High Efciency (HE) Particulate Filter, Pre-lter and Spark Arrestor

NOTE: The high efciency (HE) lter, pre-lter and spark arrestor must always be used. The pre-lter is designed

to extend the service life of the HE lter by capturing many of the larger particles. The spark arrestor is a metal screen.

Inspect the spark arrestor each time the lters are changed. If it is dirty, remove it and clean with a solution of clean

water and mild detergent. Dry the spark arrestor with a clean cloth and ensure the spark arrestor is completely dry before

reinstalling. If the spark arrestor is damaged, replace with a new spark arrestor. The HE lter and pre-lter CANNOT be

cleaned; do not attempt to remove contamination from the HE lter or pre-lter using compressed air or other means.

WARNING

Always correctly use and maintain the lter assembly. Failure to do so may reduce respirator performance, overexpose

you to contaminants, and may result in sickness or death.

a. Inspect lter and lter seal before each use and immediately replace if damaged.

b. Do not press on the lter grill when installing the lter into the lter cover. This may result in damage to the lter

membrane allowing hazardous particles to enter the breathing zone.

c. Keep lter seal clean.

d. Never attempt to clean lters by knocking or blowing out accumulated material. This may result in damage to the

lter membrane allowing hazardous particles to enter the breathing zone.

The lter-loading indicator reects particle clogging only. It does not provide any information about gas & vapor service

life. Attempting to use the lter loading indicator for gases and vapors may result in sickness, or death.

The nuisance odor pad should only be used for concentrations of organic vapors not exceeding the OSHA permissible

exposure limit (PEL) or applicable government occupational exposure limits, whichever is lower. Replace if smell or

taste is detected. Use of the nuisance pad for concentrations exceeding applicable exposure limits may result in

sickness or death.

The service life of the optional organic vapor/acid gas cartridge must be pre-determined before use. The organic

vapor/acid gas cartridge must be replaced according to an established change-out schedule, regulations, or sooner if

smell, taste, or irritation from contaminants is detected. Failure to do so may result in sickness or death.

Do not use the 3M™ Ado™ PAPR system with a heavily loaded spark arrestor or without the spark arrestor screen

properly installed. Exposing a heavily loaded spark arrestor, or lter assembly to direct contact with sparks or molten

metal spatter may damage the lter, allowing unltered air into the breathing zone, which may result in sickness or

death, and may cause the lter or blower housing to ignite, resulting in serious injury, sickness or death.

1. Inspect the HE lter to be installed. Make sure:

• Filter material is intact and dry with no tears or other damage.

• Filter gasket is present and intact with no particulates, cuts, distortions or indentations. Wipe gasket with clean,

dry cloth, if dirty. Dispose and replace lter if damage is noted.

