Installation and Technical Information

BEGA

Due to the dynamic nature of lighting products and the associated technologies, luminaire data on this sheet is subject to change at the discretion of BEGA North America. For the most current technical data, please refer to bega-us.com

BEGA 1000 Bega Way, Carpinteria, CA 93013 (805)684-0533 © copyright BEGA 2021

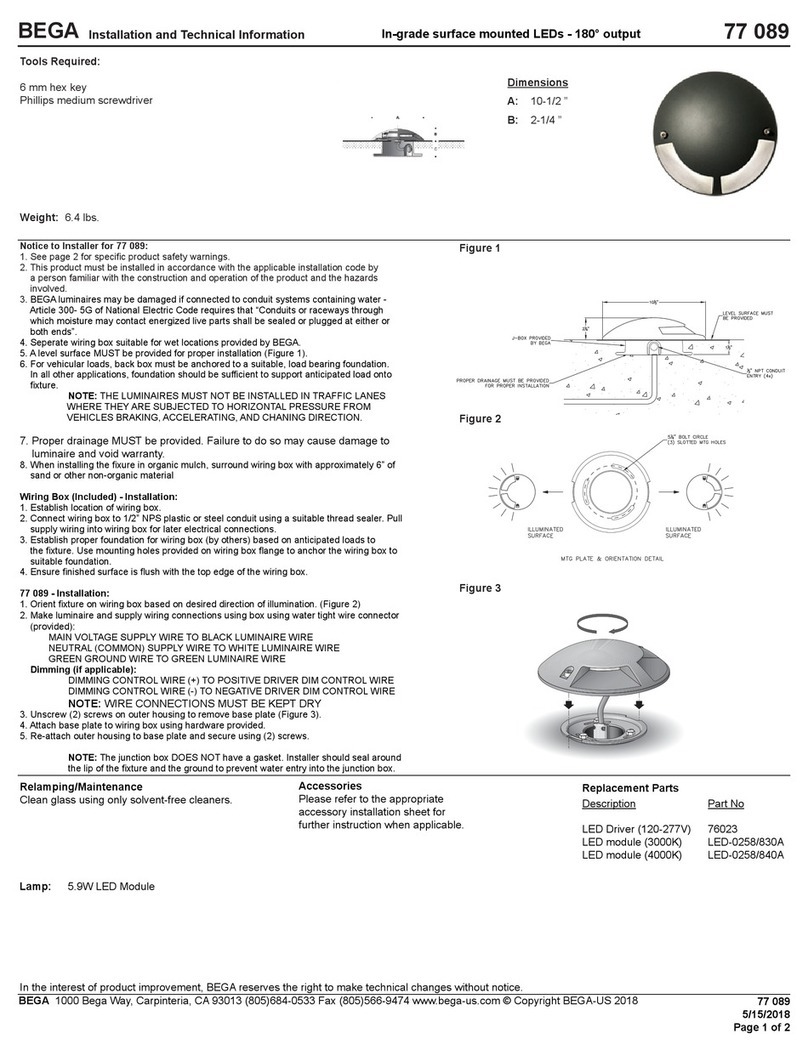

