011307-05 4

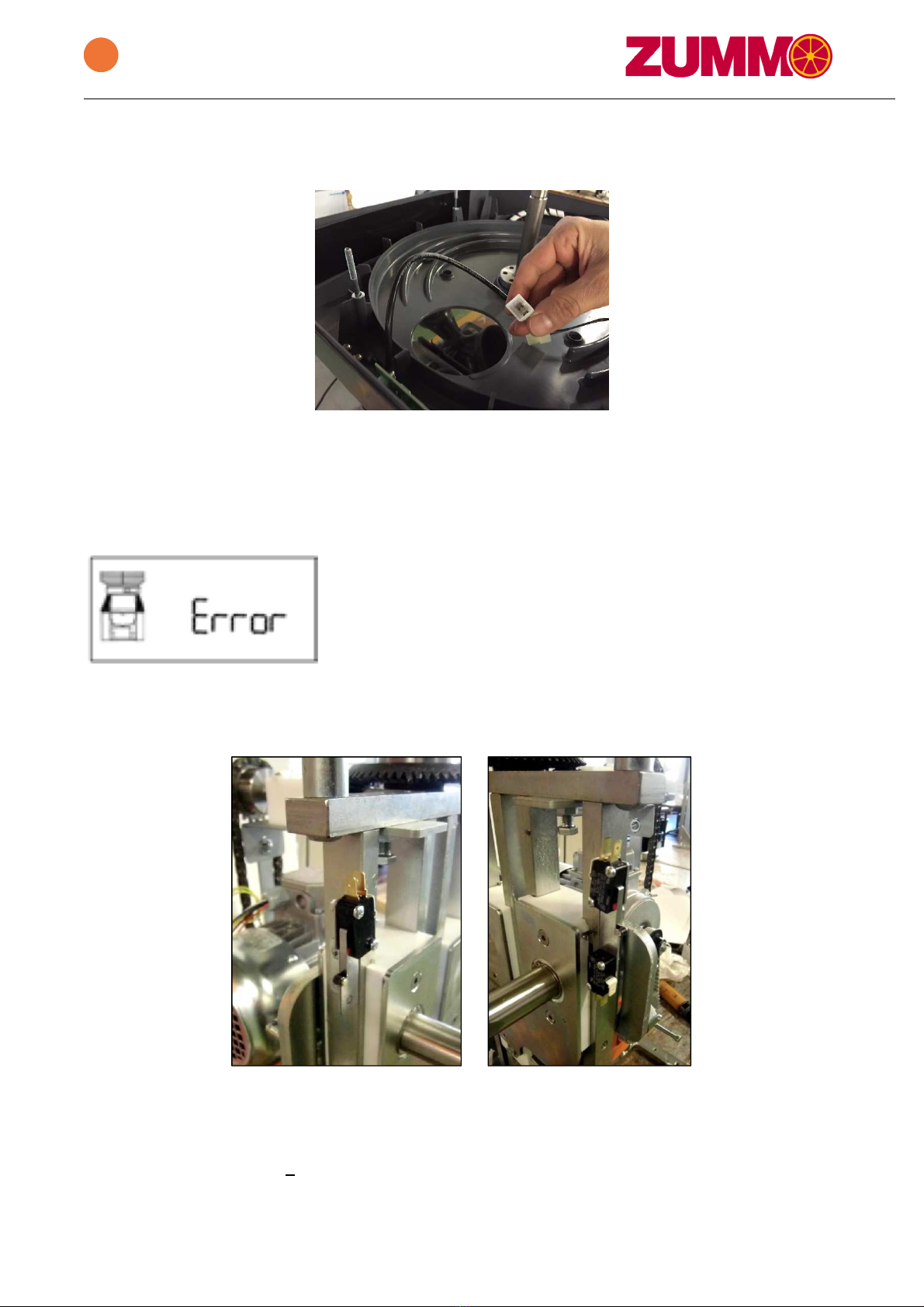

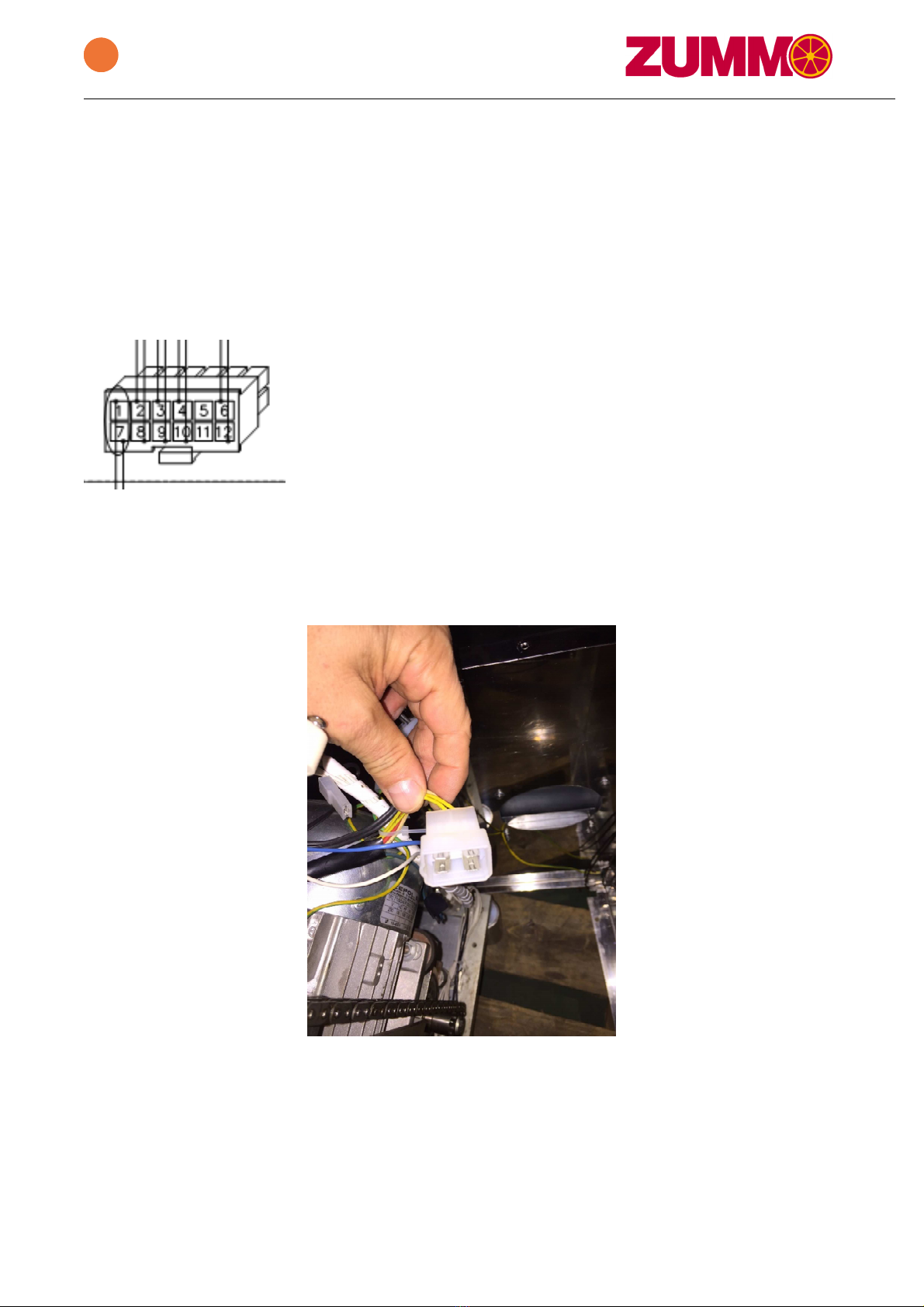

In the same way as before, pushing the switch with your fingers, you should be able to hear the

opening and closing “click”.

If this error is shown while working, check that filter tray, self-service tray and tank are all correctly

placed as they could have moved from its original position. In this case, check the condition of the

pieces. They must not be deformed.

If this error is shown when the machine is stopped, check the following:

1.3.1 Check you can hear the opening and closing “click” of the micro-switch when pushed using

your fingers. If not the case, disassemble the front, following the instructions from step #2 and check

they are not broken. If any is broken, replace it. Check connections.

1.3.2 If you can hear the “click” but they do not close the safety circuit, disassemble the hopper

track lid (follow instructions in step #2 to open the machine) and check if there is conductivity

between pins 2 and 8 with the filter tray properly fitted.

If there is no conductivity, change the micro-switches.

If there is conductivity, the failure is being caused by the circuit board and you must replace it.

