Allsteel MERGE Service manual

Other Allsteel Indoor Furnishing manuals

Allsteel

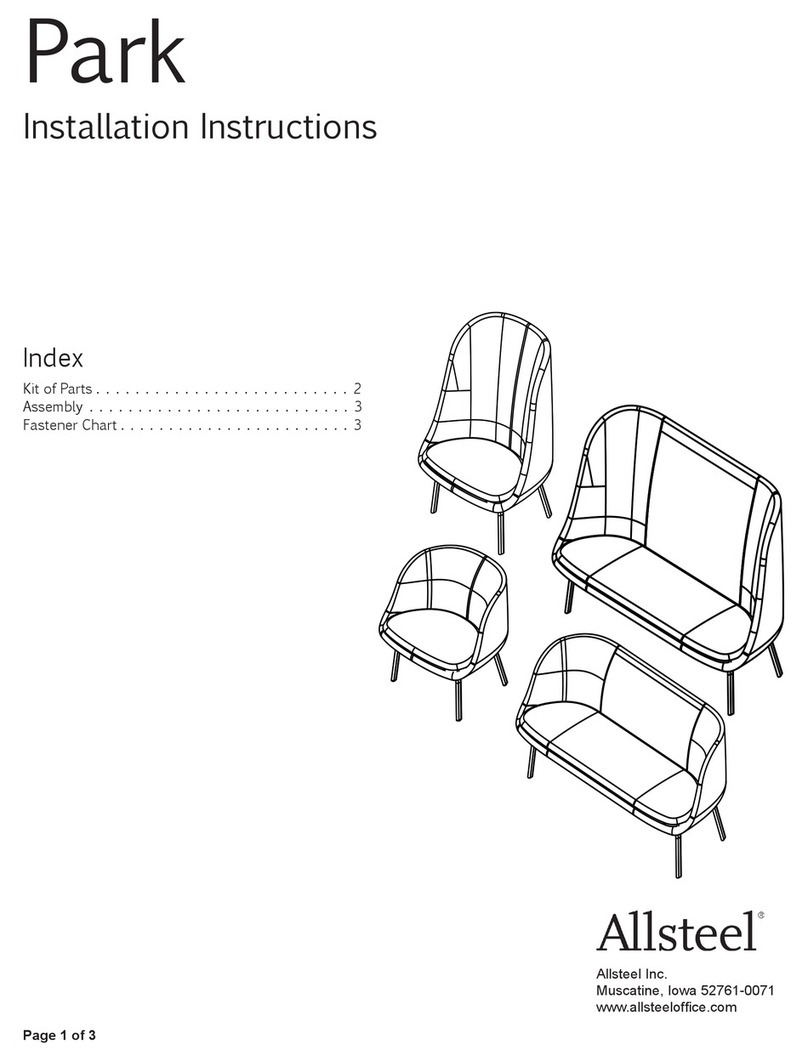

Allsteel Park Series User manual

Allsteel

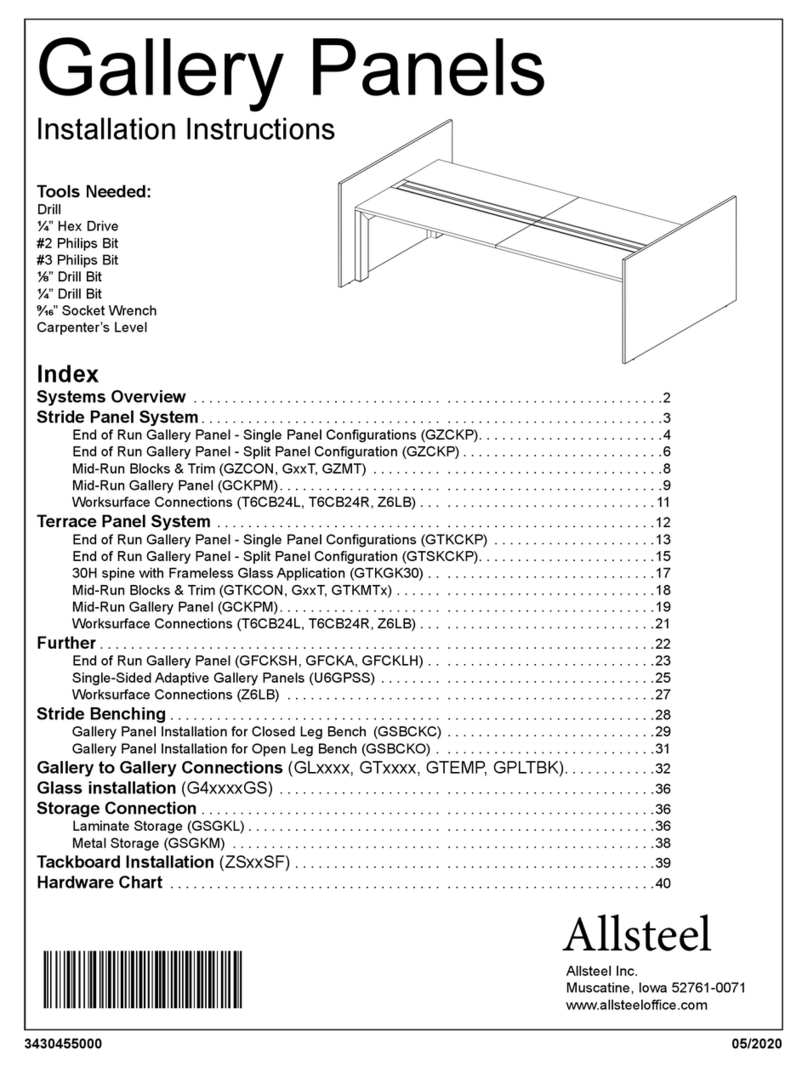

Allsteel GZCKP User manual

Allsteel

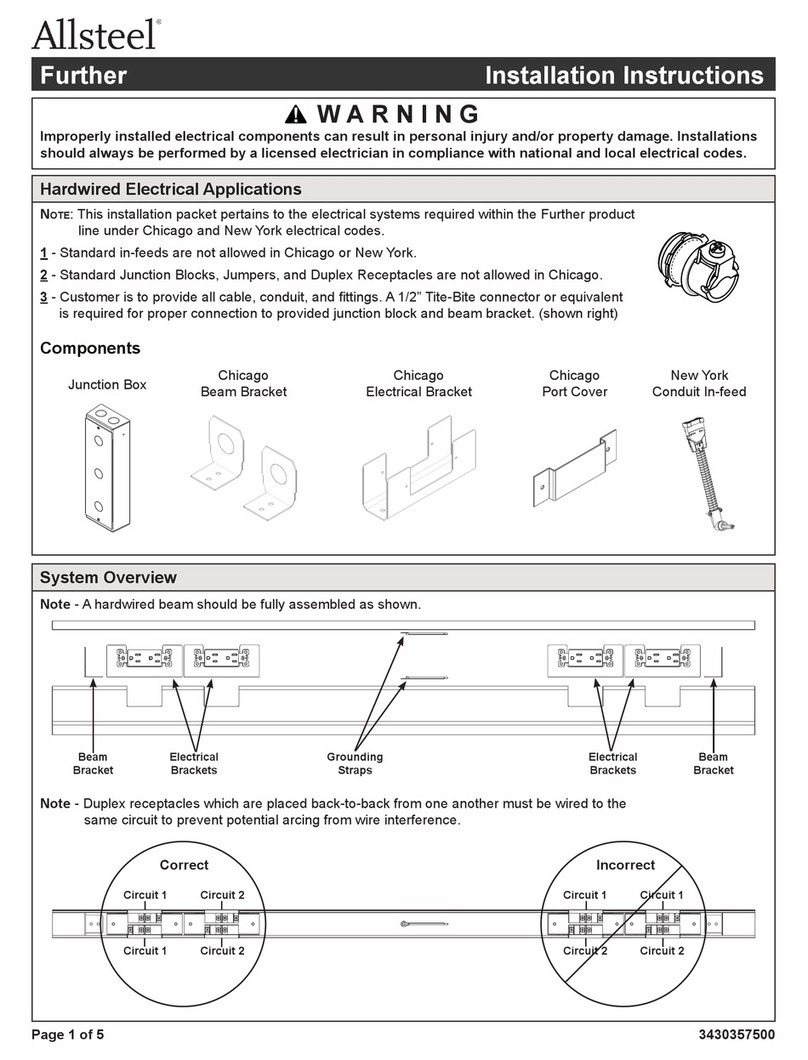