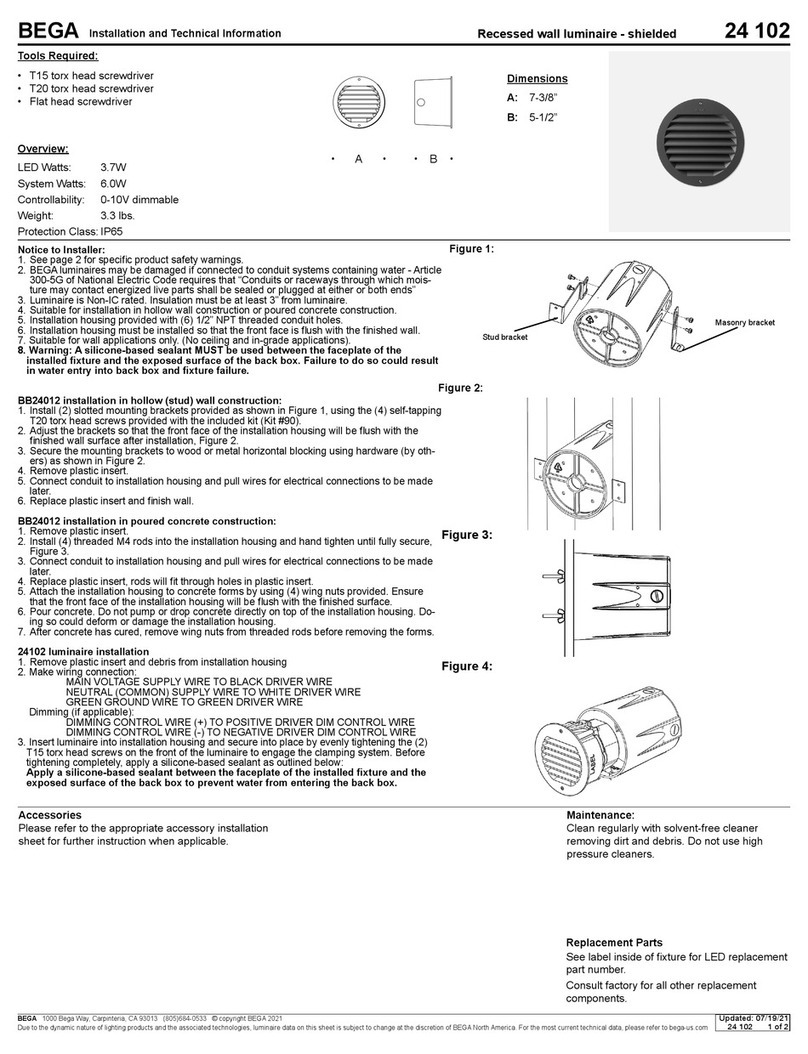

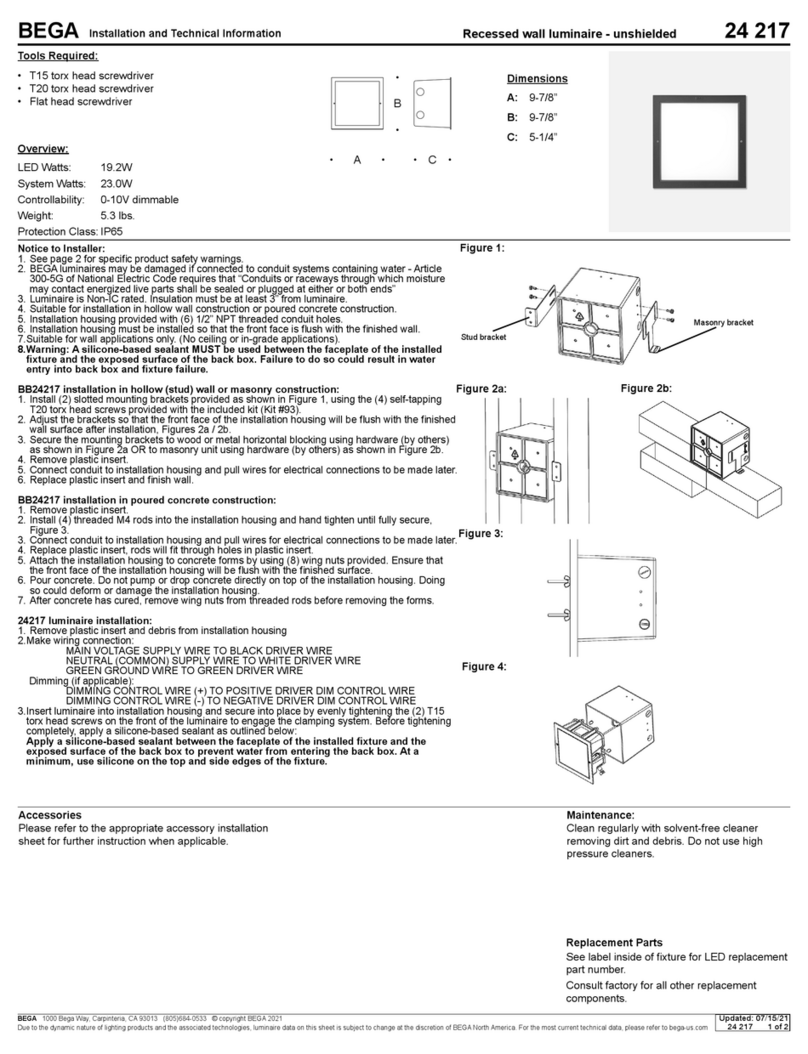

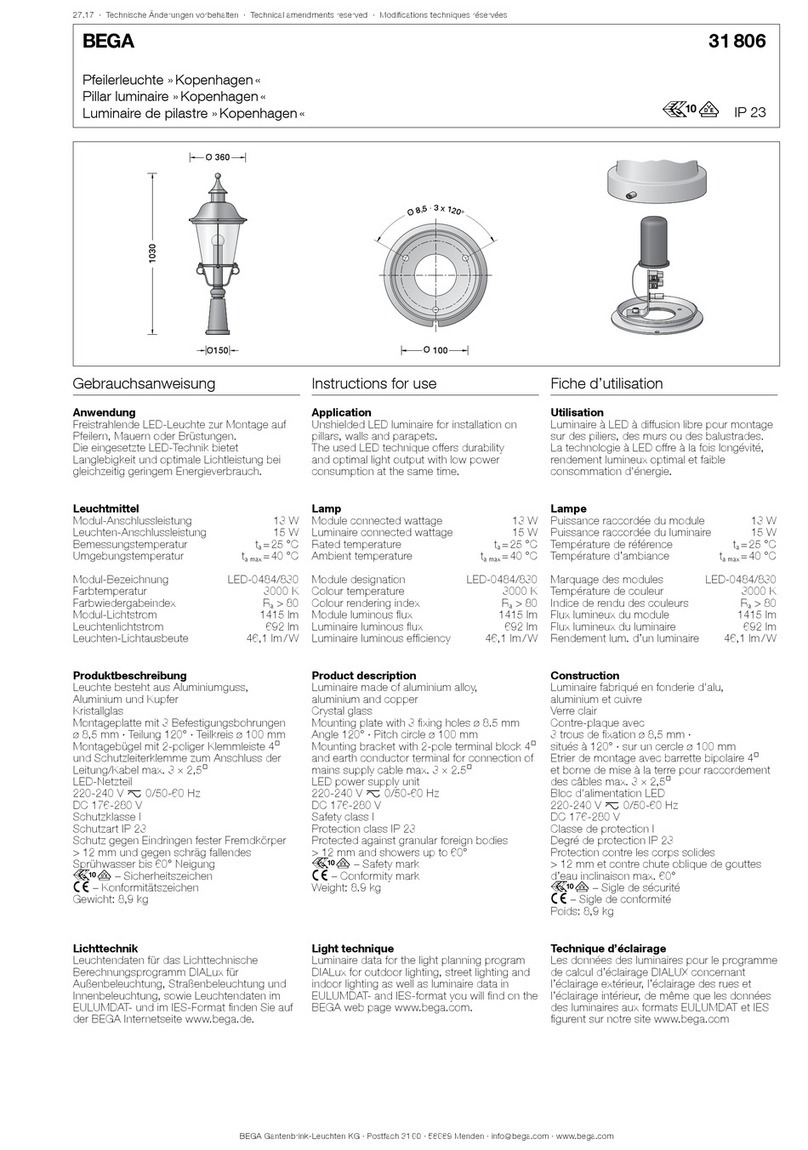

Figure 1:

Figure 2:

Overview:

LED Watts: 7.9W

System Watts: 11.0W

Controllability: 0-10V dimmable

Weight: 18.0 lbs.

Protection Class: IP67

Tools Required:

• T25 torx head screwdriver

• Small at head screwdriver

• 5mm hex head screwdriver

• 4mm hex head screwdriver

5

1

8

"

1

4

" (4X)

FOR MOUNTING

TO WIRING BOX

3

1

2

"

-

98006

FLOODLIGHT GROUND MOUNTED

3/29/21

MOUNTING PLATE DETAIL

REV

PART NO.

SIZE

TYPE:

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE PROPERTY

OF BEGA NORTH AMERICA, INC.

ANY REPRODUCTION IN PART OR AS A WHOLE WITHOUT THE WRITTEN

PERMISSION OF BEGA NORTH AMERICA, INC. IS PROHIBITED.

