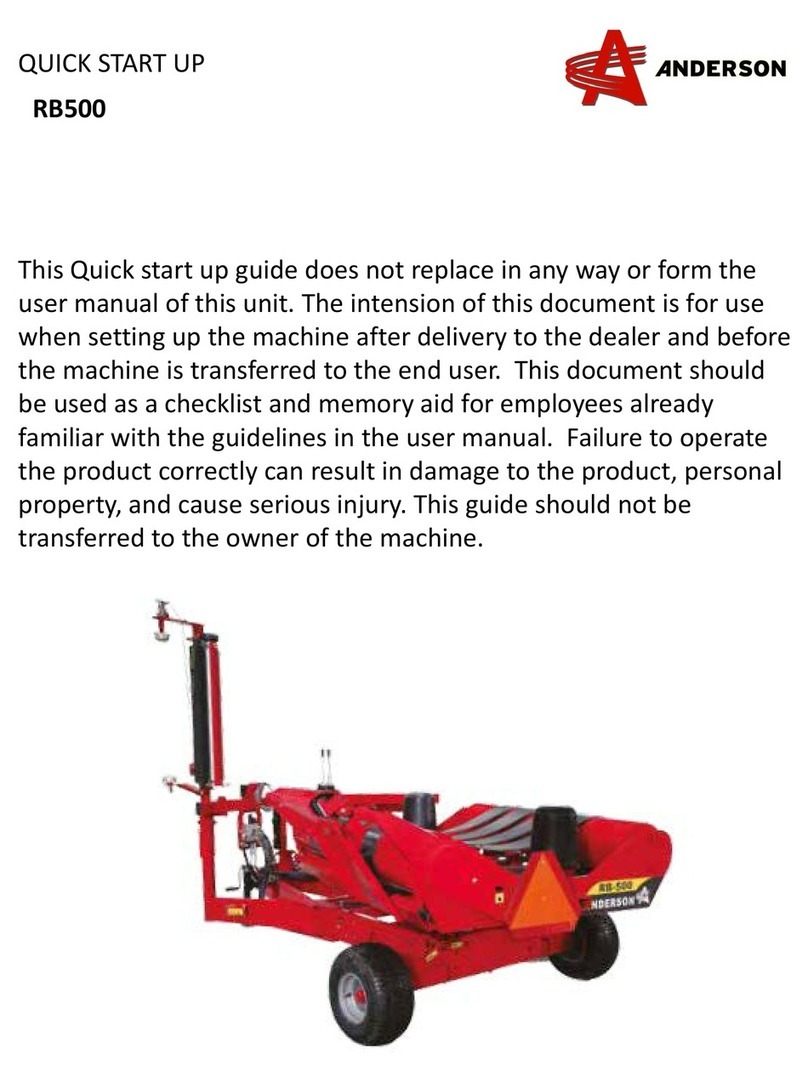

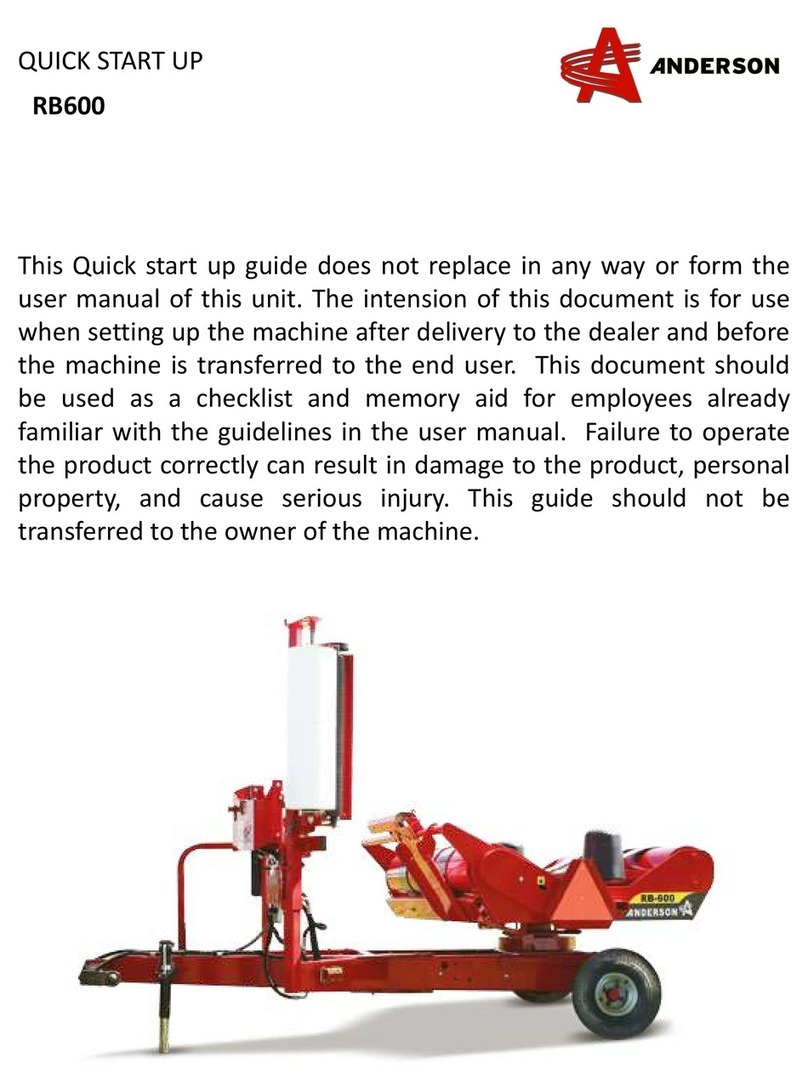

1. Find out the best wrapping area and put the machine there.

2. Remove the tongue and put it at its storage place (close to the steering wheel under the

left fender)

3. If necessary, unlock the steering axle by removing the locking pin (steering pin)

4. Unlock the front gate (mechanic) and the ball valve to release the cylinder (front gate

lock)

5. Adjust your bale guides and cone rollers on the exit ramp of the wrapper (bale size)to

the diameter of bale you will be wrapping

6. Make sure that the gas tank is full, if the wrapper is equipped with the high capacity gas

tank, open the valve under the tank and select the tank with the selector valve (close to

the Honda engine)

7. Connect the battery wires;and turn the Honda key switch to ON

8. Pull the emergency stop button to turn on the computer (control panel image) line #12

9. Select the mode on the first screen of the computer for inline and start the engine with

the computer (computer image)button # 3

10. Use the lever on the dash panel to put the engine at full throttle (control panel image)

button #2 . The computer will advise you if the engine is not at 3600rpm.It must be at

this RPM to function correctly

11. Press the green checkmark (Button 9) (this will start the automatic setup sequence)

Follow the instructions you find on the screen (If the computer requests that you take out

the bale spears do so by using the lever close to the Honda engine) (bale spear)

12. Open the cut and hold system by pressing the button #14 on the control panel.Attach

plastic to the cut and hold as shown.Then press the same button on the control panel

and the machine will load the cut and hold system (hoop will move so be careful).

13. With the lifting lever (on the main valve), level the machine to avoid the first bales from

falling down the roller bed (

14. Place the hoop wrap /move wrapper valve in the move wrapper position *Smart start*

(explanation smarts start) (control panel image)line # 8

15. Adjust the hoop speed (depending of the number of layers needed )with the valve

handle on the control panel (control panel image)line # 7

16. After 2bales are wrapped you can use the lift lever to lower wrapper and the front gate to

the ground (control panel image)line # 5

17. When you have 4to 5bales on the ground you can place the hoop wrap /move wrapper

valve in the wrap position and adjust the compaction of the bales (control panel image)

line # 9 (traction wheels will be restricted) It should be between 500 and 1000 PSI

depending of the conditions (ground, incline of the yard, bale weight, etc)

18. You can remove the controller from the dash panel and bring it inside the tractor with you.

You will need to supply 12Vto the monitor by connecting the supplied power cord *(cobo

adapter) (image XXXXX)

19. Xtract you bales with the xtractor systemTM when you have finished the tube of wrapped

bales (control panel image)line # .

Back