Anderson STACKPRO Series Setup guide

Other Anderson Farm Equipment manuals

Anderson

Anderson RBM1400 User manual

Anderson

Anderson ROUND BALE WRAPPER HYBRID User manual

Anderson

Anderson RB-400 User manual

Anderson

Anderson IFX720 Manual

Anderson

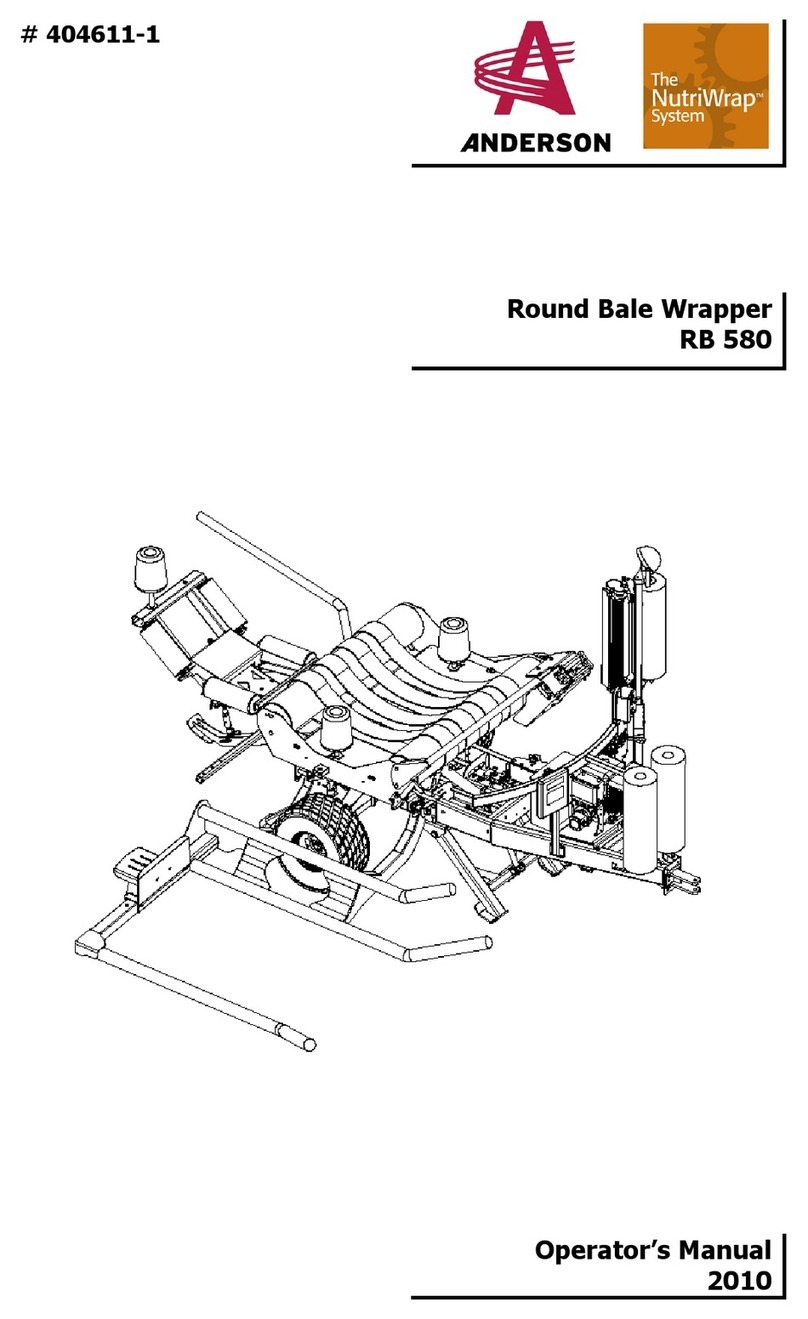

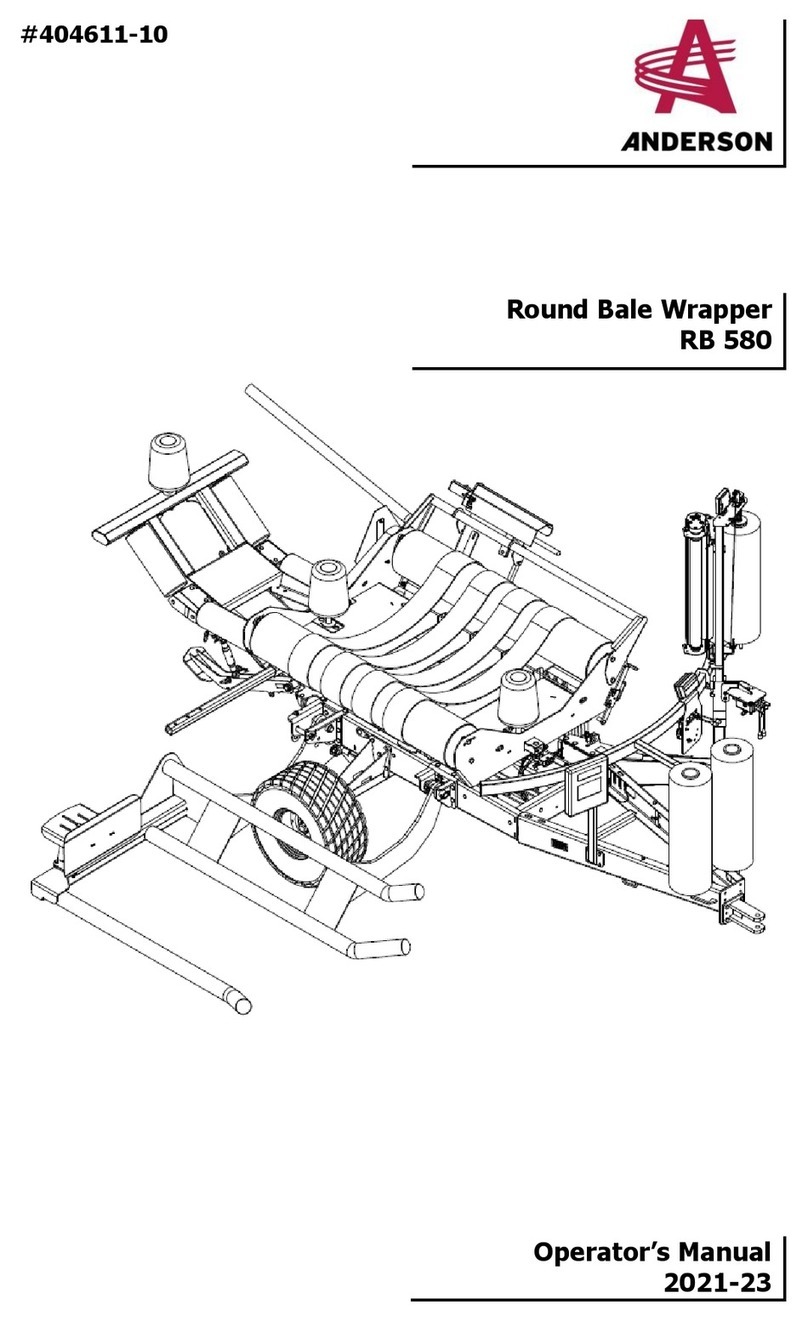

Anderson RB580 User manual

Anderson

Anderson RBM Series User manual

Anderson

Anderson RB-400 User manual

Anderson

