320

FR95

FR95

AUTOMATION FOR INDUSTRIAL SECTIONAL DOORS

AUTOMATION FOR INDUSTRIAL SECTIONAL DOORS

D811170_03

We declare that this product is in conformity with the following European

Directives:

89/336/EEC (amended by RL 91/263/CEE, 92/31/CEE and

93/68/EEC),73/23/CEE (amended by RL 93/68/CEE).

1) GENERAL OUTLINE

This controller has been designed to motorize residential and industrial sec-

tional doors.

The compactness and versatility of the installation allow the motor drive to be

fitted in a variety of ways.

The controller is available in the following versions:

FR95-C Version with possibility of manual chain-opening and

closing.

FR95-CM Version with possibility of manual chain-opening and

closing and release mechanism for maintenance (the

release mechanism disengages the drive from the

cable winder shaft of the door).

FR95-SB Version with quick release for fast manual opening and

closing. The door should be perfectly balanced.

Safety microswitches protect each manual manoeuvre command.

The motor is supplied with an electro-mechanical brake to make the gear-

motor irreversible.

2) TECHNICAL SPECIFICATIONS

VOLTAGE Single-phase 230V ±5% 50Hz

Three-phase 400V ±5% 50Hz

ABSORPTION Single-phase 1.7 A

Three-phase 0.8 A

POWER Single-phase 0.25 Kw (Hp = 0.33)

Three-phase 0.33 Kw (Hp = 0.45)

MOTOR 1400 RPM (revs./min)

CAPACITOR 12.5 µF+16 µF (starting)

BRAKE Mechanical

INSULATION CLASS F

THERMAL PROTECTION 130°C self-resetting

REDUCTION GEAR OIL AGIP ALER 68

REDUCTION GEAR RATIO 1/43

OUTPUT REVS. 33 RPM

THROUGH-SHAFT 1” (Ø. 25.4 mm)

SPEED 8m/min with Z=18 1/2” x 5/16” (fig.4)

MAX DOOR WEIGHT Single-phase 350 daN (Kg)=25 m

2

Three-phase 700 daN (Kg)= 40 m

2

TORQUE PROVIDED Single-phase 5 daN (Kgm)

Three-phase 6 daN (Kgm)

IMPACT REACTION Stop and reverse (with pressure

sensitive edge)

DRIVE Link chain or direct drive

LIMITING DEVICES Built-in limit switches

CONTROL UNIT Mizar (single-phase)

Sirio TN1 (single-three-phase)

MANUAL MANOEUVRE With chain for FR-C/CM

Rapid for FR95-SB (FR95-CM)

NUMBER OF MANOEUVRES 100 Manoeuvres/24h

WORKING TEMPERATURE -15 + 60° C

PROTECTION IP 55

CONTROLLER WEIGHT 9 Kg

DIMENSIONS See fig. 1

3) INSTALLATION OF AUTOMATION

Preliminary checks

Check the balancing of the door.

Check that the door slides along the whole of its stroke.

Check the safety devices (parachute-type, cables etc.).

If a new door is not being installed, check whether the door and its compo-

nents are worn.

Repair or replace any worn or damaged parts.

Automation reliability and safety are directly influenced by the condition of the

sectional door’s structure.

