INSTALLATION MANUAL

2) GENERAL OUTLINE

Centralizedgearmotor forbalancedrollerdoors,with adjustable electric opening

and closing limit switches.

Available in two versions, reversible (WIND RMB130B 200 - WIND RMB 170B200)

and irreversible (WIND RMB 130B 200EF), (WIND RMB 170B 200EF) and (WIND

RMB 350B 200 EF), the latter provided with electric brake.

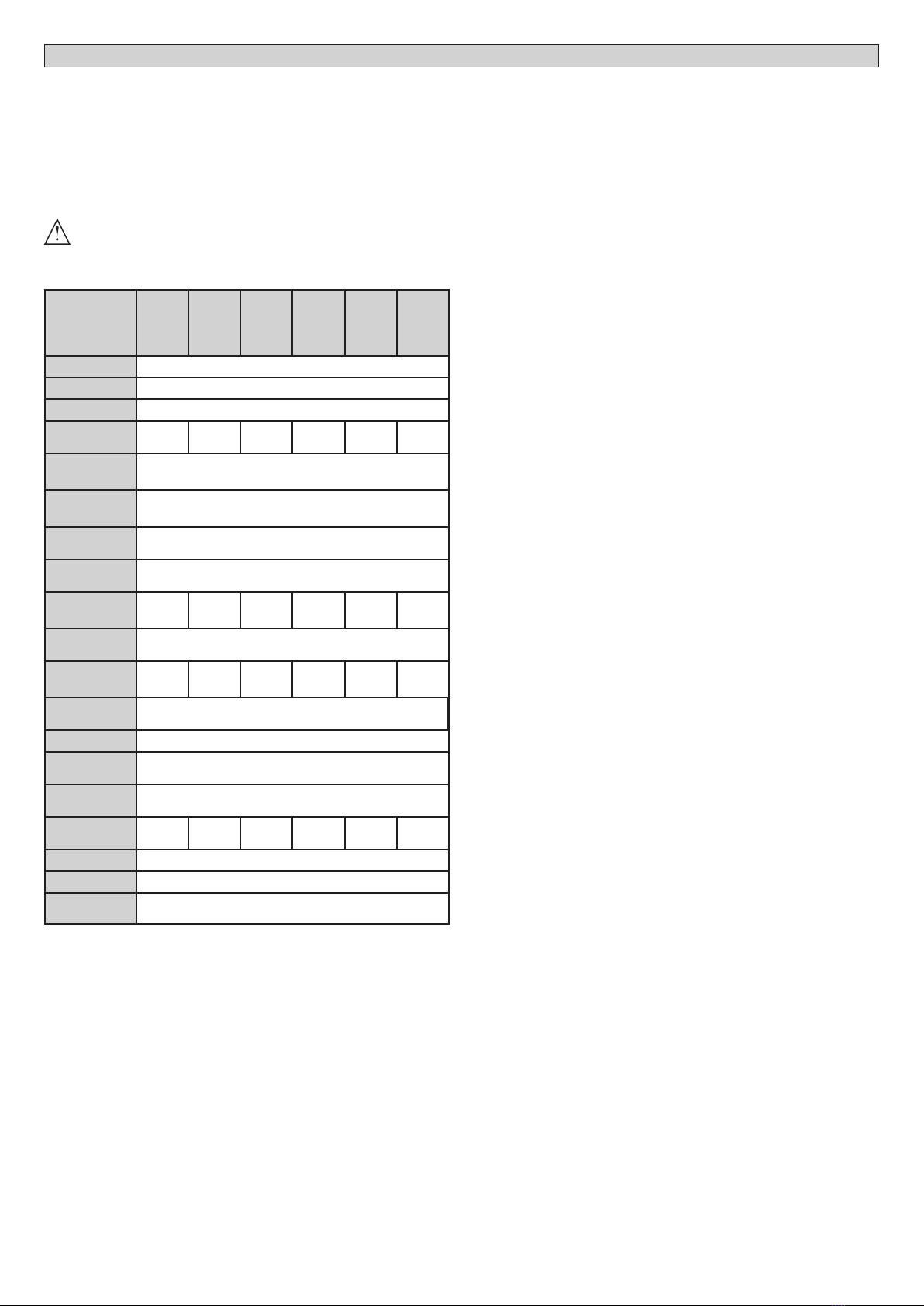

For irreversible versions, the emergency manoeuvre is carried out by means of

a knob attached to a wire.