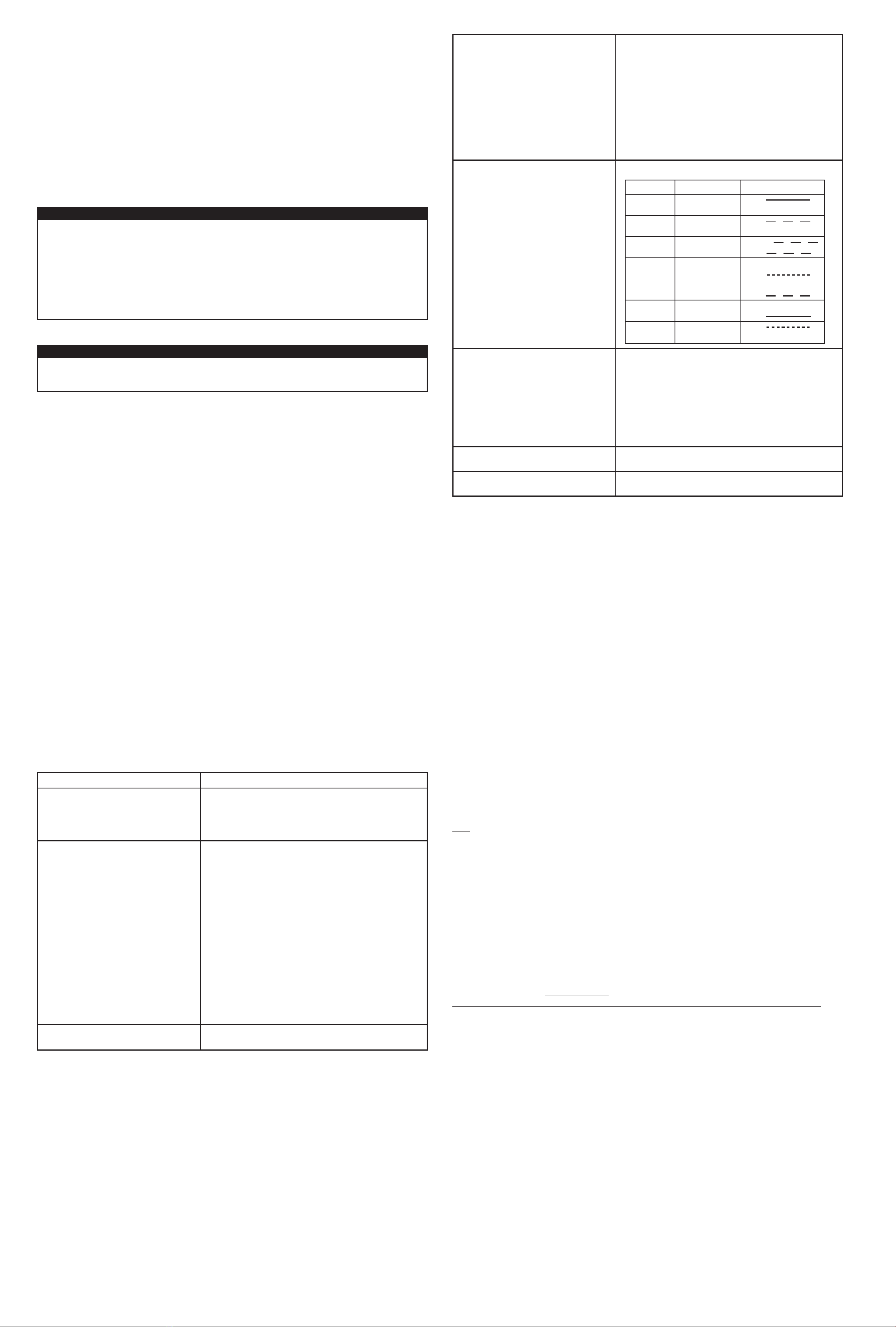

2. Remove the lter cover (Fig. 4).

3. Place the spark arrestor, pre-lter and HE lter into the lter cover, ensuring that the ribs on the HE lter are aligned

with the slots on the latch side of the lter cover (Fig. 5). Ensure all are squarely seated in the lter cover. Do not press

on the lter grill when installing the lter into the lter cover (Fig 6).

4. To reinstall the lter cover in the 3M™ Ado™ PAPR, hook the left side of the lter cover into the left side of the 3M™

Ado™ PAPR. Press down on the right side of the cover until the catch fully engages with an audible click.

Install the 3M™ Ado™ PAPR Organic Vapor/Acid Gas (OV/AG) Cartridge or Nuisance

Odor Pad Assembly

The 3M™ Ado™ PAPR has a “stackable” chemical cartridge capability that helps provide protection from certain organic

vapors and acid gases and a “stackable” nuisance odor pad assembly to help reduce nuisance odors and nuisance ozone.

NOTE: Nuisance odor refers to concentrations of organic vapors not exceeding the OSHA permissible exposure limit (PEL)

or applicable government occupational exposure limits, whichever is lower.