4) CONTROLLER INSTALLATION

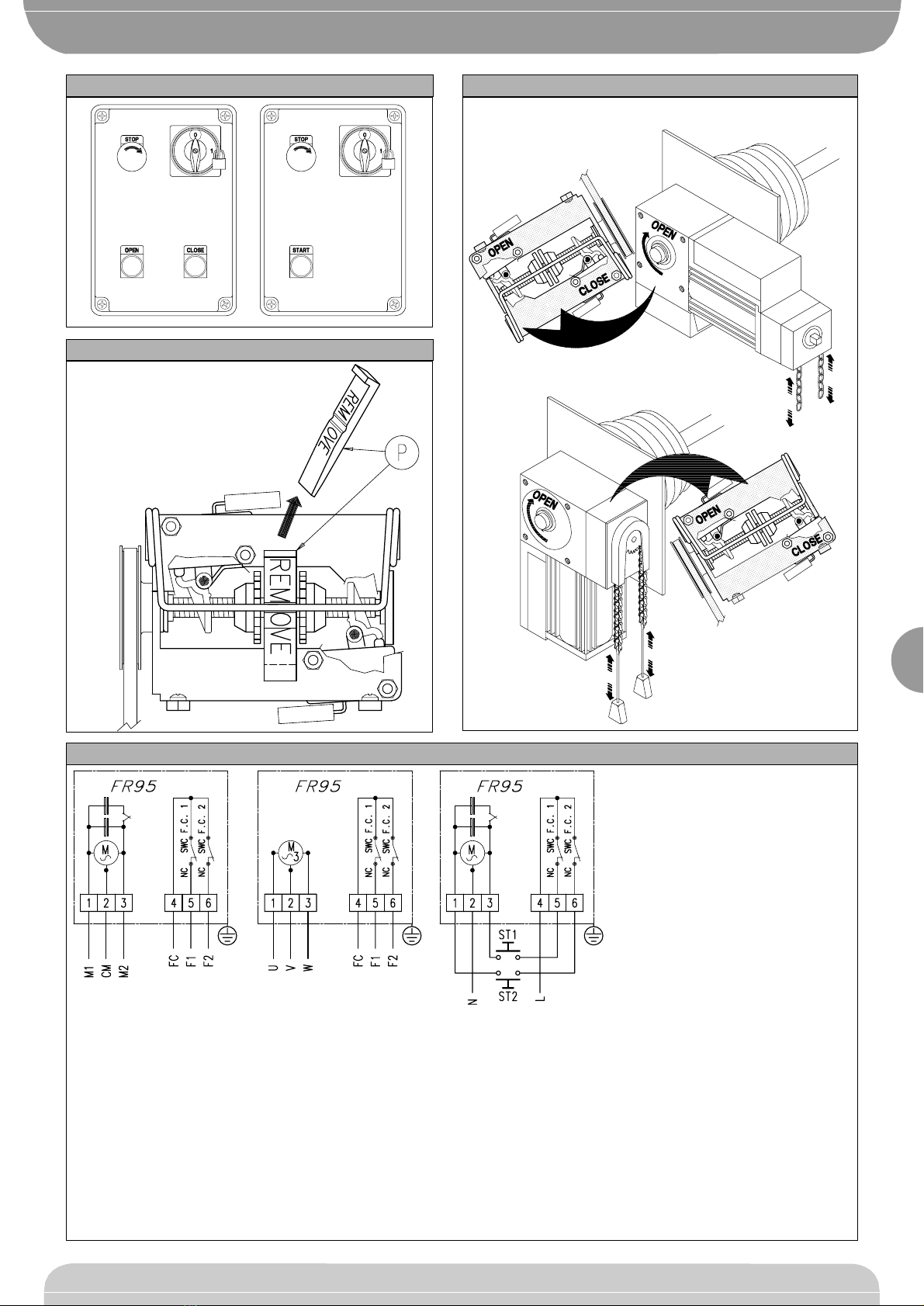

WARNING: Before fastening the controller, check whether the protection

wedge “P” (fig. 10) is present in the adjustment limit switch unit. The protec-

tion wedge prevents damage to the limit switch unit when manual opening

checks are made before adjusting the limiting microswitches.

The controller can be installed on both the right or left of the sectional door.

Direct drive

The cable winder shaft of the sectional door (Ø = 1” Ø 25.4 mm) should have

a key way and can be inserted directly into the through shaft of the controller.

The controller is directly fastened to the cable winder shaft support (fig. 2) or

to the wall using special brackets. Some manufacturers of sectional doors

supply joints with shaft for these types of motor drives.

This type of installation is suitable for sectional doors with cable winders,

which have a diameter not exceeding 80 mm in order to comply with the max-

imum speed of movement required by current standards (e.g.: in Italy the

maximum speed for UNI8612 standards is 8m/min).

Drive with reduction ratio.

The cable winder shaft is driven by a chain drive which may have reduc-

tion gears.

The gearmotor is fastened to the wall by means of the bracket provided

(fig. 3).

The drive dimensions should be in accordance with the diameter of the cable

winder for lifting the sectional door.

The vertical movement speed must correspond to the speed required by cur-

rent standards (e.g.: in Italy the maximum speed for UNI8612 standards is

8m/min).

E.g.: If the sectional door is fitted with a 140mm diameter cable winder, to

obtain an upstroke speed of approx. 8m/min, a crown wheel must be fitted

which has a pitch diameter

Øp= 140mm corresponding to a 36-tooth crown wheel for a 1/2" x 5/16" link

chain.

For this type of installation, a shaft with an 18-tooth pinion for a simple 1/2"

x 5/16" chain (fig. 4) can be supplied as an accessory.

The chain tension is adjusted by moving the motor along the grooves in the

anchoring bracket (fig. 5).

CAUTION: The chain drive should be protected in compliance with current

standards.

5) ELECTRICAL INSTALLATION SET-UP

Arrange the raceways for the connections as shown in fig. 6. Keep the power

supply connections separate from the limit switches connections.

Fit an omnipolar circuit breaker, with a contact opening of at least 3 mm,

which has protection against overloading and can be used to disconnect the

automation from the mains.

The Sirio-FR and Mizar-FR control panels are equipped with lockable cut-out

switches and fuses (fig. 7). A radio control single-twin channel receiver can be

inserted on the control boards.

Connection without the control unit can only be carried out in the single-

phase version and for “hold-to-run” control. Only use buttons with at least

10A-250V capacity (fig. 8).

6) CONNECTION TO TERMINAL BOARD

Fig. 8 shows the connection of the single-phase and three-phase gearmotor

to the terminal board.

For the electrical connection to the control unit, reference should be made to

the manual of the control unit.