Allsteel Further Series User manual

Allsteel

Allsteel Access User manual

Allsteel

Allsteel Park NA96RCF User manual

Allsteel

Allsteel Laminate Casegoods User manual

Allsteel

Allsteel Approach User manual

Allsteel

Allsteel Further User manual

Allsteel

Allsteel Park User manual

Allsteel

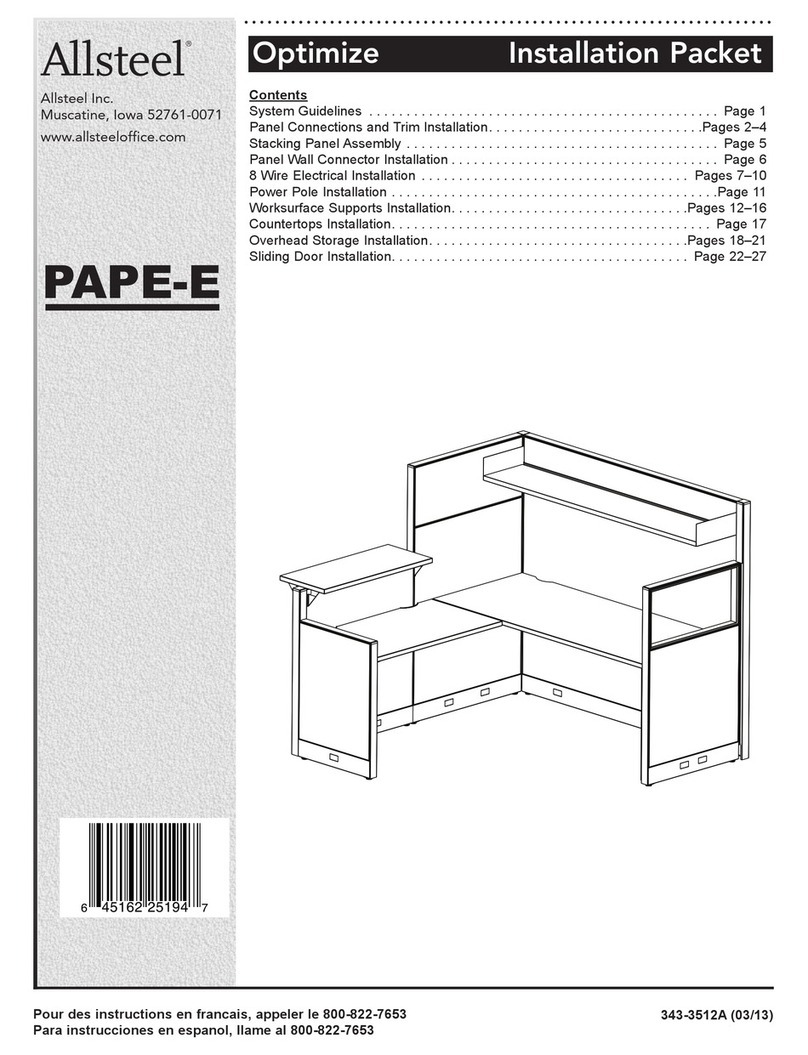

Allsteel Optimize Service manual

Allsteel

Allsteel Universal Screens User manual

Allsteel

Allsteel All-Around Table User manual

Allsteel

Allsteel Quip User manual

Allsteel

Allsteel Townhall Series User manual

