The machines must be cleaned and disinfected as frequently as indicated above. In

this process, first remove all the solid waste, and then clean and disinfect. The

following types of products can be used to disinfect the machines:

Descaling detergents/disinfectants for food use: Used either by immersion (small parts) or

sprayed (large parts and stainless-steel front of machine) in the concentration

recommended by the manufacturer. Each product must be left to act for the time indicated,

and then rinsed well to avoid contact of the juice with the product. These products usually

have a very high pH, which, with time, may degrade the polycarbonate, so it is advisable not

to exceed the product action times on transparent plastic parts.

Chlorinated disinfectant detergents for food use: Same use as the previous products. They

can be used by immersion or sprayed, bearing in mind the time recommendations given by

the manufacturer. Thoroughly rinse the parts treated before they come in contact with the

juice again.

Another option can be solutions with domestic use (4% chlorine) or industrial use (10%

chlorine) bleach. The necessary concentration for it to be effective at room temperature is

100 ppm, which means 2.5 ml of domestic bleach for every litre of water, or 1 ml of industrial

bleach per litre of water.

This part is handled by customers, so special attention is recommended. Keeping a

spare part is advisable, so that it can be changed half-way through the day.

This part is in contact with the fruit, so it is advisable to increase washing frequency in

spring and summer.

MAINTENANCE INSTRUCTIONS

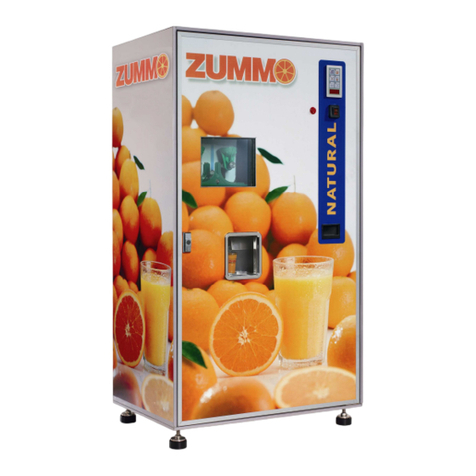

Z40 NATURE Adapt Cabinet

The Bottle Holder is recommended to be cleaned daily. This can

be completed whilst the bottle holder is fully assembled.

Once a month it is recommended the bottle holder to be cleaned

thoroughly with parts disassembled. See below disassemble

procedure.