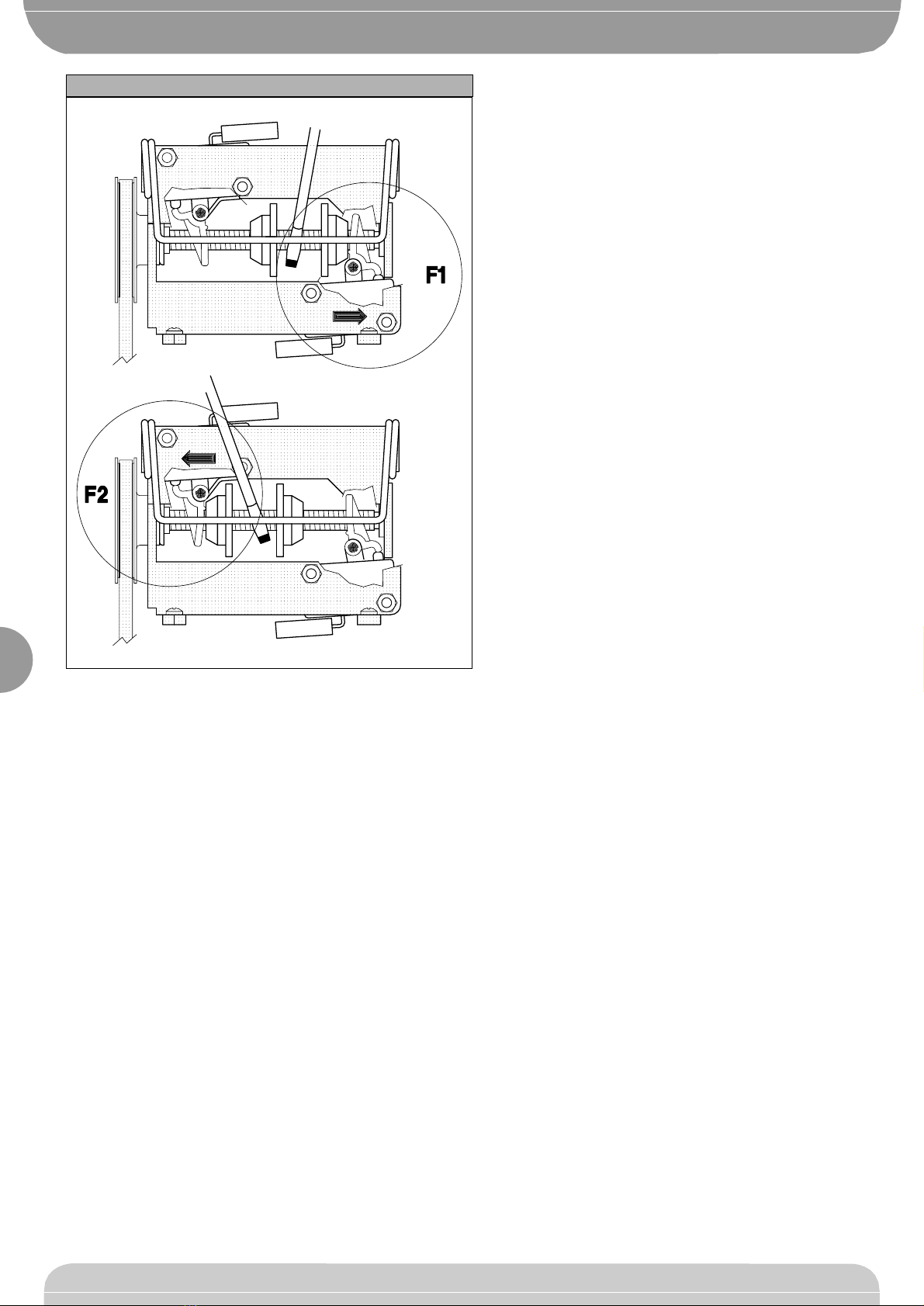

7) LIMIT SWITCH ADJUSTMENT (fig. 9)

The limit switch unit is situated on the head of the drive and is the system of

adjustment. To gain access to the adjustment unit, dismantle the pinion-type

quick release system, if any, and the box which covers the unit.

The microswitches are activated by two toothed cams which are locked in

position by a holding spring.

When the door is closed, the “door closed” adjustment cam should activate

the closing limit switch.

When the door is open, the “opening” adjustment cam should activate the

opening limit switch.

Fig. 9 shows the position of the closing and opening limit switches in relation

to the type of installation carried out.

If the adjustment cams are rotated towards each other, the stroke is

increased. If the adjustment cams are rotated away from each other, the

stroke is decreased.

The limit switch unit is equipped with a protection wedge “P” (fig.10) to pre-

vent damage to the limit switches during manual installation manoeuvres.

8) LIMIT SWITCH CAM ADJUSTMENT

WARNING: For safety reasons, microswitch adjustment must be carried out

with the power supply off.

The adjustment unit is fitted with four microswitches: 2 act as limiting devices

and 2 act as safety overstroke devices.

The overstroke microswitches, if intercepted by the cams, bring the system