41

INDEX

GB

SECTION 1: GENERAL INFORMASECTION 1: GENERAL INFORMA

SECTION 1: GENERAL INFORMASECTION 1: GENERAL INFORMA

SECTION 1: GENERAL INFORMATIONTION

TIONTION

TION

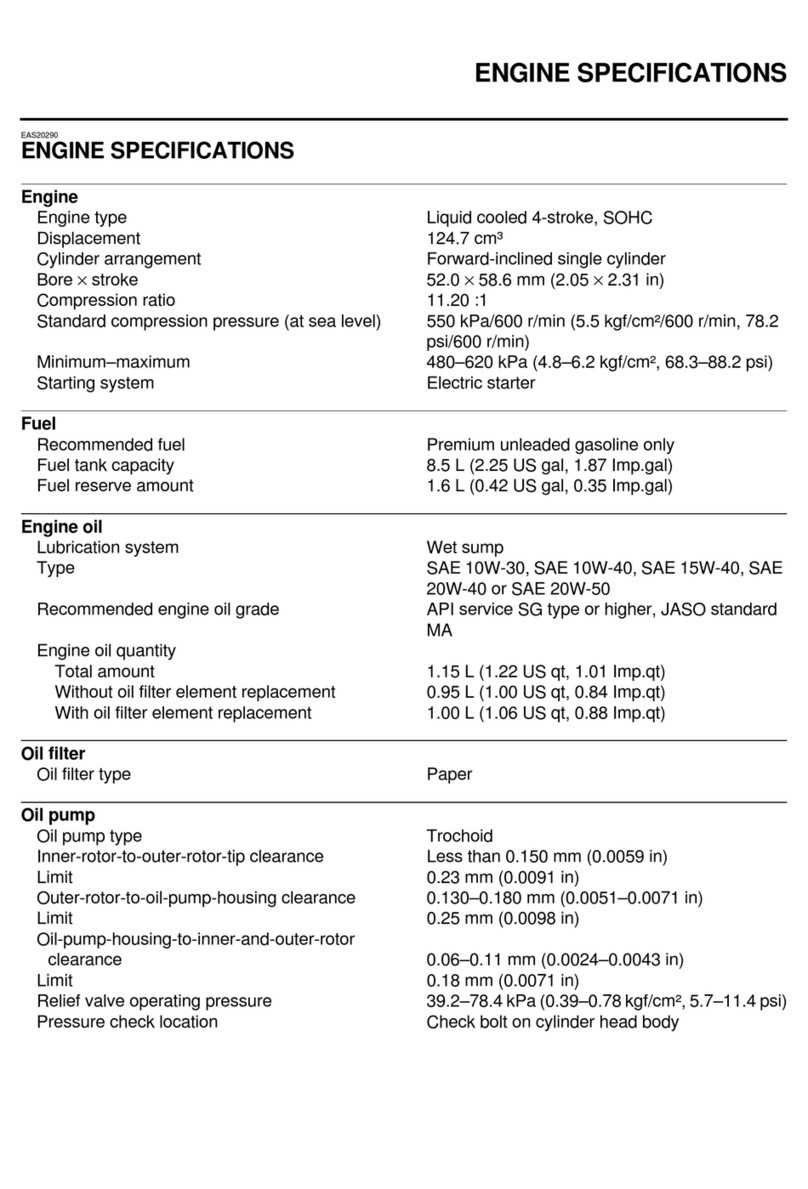

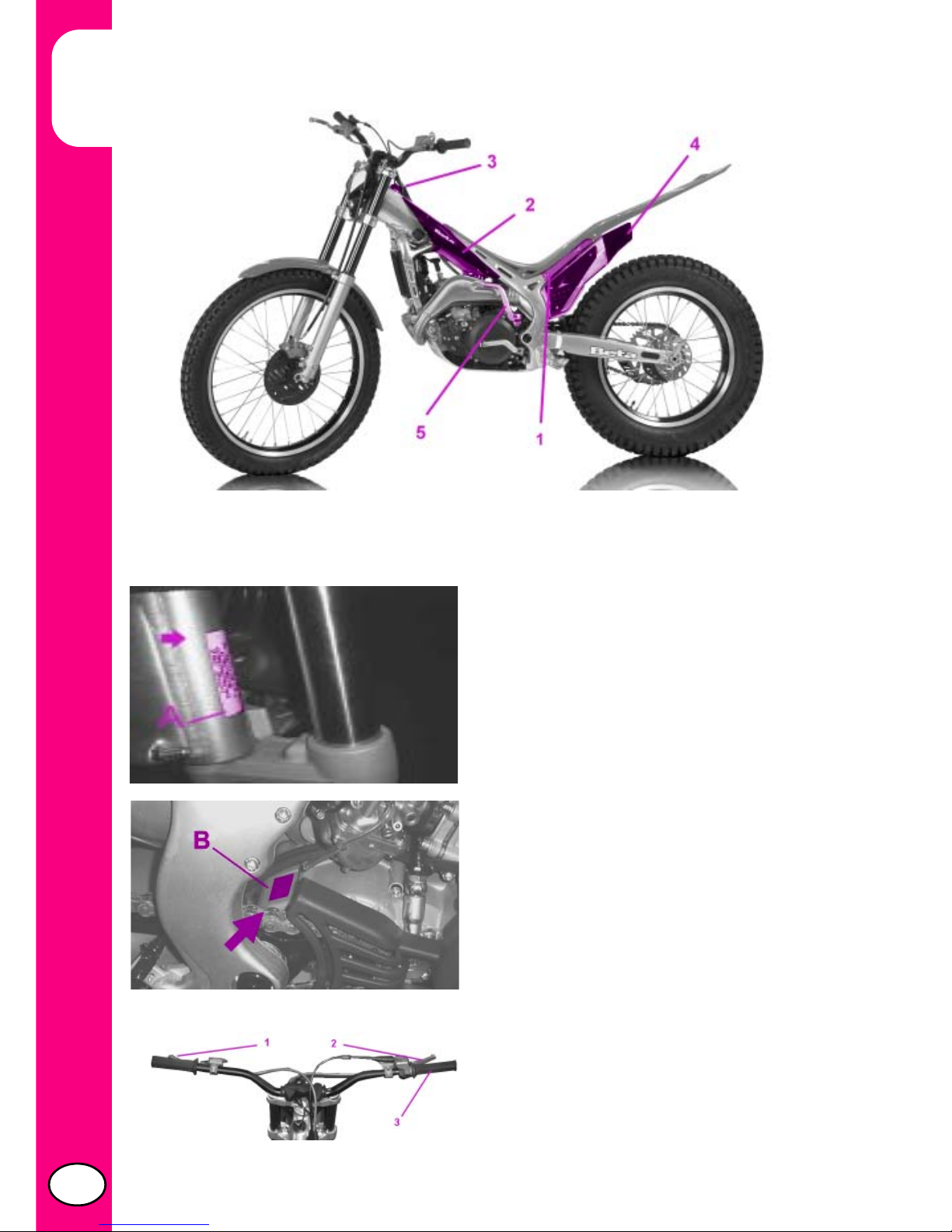

Main parts ............................................................................................. 44

Vehicle identification data................................................................................ 44

Instrument panel and controls.......................................................................... 44

Technical data .......................................................................................................... 45

Electrical diagram .................................................................................................... 46

SECTION 2: OPERASECTION 2: OPERA

SECTION 2: OPERASECTION 2: OPERA

SECTION 2: OPERATION AND USETION AND USE

TION AND USETION AND USE

TION AND USE

Check and maintenance before and after off-road use ............................................... 48

Fueling ........................................................................................................... 48

Recommended lubricants and liquids .............................................................. 49

Breaking in .................................................................................................... 49

Startup ........................................................................................................... 50

SECTION 3: MAINTENANCE AND CHECKSSECTION 3: MAINTENANCE AND CHECKS

SECTION 3: MAINTENANCE AND CHECKSSECTION 3: MAINTENANCE AND CHECKS

SECTION 3: MAINTENANCE AND CHECKS

Gearbox oil ................................................................................................ 52

Brake pump oil ........................................................................................................ 53

Clutch pump oil ....................................................................................................... 55

Fork oil ................................................................................................................... 56

Air filter ................................................................................................................... 58

Spark plug ............................................................................................................. 59

Generator ............................................................................................................59

Front brake .............................................................................................................. 60

