http://www.woosim.com 2

TableofContents

I

IN

NT

TR

RO

OD

DU

UC

CT

TI

IO

ON

N

GENERALSPECIFICATION ........................................................................................................................................4G

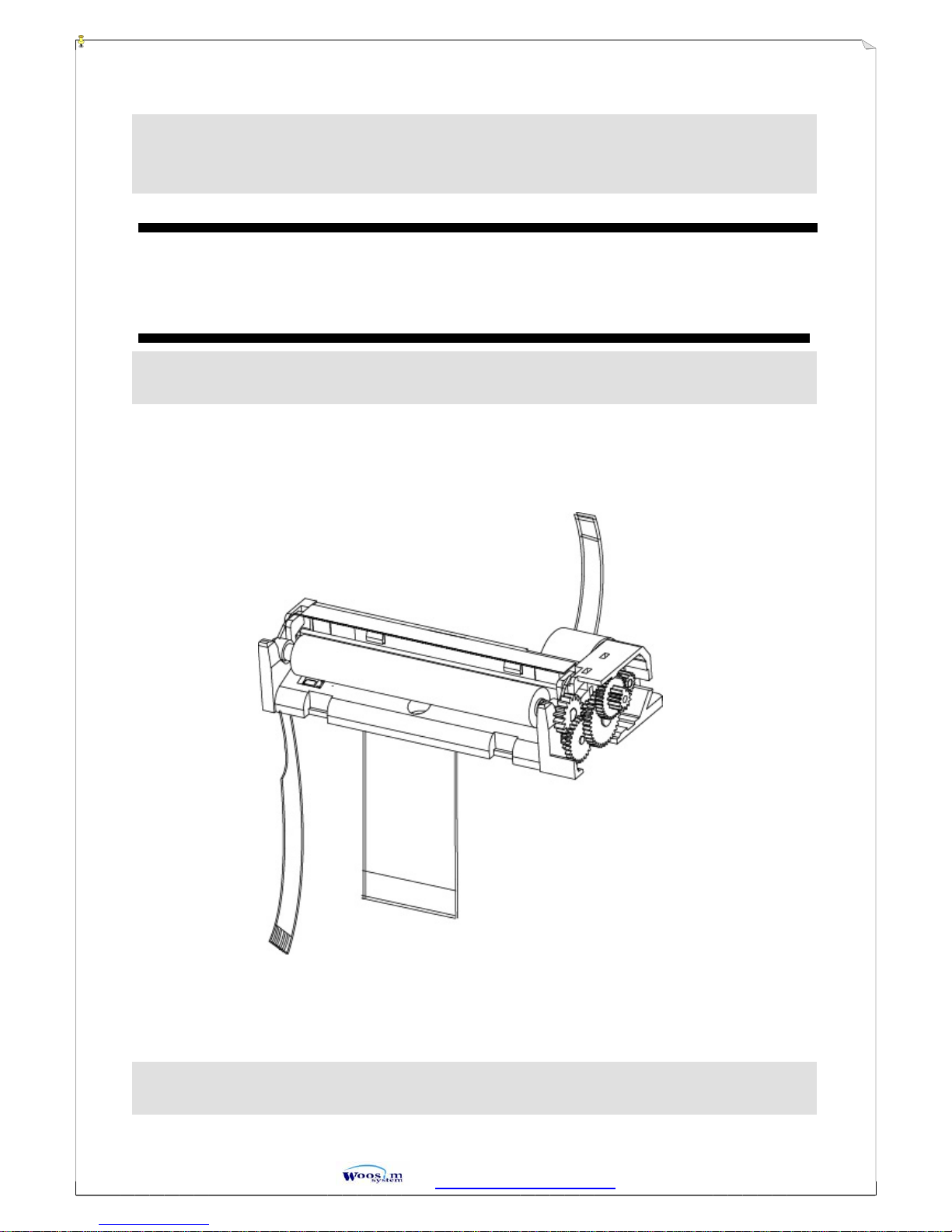

DESCRIPTION OFTHE MECHANISM......................................................................................................................5G

MAIN FEATURES...........................................................................................................................................................5G