Thegearmotorisprovidedfor42/48/60mmshaftsanda206/220mmfrictionpulley.

OnlyforUSA: motors intendedforgateswithoutUL Approving

shall not be installed on garage doors.“

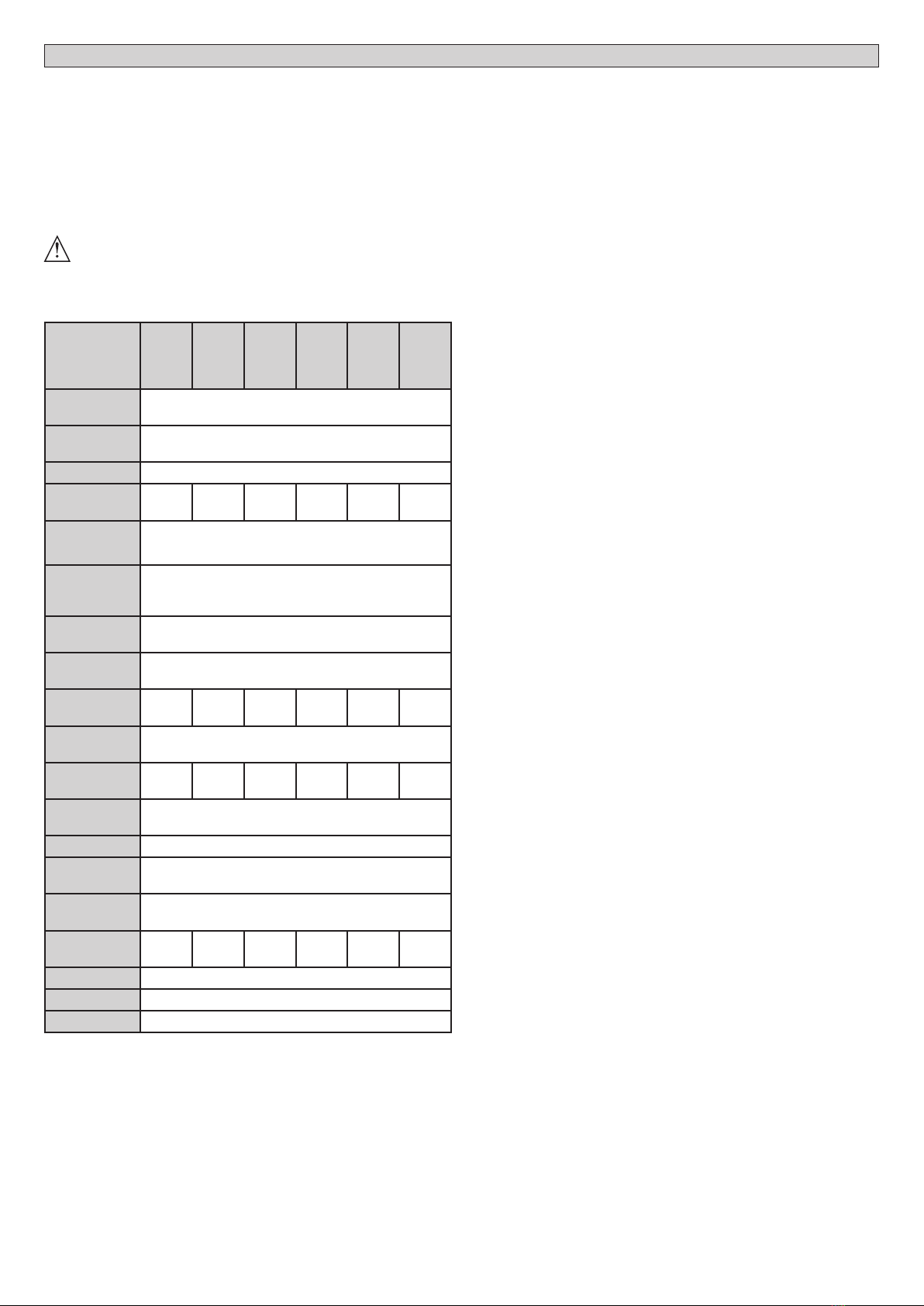

3) TECHNICAL SPECIFICATIONS

WIND

RMB

130B

200

WIND

RMB

130B

200 EF

WIND

RMB

170B

200

WIND

RMB

170B

200 EF

WIND

RMB

350B

200

WIND

RMB

350B

200 EF

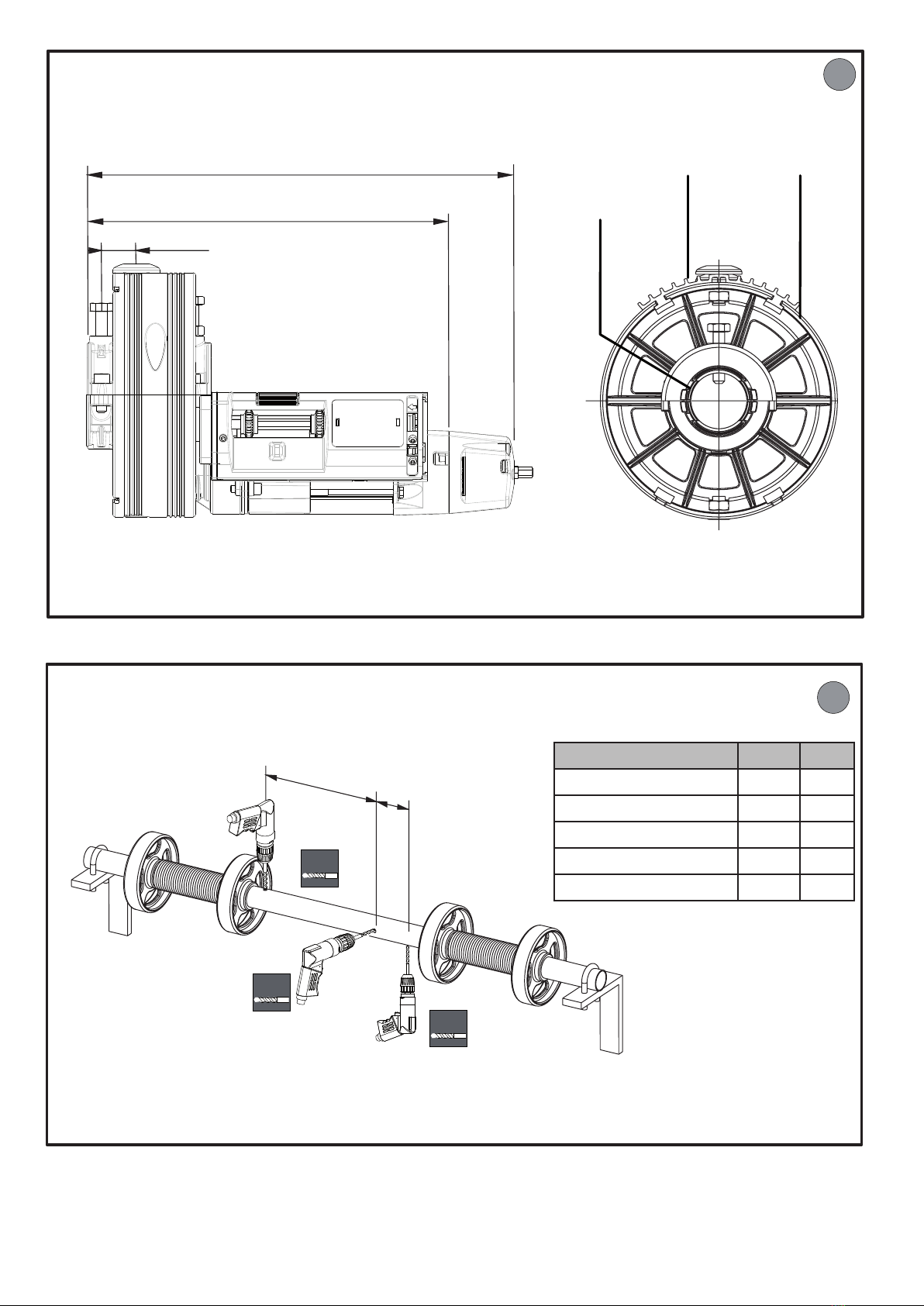

Pulleydiameter 206/220 mm

Pipe diameter 60/48/42 mm

Power supply 220-230V 50/60Hz.

Absorbed

power 400 W 400 W 600 W 600 W 1260 W 1260 W

Operating

time 4,5’

Shutter maxi-

mum stroke 6 M

Output shaft

revolutions 10min-1

Thermal

protection present

Capacitor 14 uF 14 uF 16 uF 16 uF 2x16

uF

2x16

uF

Reduction

gear lubrication

Permanent grease

Max. torque 110

Nm

105

Nm

178

Nm

168

Nm

367

Nm

357

Nm

Nominal

torque 5N

Limit devices Electromechanical, incorporated and adjustable

Working

temperature +5°C a + 40 °C

Degree of

protection IP20

Operator

weight 6,9 Kg 7,7 kg 12 kg 12,8 kg 11,5 kg 12,3 kg