DATE:

APPROVED:

P (805) 684-0533 - www.bega-us.com

DESCRIPTION:

1000 BEGA Way, Carpinteria, California 93013

B

SHEET 1 OF 1

NOT TO SCALE

DATE

DESCRIPTION

CHANGED BY

REV

Ground mounted oodlight - adjustable 98 006

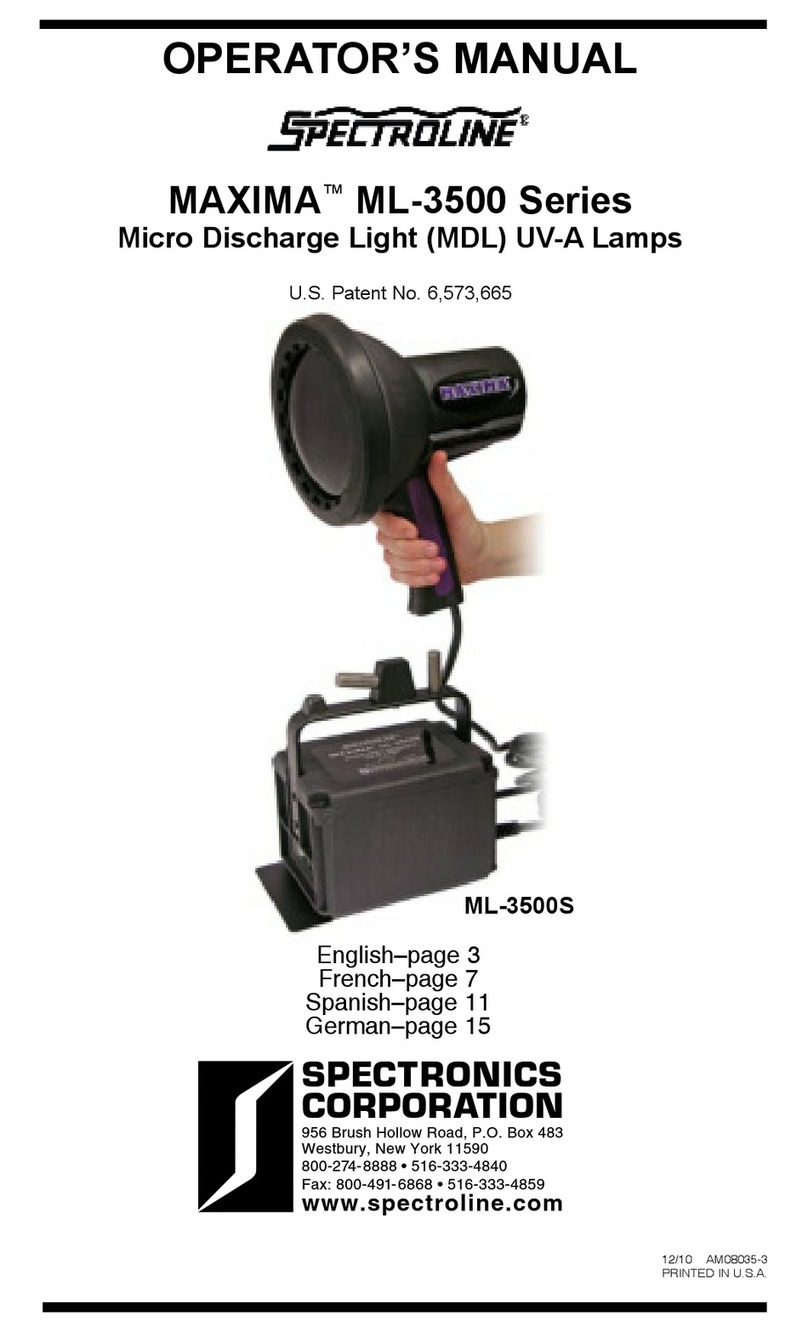

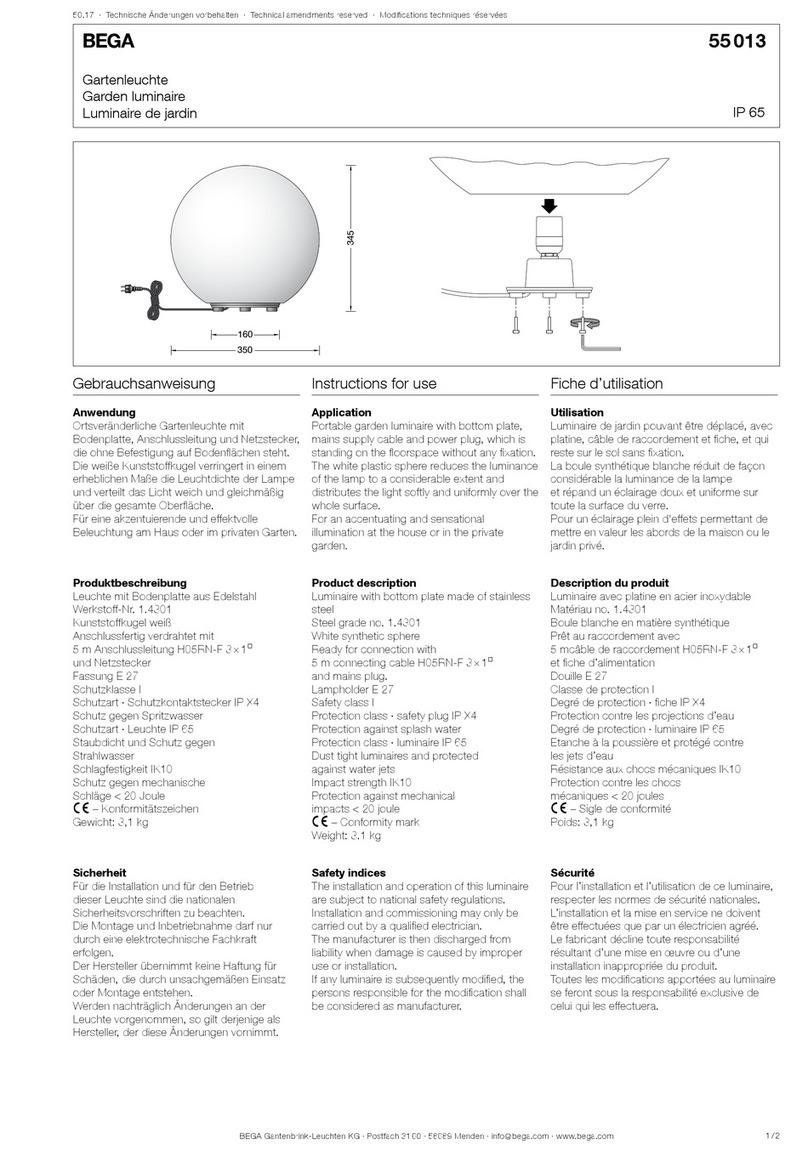

Dimensions

A: 9”

B: 9-3/4”

C: 11-3/4”

Maintenance:

Clean regularly with solvent-free cleaner

removing dirt and debris. Do not use high

pressure cleaners.

Replacement Parts

See label inside of xture for LED replacement

part number.

Consult factory for all other replacement

components.

Accessories

Please refer to the appropriate accessory installation

sheet for further instruction when applicable.

Updated: 03/29/21

98 006 1 of 2

A

B

Notice to Installer:

1. See page 2 for specic product safety warnings.

2. A wiring box suitable for outdoor locations is required for installation (by others). Luminaire

mounts directly to recessed ground installed wiring box (by others). Adequate foundation

required. Wiring box must be ush with the nished surface.

3. Proper drainage must be provided.

4. Re-enterable potting compound may be used in wiring box in installations where water entry into

the wiring box is a concern. Consult factory for details.

Luminaire wiring box installation:

1. Establish location of wiring box (by others) in ground directly below the proposed location of

luminaire.

2. Provide adequate drainage for wiring box and surrounding area

3. Provide adequate foundation for wiring box (concrete pad as required).

4. Top of wiring box must be ush with nished surface.

Luminaire 98006 installation:

1. Loosen (4) T25 torx head screws on faceplate of luminaire to remove faceplate casting, glass,

and gasket assembly.

2. Loosen (2) at head set screws on either side of the optical assembly in order to remove optical

assembly. Do not open optical assembly. Disconnect the quick connect between the optical

assembly and the driver and carefully set the optical assembly aside.

3. Loosen (4) 5mm hex head screws to remove base plate assembly from the luminaire housing.

Do not disturb water stopper assembly or cable gland.

4. Loosen (1) 4mm hex head set screw to remove mounting plate from from base plate assembly.

5. Route wires through mouting plate assembly into wiring box and make supply wire connections

inside the box:

MAIN VOLTAGE SUPPLY WIRE TO BLACK DRIVER WIRE;

NEUTRAL (COMMON) SUPPLY WIRE TO WHITE DRIVER WIRE;

GREEN GROUND WIRE TO GREEN DRIVER WIRE.

