INSTALLATION MANUAL

ENGLISH

Thank you for buying this product, our company is sure that you will be more

than satised with the performance of the product.

Read the “Instruction Manual” supplied with this product carefully, as it

provides important information about safety, installation, operation and

maintenance. This product complies with recognised technical standards

and safety regulations. We declare that this product is in conformity with

the following European Directives: 2004/108/EEC (amended by RL 91/263/

EEC, 92/31/EEC and 93/68/EEC), 2006/95/EEC, 99/5/EEC.

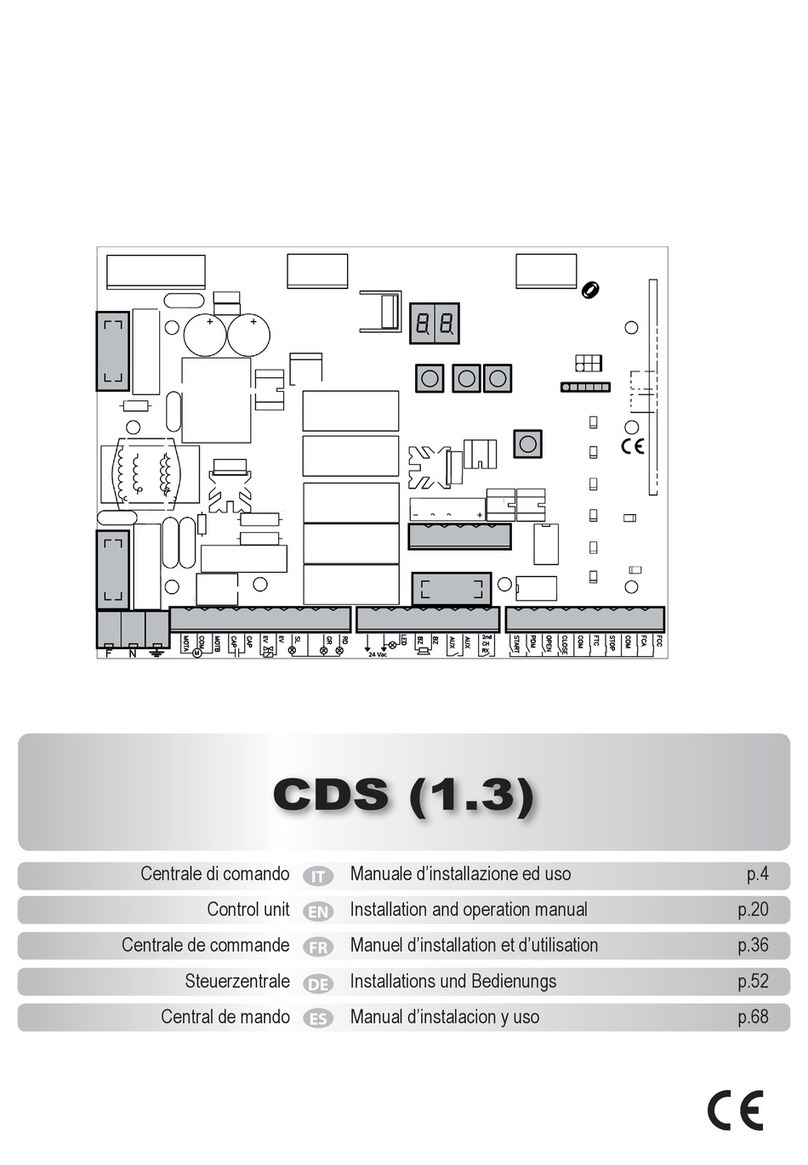

1) GENERAL OUTLINE

Elba is a control unit for motors having maximum power of 470 W (e.g.

tubular motors for roller shutters and sunshades, roll-up door openers etc.),

compatible with the EElink protocol.

It is provided with the connections for opening (or start), closing and stop

control buttons, for accessories such as the twilight sensor, anemometer

and, when requested, safety devices.