Noise level <70dB(A)

Dimensions See g. B

Maximum

cycle 20 cycles/24 hours

(* other voltages to order)

4) ACCESSORIES

- LCK external safe for release

- X EF1 electronic brake kit to be installed on WIND RMB 130B 200-WIND RMB

170B 200-WIND RMB 350B 200 EF

5) PRELIMINARY CHECKS

Before tting the motor, remove any redundant ropes or chains, and disable any

unnecessary appliance.

Check that the roll-up door characteristics are compatible with the maximum

torque specied and the operating time.

Check the weight of the roll-up door, check the diameter of the spring-holder

boxes and the diameter of the spring-holder shaft.

Choose the model with or without closing lock, depending on which is more

suitable for the type of installation.

NOTE: All the models supplied without an electric brake can be tted with one

at a later time if required. (EF KIT).

Before carrying out the installation, carefully check that:

- the roll-up door structure is sturdy and rigid;

-

the roll-up door slides evenly along its entire stroke, without any friction.

- If the manoeuvre is dicult, grease the sliding tracks.

- Repair or replace the worn or faulty components.

- The motor’s moving parts must be installed at a height greater than 2.5 m

above the oor or other surface from which they may be reached.

- Thegearmotormustbeinstalledinasegregatedandsuitablyprotectedspaceso

that it cannot be reached without the aid of tools.

The operator reliability and safety is directly aected by the condition of

the roll-up door structure.

Motor drive only facilitates operation and does not solve the problems caused

by defective or decient installation or failed maintenance of the roll-up door.

6) INSTRUCTIONS FOR FITTING 1 GEARMOTOR

1)Drillintheshutter’scentralshaft(Fig.C)oneholeØ10mm.inordertheoperator

doesn’t turn, and another Ø 12 mm. for the electric wire. If possible, place the

operator in the centre of the shutter’s shaft in an easy position for opening the

micro-switches lid to make the wire and the regulation of the limit switches.