NOTE: The OV/AG cartridge and nuisance odor pad assembly must always be used with the HE lter, pre-lter and spark

arrestor. Do not use the OV/AG cartridge or nuisance odor pad assembly alone or in combination with one another.

1. Remove the lter cover as noted above (Fig. 4).

2. Inspect the HE lter to be installed. Make sure:

• Filter material is intact and dry with no tears or other damage.

• Filter gasket is present and intact with no particulates, cuts, distortions or indentations. Wipe gasket with a clean,

dry cloth, if dirty. Dispose and replace lter if damage is noted.

3. Inspect the lter cover, the pre-lter and the spark arrestor. Replace as needed (Fig. 5, 6).

4. Inspect the OV/AG cartridge or nuisance odor pad assembly to be installed. Make sure:

• Gasket is present and intact with no particulates, cuts, distortions or indentations. Wipe gasket with a clean, dry

cloth, if dirty. Dispose and replace if damage is noted

5. Place the spark arrestor, pre-lter and HE lter into the lter cover, ensuring that the ribs on the HE lter are aligned

with the slots on the latch side of the lter cover (Fig. 5). Ensure all are squarely seated in the lter cover. Do not press

on the lter grill when installing the lter into the lter cover (Fig 6).

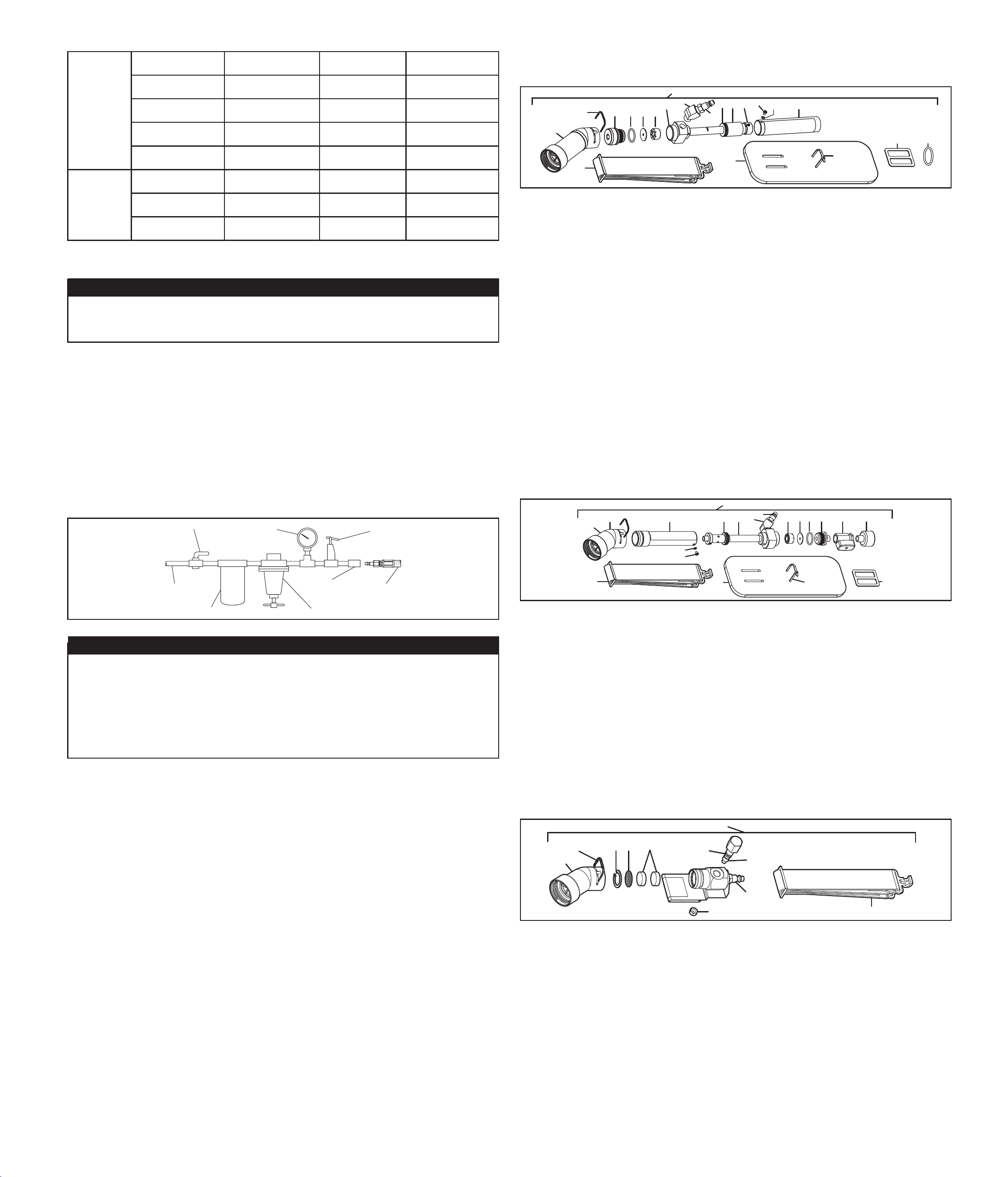

6. Hook the left side of the OV/AG cartridge or nuisance odor pad assembly into the left side of the PAPR and press the

cartridge down until its catch engages with an audible click (Fig. 7).

7. Reinstall the lter cover assembly in the 3M™ Ado™ PAPR, hook the left side of the lter cover into the left side

of the OV/AG cartridge. Press down on the right side of the cover until the catch fully engages with an audible click

(Fig8).

Replacement of the Nuisance Odor Pad

The nuisance odor pad may be replaced by pressing the expired nuisance odor pad out of the nuisance odor pad assembly

from the backside, or side with the gasket or multiple square holes. It is easiest to press the nuisance odor pad out on

the vertical edges, nearest to the frame edge, and then work the entire nuisance odor pad free from the assembly. Install