Dimming (if applicable):

DIMMING CONTROL WIRE (+) TO POSITIVE DIM CONTROL WIRE

DIMMING CONTROL WIRE (-) TO NEGATIVE DIM CONTROL WIRE

6. Attach mounting plate to wiring box using hardware by others. See mounting plate detail Figure

2.

7. Place a small bead of silicone around the edge of the wiring box and mounting plate.

8. Place the base plate assembly over the mounting plate, align as needed for xture aiming, and

secure into place by tightening (1) 4mm hex head set screw.

9. Align luminaire housing with base plate assembly and tighten (4) 5mm hex head screws to

secure into place.

10. Re-connect quick disconnect between driver and optical assembly. Replace optical assembly

in luminaire housing and tighten (2) at head set screws to secure into place. Aim the optical

assembly as needed by loosening the at head set screw on the top of the assembly. Assembly

is aimable up to 30°. Tighten the at head set screw to lock into place.

11. Replace faceplate assembly on top of luminaire housing. Ensure the gasket is seated correctly

before tightening (4) T25 torx head screws to secure into place. Tighten the screws in a star

pattern to ensure the gasket seals evenly.

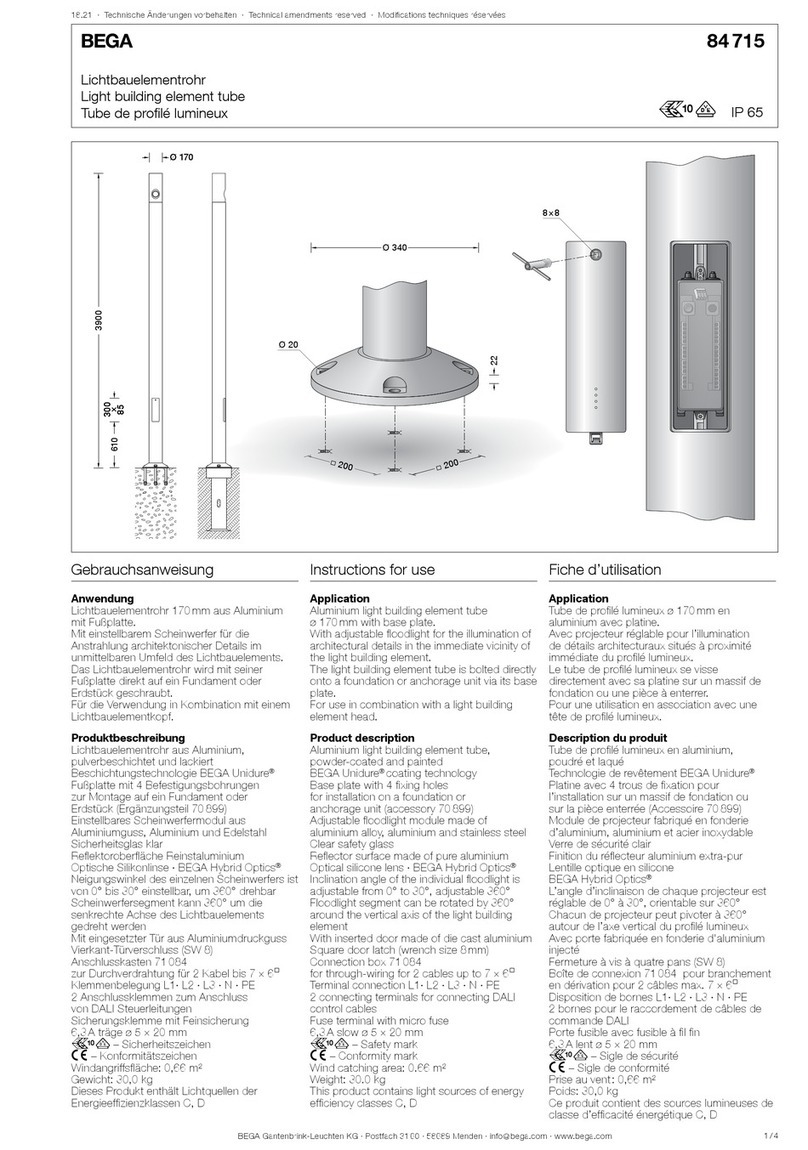

Optical

Assembly

Faceplate

Assembly

Base Plate

Assembly

Mounting

Plate

Luminaire

Housing