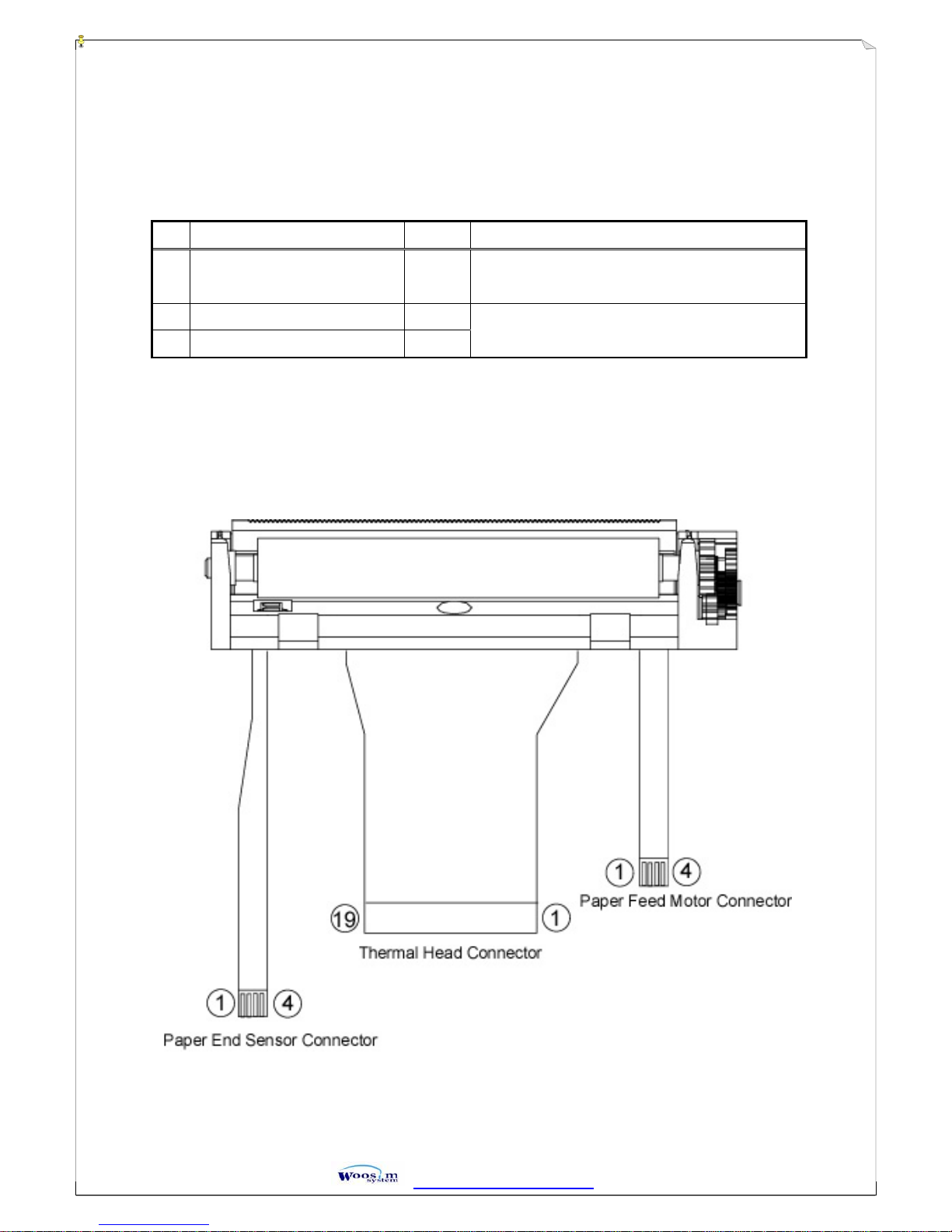

1. CONNECTIONS ..........................................................................................................................................................6G