a new nuisance odor pad by pressing it into the nuisance odor pad assembly. The nuisance odor pad may only be used

to help provide relief from concentrations of organic vapors not exceeding the OSHA permissible exposure limit (PEL) or

applicable government occupational exposure limits, whichever is lower. Replace when smell or taste occurs.

Install the Breathing Tube

Select an approved breathing tube for the headgear to be used. Refer to the 3M™ Ado™ PAPR NIOSH Approval Label for

approved headgear-breathing tube combinations.

NOTE: The SG-50W breathing tube can only be used with 9100 Air, 9100 FX Air, 9100 MP and M-series headgear. The

SG-50W breathing tube must be used when using the 9100 Air or 9100 MP welding helmets with HE lter-OV/AG cartridge

combination and must be used with M-400 headgear when used with any Ado PAPR conguration.

1. Inspect the PAPR end of the breathing tube (2 small prongs) to conrm the rubber “O” ring is in place. Replace if

missing or damaged.

2. Insert the 2 prongs on the PAPR end of the breathing tube into the parallel slots in the air outlet of the motor blower

and twist 1/4 turn to the right to lock into place.

Connect to 3M™ Headgear

Refer to the separate User Instructions provided with the approved headgear for procedures to connect the breathing tube.

Leather Belt Replacement

1. Remove the belt from the 3M™ Ado™ PAPR by unfastening the belt’s two hook and loop straps and pulling the

3M™ Ado™ PAPR away from the unfastened belt.

2. Replace the belt:

• Thread each hook and loop strip through the slot on the back of the unit, and then on through the slot on the

leather belt (Fig. 9). The “UP” arrow should be pointing towards the top of the PAPR.

• Tightly pull the two hook and loop strips prior to fastening them to one another. When attached properly, the 3M™

Ado™ PAPR will sit tight against the belt and will stay in place.

Backpack

The BPK-01 backpack may be used in place of the belt (Fig. 9A):

1. With either end of the motor/blower towards the top of the backpack (end with the drag handle), thread the backpack

strap through the top retaining slot on the motor/blower and the large retaining sleeve (Fig. 9A, #1) on the backpack.

