2 - LUX FC

1) GENERALITA'

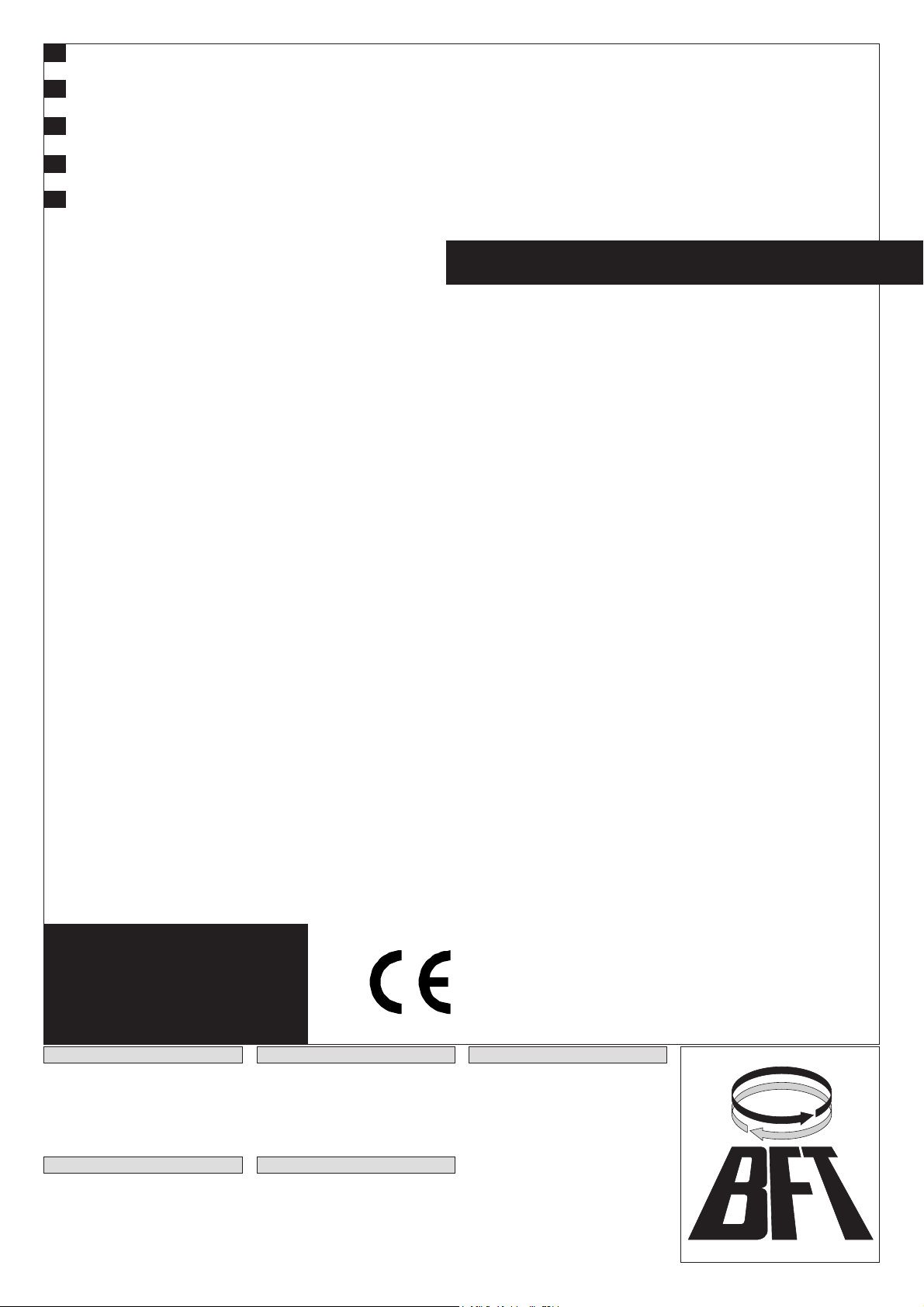

Versione LUX 2B ideale per cancelli senza fermo darresto centrale (per zone innevate o quando il cancello è molto alto dal suolo). Un particolare sistema

