1 689 989 132 2011-09-09| Robert Bosch GmbH

6 | BAT 131 | Perform Testen

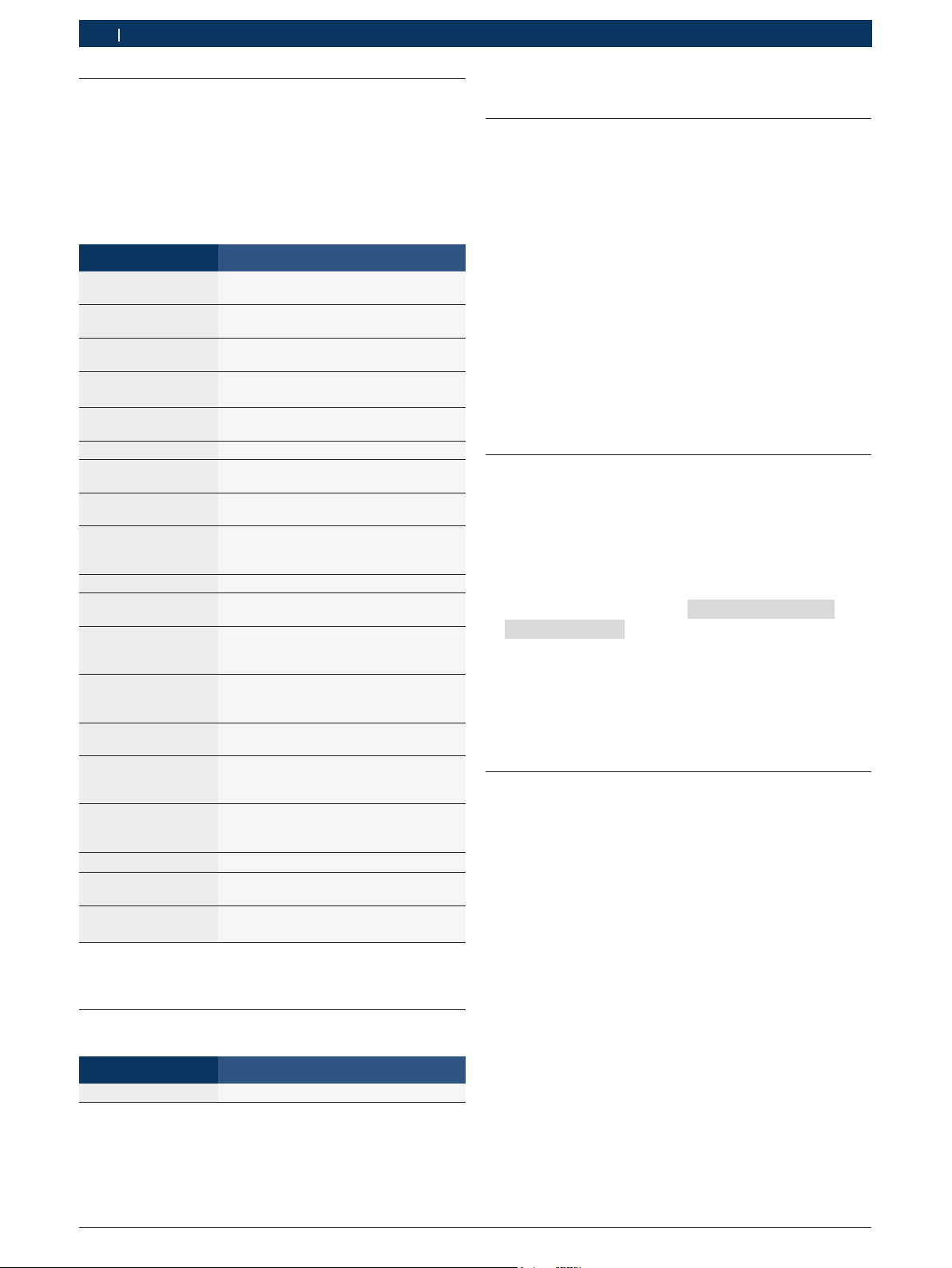

3.6 Menu

1. Press to access the Menu.

2. Use the or to highlight the line you want to

edit.

3. Press Eto edit the line or save your changes.

4. Use

or

to select the function to use or edit.

5. Press Eto move to the next location.

6. Press to return to the Menu.

Option Description

Perform Test Begin the Battery and System Test pro-

cedure.