2. Thread the strap through the lower retaining slot on the motor/blower and the small retaining sleeve (Fig. 9A, #2) on

the backpack.

3. Thread the strap through the buckle (Fig. 9A, #3) and tighten down.

4. Don the backpack and adjust the shoulder straps for a comfortable t.

On and Off

To turn the 3M™ Ado™ PAPR Motor/Blower on, press and hold the ON button on the top of the motor/blower for 2

seconds (Fig. 10). The unit will automatically perform a self diagnostic.

• All three LED (2 green, 1 red) on the power switch and the audible alarm will come on for 1 second. The 2 green LED

will remain on (Fig. 10).

• The 3M™ Ado™ PAPR Battery Pack and lter LEDs will light up sequentially and then light and remain on showing

the current status of each.

To turn off the motor/blower, press and hold the OFF button on the top of the motor/blower for 2 seconds. The red LED will

come on and the audible alarm will sound for 1 second as the motor/blower turns off.

INSPECTION

WARNING

Always correctly use and maintain the lter assembly. Failure to do so may reduce respirator performance, overexpose

you to contaminants, and may result in sickness or death.

a. Inspect lter and lter seal before each use and immediately replace if damaged.

b. Always properly install the lter into the blower unit.

c. Keep lter seal clean.

d. Never attempt to clean lters by knocking or blowing out accumulated material. This may result in damage to the

lter membrane allowing hazardous particles to enter the breathing zone.

Do not repair or modify any component of this system. Do not use with parts or accessories other than those

manufactured by 3M as described in these User Instructions or on the NIOSH approval label for this respirator. Failure to

do so may adversely affect respirator performance and result in sickness or death.

This 3M™ Ado™ PAPR Assembly is one component of an approved respiratory protection system. Always read and

follow all User Instructions supplied with your 3M™ headgear and other system components in order to ensure correct

system operation. Failure to do so may result in injury, sickness, or death.

Before each entry into a contaminated area, perform the following pre-use inspection to help ensure proper function of the

respirator system. Refer to the specic Assembly subsection of this User Instructions for proper assembly procedures.

NOTE: There are no serviceable parts inside the 3M™ Ado™ PAPR Assembly. The motor/blower unit must not be opened

to attempt repairs.

Visual Inspection

1. PAPR Assembly: Visually inspect the entire PAPR assembly including the motor/blower, cover, lter/cartridge, breathing

tube, battery pack, belt and headgear. Replace any missing or damaged parts only with 3M™ Ado™ PAPR

Replacement Parts before proceeding.

2. Battery Pack: Conrm that the battery pack is fully charged and charge is sufcient for duration of the work period.

The battery pack must be securely latched to the motor/blower.

3. Breathing Tube: Examine the entire breathing tube for tears, holes or cracks. Bend the tube to verify that it is exible.

Ensure the o-ring located on the PAPR end of the breathing tube is present with no gaps or cracks in the ring. Replace

breathing tube if any damage is noted or suspected.

4. Filter/Cartridge:

• Inspect the pre-lter and spark arrestor. Ensure they are intact, clean and squarely tted into the lter cover.

• Inspect the HE lter and gasket for particles, tears, cuts, distortion or indentations. Do not attempt to clean the HE

lter. Replace the HE lter if any damage is noted or suspected. Ensure it is in place in the lter cover.

• Ensure the lter cover is securely latched to the PAPR motor/blower.

•

If used, ensure the nuisance odor pad assembly or chemical cartridge is securely attached to the PAPR and lter cover.