Anderson M-160 User manual

Anderson

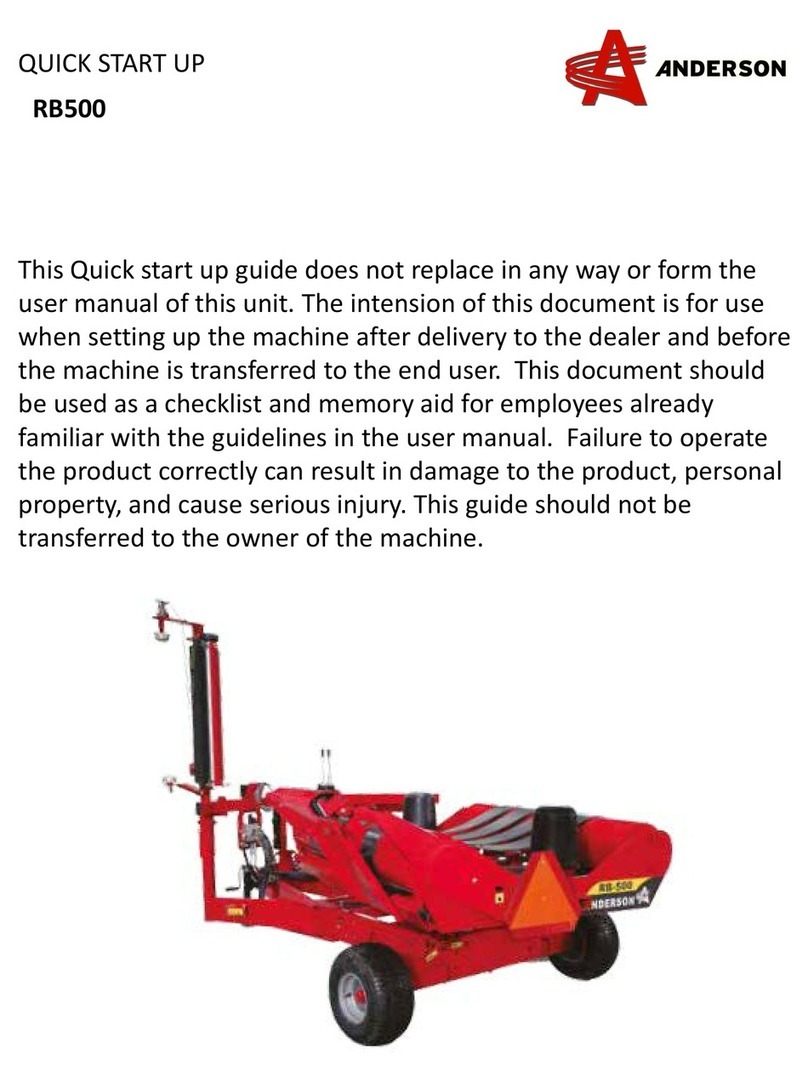

Anderson RB-500 Operator's manual

Anderson

Anderson RB-200 User manual

Anderson

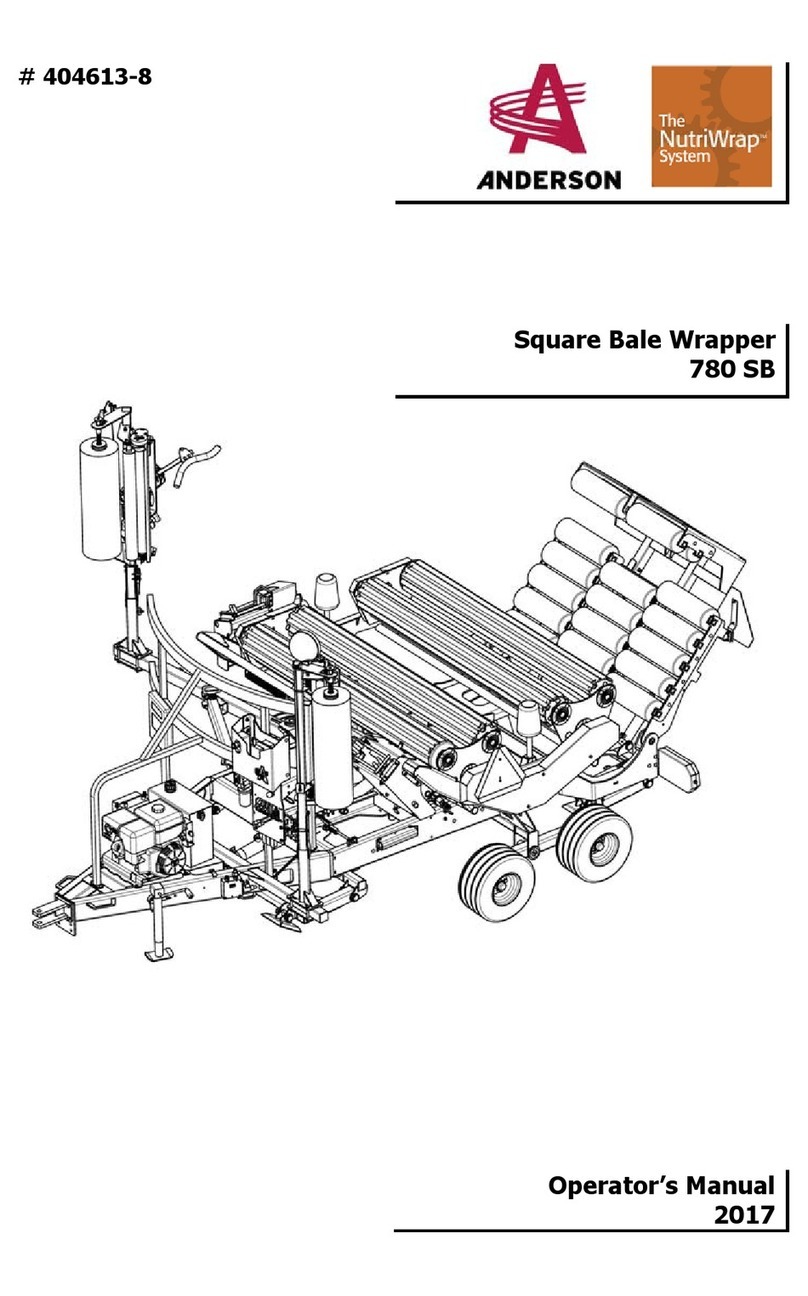

Anderson NutriWrap 780 SB User manual