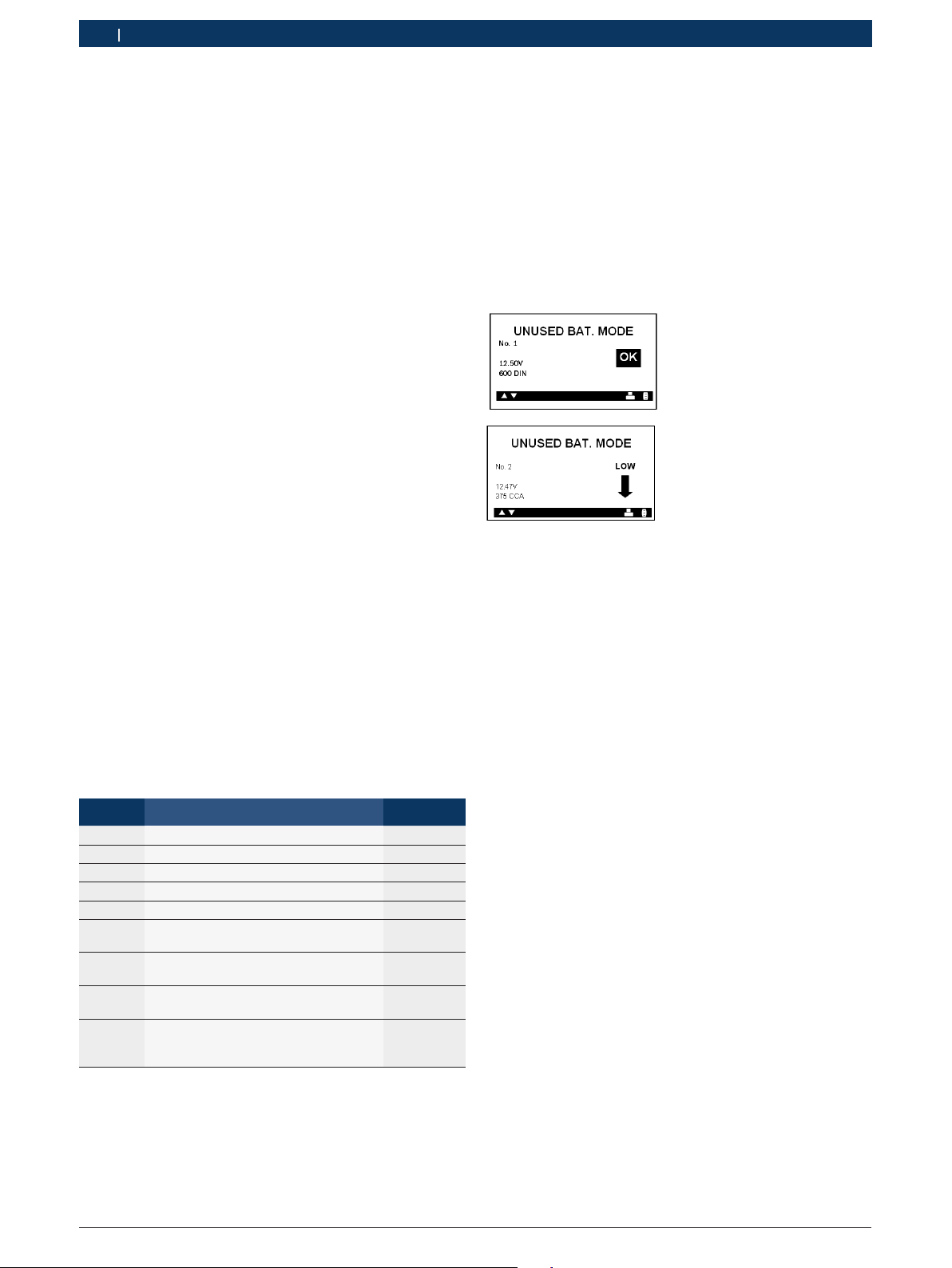

Unused Battery

Mode

Perform a quick test on batteries in in-

ventory.

ON Perform Unused Battery Test, Clear or

add to memory,

OFF Turn off "Unused Battery Mode"

View Test Results View Unused Battery Mode test results.

S/N Input Enable or disable serial number if a bad

cell is detected.

Voltmeter Start the test battery voltage.

View / Print Display the previous test result. Press

the button to print the results.

Export / Clear Data Export the last test result to a USB-type

jump drive1) or clear the tester memory.

Counter RDeletion of results.

RShows a summary of the results of

the measurements taken.

Settings Customize tool options to fit your needs.

Language Select a language for the tester.

Default: English

Set Address Create a header for your printed test re-

sults with your business location infor-

mation.

Set Time Select 24-hour or AM/PM and set the

time.

Default: AM/PM

Set Date Select the date format and date.

Default: MM/DD/YYYY

Contrast Adjust the contrast setting of the tes-

ter display.

