GENERAL SA ETY

WARNING! An incorrect installation or improper use of the product can cause damage to persons, animals or property.

•Automation should be installed on a gate which is moving freely. Any issue with the smooth opening of closing of a gate will not be corrected

by adding automation.

•Scrap packing materials (plastic, cardboard, polystyrene etc) according to the provisions set out by current standards. Keep nylon or polystyrene

bags out of children s reach.’

•Keep this instruction manual for future reference.

•This product was exclusively designed and manufactured for the use specified in the present documentation. Any other use not specified in this

documentation could damage the product and be dangerous.

•The Company declines all responsibility for any consequences resulting from improper use of the product, or use which is different from that

expected and specified in the present documentation.

•Do not install the product in explosive atmosphere.

•The Company declines all responsibility for any consequences resulting from failure to observe Good Technical Practice when constructing

closing structures (door, gates etc.), as well as from any deformation which might occur during use.

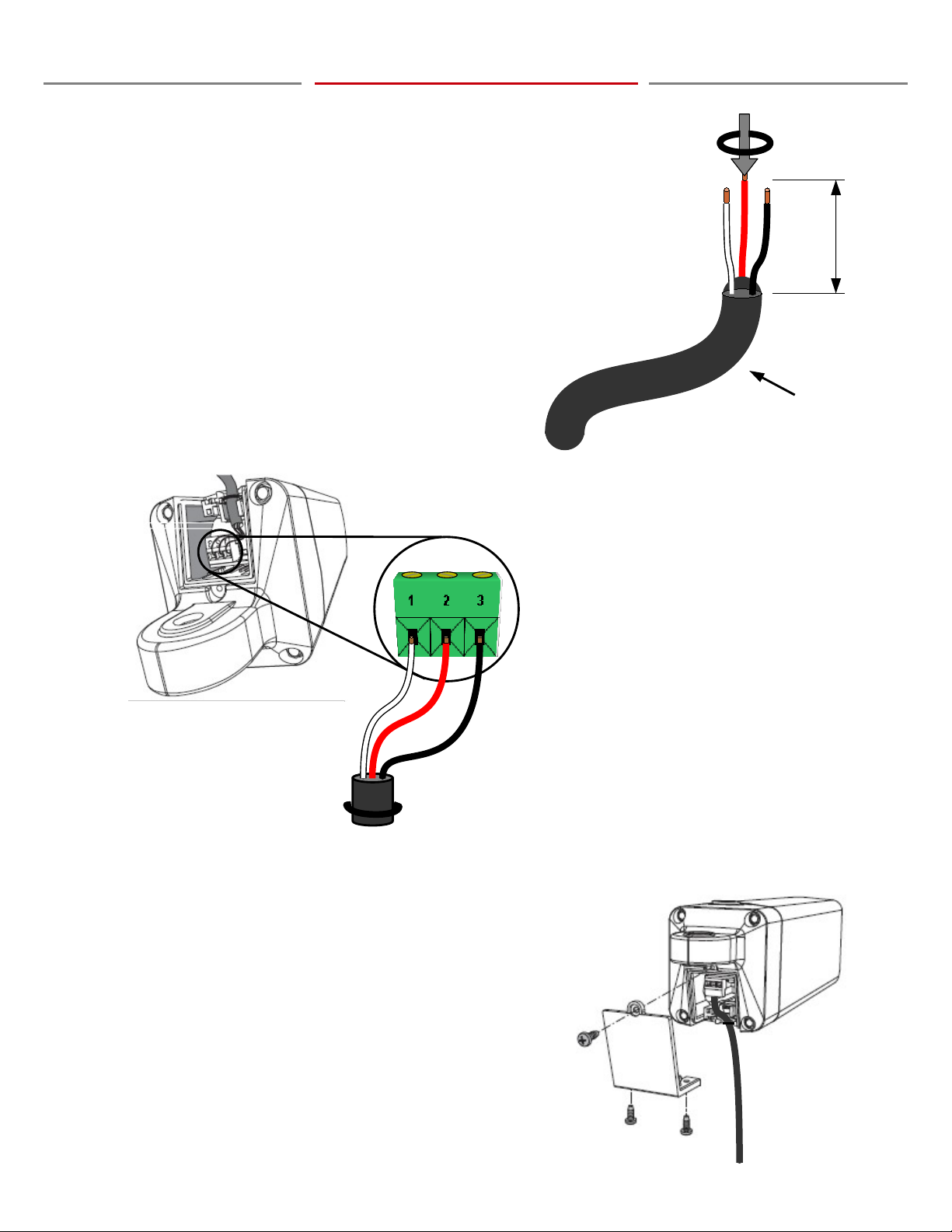

•ollow and comply with national and/or local electrical codes when performing any electrical installation.

