JOINT - Ver. 02 -

9

D811292_02

2) GENERAL OUTLINE

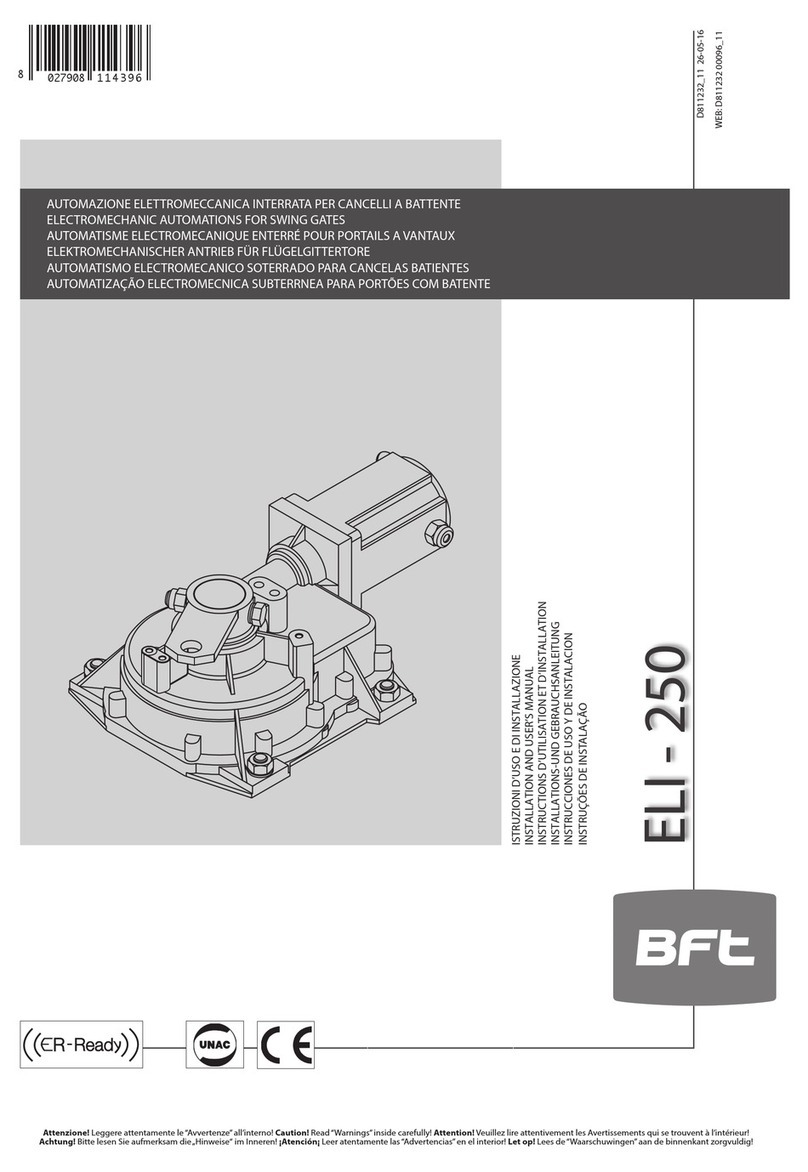

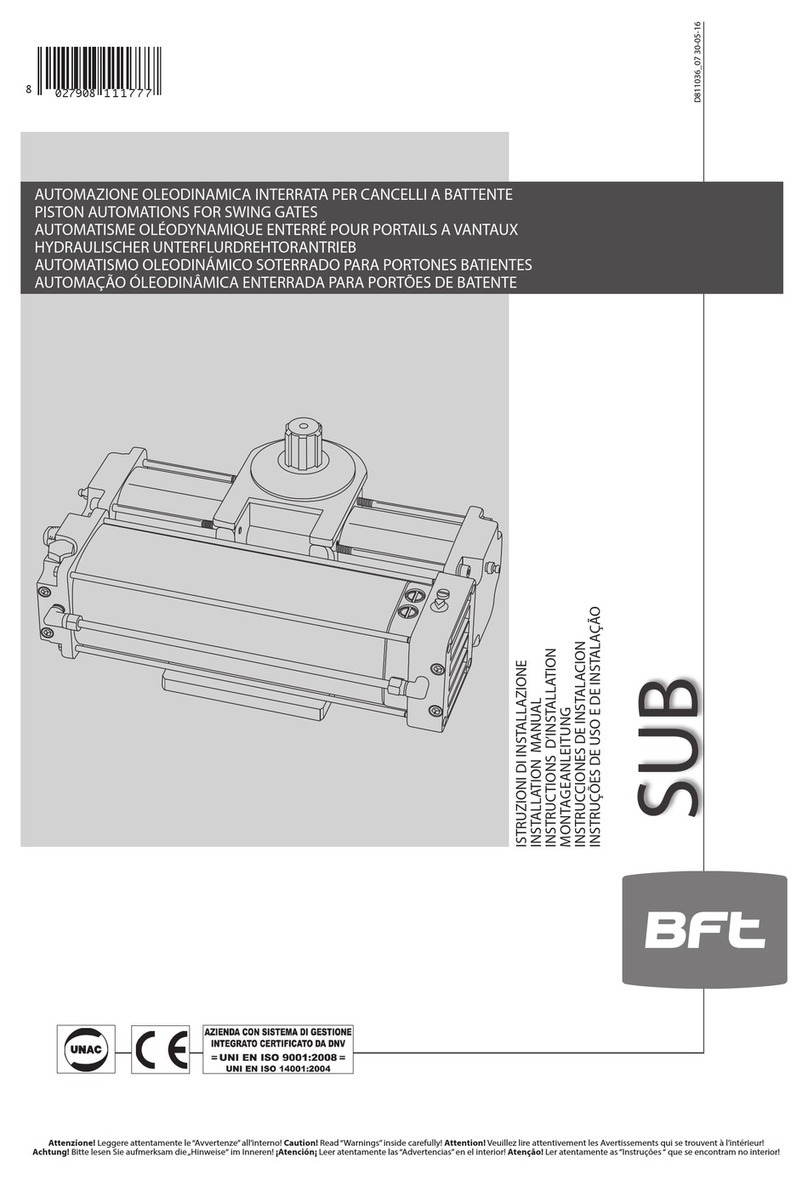

This controller is suitable for residential use and has been designed for

swing gates with particularly large gate posts. The drive arm, built with a

special anti-shearing shape, allows the leaves to be moved when the

controller is considerably out of place with respect to the fulcrum of the

leaves. The non-reversible electro-mechanical gearmotor maintains the

stop during closing and opening. The release lever, fitted in each controller

and situated inside the door fitted with personalised key, allows the manual

manoeuvre to be easily carried out.

WARNING! The installation, the maintenance and the repair should be

done by responsible and qualified persons with an updated knowledge of

the current safety standards. It’s strictly forbidden to service the automation

when the power is on.

ATTENTION! The JOINT model controller is not equipped with mechanical

torque adjustment. It is compulsory to use a control panel of the same

manufacturer, in compliance with the basic safety requirements of directives

73/23/CEE, 89/336/CEE, 89/37/CEE equipped with appropriate electric

adjusment of the torque.

3) TECHNICAL SPECIFICATIONS

Voltage:....................................................................... 120V±10% 50Hz (*)

Motor: ....................................................................Single-phase 1400min-1

Power: ................................................................................................300W

Absorption: ........................................................ 1.7A (230V); 3,4A (120V)

Capacitor: ..................................... 10µF 450V (230V); 40µF 250V (120V)

Insulation class: ........................................................................................ F

Thermal protection: ........................... 266°F ........... (130°C) self-resetting

Lubrication: ................................................................... Permanent grease

Reduction ratio: ................................................................................. 1/812

