- 25 -

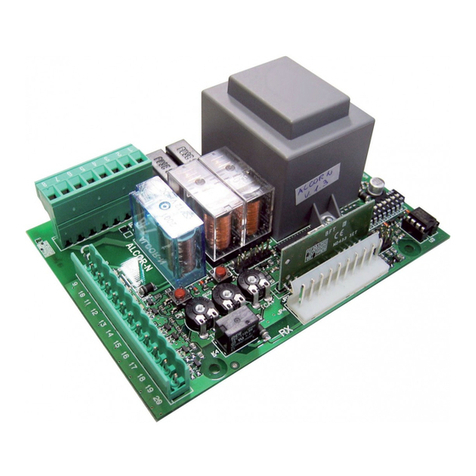

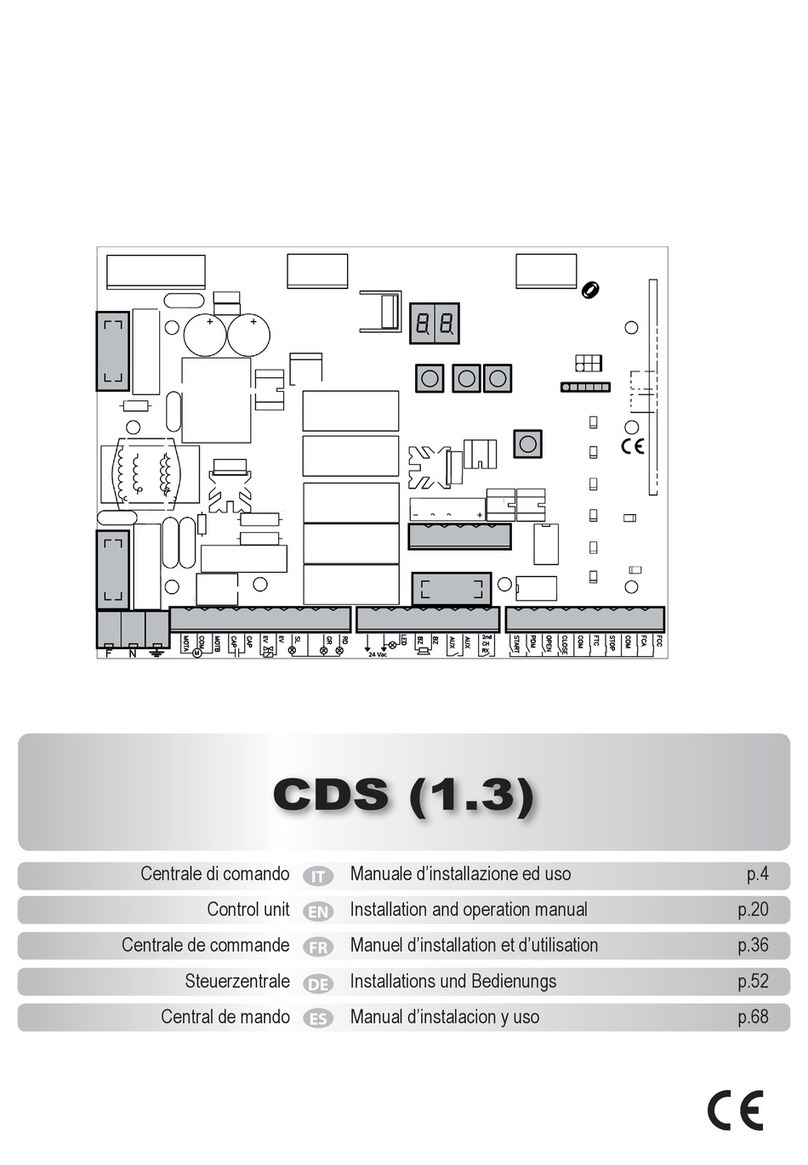

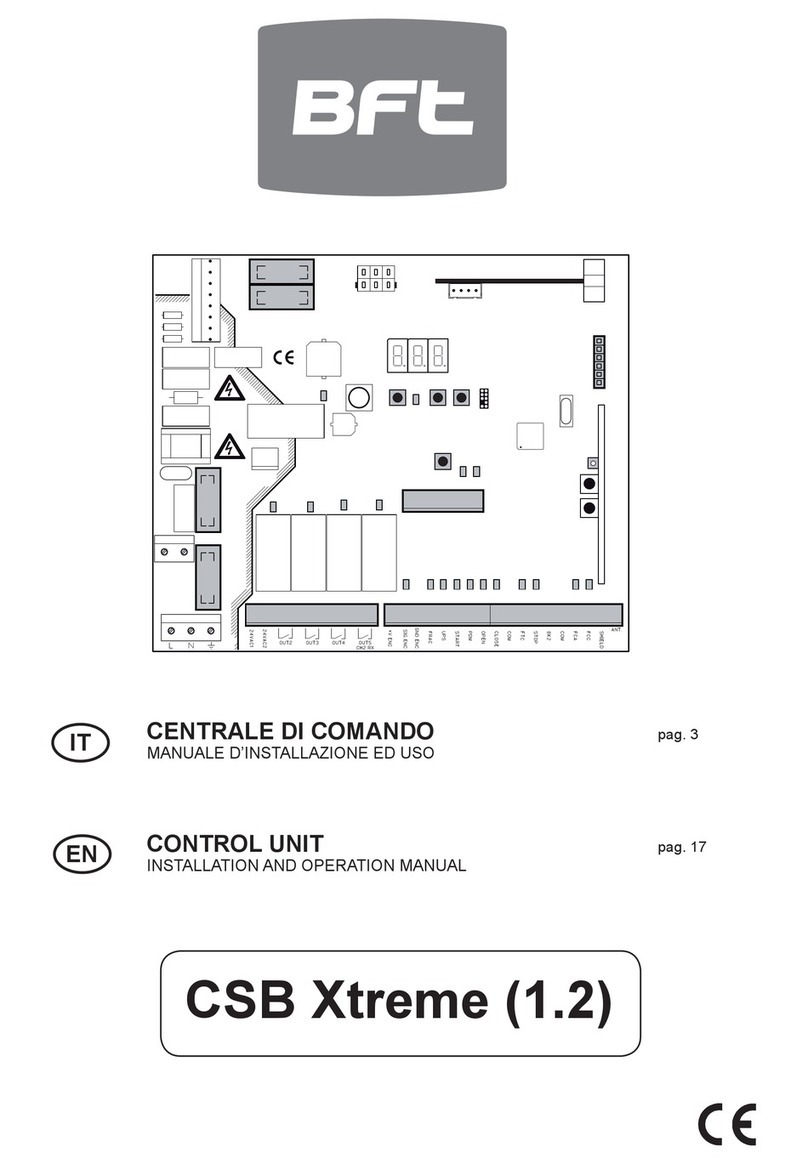

Control unit

EN

ENGLISH

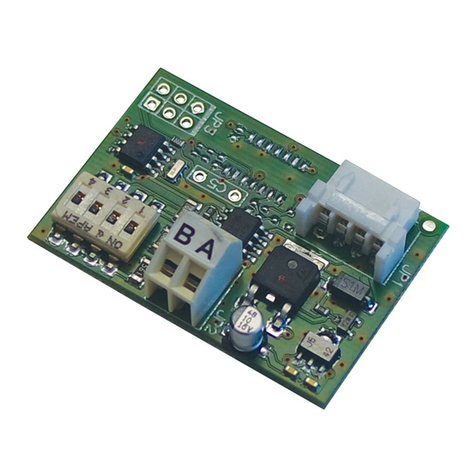

6. INPUT AND OUTPUT FUNCTIONALITY AND CONNECTIONS

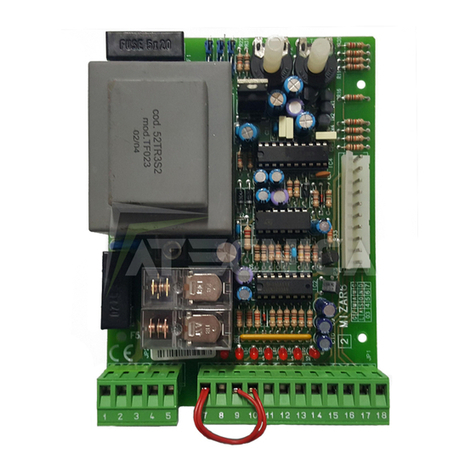

6.1 J2 POWER TERMINAL BLOCK

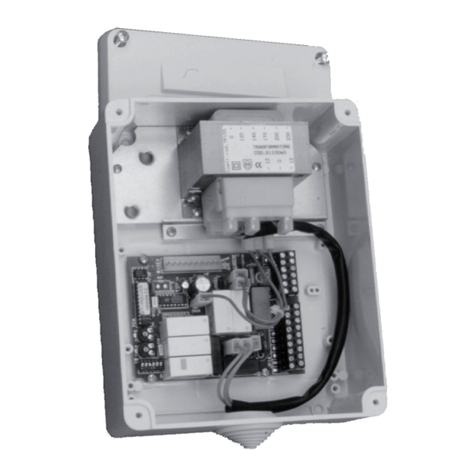

3.1 CONTROL PANEL DIMENSIONS

3. TECHNICAL SPECIFICATIONS

- Power supply: 230Vac +-10%, 50/60Hz

- Motor output: 230Vac; 13A max

- Flashing light/trac light: 230Vac; 40W max

- Accessory output: 24Vac; 1A max

-Operating ambient temperature -25° +60° C

4. INSTALLATION SAFETY

In order to reach the level of safety required by current regulations, read the following prescriptions carefully.

1) Make all connections in the terminal block after carefully reading the instructions given in this manual and observing the general

rules and technical standards governing electrical systems.

2) Upstream from the installation, t an omnipole miniature circuit breaker with a contact gap of at least 3 mm.