di molle interne, permette di mantenere il cancello bloccato in chiusura anche senza battuta darresto. Il sistema a molle (fig.1), evita allo stelo di andare

a finecorsa e mantiene lelasticità sufficiente a compensare la dilatazione dellolio dovuta agli sbalzi di temperatura climatici. In zone ventose, il blocco

in apertura, mantiene il cancello aperto. Se il cancello rimane aperto per tempi brevi (Max. TCA), si possono evitare i fermi d'arresto in apertura. In caso

contrario, consigliamo di adottore i fermi d'arresto in apertura.

1) GENERAL OUTLINE

LUX 2B is ideal for gates that do not have a central gate stop (for areas prone to snowfalls or when the gate is high above the ground). A special inner

spring-system (fig.1) keeps the gate locked in closed position even when there is no gate stop. The spring system prevents the rod from reaching the

end of its stroke and provides elasticity to compensate for the expansion of the oil caused by sudden changes in the outdoor te mperature. In windy places,

the open position lock keeps the gate open. If the gate only stays open for short amounts of time, opening gate stops do not need to be used. In all differente

condition, ex. the gate stays open for longer periods of time (Max. TCA), we recommend the use of gate stops for the open position.

1) GENERALITES

Version LUX 2B, idéale pour des portails sans butée darrêt central (pour des zones enneigées ou si le portail est placé très en haut par rapport au sol).

Un système spécial de ressorts internes (fig.1) permet de maintenir le portail bloqué en fermeture même sans butée darrêt. Le système à ressorts évite

à la tige daller à la fin de course et maintient lélasticité suffisante à compenser la dilatation de lhuile due aux écarts de température. Dans des régions

venteuses, le butée en ouverture maintient le portail ouvert. Si le portail reste ouvert pour de courtes périodes (Max. TCA), il est possible déviter les butées

darrêt en ouverture. Dans le cas contraire, nous conseillons dadopter les butées darrêt en ouverture.

1) ALGEMEINES

Version LUX 2B, ideal für Tore ohne Mittelfeststeller (für schneereiche Gebiete oder für Tore, die besonders hoch über dem Boden stehen). Durch ein

besonderes, internes Federsystem kann (Abb.1) das Tor auch ohne Anschlag in Schließposition gehalten werden. Das Federsystem hindert den Schaft

daran, den Endanschlag zu erreichen, und behält eine ausreichende Elastizität zum Ausgleich der Ölausdehnung durch klimatische

Temperaturschwankungen bei. In windigen Gebieten hält die Öffnungssperre das Tor offen. Wenn das Tor nur kurz (Max. TCA) offen bleibt, kann auf

die Feststeller der Öffnungsposition verzichtet werden. Andernfalls empfehlen wir die Feststeller der Öffnungsposition einzusetzen.

1) GENERALIDADES

Versión LUX 2B ideal para cancelas o verjas sin tope central de detención (para zonas nevadas o cuando la verja está muy alta respecto al suelo). Un

sistema especial de muelles en el interior (fig.1) permite mantener la verja bloqueada cuando está cerrada, aun sin tope. El sistema de muelles evita

que la barra vaya hasta el tope del recorrido y mantiene la elasticidad necesaria para compensar la dilatación del aceite debida a los cambios climáticos

que hacen variar la temperatura. En zonas con mucho viento, el bloqueo en apertura, mantiene la verja abierta. Si la verja permanece abierta durante

períodos breves (Max. TCA), se pueden evitar los topes de detención en apertura. Por el contrario, le aconsejamos de adaptar los toper de parada en

apertura.

