Boom-WidthSettings

Theboom-widthsettingsarepre-populatedatthe

manufacturingplant(Figure9).

CalibrationScreen

ToaccesstheCalibrationscreen,pressbutton2ontheMain

Menuscreen(Figure6)untilyoureachCalibration,andpress

button4toselectCalibration.

Note:Pressingbutton5atanytimecancelscalibrations.

Ifyoudoso,themachineautomaticallyusesthecurrent

calibrationrates.

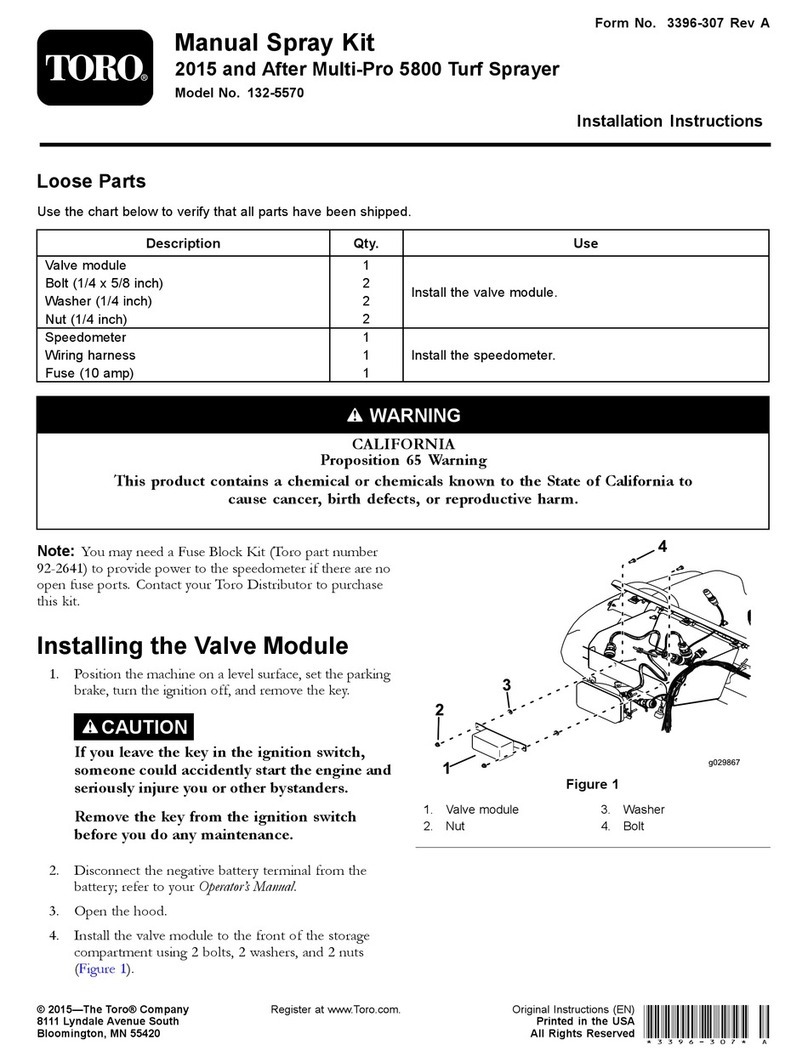

Figure21

FlowCalibration

Performtheowcalibrationbeforeusingthemachineforthe

rsttime,ifyouchangethenozzles,orasneeded.

Note:Itisrecommendedtoperformanozzle-uniformity

testbeforestartingaFlowCalibration.

1.Setthemachineintomanualmode,closethe

boom-sections-bypassvalve,turnonthesprayerpump,

turnoffagitation,andsettheenginetofullthrottle.

2.ToaccesstheFlowscreen,pressbutton4onthe

Calibratescreen(Figure21)toselectFlow .

3.Fillthesprayertankwithaminimumof700L(150US

gallons)ofwaterandapplytheparkingbrake.

4.Pressbutton2tomovetothenextstepandtoviewthe

SelectNozzleColorscreen.

5.Usebutton3andbutton4toselectthenozzlethat

youareusing.

6.Pressbutton2tomovetothenextstepandtoviewthe

ToProceedscreen.

7.Pressbutton2tomovetothenextstepandtoviewthe

15SecondCatchTestscreen.

Note:Itisrecommendedtostartthe15secondcatch

testat2.75bar(40psi),thenadjustfromthere.

Allboomsectionsmustbeonwhenperformingthe

catchtest.

8.Startat2.75bar(40psi)andusetheapplication-rate

switchtoadjustthespraypressuresoacatchtestyields

thevolumedisplayedfortheselectednozzlecolor.

9.Pressbutton2tomovetothenextstep.

10.Turnonallboomsections,turnonthemasterboom,

andpressbutton2tobegincalibration.

Note:Calibrationtakesseveralminutes.

Note:Asthemachinesprays,theInfoCenterdisplays

thevolumeofuidthatitiscounting.

Important:Donotturnoffthepumporany

boomsduringcalibration.

11.Ifthecalibrationissuccessful,aCalibrationSuccessful

screenappears;pressbutton5toexit.

12.Ifthecalibrationisnotsuccessful,aCalibrationFailed

screenappearswiththereasoningbehindwhythe

calibrationfailed;pressbutton5toexitandrestartthe

calibration.

SpeedCalibration

1.Ensurethatthetiresareproperlyinated;refertothe

Operator’sManual.

2.ToaccesstheSpeedscreen,pressbutton2onthe

CalibratescreenuntilyoureachSpeed,thenpress

button4(Figure21)toselectSpeed.

3.Fillthesprayertankwithaminimumof700L(150US

gallons)ofwaterandapplytheparkingbrake.

4.Pressbutton2tomovetothenextstepandtoviewthe

SpeedCalibrationscreen.

5.Markoffthedesireddistancebeforeproceedingtothe

nextscreen.

6.Pressbutton2tomovetothenextstep.

7.Pressbutton3toincreasethedesireddistanceorpress

button4todecreasethedesireddistance(Figure22).

Note:Ifyouchoosetocancelthecalibrationby

pressingbutton5,thesystemautomaticallydefaultsto

thepreviously-storeddistance.

10