1.4 Motor thermal sensor.

The display will show the following image:

The motor contains, in the stator coil winding, a thermal sensor that opens at 105ºC (221º F). When

the motor temperature reaches that value, the sensor opens the safety circuit; the display will then

show an error and leaves the machine temporarily out of order. After a few minutes, once the motor

temperature has dropped down to an acceptable value, the error message will disappear and the

machine will become operative again, without having to unplug it from the main power.

The reason can be:

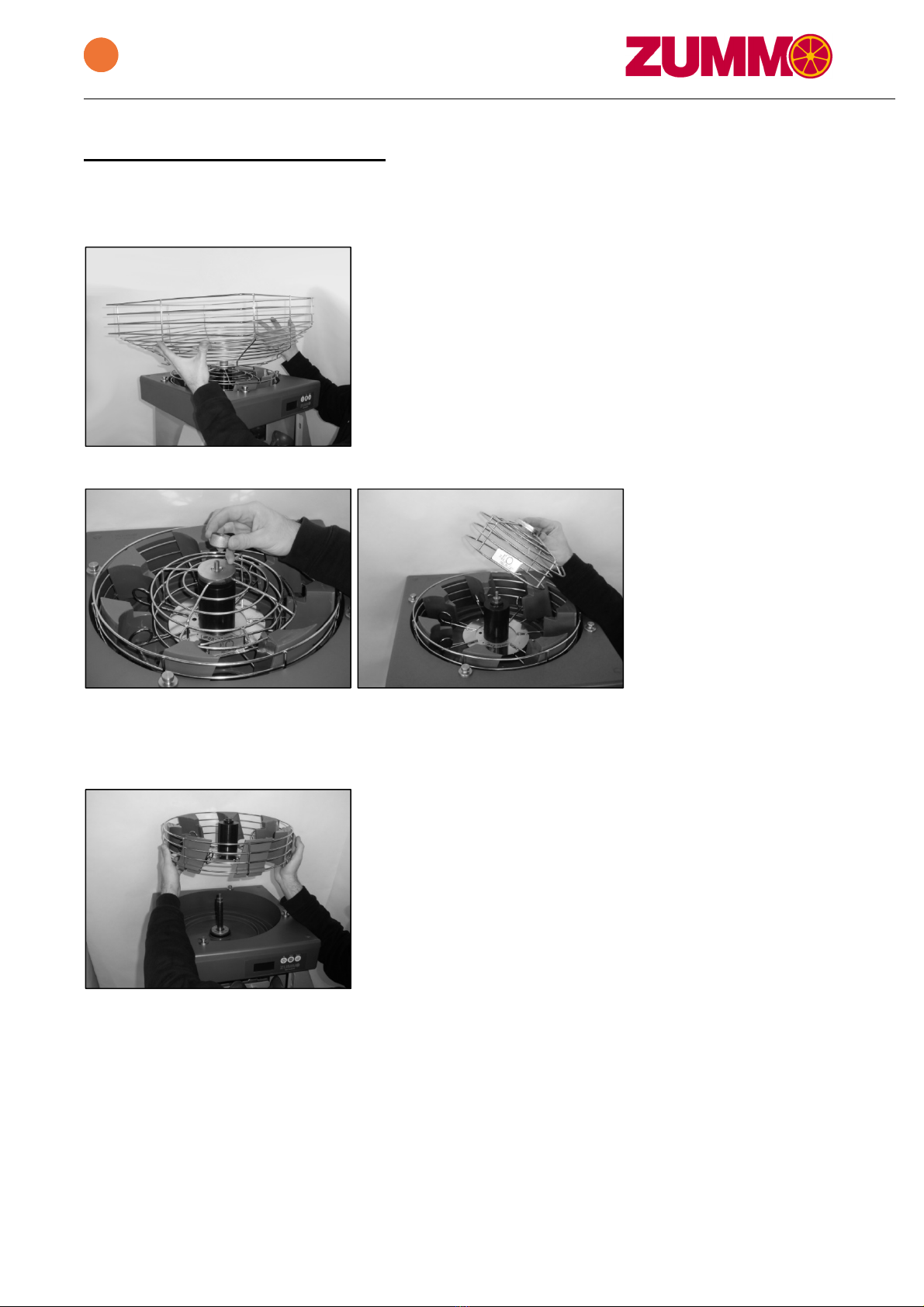

- The fan placed in the main body does not work; hence it does not cool down the motor.

Check fan connections. If properly plugged in, check the tension arriving to connectors

(between 110-240 volts AC depending on versions). If tension arriving and fan still not

working, change the fan.