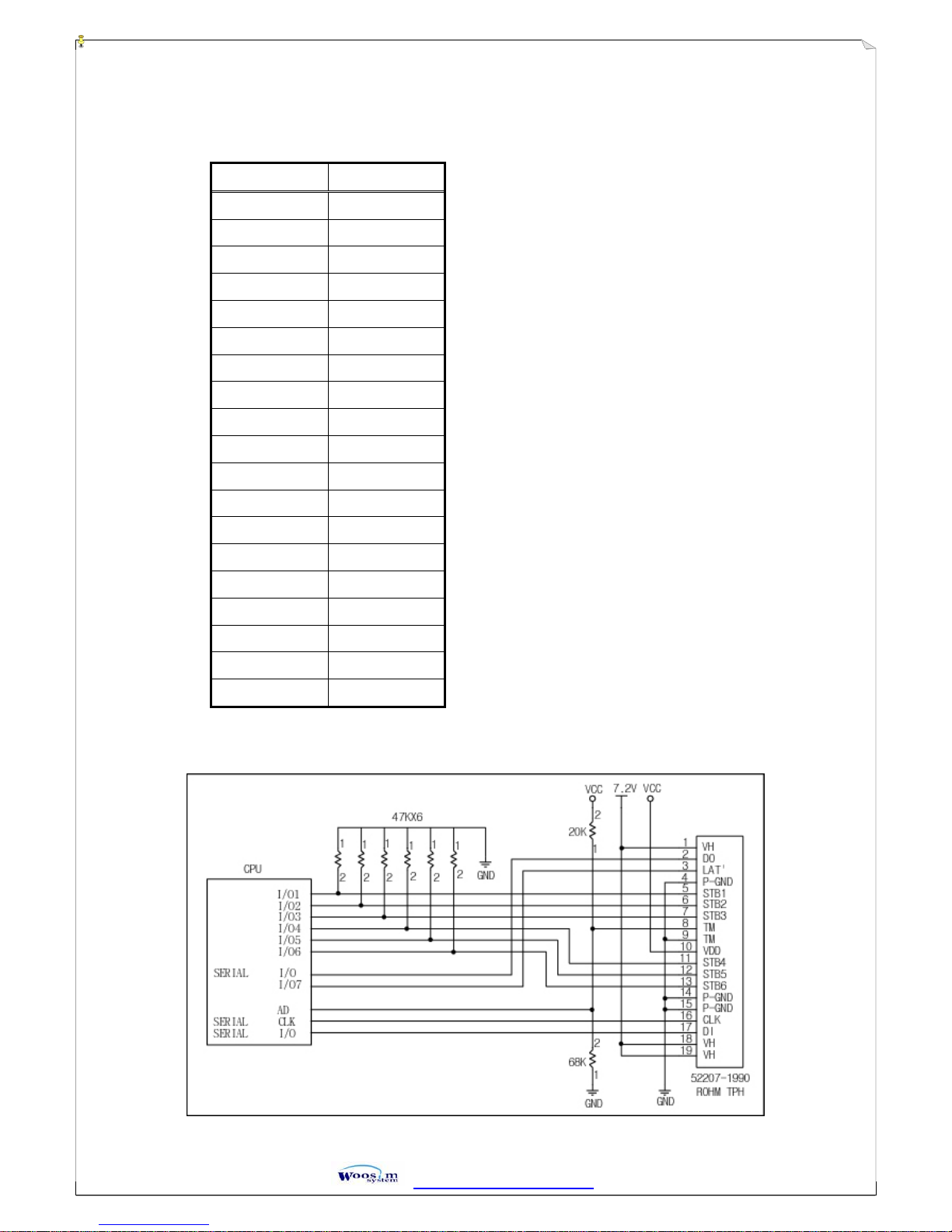

1.1 Thermal print head....................................................................................................................................................7G

1.1.1 Thermal head connectors pin assignments.........................................................................................................7G

1.1.2 Thermal head block diagram..............................................................................................................................7G

1.2 Paper Feed Motor Connector....................................................................................................................................8G

1.2.1 Paper feed motor connector’s pin assignments..................................................................................................8G

1.2.2 Paper feed motor block diagram........................................................................................................................8G

