Store key. Performs the storage in the memory of the test set of the current results. If the result is running, it will provide a

snap shot at the moment the key is pressed. The store function provides an automatic storage with automatic naming and

time stamping function. To manipulate a stored file, please go to files.

History key. The history key resets any blinking LED due to a history condition. For more details on the LED, please go to

LEDs.

Help key. The help key brings the user to the online help, regardless of the current user interface location of the unit.

Arrow key. The arrow key moves the cursor in any of the four supported directions (left, right, up, down). The arrow key

works in conjunction with the Enter and Escape keys.

Enter key. The enter key provides an enter sequence to the user interface. It is used in non touch-screen operation mode to

enter menus and functions.

Escape key. The escape key provides an escape sequence to the user interface. It is used in non touch-screen operation

mode to escape menus and functions.

Note: By pressing Home and Help buttons simultaneously, the tester enters a sleep mode which helps

preserve battery life. To exit the sleep mode, press Home and Help simultaneously once more.

Go back to top

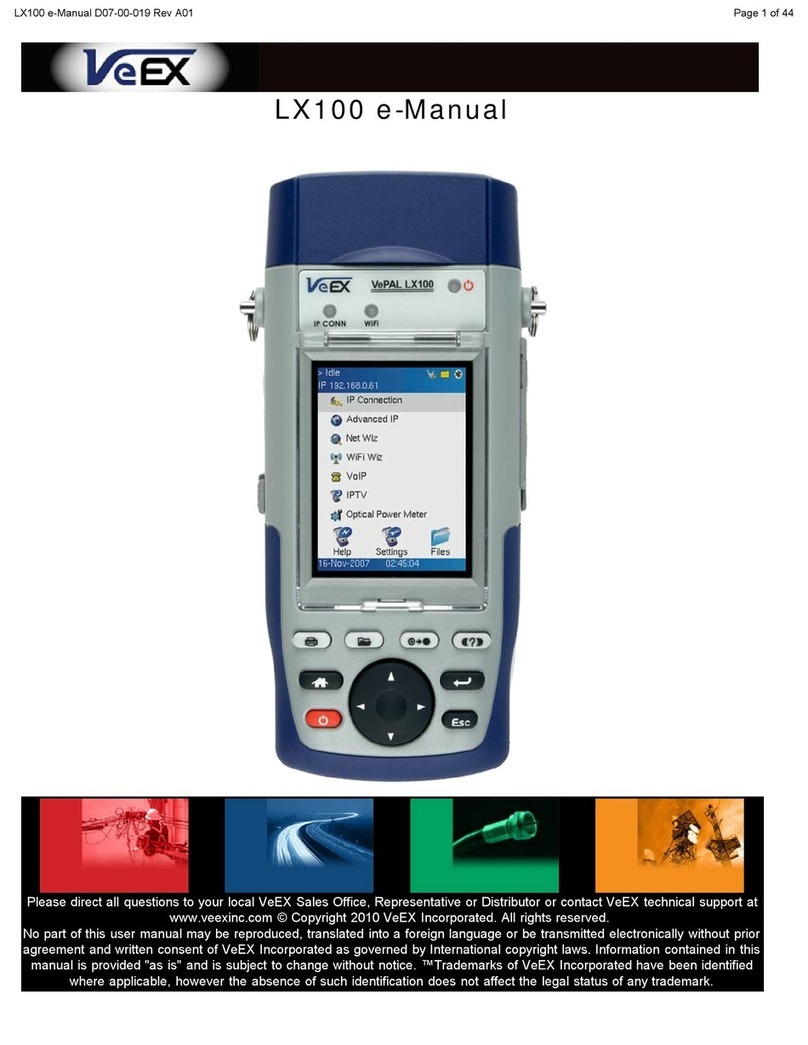

4.2 Touch-Screen Display

The LCD supports touch-screen operations. In order to use the unit in touch-screen mode, open the transparent door covering the

screen. Then take out the stylus available on the top door i.e. door protecting the connector panel. Keep the LCD cover closed

when using the unit on non touch-screen mode, and use the arrow, enter, and escape keys. The location of the cursor on the

screen is indicated by a focus state. The focus state varies depending on the function or section of the test set. Please observe the

following precautions;

- Never use excessive pressure on the touch-screen as this may damage its functionality

- Never use sharp objects such as a pen, screwdriver etc. as this may damage the surface

- Clean the surface of the touch-screen using a soft cloth and mild detergent only. Do not use alcohol.

Go back to top

4.3 Battery

The VPAL is equipped with an intelligent Lilon rechargeable battery pack which is located in the rear of the unit. The battery will be

partially charged upon delivery so it is recommended to charge the battery fully before use. It is recommended to charge the battery

at room temperature to preserve its life and to obtain maximum charge. The battery can be removed during operation provided the

unit is connected to the AC Main using the supplied AC adapter. Removing the battery, when not connected to the AC Main will

cause the unit to shutdown. Remove the rubber cover on the left side to connect the AC Main adapter to the unit.

Go back to top

4.4 Connectors and Panels

RF Test Ports:

To access the RF test connectors, please open the top cover.

CX100/110/120/150/180 series e-Manual D07-00-002 Rev B01