Output revs.: .......................................................................... 1.7 min-1max

Output shaft: ................................................................. 20x20 hollow shaft

Opening time 90°: ................................................................................. 15s

Torque provided: ................. 320Nm (~32kgm)........236.01lbf/ft (~70.54lb)

Max. leaf weight and length:

for 2.5m leaf length................ 2000N (~200kg)........449.61 lbf (~440.92lb)

for 2m leaf length ................... 2500N (~250kg).........562.02lbf (~551.15lb)

Impact reaction: ................................... Electric clutch (with control panel)

Drive: ..........................................................................................Lever arm

Stopping:...................................................... Built-in electric limit-switches

Manual manoeuvre: ........................................ Door with personalised key

Number of manoeuvres: ................................................................ 100/24h

Working temperature: ................... -15 ÷+60 C..........................°59÷140°F

Protection: ......................................................................................... IP 44

Controller weight: ....... 160N (~16kg) 35.96 lbf .........................(~35.27 lb)

Dimensions: ..................................................................................See fig.1

*Special supply voltages on request buckle “M” of the operator. Refer to the

relevant instruction manual for connection of the control panel.

4) INSTALLATION OF AUTOMATION

Preliminary checks

Check:

- That the structure of the gate is rigid and strong enough. The fixing

position should be assessed according to the structure of the leaf. In any

case, the manoeuvring arm must push against a reinforced point in the

leaf (fig.2).

- That the leaves move manually for the whole of their stroke. If a new gate

is not being installed, check whether its components are worn.

Repair or replace any worn or damaged parts.

