Vingtor Stentofon Exigo Ex EAPFX-1 User manual

Other Vingtor Stentofon Intercom System manuals

Vingtor Stentofon

Vingtor Stentofon ECPIR-3P User manual

Vingtor Stentofon

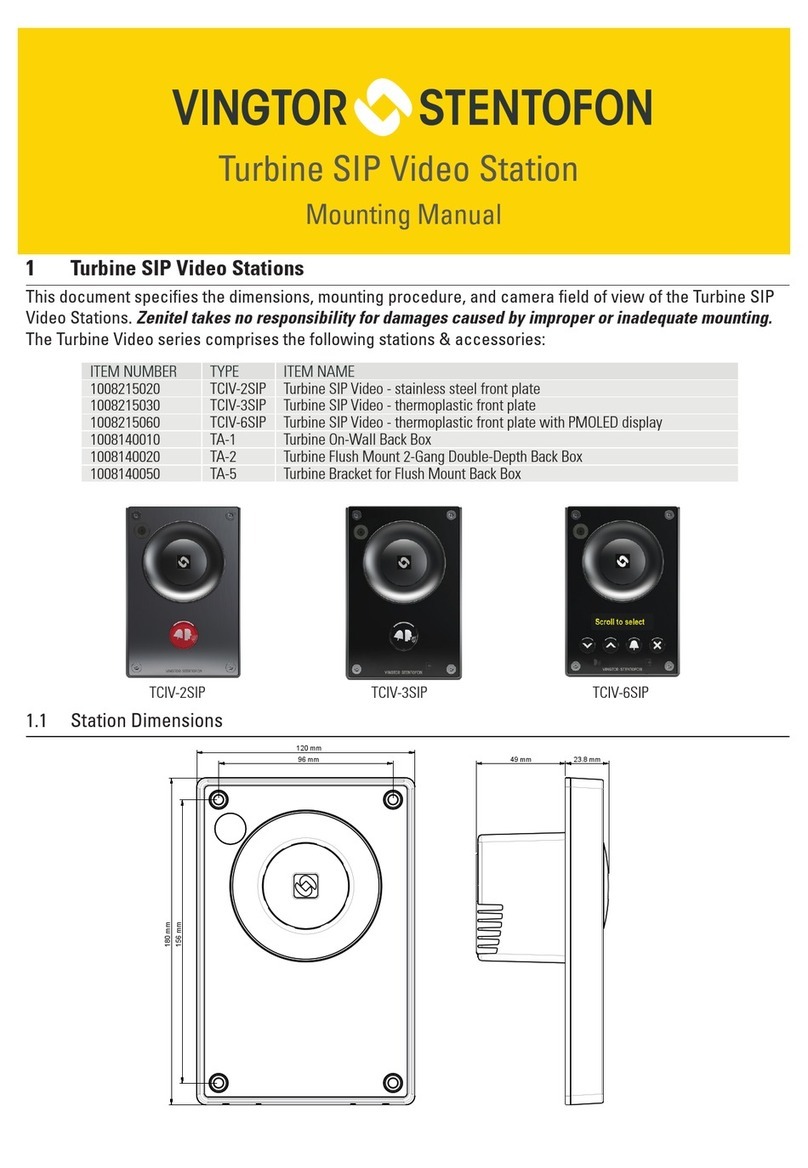

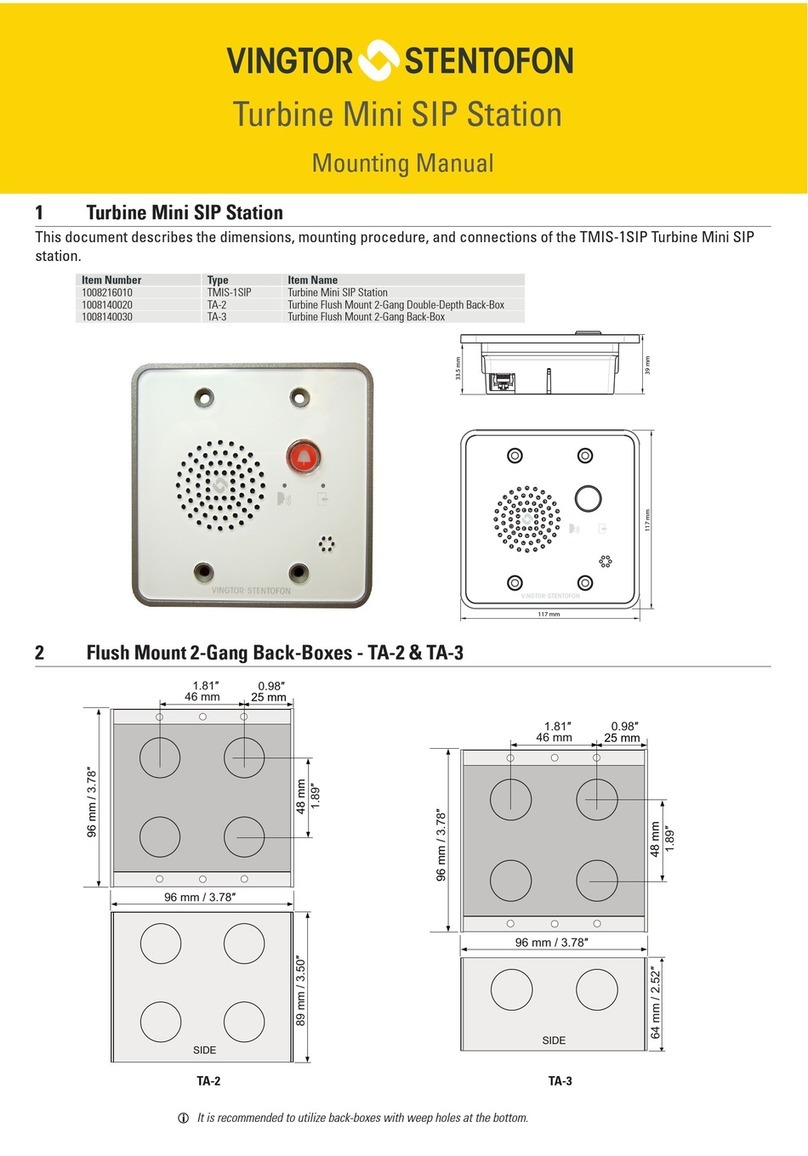

Vingtor Stentofon Turbine Mini SIP Station Guide