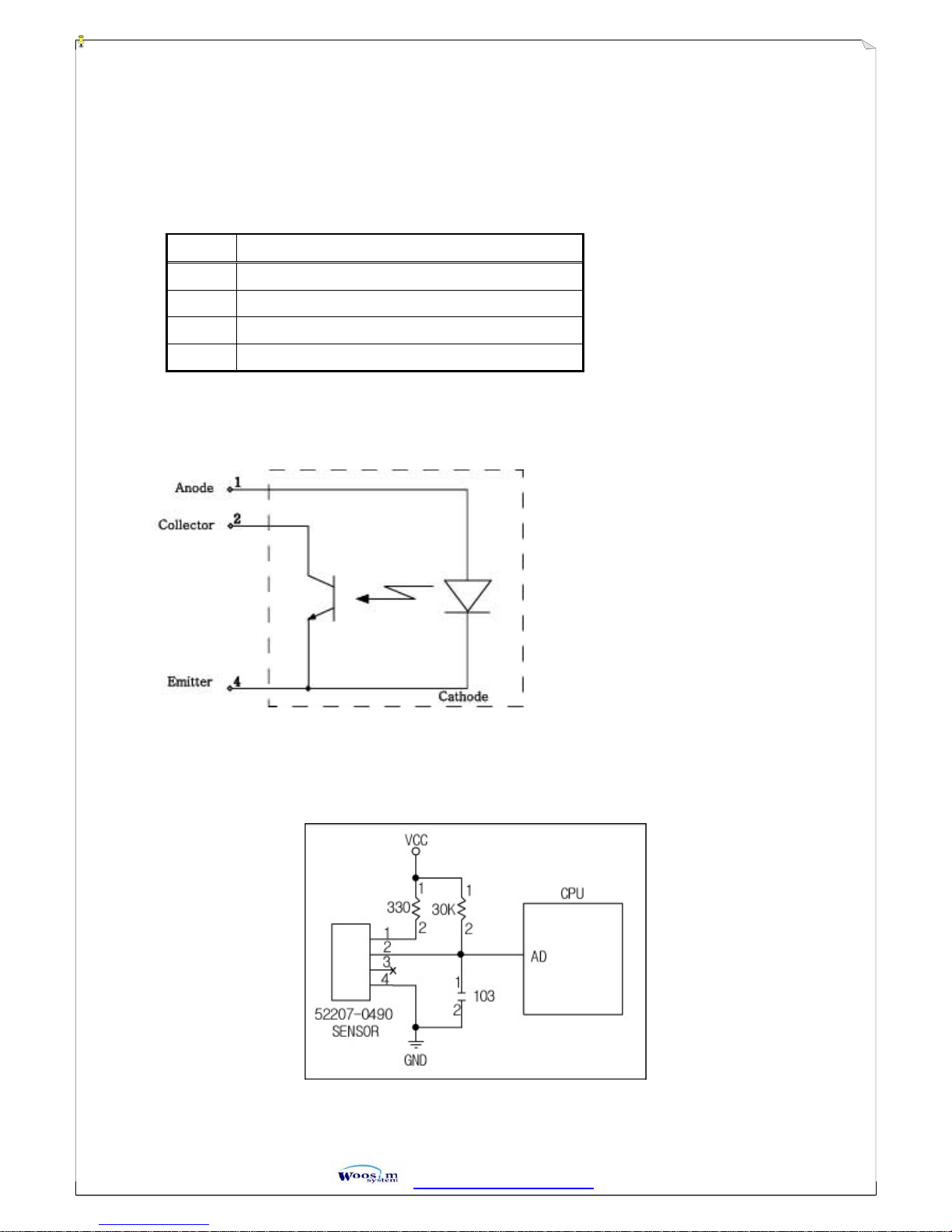

1.3 Paper end Sensor Connector.....................................................................................................................................9G

1.3.1 Paper end sensor connector’s pin assignments ..................................................................................................9G

1.3.2 Paper end sensor block diagram ........................................................................................................................9G

2. PRINT HEAD .............................................................................................................................................................10G

2.1 Outlines...................................................................................................................................................................10G

2.2 Maximum Conditions at 25................................................................................................................................10G

2.3 Typical Printing Conditions at 25.......................................................................................................................10G

2.4 Ambient Conditions................................................................................................................................................11G

2.5 Print Quality (at standard Conditions and operation temperature is higher or equal 5)...................................... 11G

2.6 Printhead Life on Standard Printing Conditions..................................................................................................... 11G

2.7 Operation Precautions.............................................................................................................................................12G

2.8.................................................................................................................................................................................14G

2.8.1 Circuit Diagram...............................................................................................................................................14G

2.8.2 Electrical characteristics of Circuit..................................................................................................................15G

2.8.3 Timing chart.....................................................................................................................................................16G

2.8.4 THERMISTOR SPECIFICATION..................................................................................................................17G

3. PAPER FEED MOTOR.............................................................................................................................................18G

3.1 Ratings....................................................................................................................................................................18G

3.2 Electrical characteristics.........................................................................................................................................18G

3.3 Mechanical properties.............................................................................................................................................19G

3.4 Excitation ( 2 phase, Full step ) ..............................................................................................................................19G

3.5 Environmental properties........................................................................................................................................19G

4. PAPER END SENSOR...............................................................................................................................................20G