Default: 10

Temperature Units Select the temperature units Degrees °F

or Degrees °C.

Default: Degrees F

Amp Clamp Prompt for Amp Clamp availability.

Version Info Lists the software version, software ver-

sion date, and serial number.

Update Update the tester's internal operating

software.

1) After export to an USB stick you can open the text-file with

extension ""bty" preferable with Excel.

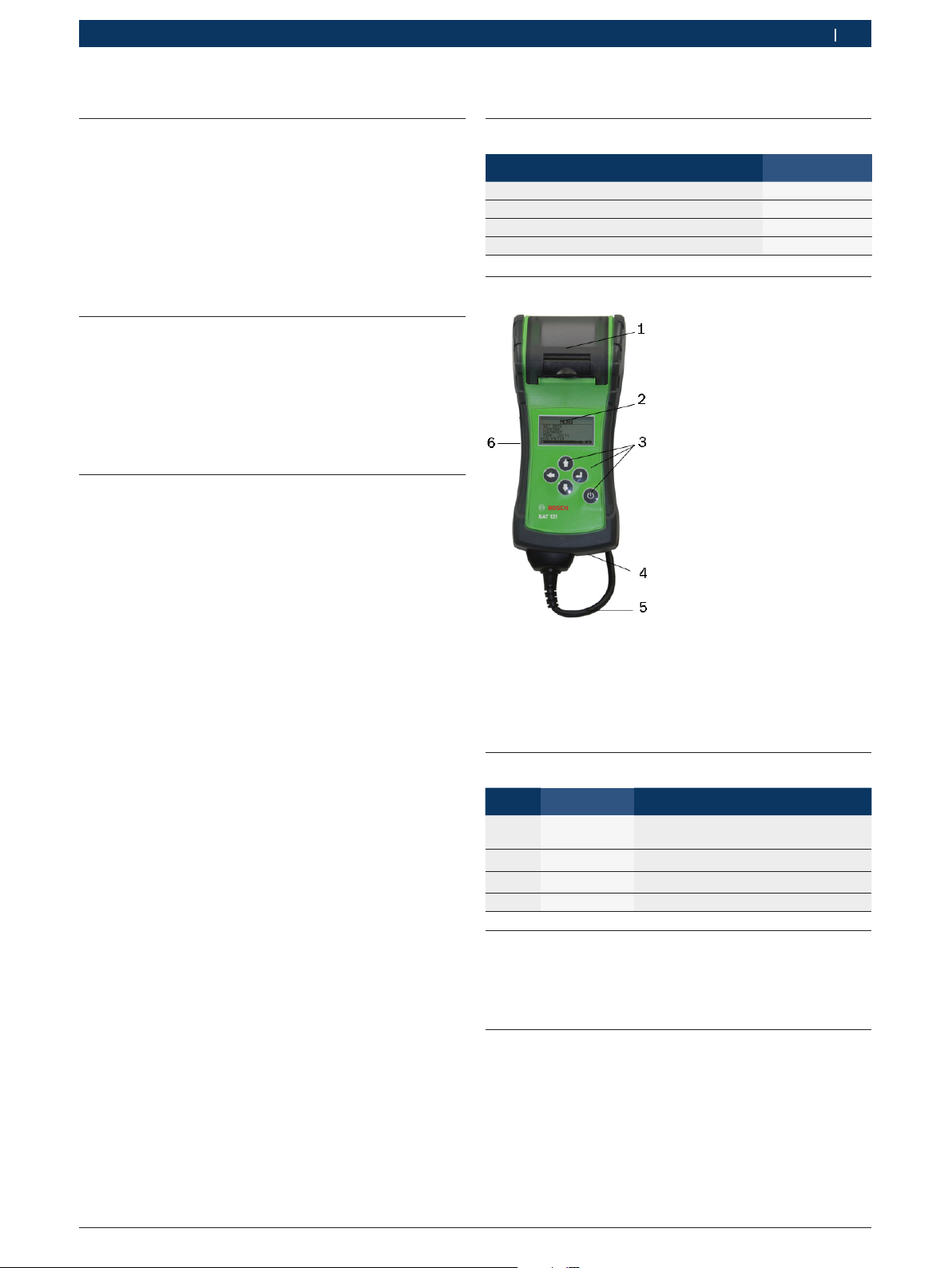

3.7 Special accessory

Designation Item number

Current probe 1 681 354 034

4. Perform Test

4.1 Test Preparations

Before connecting the tester, clean the battery posts

or side terminals with a wire brush and a mixture of

baking soda and water. When testing side-post batte-

ries, install and tighten lead terminal adapters. A set of

adapters is included with the tester.