Vingtor Stentofon

Vingtor Stentofon TFIE-1 Guide

Vingtor Stentofon

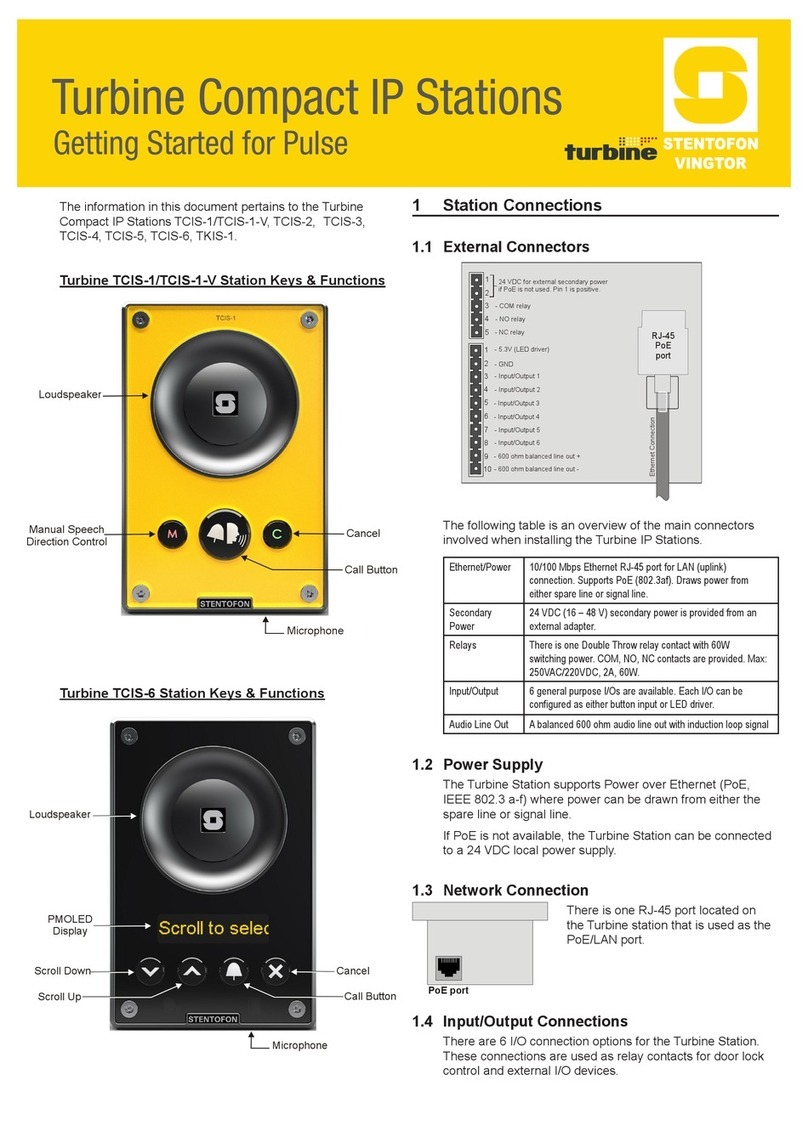

Vingtor Stentofon TCIS-1 User manual

Vingtor Stentofon

Vingtor Stentofon TCIS Series User manual

Vingtor Stentofon

Vingtor Stentofon ITSV-1 User manual