3) If there isn’t one already, install a residual current device with a threshold of 30 mA.

4) Check the eectiveness of the grounding system and connect to it all the parts of the automation tted with a terminal or grounding

cable.

5) Fit at least one external warning device, such as a trac light or ashing light, along with a warning or danger sign.

6) Fit all the safety devices required by the type of installation, taking into consideration the risks it can cause.

7) Separate the power lines (min. sect. 1.5 mm2) from the low-voltage signal lines (min. sect. 0.5 mm2) in the ducts.

LINE 230V

230V 50/60Hz power supply with varistor internal protection and 5A T (5x20) plus 16A T (6.3x32) fuses.

Connect the phase and neutral as shown on the screen printing. Use a cable type H07RN-F 2x1.5+E min.

Connect the yellow/green wire of the power supply mains to the earth terminal of the appliance.

5. PRELIMINARY OPERATION

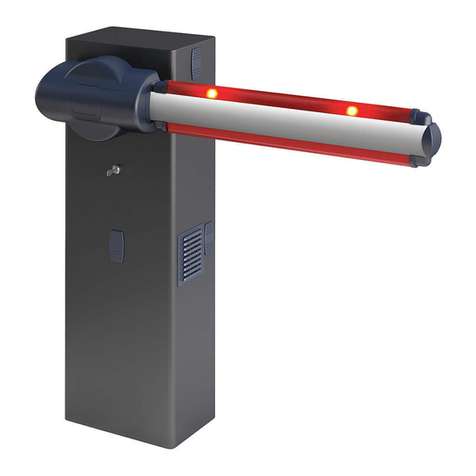

BOLLARD TABLE

LN E

-Operating ambient humidity up to 95%

non condensing

-Protection degree IP55

