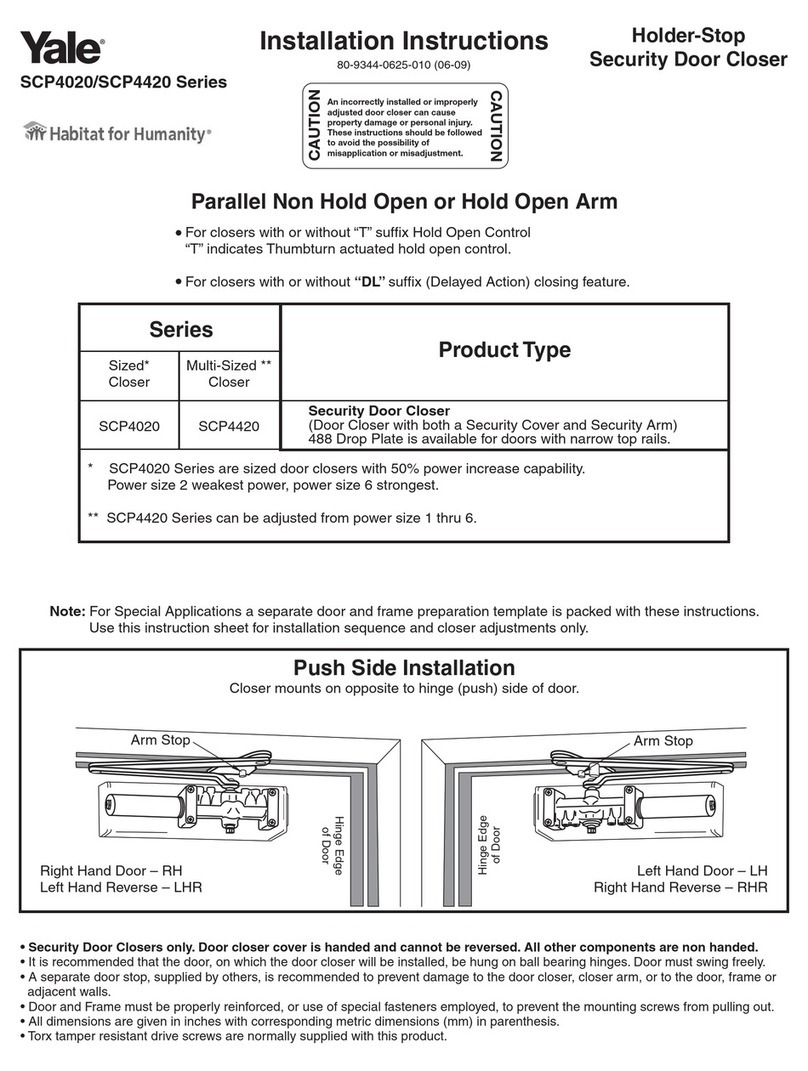

Yale SCP400 Series User manual

Other Yale Door Lock manuals

Yale

Yale Code Handle Manual

Yale

Yale SCP4020 Series User manual

Yale

Yale Doorman User manual

Yale

Yale YDM4109 User manual

Yale

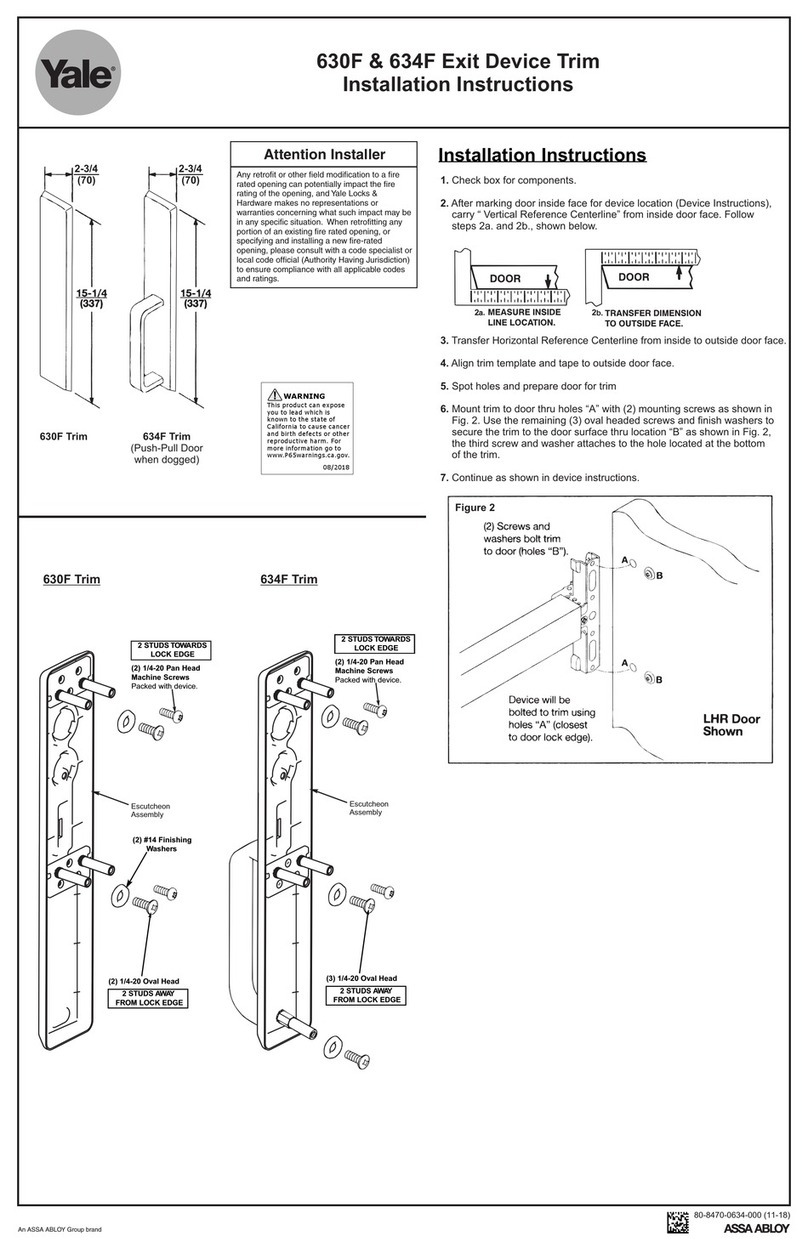

Yale 630F User manual

Yale

Yale Essential YDME-50 User manual

Yale

Yale P-DL01 User manual

Yale

Yale Doorman User manual

Yale

Yale T1L Technical specifications