Automation reliability and safety are directly influenced by the condition

of the gate’s structure.

5) FIXING OF SUPPORTING PLATE (Fig.2)

The controller is supplied complete with anchoring bracket and lever arm.

Once the reinforcement point of the leaf has been identified with the gate

closed,drawan imaginary horizontal line from the centre of the reinforcement

point to the gate post (fig.2). Position the anchoring bracket according to the

values given in fig. 2 for openings of up to 90°or in fig.3 for openings greater

than 90°up to a maximum of 125°.

The bracket fixing position must be flat and parallel to the leaf. Use screws

or expansion bolts which are suited to the type of gate post. If the surface

of the gate post is not regular, use expansion bolts with studs so that the

parallel plate of the leaf can be adjusted (fig.4).

- Fasten the gearmotor to the gate post using the 4 screws, pointing the

gearmotor to the left or the right (fig.5).

- Assemble the lever arm as shown in fig.6.

DX= assembly on the right leaf

SX= assemby on the left leaf

Choose the most suitable position of ‘F’ bracket for the fastening to the leaf.

- Insert the square of the first lever in the output shaft of the gearmotor and

fasten it (fig.7).

- Release the controller by activating the release lever so that the arm can

move easily (see the “EMERGENCY MANOEUVRE” paragraph).

- The correct position for the controller arm is shown in fig.8. The leaf

fixing point “A” can be identified by positioning the arm so that it is in

accordance with the distance shown in fig.8.

- Fix the angular towing bar “A” to the leaf by welding or using screws.

- With the controller released, check the correct movement of the arm.

- Repeat the same operation for the other leaf, if installed.

6) ELECTRICAL INSTALLATION SET-UP

Arrange the electrical installation as shown in fig.9.

The power supply connections must be kept separate from the auxiliary

connections (photocells, sensitive edge, etc.). Fig.9 shows the cross-

section and the number of connections. CAUTION! Connection to the

mains must be carried out using the type of multipolar cable specified in the

standards (UL1015). In fig.10 you will find the junction-box of the operator

and the position of the cable holder which should be fixed with an adequate

tightening of the bolt. In case the motor tours in the opposite side, you

should invert the running buckle "M" of the operator. Refer to the relevant

instruction manual for connection of the control panel.

7) LIMIT SWITCH ADJUSTMENT

- Remove the casing of the limit switches.

- Identify the limit switches following fig.12 for the right-hand controller

and following fig.11 for the left-hand controller.

- Adjustthe opening and closing cams respectively with thegatecompletely

open and completely closed.

- Turn the identified cam until the intercepting limiting microswitch triggers

and lock the cam in position by tightening the screw.

- Make sure that limit switch intervention is correct and refit the cover

which was previously removed.

- Fit the casing.

- If the control unit has working time adjustment (TW), this should be

adjusted to a value which is slightly higher than the intervention of the

controller limit switches.

8) ADJUSTMENT OF LEAF PHASE DISPLACEMENT

In case of gates with two leaves, the control panel should include a delay

setting function on closing of the second leaf to guarantee a correct closing

manoeuvre. For the wiring of the motor which should close with a slight

delay, refer to the instructions for the control panel installed.

9) MOTOR TORQUE ADJUSTMENT

The adjustment of the motor torque (anti-squashing) is performed on the

control panel. See control unit instruction manual.

The adjustment should be set for the minimum force required to carry out

the opening and closing strokes completely observing, however, the limits

of the relevant standards in force.

CAUTION! Excessive torque adjustment may jeopardise the anti-squash

safety function. On the other hand insufficient torque adjustment may not

guarantee correct opening or closing strokes.

10) EMERGENCY MANOEUVRE

The emergency manoeuvre can be carried out form the inside by activating

the appropriate lever on each controller, as in fig.13, and pushing the panel

by hand. To restore motorised operation, turn the lever to its initial position

and close the hatch having a personalised key.

11) AUTOMATION CHECK

Before allowing the automation to be used normally, carry out the following

procedure very carefully:

- Check the correct functioning of all safety devices (limit microswitches,

photocells, sensitive edges etc.).

- Check that the thrust (anti-squash) force of the leaf is within the limits set

by current regulations.

- Check the manual opening command.

- Check the opening and closing operations with the control devices in use.

- Check the standard and customised electronic functioning logic.

12) AUTOMATION OPERATION

Since the automation can be remote-controlled by means of a remote

control device or a start button, and so out of sight, the good working order

of all the safety devices should be checked regularly. In the event of any

anomalous functioning of the safety devices, consult a specialised

technician immediately. Keepchildrenatasafe distance from the automation

operation area.

INSTALLATION MANUAL ENGLISH