-Storage ambient temperature -25° +60° C

- Before sending a command to the automation, make sure to have selected correctly the type of bollard as follows:

Bollard selection

- Hold down buttons F and + for 5 seconds to select the connected bollard.

- Select the type of bollard using the buttons +/-.

- Press F and + to conrm.

- Select network frequency through Ht parameter. (see 3rd level programming).

- (Hydraulic bollards only) Select the pressure switch type with the parameter 33(see 3rd level programming).

- Check the connection method for simultaneous operation, if controlling multiple deterrent devices simultaneously (see paragraph 10).

*

PILLAR B 275/600

(

EASY Ø115-500 - STOPPY B 115/500

R

STOPPY Ø210-500

*

PILLAR B 275/800 - XPASS B 275/800C

(

EASY Ø200-700 - STOPPY B 200/700

R

STOPPY Ø210-700

+

PILLAR B 275/600.6C SD

)

NOT AVAILABLE

8

NOT AVAILABLE

+

PILLAR B 275/800.6C SD - XPASS B 275/800C SD

,

NOT AVAILABLE

8

NOT AVAILABLE

+

XPASS B 1200C

&$

NOT AVAILABLE

*

NOT AVAILABLE

'

STOPPY MBB 219-500.C

&%

NOT AVAILABLE

'

STOPPY MBB 219-700.C