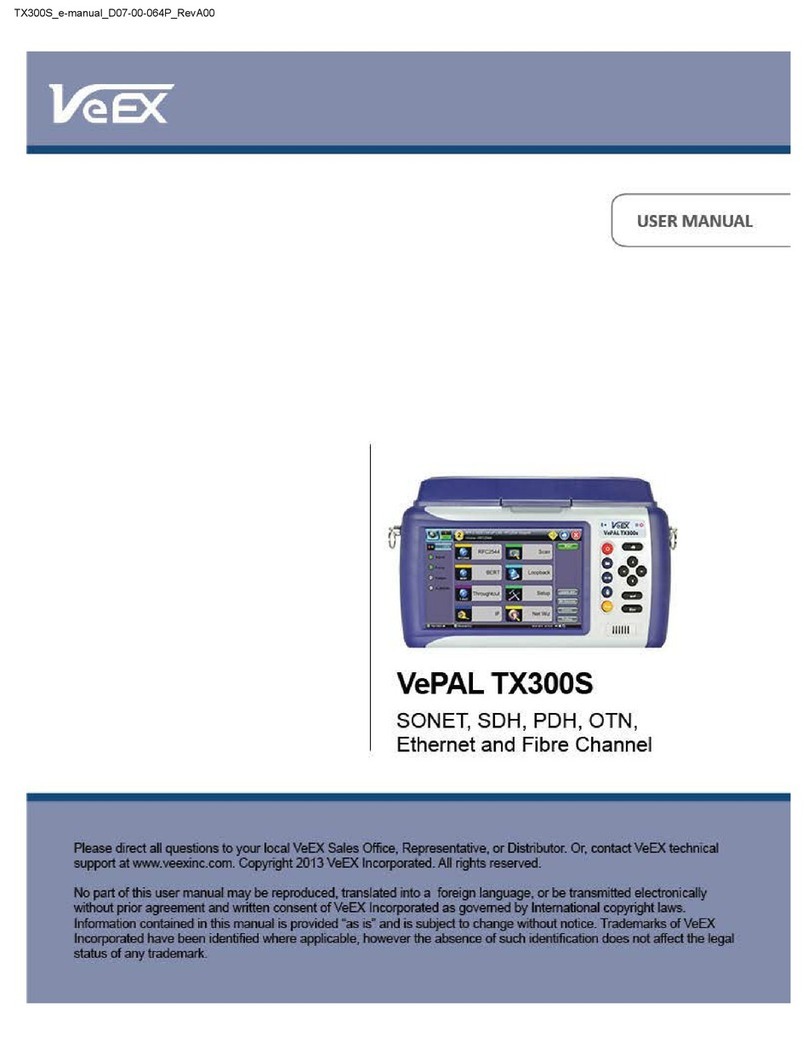

VePAL TX300

Quick Reference Guide

Conguration (DS1 Loop)

*Note: This determines the type of sent loopback code. Sent in the ESF

framing data link are ESF-DFL codes; therefore, ESF framing must be used

to select ESF. IN-BAND is the most common type deployed in networks.

INBAND can be transmitted with any type of framing. However, some

loopback devices will not respond to IN-BAND loopback codes when

transmitted with ESF framing. When in doubt, select IN-BAND when using

SF framing and ESF-DFL when using ESF framing.

HDSL:

NLOC – 1111000, DSX-1 signal is looped back to the network at the HLU.

NDU1 – 110000, DSX-1 signal is looped back to the network at doubler1.

NDU2 – 111000, DSX-1 signal is looped back to the network at doubler2.

NREM – 1110000, DSX-1 signal is looped back to the network at the HRU.

CREM – 1111110, Customer Remote. Invokes HLU loopback towards

the customer.

CDU1 – 111100, Signal from the customer is looped back to the customer

at doubler1.

CDU2 – 111110, Signal from the customer is looped back to the customer

at doubler2.

CLOC – 1111100, Signal from the customer is looped back to the customer

at the HRU

Generic

Loopback

Commands

USER: Select the desired loopback code with keypad.