Anderson

Anderson RBMPRO Setup guide

Anderson

Anderson TRB-2000 User manual

Anderson

Anderson RB580 User manual

Anderson

Anderson RB-200 User manual

Anderson

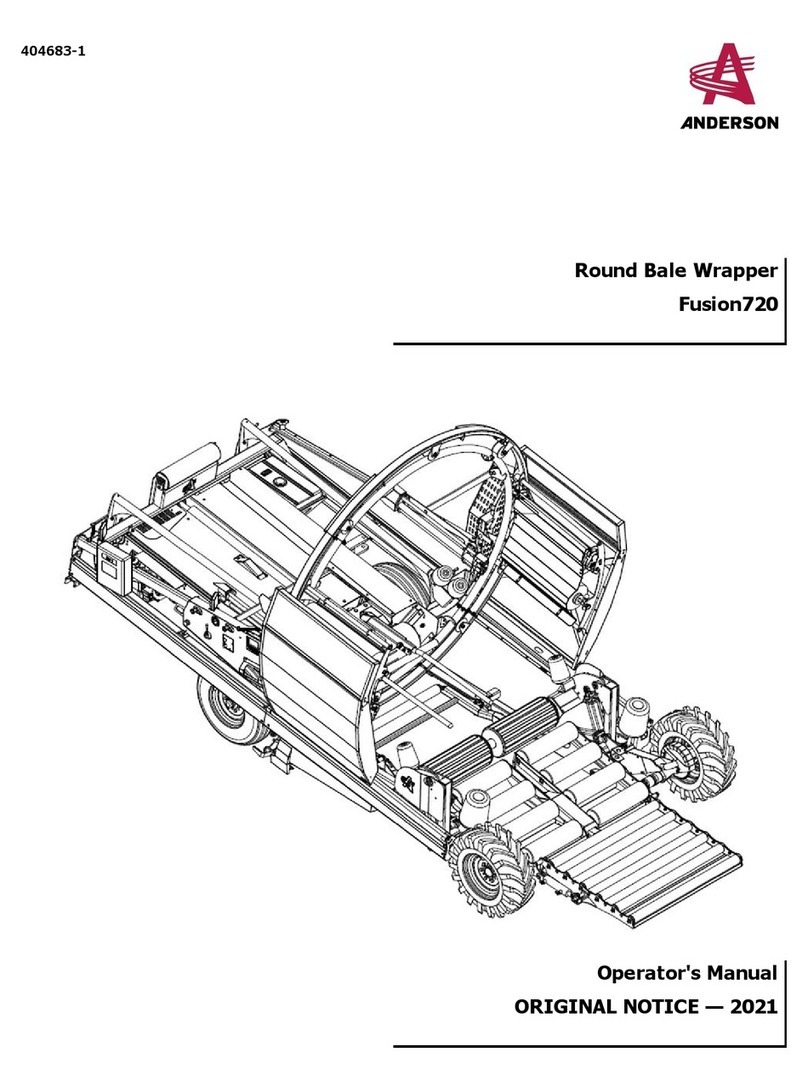