Yale

Yale YRD210 Technical specifications

Yale

Yale Helios S User manual

Yale

Yale YDG313 User manual

Yale

Yale Conexis L1 User manual

Yale

Yale YDM4109 User manual

Yale

Yale eBOSS E5400LN Series User manual

Yale

Yale YDM2107 User manual

Yale

Yale Doorman User manual

Yale

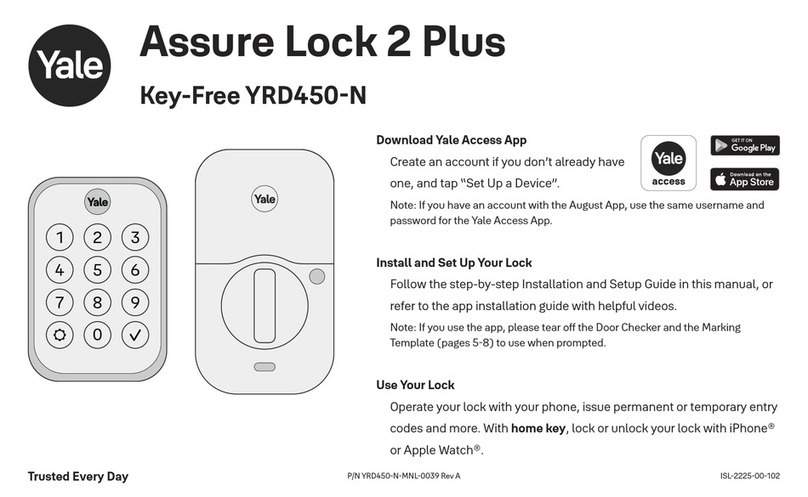

Yale Assure Lock 2 Plus User manual

Yale

Yale Assure Lock YRC256 Technical specifications

Yale

Yale Conexis L1 User manual