2) DATI TECNICI

Alimentazione :230V±10% 50/60Hz

Motore :monofase 2800 RPM

Potenza assorbita :280W

Condensatore :6.3µF

Corrente assorbita :1.4 A

Massima pressione :30 BAR

Portata pompa :1.25L/min

Forza di spinta :3000 N

Forza di trazione :2600 N

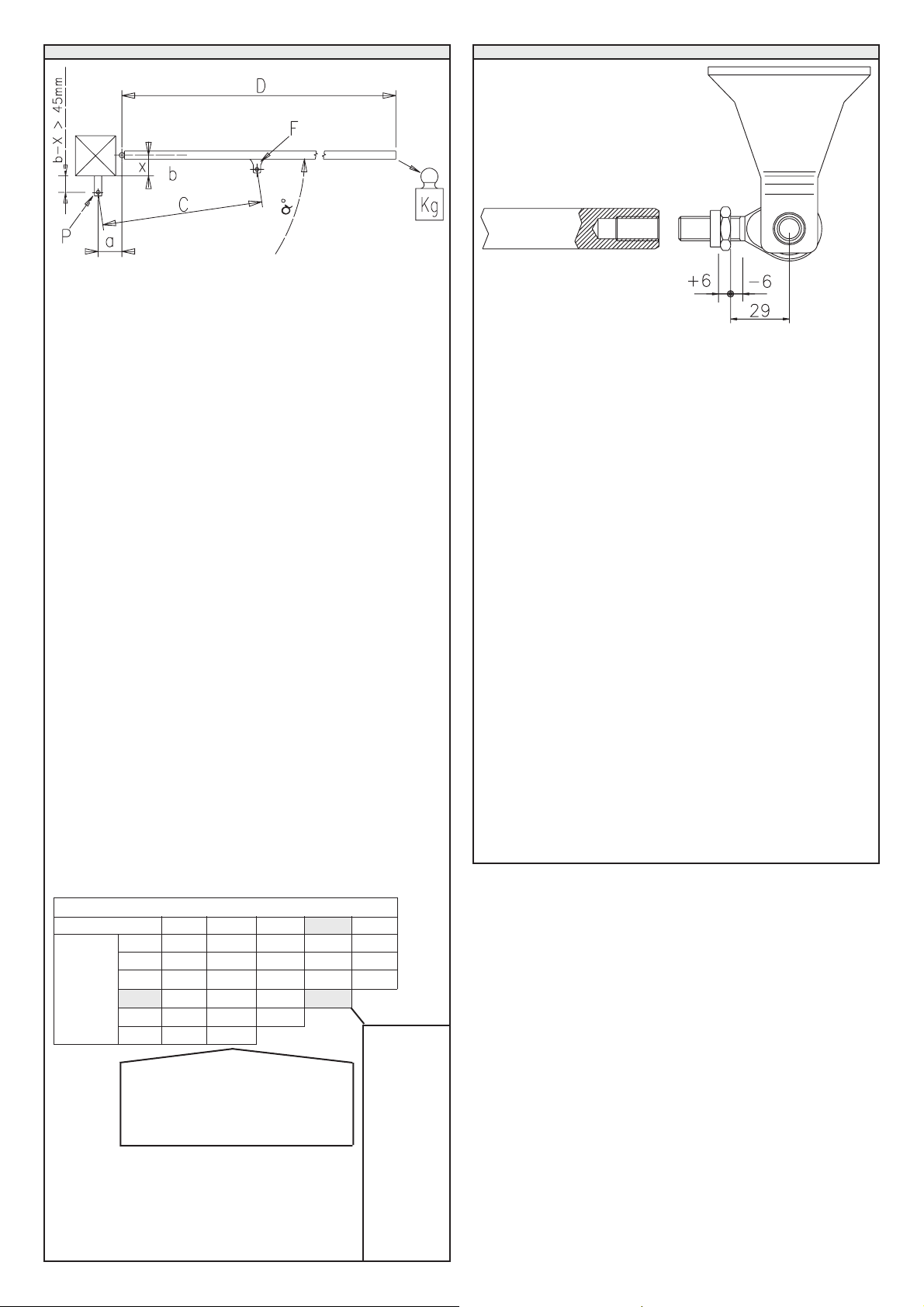

Corsa utile :280mm + compressione molle

Compressione molle :a 100Kg = 280+ 6.25mm

(regolabile con By-pass solo :a 200Kg = 280+ 8.9mm

in chiusura) :a 300Kg = 280+13.4mm

Reazione allurto :Frizione idraulica

Manovra manuale :Chiave di sblocco

Max numero manovre :500 manovre/24h

Protezione termica :160°C

Temperatura ambiente :-10 +60 C°

(scheda SPL per temperature inferiori a 5°C)