Allsteel

Allsteel A8 User manual

Allsteel

Allsteel Trooper User manual

Allsteel

Allsteel Harvest Rustic Standing Height Table User manual

Allsteel

Allsteel Terrace DNA User manual

Allsteel

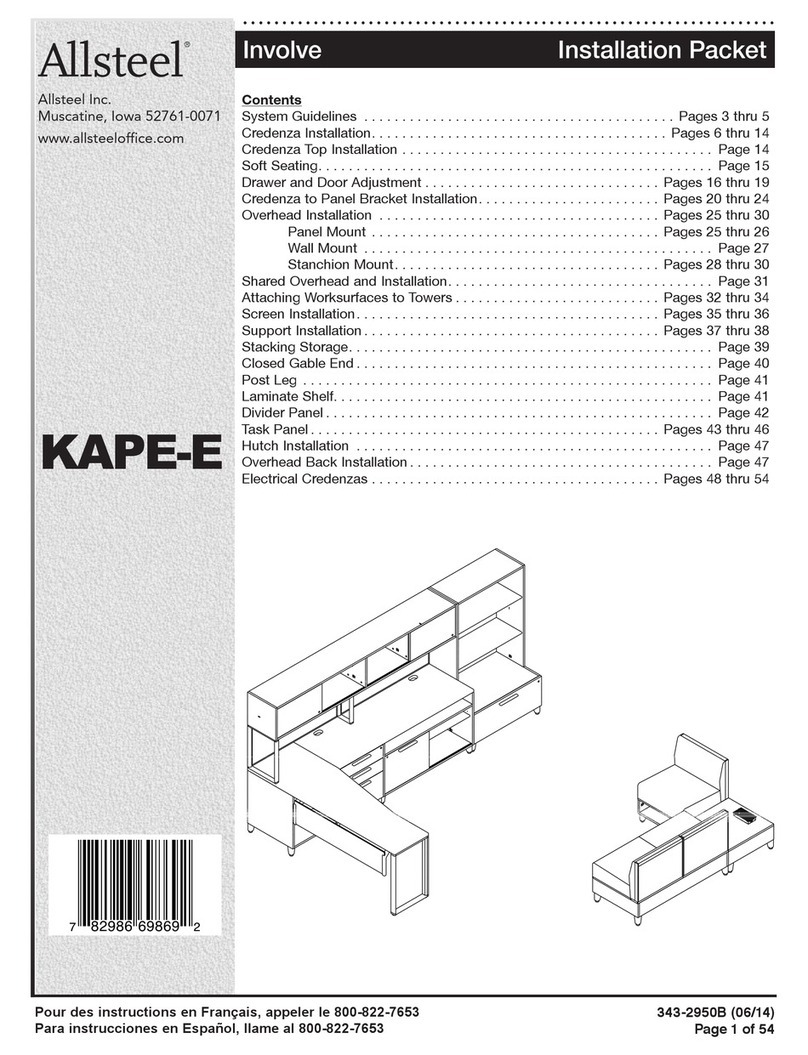

Allsteel Involve KAPE-E Service manual