Popular Door Lock manuals by other brands

Dorma

Dorma MUNDUS PREMIUM GK 50 Mounting instruction

SCOOP

SCOOP Pullbloc 4.1 FS Panik Assembly instruction

Siegenia

Siegenia KFV AS3500 Assembly instructions

Saflok

Saflok Quantum ädesē RFID installation instructions

ArrowVision

ArrowVision Shepherd 210 installation manual

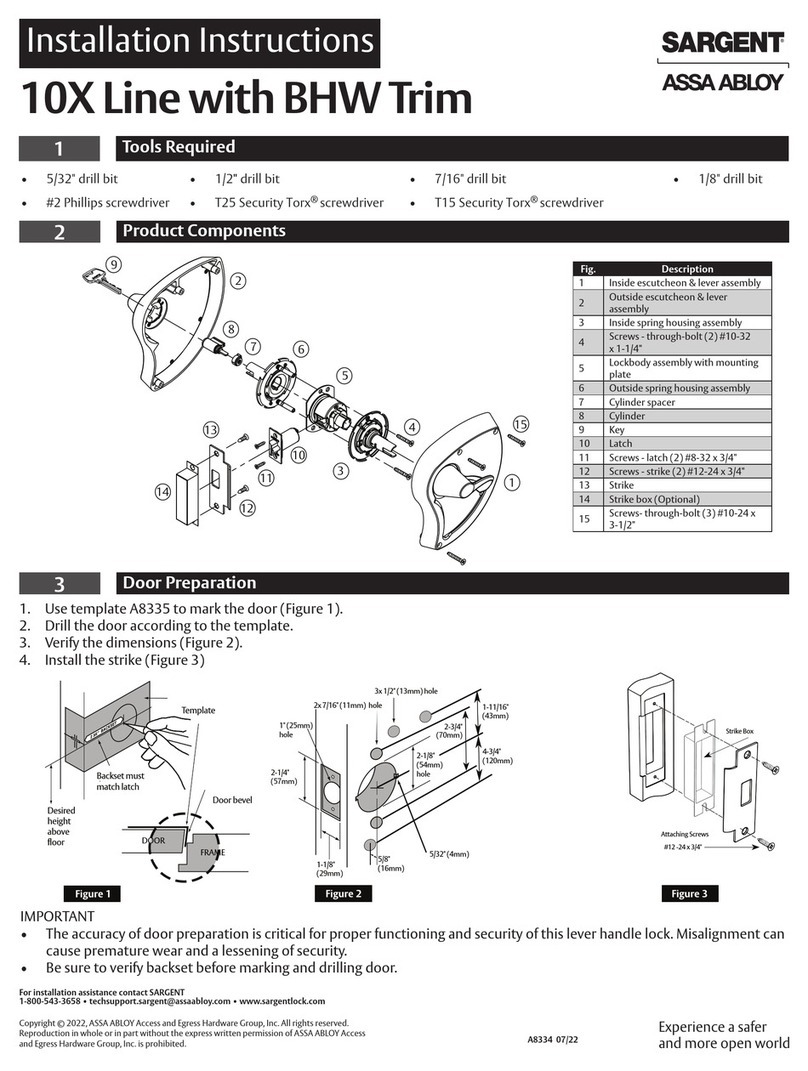

Assa Abloy

Assa Abloy Sargent 10X Line installation instructions