•Disconnect the electrical power supply before carrying out any work on the installation. Also disconnect any buffer batteries, if fitted.

•it all the safety devices (photocells, electric edges etc.) which are needed to protect the area from any danger caused by squashing, conveying

and shearing, according to and in compliance with the applicable directives and technical standards.

•It is recommended to position at least one luminous signal indication device (blinker) where it can be easily seen for additional safety

•The Company declines all responsibility with respect to the automation safety and correct operation when other manufacturer s components are ’

used.

•Only use original parts for any maintenance or repair operation.

•Do not modify the automation components, unless explicitly authorized In writing by the Company.

•Instruct the product user about the control systems provided and the manual opening operation in case of emergency.

•Anything which is not expressly provided for in the present instructions, is not allowed.

•Installation must be carried out using the safety devices and controls prescribed by the UL 325 Standard.

CHECKING INSTALLATION

Before the automated device is finally put into operation, perform the following checks meticulously:

•Make sure all components are fastened securely.

•Check that all safety devices (photocells, pneumatic safety edge, etc.) are working properly.

•Check the emergency operation control device.

•Check opening and closing operations with the control devices applied.

•Check the electronic logic for normal (or personalized) operation in the control panel.

ADJUSTING OPERATING ORCE

WARNING: Operating force is adjusted with extreme precision by means of the control unit s electronic control. Operation at the end of travel is ’

adjusted electronically in the control panel. To provide good anti-crush safety, the operating force must be slightly greater than that required to

move the leaf both to close and to open it.

CONTROL

There are various options when it comes to the control system (manual, remote control, access control with magnetic badge, etc.) depending on

the installation s needs and characteristics. See the relevant instructions for the various control system options. People due to use the ’

automated device must be instructed how to control and use it.

OPERATIONAL SA ETY

The installer is responsible for communicating the following information to the end-user:

This product has been designed and built solely for the purpose indicated herein. Uses not contemplated herein might result in the product

being damaged and could be a source of danger.

The irm disclaims all responsibility resulting from improper use or any use other than that for which the product has been designed, as

indicated herein, as well as for failure to apply Good Practice in the construction of entry systems (doors, gates, etc.) and for deformation that

could occur during use. If installed and used correctly, the automated system will meet the required level of safety. Nonetheless, it is advisable

to observe certain rules of behavior so that accidental problems can be avoided:

● Keep adults, children and property out of range of the automated system, especially while it is operating.

● Operate the system when the full path of the gate is within sight.

● It is essential to frequently check that all safety devices are in good working condition.

● This application is not meant for use by people (including children) with impaired mental, physical or sensory capacities, or people who

do not have suitable knowledge, unless they are supervised or have been instructed by people who are responsible for their safety.

● Children must be supervised to ensure they do not play with the system. Keep remote controls or other control devices out of reach of

children in order to avoid the automated system being operated inadvertently.

● Check the system frequently, especially hinges, cables, springs or supports, to detect any loss of balance and signs of wear or damage.

● When cleaning the outside or performing other maintenance work, always cut off mains power.

● Keep the photocells optics and illuminating indicator devices clean. Check that no branches or shrubs interfere with the safety devices ’

(photocells).

● Do not use the automated system if it is in need of repair. In the event of a malfunction, cut off the power, activate the emergency

release to allow access and call in qualified technical personnel (professional installer).

● If the automated system requires work of any kind, employ the services of qualified personnel (professional installer).

● Anything that is not explicitly provided for in these instructions is not allowed.

● The operator s proper operation can only be guaranteed if the information given herein is complied with. The irm shall not be ’

answerable for damage caused by failure to comply with the installation rules and instructions featured herein.

● Have the complete system checked including all safety devices by a qualified professional technician at least once a year.

Descriptions and illustrations herein are not binding. While we will not alter the product s essential features, the irm reserves the right, at ’

any time, to make those changes deemed necessary to improve the product from a technical, design or commercial point of view, and will not be

required to update this publication accordingly.

OPERATIONAL SAFETY 3