In case of electric brake, make another drill of Ø 10 mm. for the cable of the

manual release.

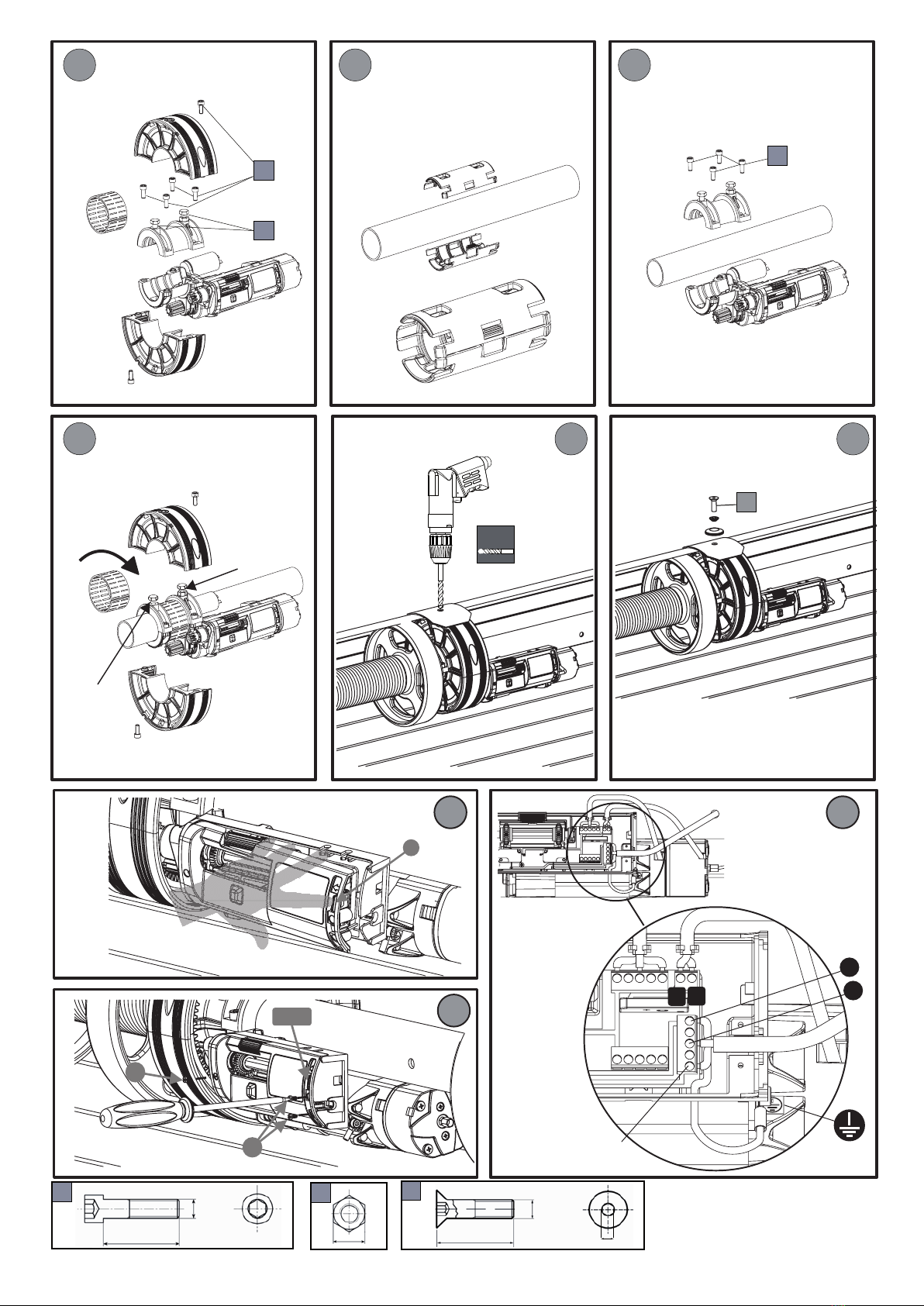

2) Open the pulley unscrewing the M8x25 screws remove the plastic roller band

without folding it and keep it in a clean place. Separate the gear-motor’s body

removing the 4 screws with the 6mm. (g. D). hexagonal wrench.

