FormNo.3439-786RevA

GeoLink®CL-55ModemKit

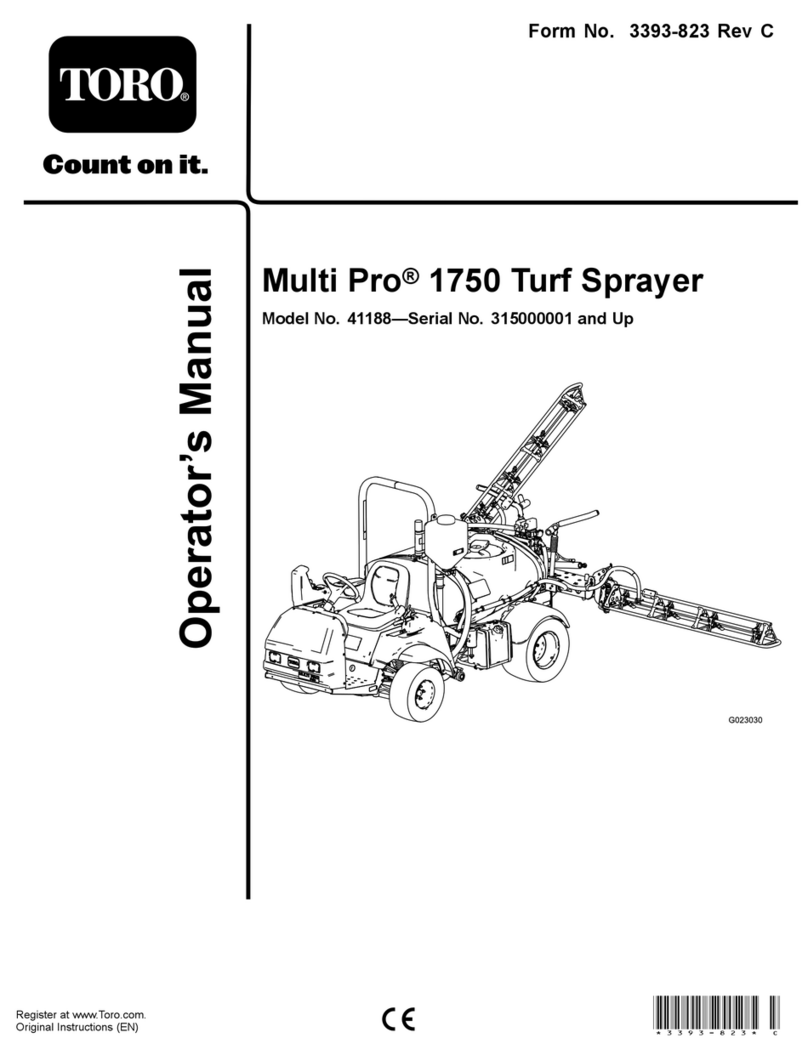

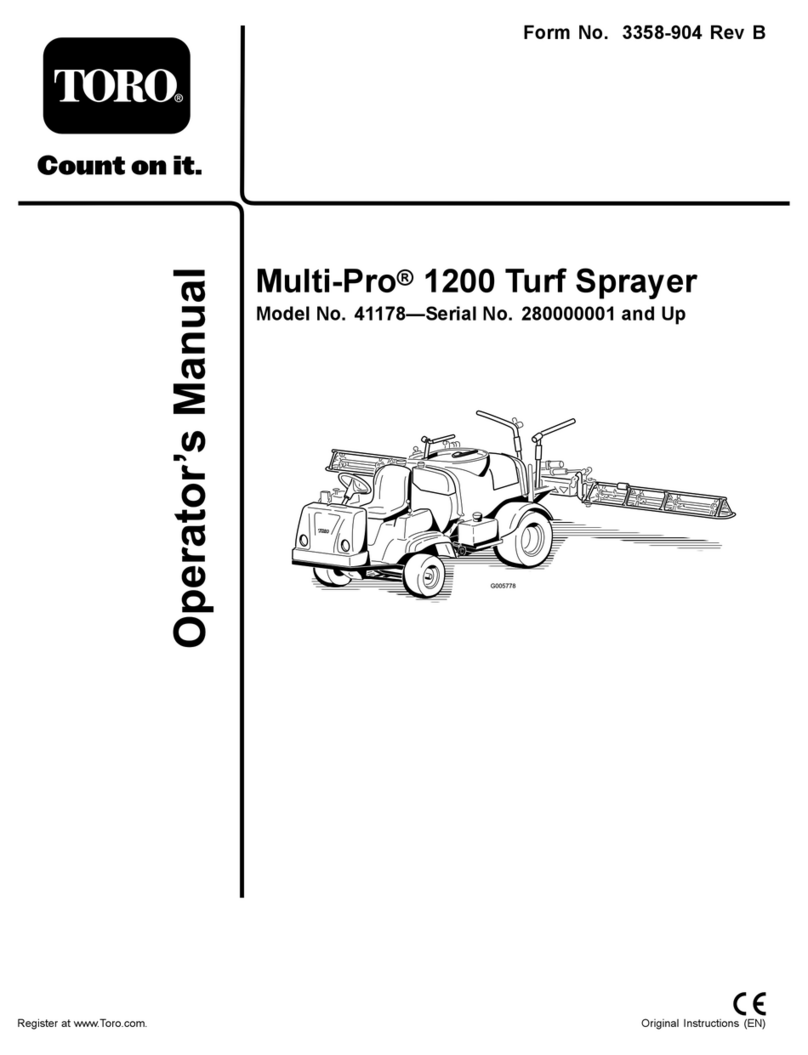

MultiPro®1750or5800TurfSprayer

ModelNo.41638

ModelNo.41639

InstallationInstructions

Introduction

TheCL-55modemkitupdatestheGeoLink®spraysystem.TheGeoLinkspraysystemisanattachmentfor

aturfsprayapplicationvehicleandisintendedtobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisdesignedprimarilyforsprayingonwell-maintainedlawnsinparks,golfcourses,sportselds,

andoncommercialgrounds.

Visitwww.Toro.comforproductsafetyandoperationtrainingmaterials,accessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Contents

Introduction...............................................................1

Setup........................................................................2

1GettingaCurrentCopyoftheSoftware

GuideandQuickStartGuide...........................4

2PreparingtheMachine.....................................4

3ExportingSprayerDisplayInventoryItem

Data................................................................4

4RemovingtheX30SprayerDisplay..................5

5InstallingtheX25MonitorKit(sold

separately)......................................................6

6VerifyingtheU-BootFirmwareVersion.............9

7UpdatingtheGeoLinkSoftware.......................9

8DisconnectingtheBattery..............................12

9RemovingtheSeatandtheEngine-Access

Panel.............................................................14

10RemovingtheRightFrontFender................15

11InstallingtheModem-Antenna

Bracket..........................................................17

12InstallingtheModemAntennatothe

Machine........................................................19

13AssemblingtheModemDataHarnessto

theMachine..................................................21

14RemovingtheTerminatingResistor..............25

15AssemblingtheModemPowerHarness

totheMachine..............................................25

16InstallingtheCL-55Modem.........................30

17ConnectingtheBattery................................34

18SecuringtheDataHarness..........................37

19InstallingtheRightFrontFender..................37

20InstallingtheEngine-AccessPaneland

theSeat........................................................38

21CompletingtheInstallationoftheCL-55

ModemKit.....................................................40

22PoweringtheGeoLinkComponents.............40

23ConguringtheGPSCorrection

Source..........................................................41

24CreatingaSprayJob...................................43

25PerformingaFlowMeterCalibration............43

26VerifyingtheCellularStatus.........................44

27PerformingaCompassCalibration...............44

28ClearingNVRAM.........................................44

29PerformingaCompassCalibration...............46

©2020—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved*3439-786*A