!Do not test at or with steel bolts. Failure to install

terminal adapters or installing terminal adapters

that are worn or dirty may result in inaccurate test

results. To avoid damage, never use a wrench to

tighten the adapters more than ¼ turn.

iIf you are testing in the vehicle, make sure all acces-

sory loads are off, the key is not in the ignition, and

the doors are closed.

4.2 Connecting BAT 131

1. Connect the red clamp to the positive (+) terminal

2. Connect the black clamp to the negative (–) terminal.

!For a proper connection, rock the clamps back and

forth. The tester requires that both sides of each

clamp be firmly connected before testing. A poor

connection will produce a CHECK CONNECTION or

WIGGLE CLAMPS message. If the message appears,

clean the terminals and reconnect the clamps.

iThe preferred test position is at the battery termi-

nals. If the battery is not accessible, you may test at

the jumper post; however, the available power mea-

surement may be lower than the actual value.

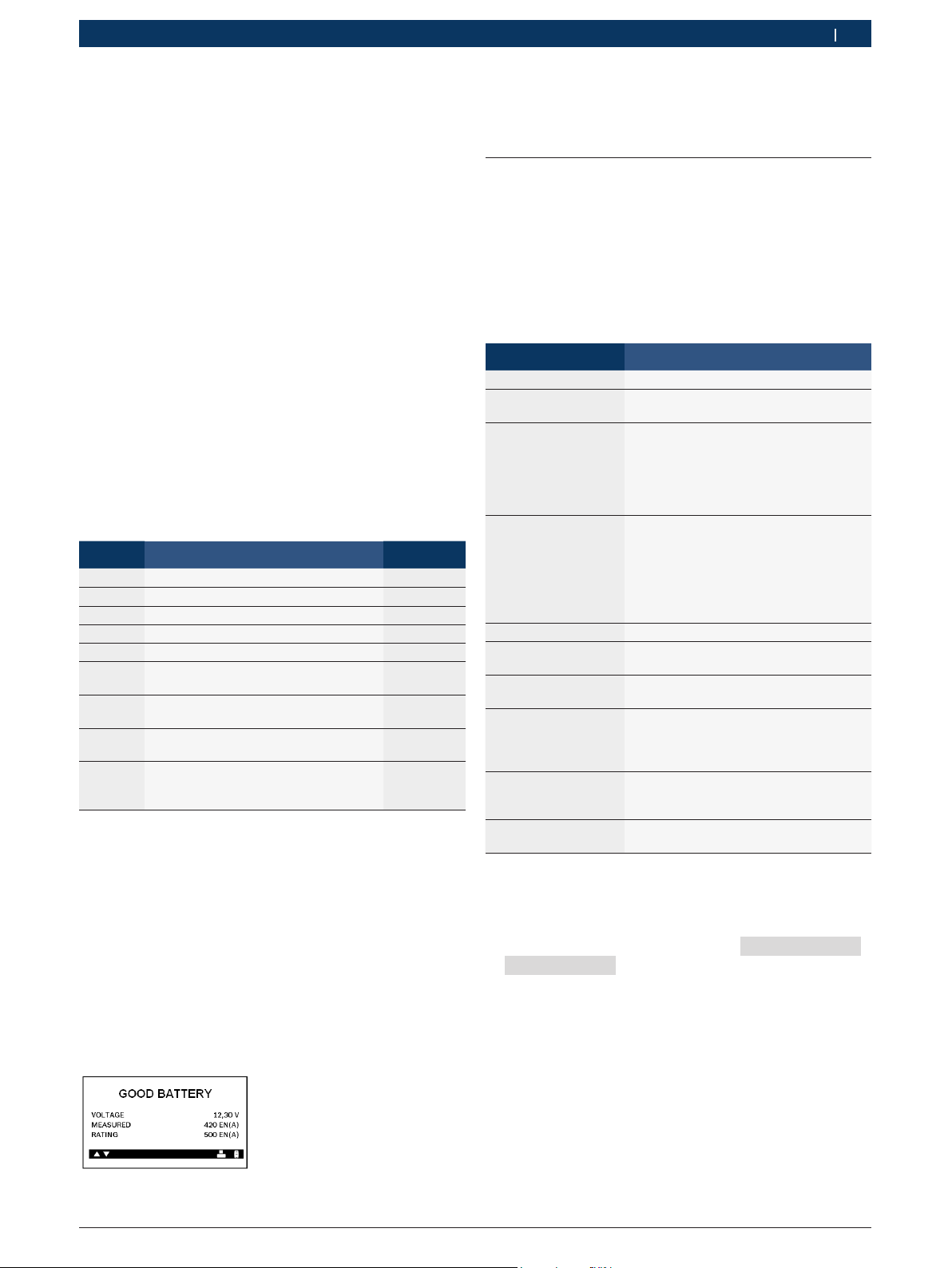

4.3 Battery Test

1. BAT. LOCATION

Scroll to and select IN VEHICLE or OUT OF VEHICLE

for a battery not connected to a vehicle.