Couple the two parts of the gear-motor around the door’s shaft and joint them

screwing the 4 screws on the gear-motor’s support (g. E-F).

Tighten the M10x40 screw (Fig. G) entering it into the Ø 10 mm. hole of the

shutter’s shaft.

Put again the plastic roller band in its place.

3) The operator should be xed, lined and the pulley must turn freely.

Make a hole Ø 10 mm. in the last canvas of the roll-up door at the same location

of the hole and nut M10 of the pulley (Fig. H). If the roll-up door is waved or

not regular, it is necessary to couple a at metal piece of 1 meter to the pulley.

Travel the electric cable trough the shaft’s hole de Ø 12 mm. Avoiding any

contact with the rotating parts and make the wires. In case of motor with

electric brake travel also the brake cable through the hole of Ø 12 mm. drilled

in the shaft, and mount the manual release.

For a proper release the exible cable of the brake should not do any exag-

gerated curve.

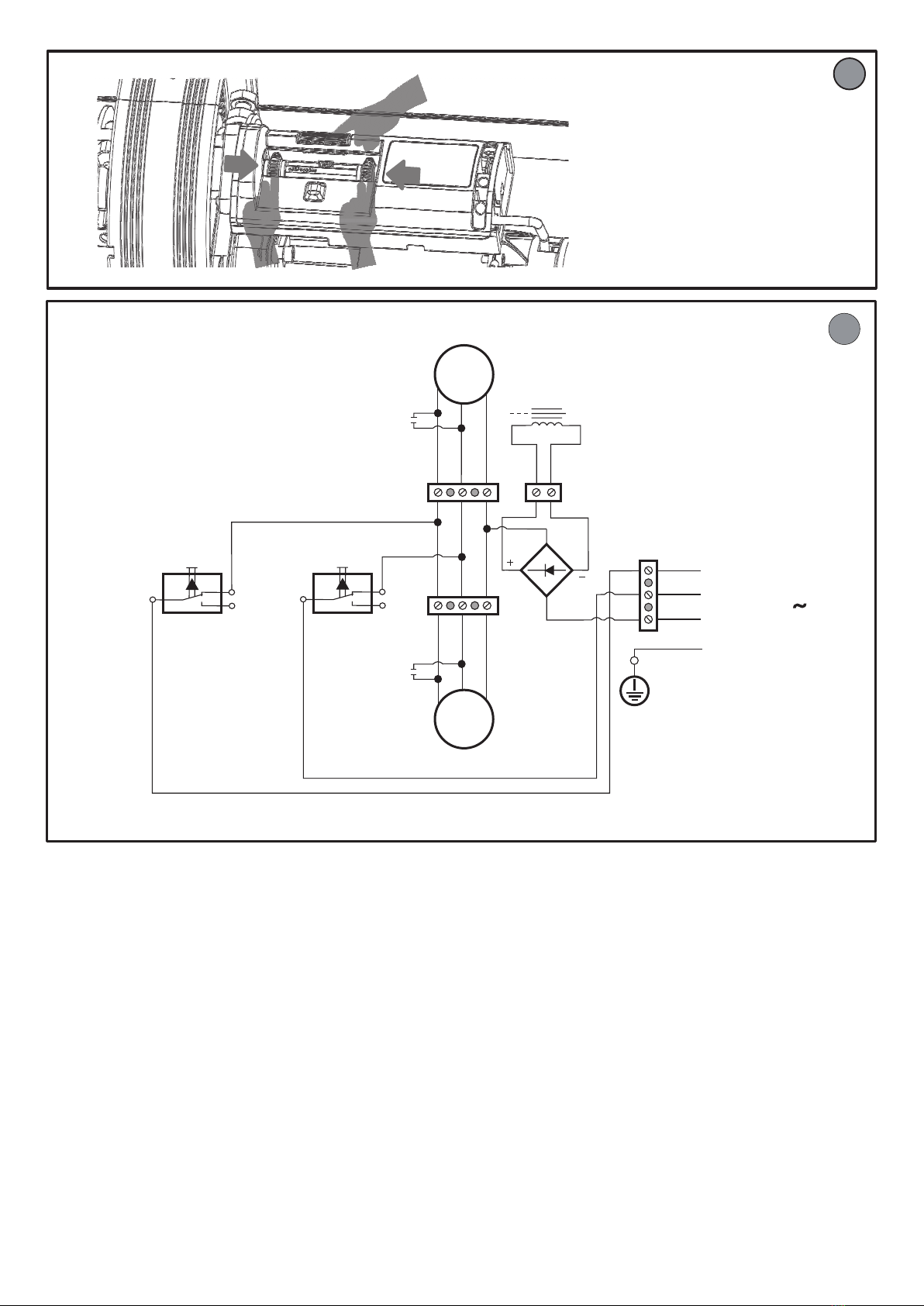

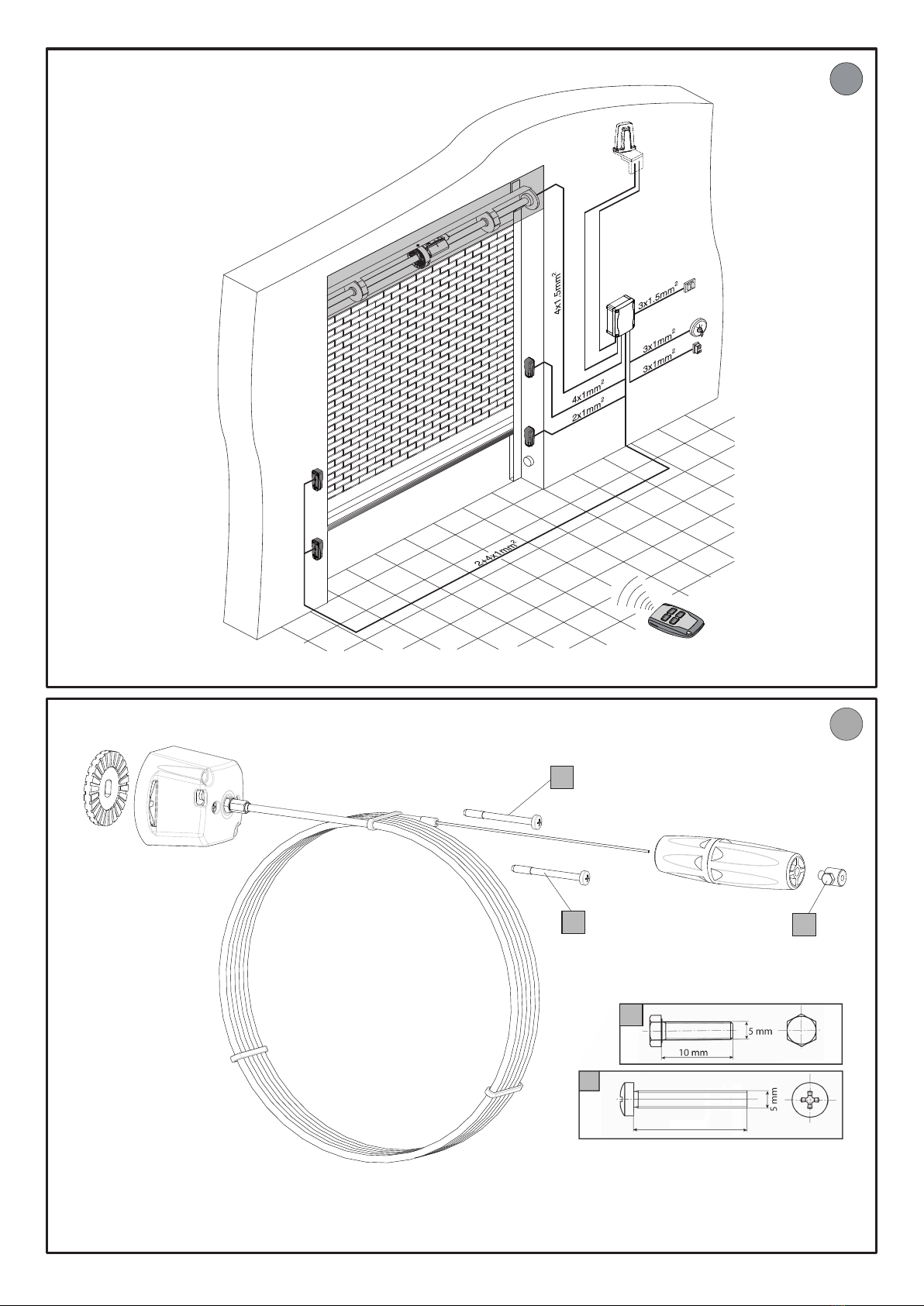

7) ELECTRIC INSTALLATION SETUP

Provide electrical installation complying with the CEI standards actually in force.