When the key is pressed, a START command is generated.

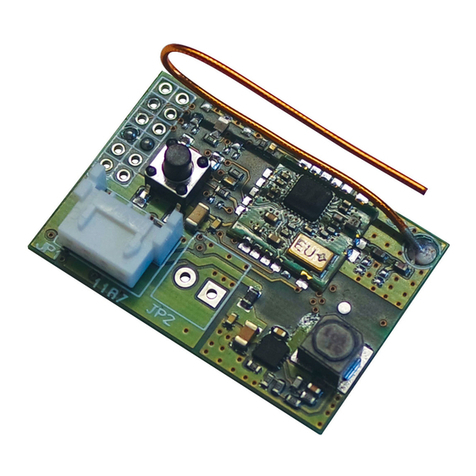

The commands can also be sent via radio through; the transmitters can

directly be memorised by means of the key and the LED present on the

board or by means of the radio self-learning method or using the cloning

mechanism.

If the control unit allows it, set up a centralised control system via wire,

which can be divided into 8 or more zones, without having to interfere with

the wiring.

2) GENERAL SAFETY

WARNING!An incorrect installation or improper use of the product can

cause damage to persons, animals or things.

• The “Warnings” leaet and “Instruction booklet” supplied with this

product should be read carefully as they provide important information

about safety, installation, use and maintenance.

• Scrap packing materials (plastic, cardboard, polystyrene etc) according

to the provisions set out by current standards. Keep nylon or polystyrene

bags out of children’s reach.

• Keep the instructions together with the technical brochure for future

reference.

• This product was exclusively designed and manufactured for the use

specied in the present documentation. Any other use not specied in

this documentation could damage the product and be dangerous.

• The Company declines all responsibility for any consequences resulting

from improper use of the product, or use which is different from that

expected and specied in the present documentation.

• Do not install the product in explosive atmosphere.

• The Company declines all responsibility for any consequences resulting

from failure to observe Good Technical Practice when constructing closing

structures (door, gates etc.), as well as from any deformation which might

occur during use.

• The installation must comply with the provisions set out by the following

European Directives: 2004/108/EEC, 2006/95/EEC, 98/37/ECC and

subsequent amendments.

• Disconnect the electrical power supply before carrying out any work on

the installation. Also disconnect any buffer batteries, if tted.

• Fit an omnipolar or magnetothermal switch on the mains power supply,

having a contact opening distance equal to or greater than 3 mm.

• Check that a differential switch with a 0.03A threshold is tted just before

the power supply mains.

• Check that earthing is carried out correctly: connect all metal parts for

closure (doors, gates etc.) and all system components provided with an

earth terminal.

•

The Company declines all responsibility with respect to the automation safety

and correct operation when other manufacturers’ components are used.

• Only use original parts for any maintenance or repair operation.

• Do not modify the automation components, unless explicitly authorised

by the company.

• Instruct the product user about the control systems provided and the

manual opening operation in case of emergency.

• Do not allow persons or children to remain in the automation operation area.

• Keep radio control or other control devices out of children’s reach, in

order to avoid unintentional automation activation.

• The user must avoid any attempt to carry out work or repair on the automa-

tion system, and always request the assistance of qualied personnel.

• Anything which is not expressly provided for in the present instructions,

is not allowed.

• This application is not meant for use by people (children included) with

impairedmental, physicalorsensorycapacities, orpeoplewho donothave

suitable knowledge, unless they are supervised or have been instructed

by people who are responsible for their safety.

3) TECHINCAL SPECIFICATIONS

Mains power supply:....................................................230V~ ±10%, 50Hz*

Motor current: .......................................................................................... 2A

Motor power:.......................................................................................470W

Number of storable radio-controls: ...........................................................63

Reception frequency:.................................................................433.92MHz

Current for external attachments:....................................................... 70mA

Maximum Number of zones with wire control (master):: ..................8 o 127

Max. connection length:.......................................................................250m

Weight: ....................................................................................350g approx

(* other voltages available on request).

