INTRODUCTION

APOLLO USER GUIDE

2

IMPORTANT

THIS PRODUCT MUST BE INSTALLED IN ACCORDANCE WITH THE APPLICABLE INSTALLATION

CODE BY A PERSON FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF THE PRODUCT,

ITS COMPONENT PARTS AND THE HAZARDS INVOLVED.

Thank you for purchasing this UFO Apollo lighting system.

Please read these instructions fully before performing any installation, operation or maintenance on the

system and before connecting power to your Apollo lighting system. Follow all warnings and instructions

carefully.

Please keep this manual for future reference.

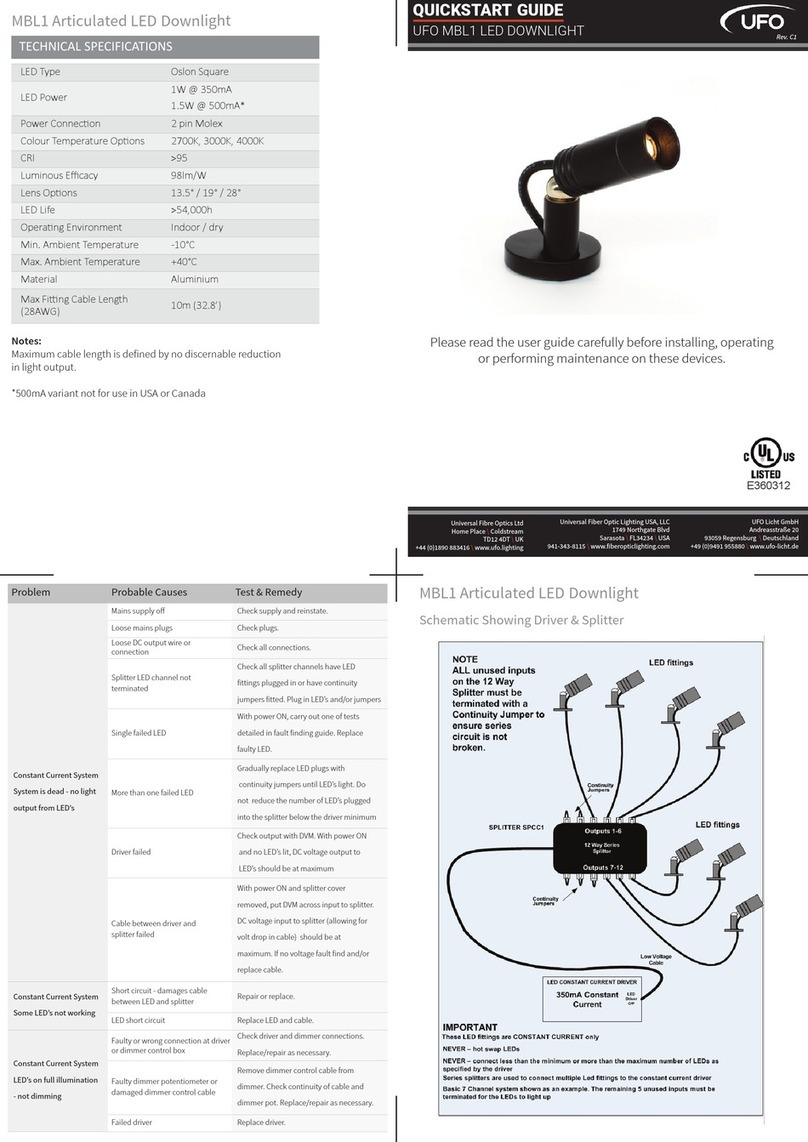

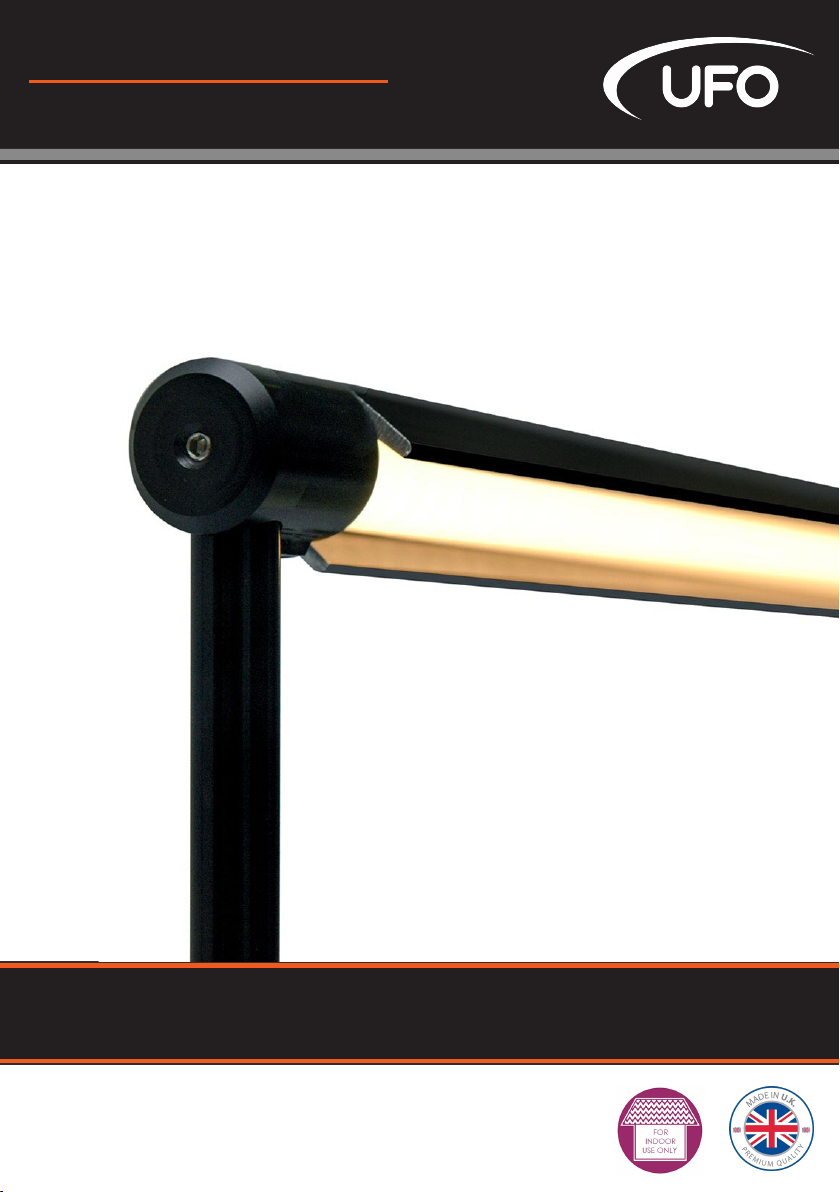

The UFO Apollo is a configurable LED lighting system which has been specifically designed for ease-of-use

in many installation environments. Available in a variety of lengths and heights, with a black or silver finish

and with tuneable colour-temperature which can be adjusted between 1800K and 6500K.

Please carefully follow the warnings and information below and throughout this manual. Failure to do so

could lead to functional and/or structural failure of the Apollo system, causing damage to the Apollo

system and to adjacent items, fixtures and fittings. UFO will accept no responsibility for such failures, nor

damage caused as a result, and this would also invalidate the UFO warranty.

Apollo systems must be installed and used only in accordance with the UFO-supplied system design and

in accordance with the assembly & installation instructions in this manual.

The UFO Apollo bodies and legs are designed and assembled cut to length by UFO and cannot be cut or

modified on site. Any attempt to cut or modify these products will invalidate warranty for the complete

UFO Apollo installation.