The power supply connections must be kept totally separate from the service

connections (photocells, safety edges, control devices etc.).

WARNING! For the connection to the power supply, use a multipolar cable

having minimum 4x1.5 sq mm cross section and complying with the previ-

ously mentioned regulations (for example, if the cable is not protected it

must be at least equal to H07 RN-F, whereas if it is protected it must be at

least equal to H05 VV-F with a 4x1.5 sq mmsection).

Connect the control and safety devices in compliance with the standards actually

inforce.Fig.Oindicatesthenumber ofconnections andthecrosssectionforpower

supply cables approximately 100 metre long; in case of longer cables, calculate

the cross section for the true operator load. When the auxiliary connections are

over 50-metre long or pass through critical disturbance areas, it is recommended

to decouple the control and safety devices by means of suitable relays.

These are the main components for an operator (g. O):

I) Type-approved omnipolar circuit breaker having adequate capacity,

with at least 3,5 mm contact opening, provided with protection against

overloadsandshortcircuits,suitableforcuttingouttheoperatorfromthe

power supply mains. If not already present, a type-approved omnipolar

switch with a 0.0.3 A threshold should be installed in the circuit before

the operator.

QR) Control panel and incorporated receiver

S) Key selector

AL) Blinker

M) Operator

CS) Safety edge

CC) Edge control device

Ft, F) Pair of photocells

T) 1-2-4 channel transmitter.

8) ELECTRIC WIRE (Fig. J-K)

Todoconnectionsremoversttheprotectinglid ofthelimit switches[Fig.J]Travel

the electric cable through the stung box and do the wires. It is very important

the correct wiring of the common (N blue) and the ground.

SAFETYRULE:theelectriccablemustbe connectedupline withan all-polediscon-

nect device with a minimum contact clearance of 3.5 mm. In the type WIND RMB

130B 200 EF, WIND RMB 170B 200 EF e WIND RMB 350B 200 EF with brake the

electric brake is yet wired. In case of no brake it is compulsory a jumper between

the two terminals [Fig.N]. For tting the electric brake, remove the jumper and

connect the two wires of the reel [Fig.N].

9) CHECKING THE OPERATION DIRECTION (Fig. M)

Place the closing stop collar (Fig.M) next to press the micro-switch. Switch on

8- WIND RMB 200 B

D814092 4BA96_06