Air ow check

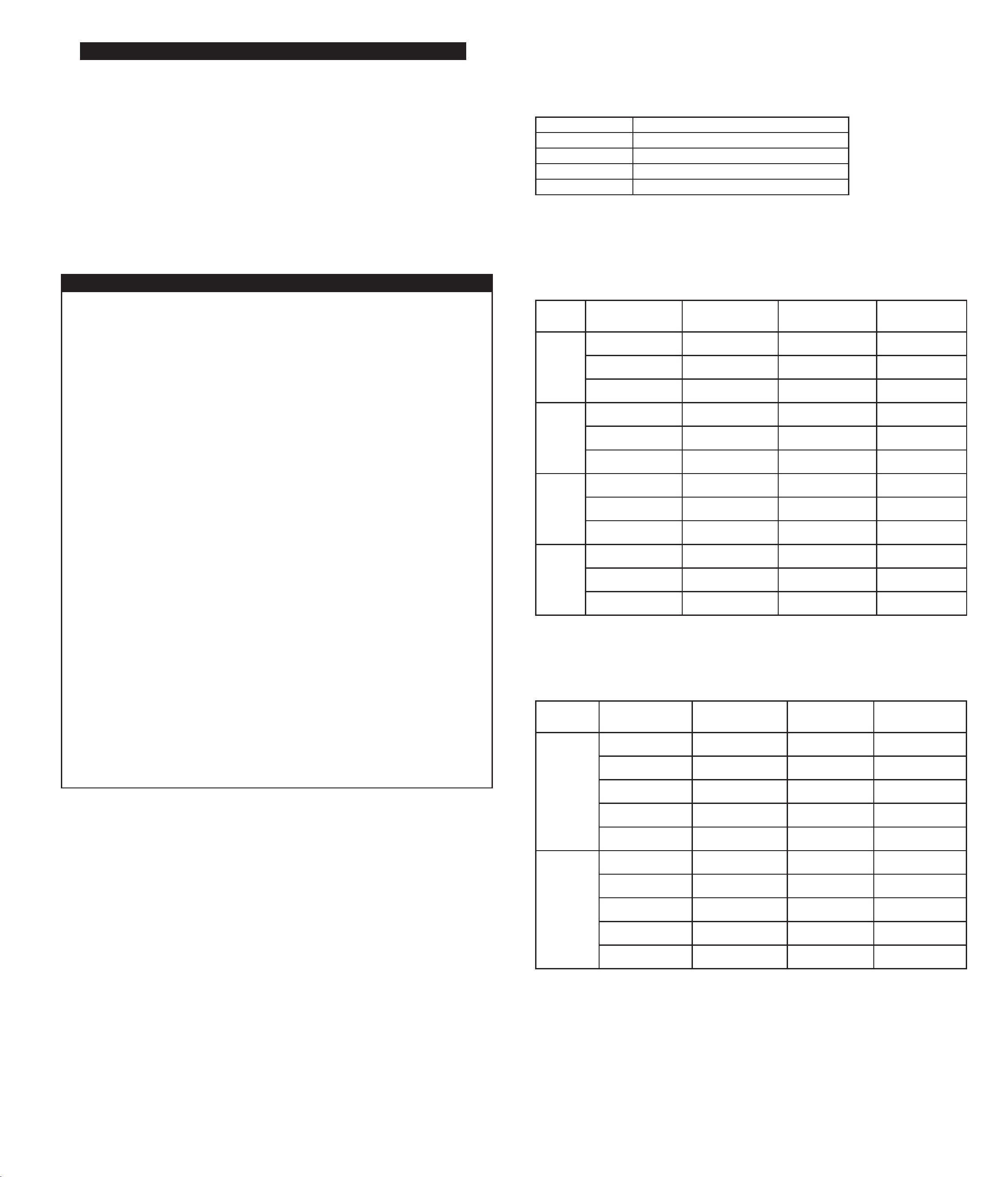

1. Ensure the ball in the 15-0099-05 or 15-0099-21 ow indicator moves freely in its tube. Rinsing with clean water

may help free a stuck ball. Allow the tube and ball to dry completely prior to using.

• For all 3M™ Ado™ Breathing Tubes (except L-122SG) follow Steps 2 – 7 with the 15-0099-05 ow

indicator.