Allsteel

Allsteel Mind-Share Service manual

Popular Indoor Furnishing manuals by other brands

DIY BBQ

DIY BBQ TV-Chimney Module instruction manual

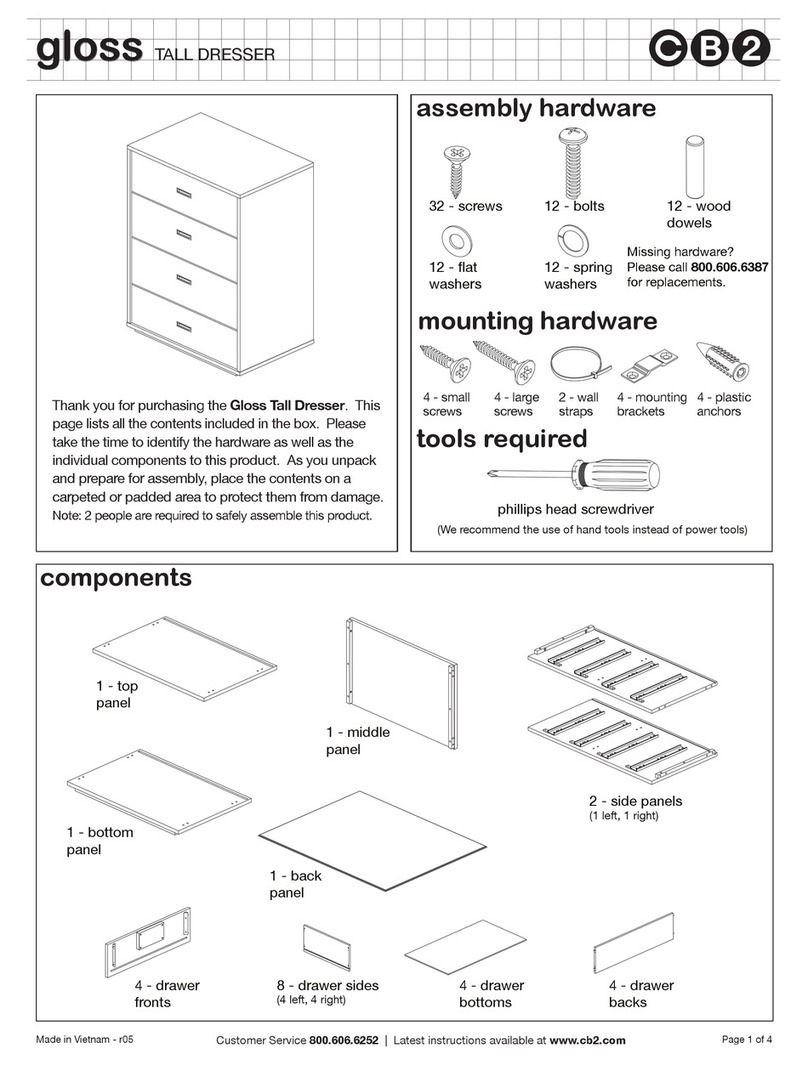

CB2

CB2 GLOSS Assembly instructions

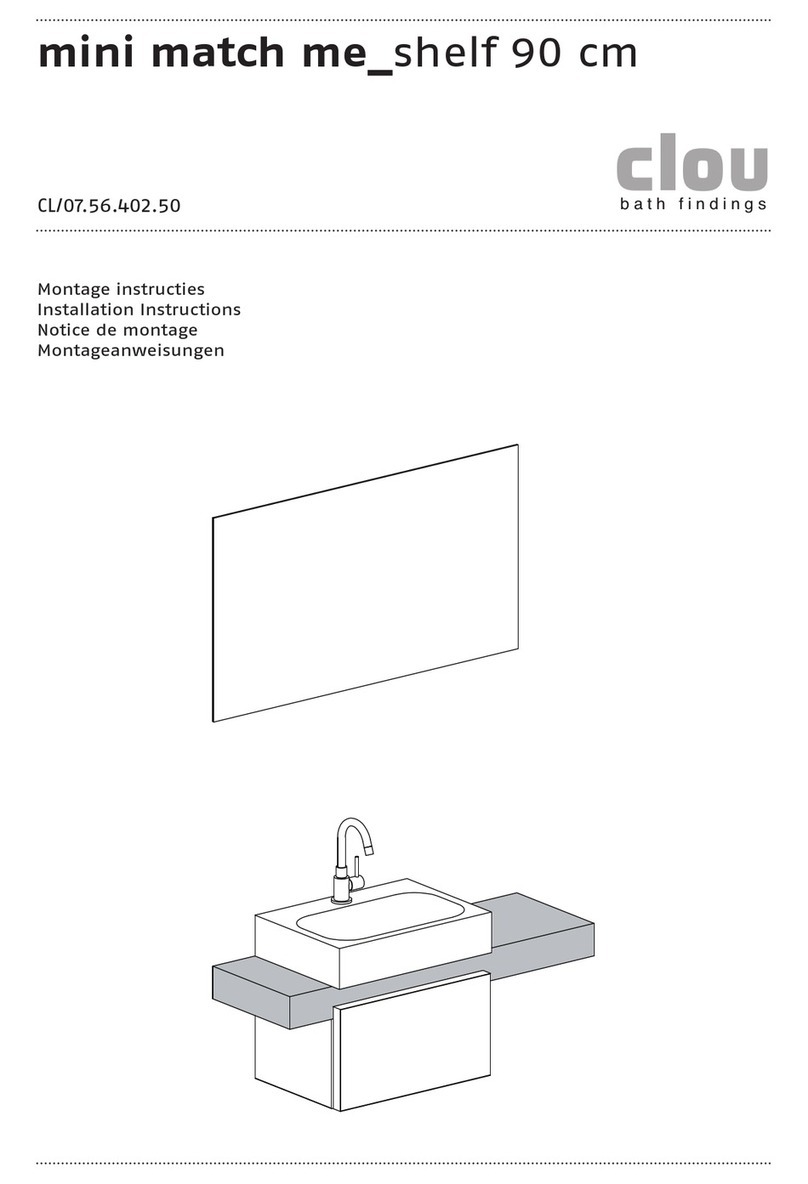

Clou