Vingtor Stentofon

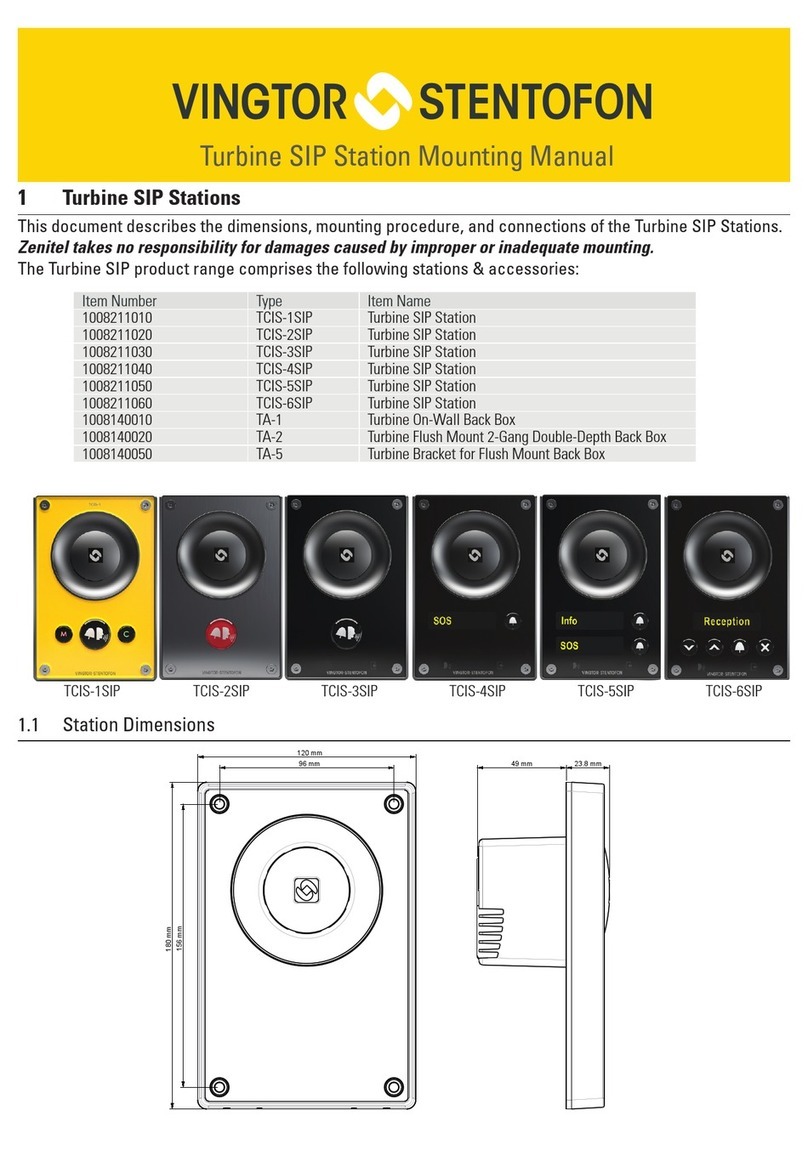

Vingtor Stentofon TCIS-1SIP Guide

Vingtor Stentofon

Vingtor Stentofon Turbine Compact Analog TCAS Series Guide

Vingtor Stentofon

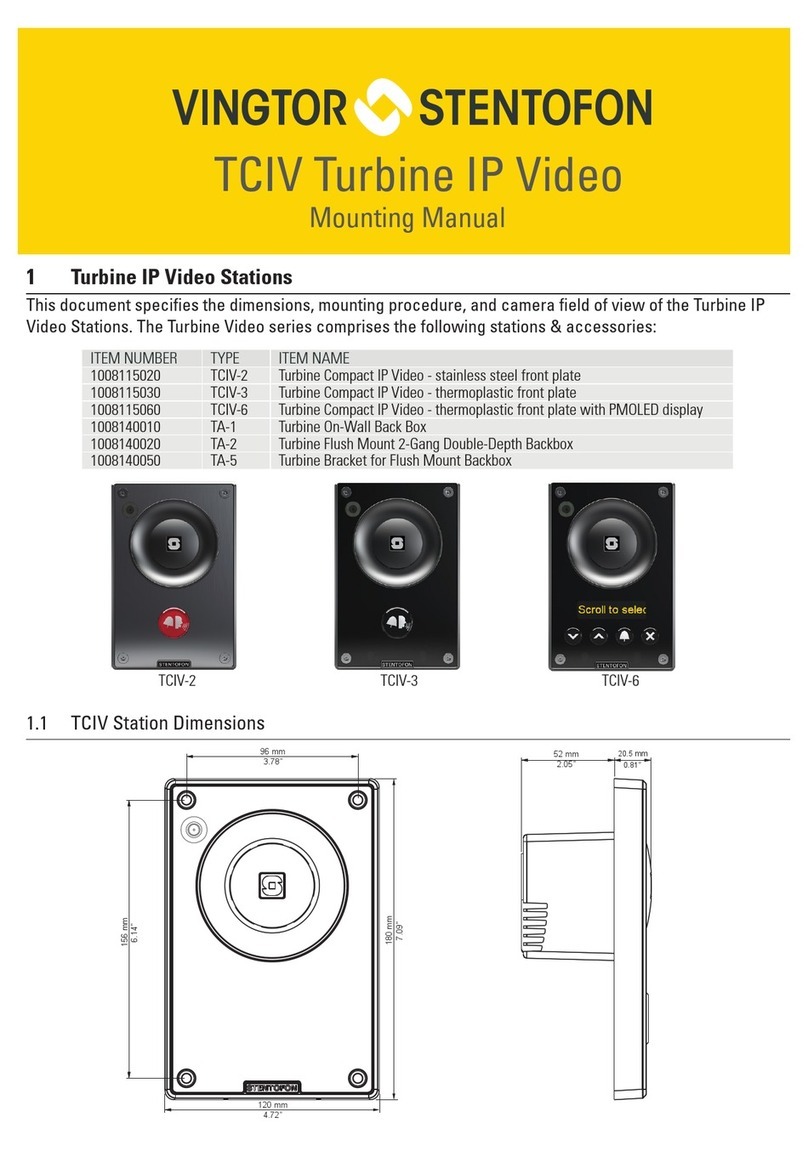

Vingtor Stentofon TCIV-2 Guide

Vingtor Stentofon