Grado di protezione :IP 65

Peso operatore :8.7 Kg

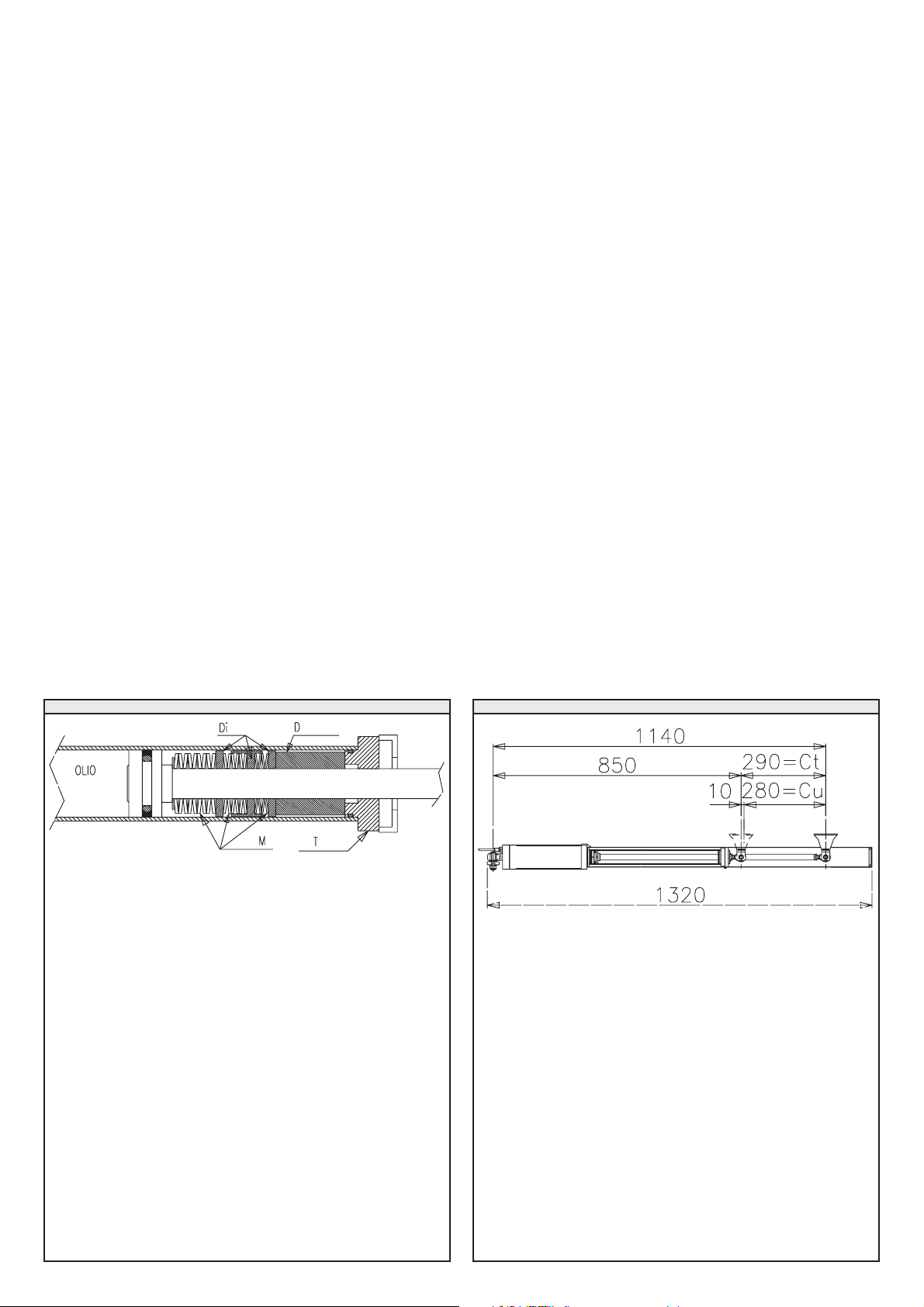

Dimensioni :Vedi fig.2

Olio :IDROLUX

2) TECHNICAL SPECIFICATIONS

Power supply :220V±10% 50Hz

Motor :single-phase, 2800 RPM

Power absorption :280 W

Capacitor :6.3µF

Current absorption :1.4 A

Maximum pressure :20 BAR

Pump delivery :1.25L/min

Pushing force :3000 N

Pulling force :2600 N

Working stroke :280mm + spring compression

Spring compression :with 100Kg = 280+6.25mm

(adjusted using closing :with 200Kg = 280+8.9mm

By-pass valves) :with 300Kg = 280+13.4mm

Impact reaction :Hydraulic clutch

Manual manoeuvre :Release key

Max. no. of manoeuvres :500 Manoeuvres/24h

Thermal protection :130°C

Operation temperature :-10 +60 C°

(SPL board for temperatures less than -10°C)

Protection :IP 65

Controller weight :8.7 Kg

Dimensions :See fig.2

Oil :IDROLUX

2) CARACTÉRISTIQUES TECHNIQUES

Alimentation :230V±10% 50/60Hz

Moteur :monophasé, 2800 tr/min

Puissance absorbée :280 W

Condensateur :6,3µF

Courant absorbé :1,4 A

Pression maximale :30 BAR

Débit de la pompe :1,25l/min

Force de poussée :3000 N

Force de traction :2600 N

Course utile :280mm + compression des ressorts

Compression des ressorts :à 100Kg = 280+6,25mm