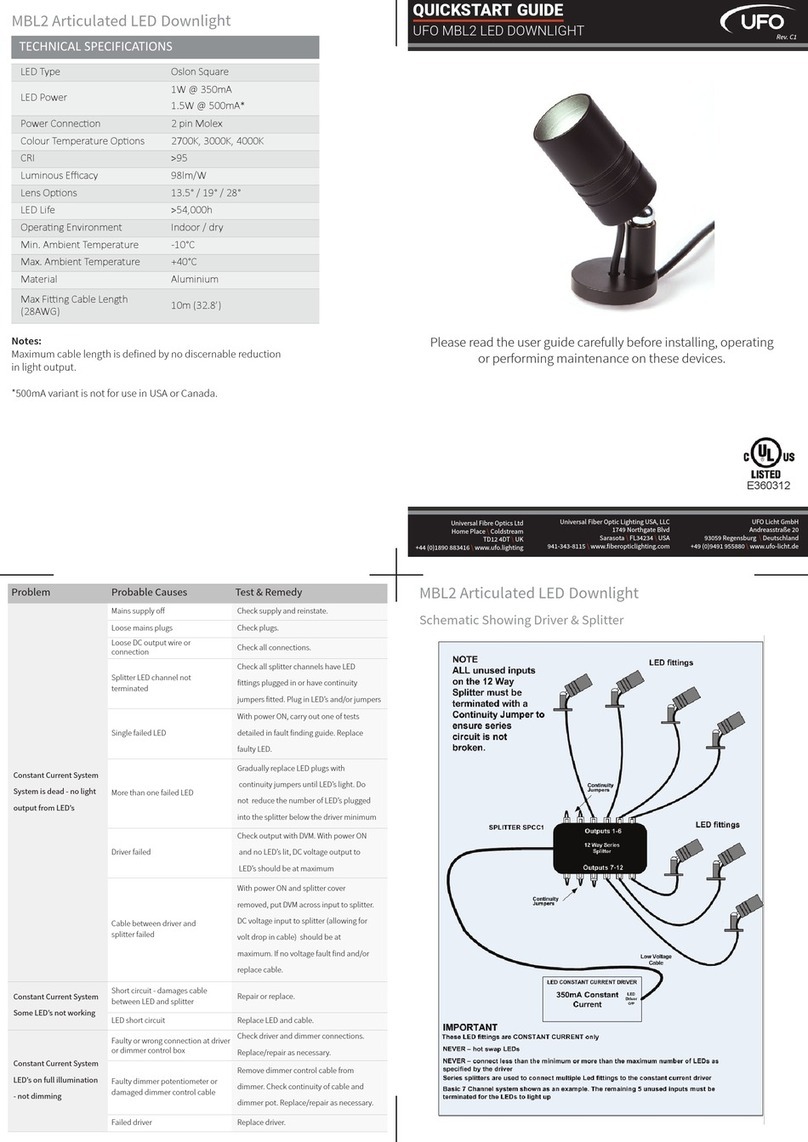

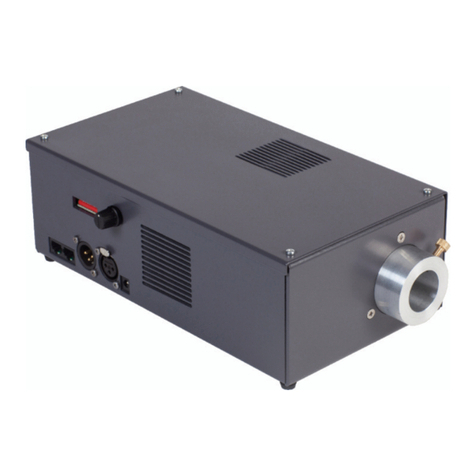

Apollo LED fittings operate from a constant-voltage, 24V DC supply. They should not be connected to a

constant-current driver. Apollo LED fittings are only dimmable with an appropriate constant-voltage

dimmer driver. Constant-current and constant-voltage LEDs cannot be intermixed on the same driver.

WARNING – These constant-voltage LED fittings operate on a 24V DC supply only. Connecting these fittings

to a dierent voltage supply is likely to cause malfunction and may even result in catastrophic damage to

the LED devices within them. Always check the output voltage of the PSU/driver to ensure correct output

voltage prior to powering up the system.

Ensure also that the selected power supply has suicient power capability for the length of LED tape/track

being driven and also voltage drop in the supply cable. The LED tape will generate a load depending on

type fitted and tape length as detailed below

• Fixed colour-temperature (2700K, 3000K or 4000K) = 14.4 Watts per metre

• Tuneable colour-temperature (1800K to 6500K) = 12 Watts per metre

The Apollo system is suitable for indoor/dry areas only and must not be installed in damp or wet

conditions.

WARNINGS AND IMPORTANT SAFETY INFORMATION