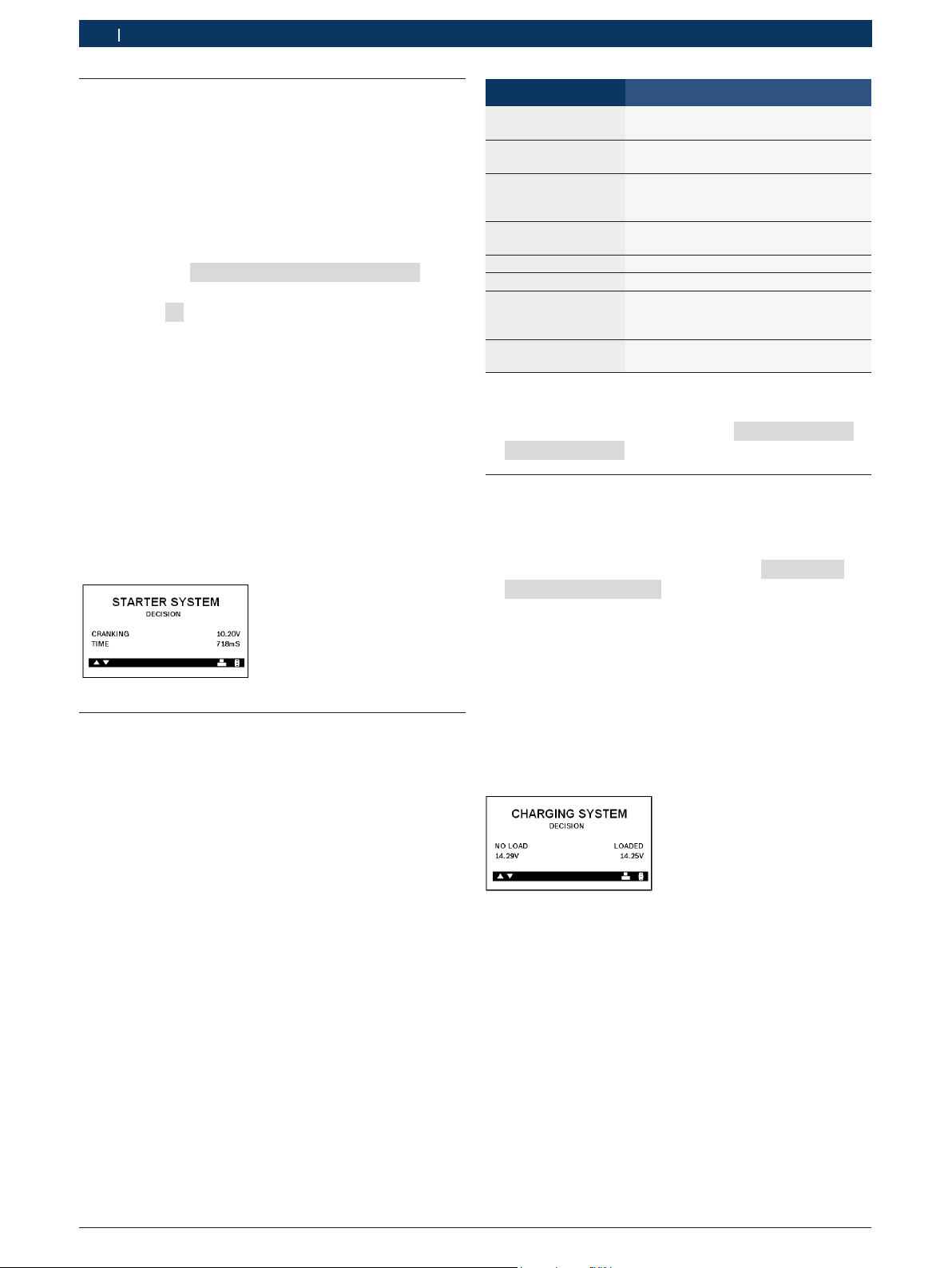

iFollowing an "IN VEHICLE" test you will be prompted

to test the starting and charging systems.

!The performance of the starting and charging sys-

tems depends on the battery’s condition. It is impor-

tant that the battery is good and fully charged before

any further system testing.