4) WIRING

WARNING! For connection to the mains, use a multipolar cable having

a minimum cross section of 3x1.5 mm2and complying with the current

standards. (For example, if the cable is not protected, it must be at least

equal to H07 RN-F, whereas if it is protected it must be at least equal

to H07 VV-F with a 3x1.5 sq mm2cross section).

WARNING: Wiring must be carried out by qualied, expert personnel in

a professional manner and in accordance with all regulations in force,

using appropriate materials.

Adisconnectingswitch mustbeinstalledupline fromthesystemwith acontact

separation of at least 3 mm and offering a thermal-magnetic and differential

protection capacity that is adequate for the equipment’s power demand. For

wiring, use only cables that meet harmonized or national standards and

have a cross-section coordinated with the safety devices upline, with the

equipment’s power demand and with installation conditions.

When running cables to the motor assembly for connection of accessories,

safety devices and controlgear, keep mains power wiring well separated

from low-voltage accessory wiring. To ensure there are no breaks in the

earth circuit, connect the actuator’s earth wire to the earth wire of the

power supply using the relevant terminal provided.

Serial line connections to produce a hardwired centralized control system

must be made using only twisted pair cabling of the kind used for telephone

systems.Whenusinga telephone cablewithmorethanonepair,it is essential

to use wires from the same pair.

The length of the telephone cable between one unit and the next must

not be greater than 250 m.

Control buttons musthavemarkingstoshowtheactualdirectionof movement.

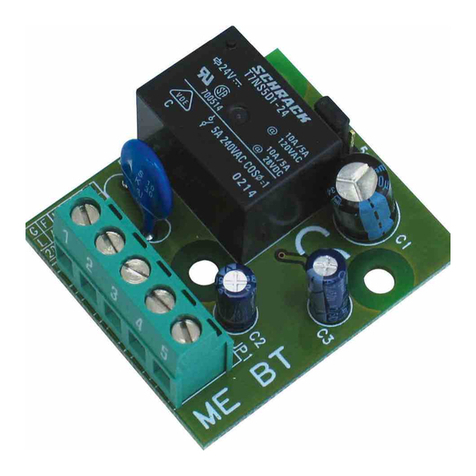

In the event you are connecting devices to the STOP and PHOTOCELL

terminals, you will need to remove the factory-connected jumpers. If

several devices are to be connected to one of these inputs, they must

be connected in series with each other.

TERMINAL

DESCRIPTION

1-2 Single-phase mains power (1=N, 2=L)

3-4-5

Motor connection:

3 start 1 + capacitor

4 common

5 start 2 + capacitor

6-7 OPEN/START INPUT (N.O.)

6-8 CLOSE INPUT (N.O.)

6-9

STOP/WIND SENSOR INPUT

A STOP control can be connected to this input, or a wind

sensor can be connected to provide automatic closing when

wind speed reaches a settable threshold. The setting is

made by adjusting DIP switches n° 1 and 2.

6-10 PHOT INPUT (N.C.)

The safety device operates locally only.

6-11

TWILIGHT SWITCH INPUT (N.O.)

Atwilight switch can be connected to this input to provide automatic

opening and closing as environmental light conditions change.

Whenthecontactcloses,aclosecommandissenttotheactuator;

when the contact opens again, the actuator is made to open.

12-13 24V~ max. 70mA output - power supply to photocells or

other devices.

14-15 Antenna input for built-in radio-receiver board

(14: SIGNAL. 15: BRAIDING)

5) ADJUSTING PARAMETERS AND OPERATING LOGIC

5.1) ADJUSTING OPERATING TIME AND AUTOMATIC CLOSING TIME

TW trimmer (g. 1): operating time adjustable from a minimum of 10 sec. to

a maximum of 240 sec..

TCA trimmer (g. 1): automatic closing time adjustable from a minimum of 3

sec. to a maximum of 180 sec..