(réglable avec soupapes :à 200Kg = 280+8,9mm

de dérivation en fermeture) :à 300Kg = 280+13,4mm

Réaction au choc :Embrayage hydraulique

Manoeuvre manuelle :Clé de déblocage

N° maxi de manoeuvres :500 manoeuvres/24h

Protection thermique :160°C

Température ambiante :-10 +60 C°

(carte SPL pour des températures inférieures à -10°C)

Degré de protection :IP 65

Poids de lopérateur :8,7 Kg

Dimensions :Voir fig.2

Huile :IDROLUX

2) TECHNISCHE DATEN

Stromversorgung :230V±10% 50/60Hz

Motor :einphasig 2800 U/min.

Leistungsaufnahme :280W

Kondensator :6,3µF

Stromaufnahme :1,4A

Höchstdruck :30 bar

Pumpenförderleistung :1,25 l/min

Druckkraft :3000 N

Zugkraft :2600 N

Nutzhub :280 mm + Federspannung

Federspannung :bei 100 kg =280 + 6,25 mm

(über Umgehungsventile :bei 200 kg =280 + 8,9 mm

der Schließung regulierbar) :bei 300 kg =280 + 13,4 mm

Stoßreaktion :Hydraulikkupplung

Bedienung von Hand :Entsperrschlüssel

Max. Öffnungs-und Schließvorgänge :500 Bedienungen/24h

Wärmeschutz :160°C

Außentemperatur :-10 +60°C

(SPL-Karte für Temperaturen unter 5°C)

Schutzkategorie :IP 65

Operatorgewicht :8,7 Kg

Abmessungen :Siehefig.2

Öl :IDROLUX

www.BFTGateOpeners.com | (800) 878-7829