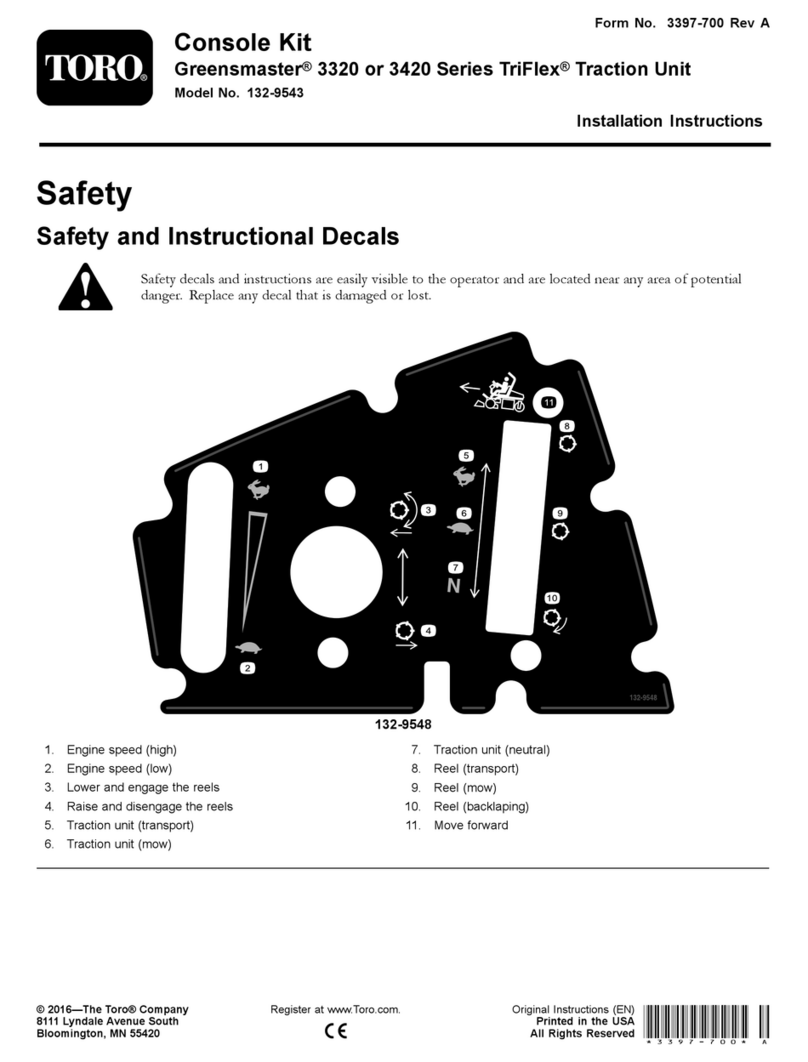

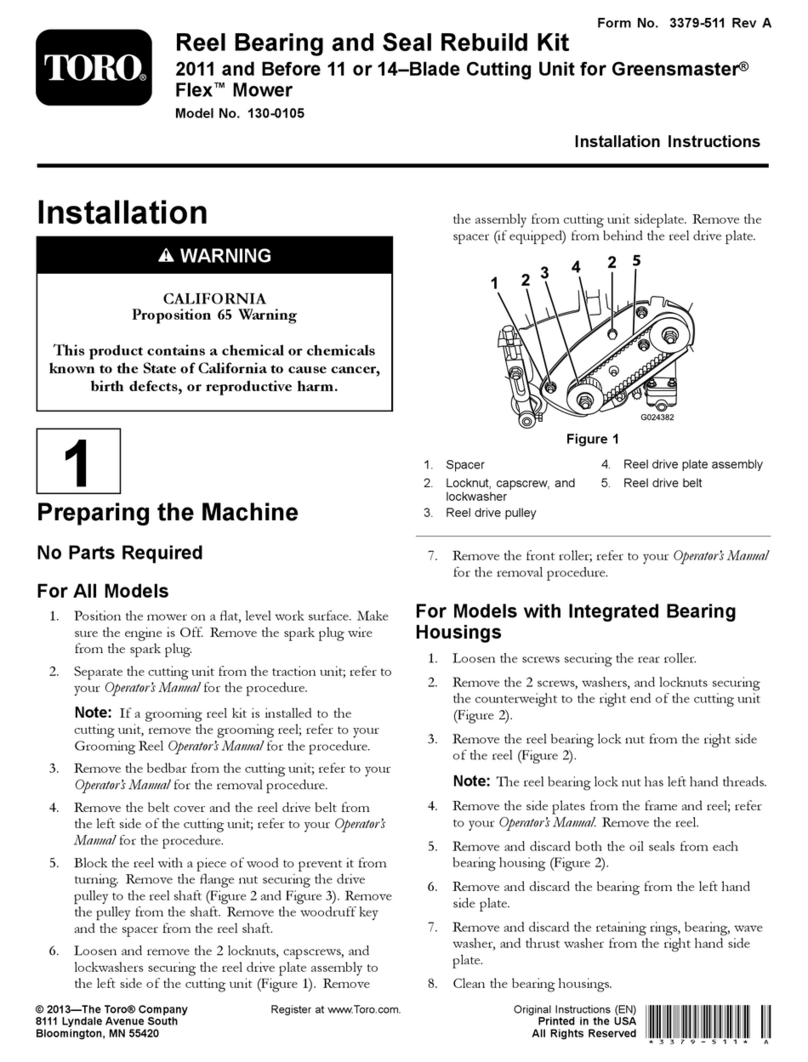

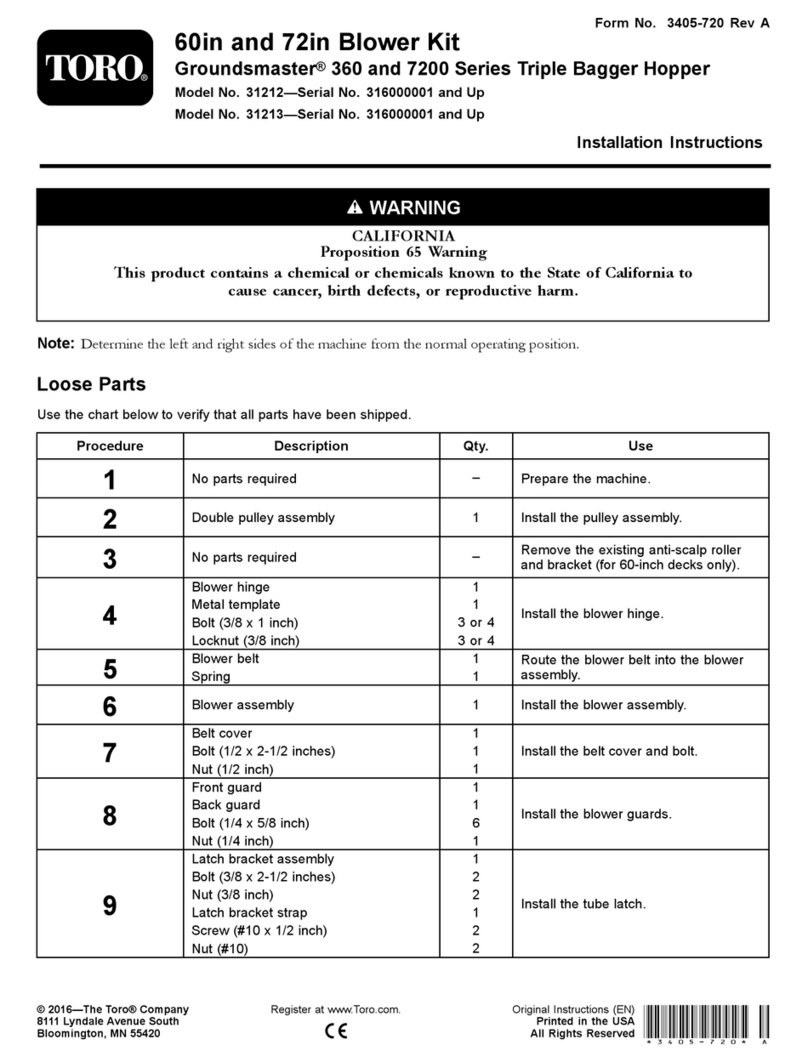

8.Removetherightconsolecoverasshownin

Figure1.

g204998

Figure1

1.Righttoolboxcover2.Rightconsolecover

3