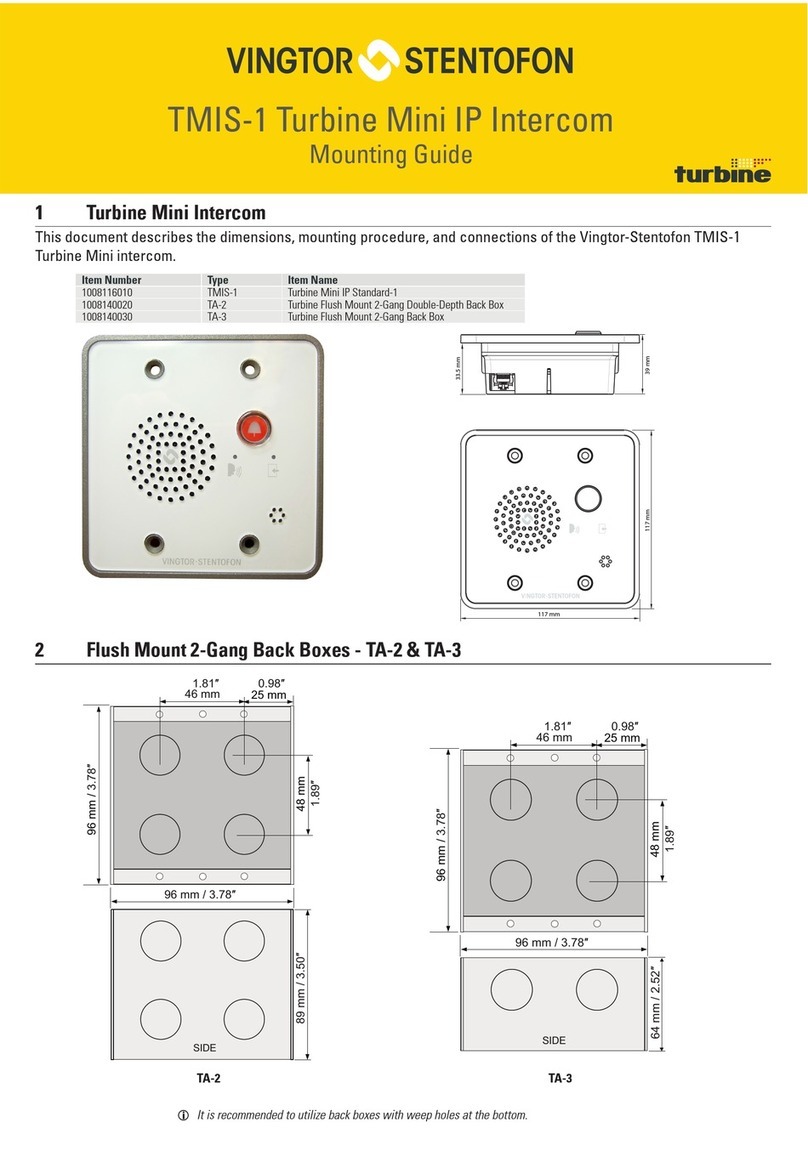

Vingtor Stentofon Turbine TMIS-1 Installation instructions manual

Popular Intercom System manuals by other brands

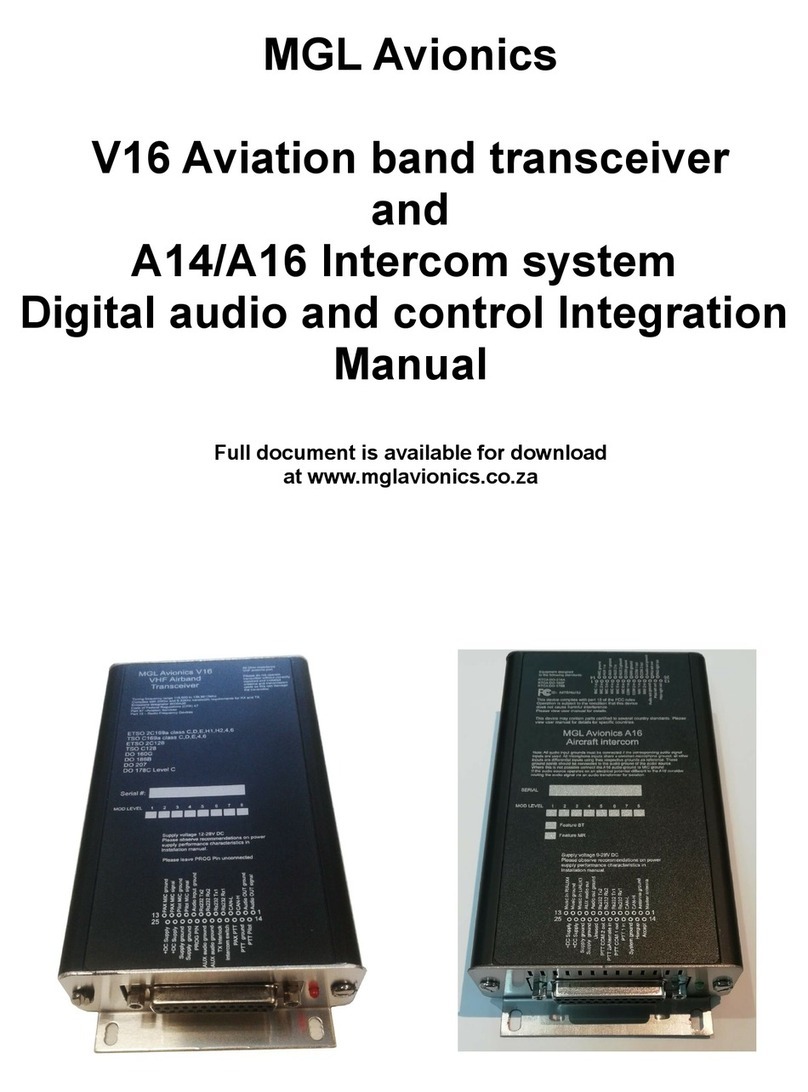

MGL Avionics

MGL Avionics V16 manual

SSS Siedle

SSS Siedle BVI 750-0 Installation & programming

urmet domus

urmet domus AIKO 1716/1 quick start guide

urmet domus

urmet domus IPerVoice 1039 Installation

Alpha Communications

Alpha Communications STR QwikBus TT33-2 Installation, programming, and user's manual

Monacor

Monacor ICM-20H instruction manual