• For L-122SG approved breathing tube, follow Steps 8 – 13 with the 15-0099-21 ow indicator adapter.

All 3M™ Ado™ PAPR Approved Breathing Tubes, Except L-122SG (15-0099-05 Indicator)

2. Insert the breathing tube into the air outlet as noted above.

3. Turn the 3M™ Ado™ PAPR on.

4. Insert the airow indicator (15-0099-05) onto the end of the breathing tube (Fig. 11).

5. Allow the 3M™ Ado™ PAPR to run for 2 minutes to stabilize air ow prior to reading air ow indicator.

6. With the airow indicator in a vertical position, ensure that the bottom of the ball rests at or above, the minimum ow

mark (Fig. 11). If the airow indicator ball fails to rest at or above the minimum ow level, refer to the trouble-shooting

guide at the end of these User Instructions.

7. Check the low airow alarm:

• With 3M™ Ado™ PAPR turned on, remove the air ow indicator and tightly cover the end of the breathing tube

with the palm of your hand.

• The motor will automatically speed up to compensate for the low air ow condition.

• Continue to press your palm tightly against the end of the breathing tube, making a tight seal. After approximately

15-30 seconds, the unit will sound an audible alarm and the center, red LED on the ON/OFF switch will come on

(Fig. 10). Proceed to Step 14.

NOTE: If the oating ball of the air ow indicator fails to rest at or above the minimum ow level, refer to the

trouble-shooting guide at the end of these User Instructions.

L-122SG breathing tube (use ow indicator rubber adapter 15-0099-20 with ow

indicator 15-0099-05 or 15-0099-21 assembly)

8. Insert the air ow indicator adapter onto the end of the 3M™ Ado™ PAPR Air Flow Indicator (Fig. 12).

9. Insert air ow indicator adapter unit into the outow port on the 3M™ Ado™ PAPR (Fig. 13).

10. Turn the 3M™ Ado™ PAPR on.

11. Allow the 3M™ Ado PAPR to run for 2 minutes to stabilize air ow prior to reading air ow indicator.

12. Hold the air ow indicator vertically at eye level, ensure that the bottom of the oating ball rests at or above, the

minimum ow mark (Fig. 14).

13. Check the low air ow alarm:

• With 3M™ Ado™ PAPR on, remove the air ow indicator and tightly cover the end of the 3M™ Ado™ PAPR

outow port with the palm of your hand.

•The motor will automatically speed up to compensate for the low air ow condition.

• Continue to press your palm tightly against the end of the breathing tube, making a tight seal. After approximately

15-30 seconds, the unit will sound an audible alarm and the center, red LED on the ON/OFF switch will come on

(Fig. 10). Continue to Step 14.

NOTE: If the oating ball of the air ow indicator fails to rest at or above the minimum ow level, refer to the

trouble-shooting guide at the end of these User Instructions.

Continued from Step 7 and 13

14. Remove your hand from the end of the breathing tube or air outlet port. The audible alarm and red LED should both

stop, while the motor returns to a slower speed.

15. If the PAPR does not operate as described in all of the above procedures, refer to the trouble-shooting guide at the end

of these User Instructions.

16. Turn the unit off.

17. Attach breathing tube (if previously removed) and headgear to 3M™ Ado™ PAPR system.

ENTERING AND EXITING A CONTAMINATED AREA

Prior to entering the contaminated area, complete the inspection procedures listed in this User Instructions.

1. Turn the motor/blower on.

2. Check air ow and alarms. NOTE: High environmental noise levels or use of hearing protection may interfere with the

user hearing the audible alarms. User should check for the visual alarms more frequently in high noise environments.

3. Don the 3M™ Ado™ PAPR Assembly and headgear. Enter the work area.

4. Leave the contaminated area immediately if any of the following conditions occur:

a. Any part of the system becomes damaged.

b. Air ow into the respirator decreases or stops.