AB-6579

∗

Azbil Corporation’s controller Infilex series: Infilex is named for “Infinity” and “Flexible”.

1

Specifications/Instructions

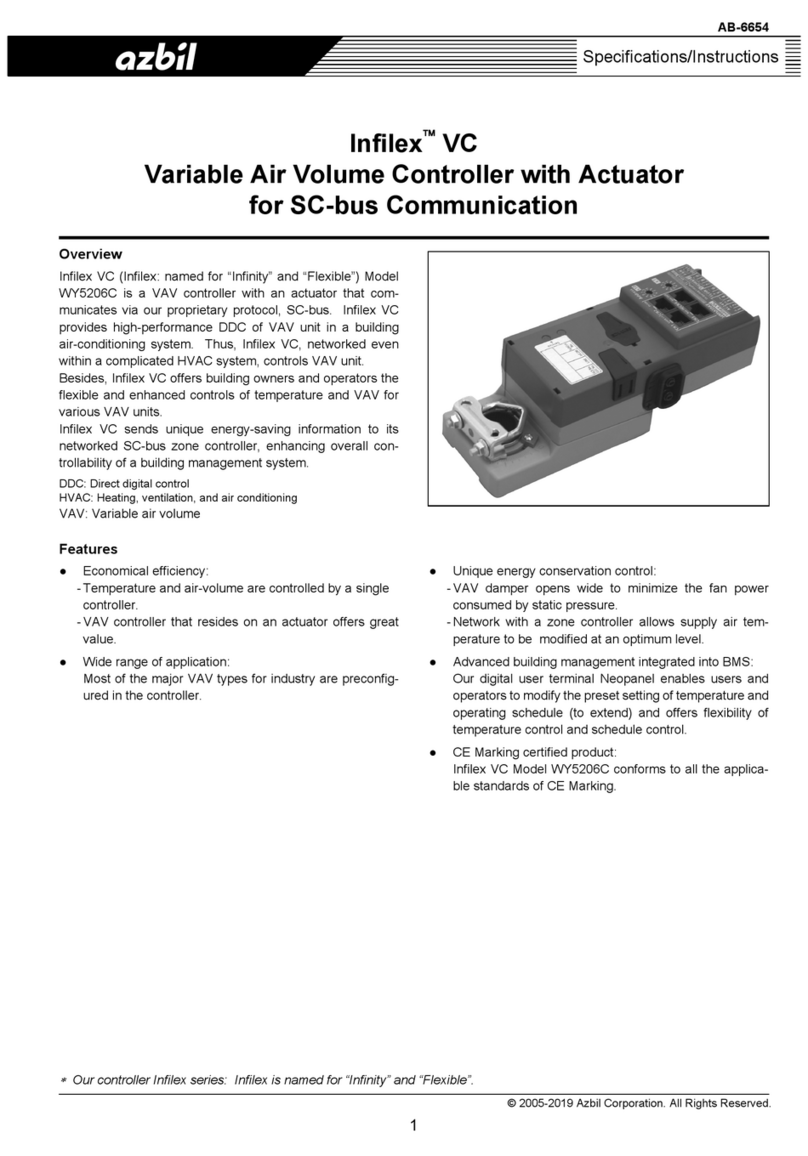

Infilex™ZM

Zone Manager

Model WY5322

General

Infilex ZM (Infilex: named for “Infinity” and “Flexible”) Model

WY5322, integrated into BMS (building management

system), manages remote units (also called as

‘sub-controllers’), such as Infilex VC, Infilex FC, and

Infilex SC.

Up to 50 remote units can be connected. Infilex ZM can

control these units separately as well as per group.

Infilex ZM communicates with BMS (savic-net™FX) through

the transmission trunk line LC-bus (LonTalk®protocol) and

with the remote units through the transmission trunk line

LS-bus (LonTalk®protocol).

Features

•Compact design

Small size body ensures space saving.

•Installation:

A quick-fit screwless (clamp) terminal block is used for

the communication terminal block of the I/O module,

ensuring the labor saving of the wiring work.

Additionally, either DIN rail mounting or screw mounting

can be selected.

•Management of remote units

Infilex ZM manages the connected remote units (Infilex

VC, Infilex FC, Infilex SC, etc., max. 50 units

connectable), allowing the BMS center unit to execute

ON/OFF operation, failure monitoring, measuring, and

setting of each remote unit separately. Infilex ZM can

also manages the remote units by group and is

applicable to any group configuration consisting of up to

50 units of Infilex VC and Infilex FC. Additionally, Infilex

ZM provides flexible management. For example, group

ON/OFF can be commanded even when individual

measuring is commanded.

•Risk diversification and high-speed supervision

Infilex ZM has 50 programs of time schedules, analog

alarm monitoring, and runtime/cycle-count integrating in

order to manage the connected Infilex VC, Infilex FC,

Infilex SC, etc. This achieves diversification of risks and

high-speed supervision of BMS.

•Various controls

One Infilex ZM controls up to 4 sets of VAV (VAV:

variable air volume, controlled by Infilex VC) and AHU

(controlled by Infilex GC or Infilex AC). Load reset

control of supply air temperature, fan speed control,

interlocking operation are available. Additionally, the

mixing loss control of the interior VAV and perimeter

FCU (fan coil unit) can be performed.

•Support functions

Infilex ZM supports to adjust VAV by setting the

max./min. air volume levels of all VAV units included in a

specified set. Infilex ZM also supports to adjust

AHU/FCU flow rate and to flush the piping by fully

opening and closing all the valves that the Infilex FC and

Infilex SC control.

•CE Marking certified product:

Infilex ZM conforms to all the applicable standards of CE

Marking (Class A).