Clou mini match me CL/07.56.402.50 installation instructions

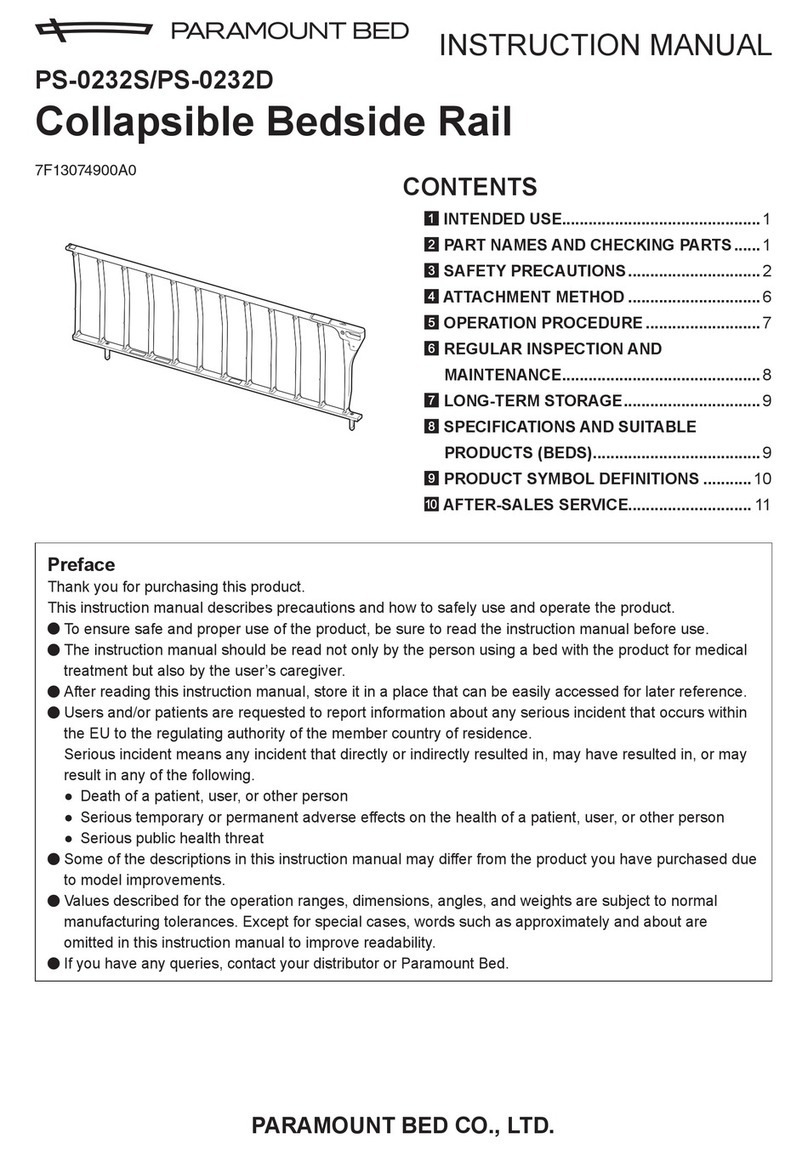

PARAMOUNT BED

PARAMOUNT BED PS-0232S instruction manual

J.Burrows

J.Burrows JBTOCR12GY Assembly instructions

Allen + Roth

Allen + Roth SERENA PARK LOVESEAT FRS90466 quick start guide