Anderson Fusion720 User manual

Anderson

Anderson Double stretcher User manual

Anderson

Anderson RB-200 User manual

Anderson

Anderson RB 680 User manual

Anderson

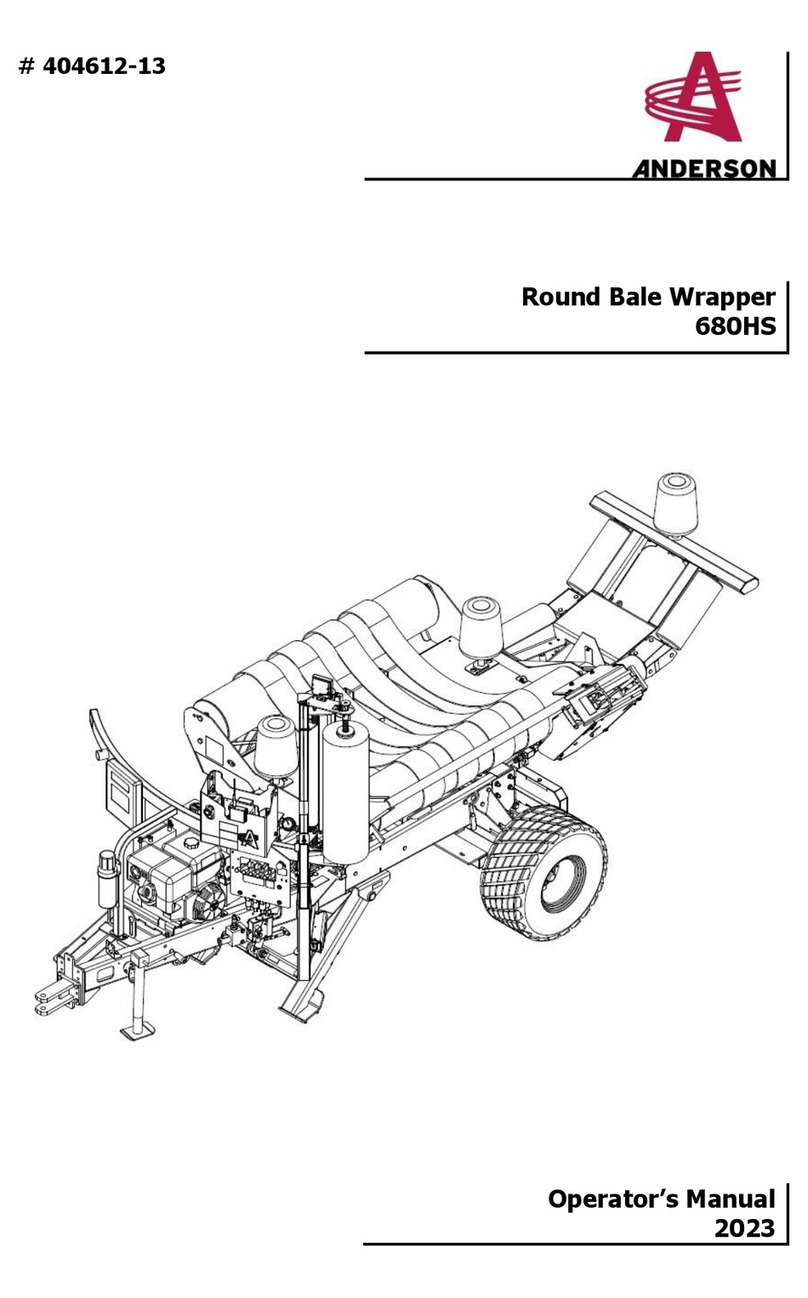

Anderson 680HS User manual