Rear brake ............................................................................................................... 61

Liquid coolant .......................................................................................................... 62

Silencer .................................................................................................................... 62

Carburettor ............................................................................................................... 63

Valve petals ............................................................................................................. 63

Rear shock absorber leverage .......................................................................................64

Checks after cleaning ............................................................................................... 65

Maintenance schedule .............................................................................................. 66

SECTION 4: ADJUSTEMENTSSECTION 4: ADJUSTEMENTS

SECTION 4: ADJUSTEMENTSSECTION 4: ADJUSTEMENTS

SECTION 4: ADJUSTEMENTS

Adjustement of brake ............................................................................................... 68

Adjustement of clutch ............................................................................................... 68

Adjustement of idling speed ...................................................................................... 69

Adjustement of gas clearance ................................................................................... 69

Adjustement air ..............................................................................................69

Check and adjustement of steering gear..................................................................... 69

Tightening the chain ................................................................................................. 70

Adjustement of front suspension ................................................................................ 71

Adjustement of rear shock absorber .......................................................................... 72

SECTION 5: WHASECTION 5: WHA

SECTION 5: WHASECTION 5: WHA

SECTION 5: WHAT TT T

T TT T

T TO DO IN AN EMERGENCYO DO IN AN EMERGENCY

O DO IN AN EMERGENCYO DO IN AN EMERGENCY

O DO IN AN EMERGENCY

Troubleshooting ........................................................................................................ 74

ALPHABETICAL INDEXALPHABETICAL INDEX

ALPHABETICAL INDEXALPHABETICAL INDEX

ALPHABETICAL INDEX

Index ....................................................................................................................... 75