Safety requirements and notes | TCE 260 | 7 en

1 987 AT7 374 2015-09-02|Robert Bosch GmbH

RMachine nameplate

$Each machine is equipped with the appointed

technical parameter and serial number.

Warning

It is prohibited to dismantle the nameplate on the ma-

chine.

REach machine is equipped with the appointed techni-

cal parameter and serial number.

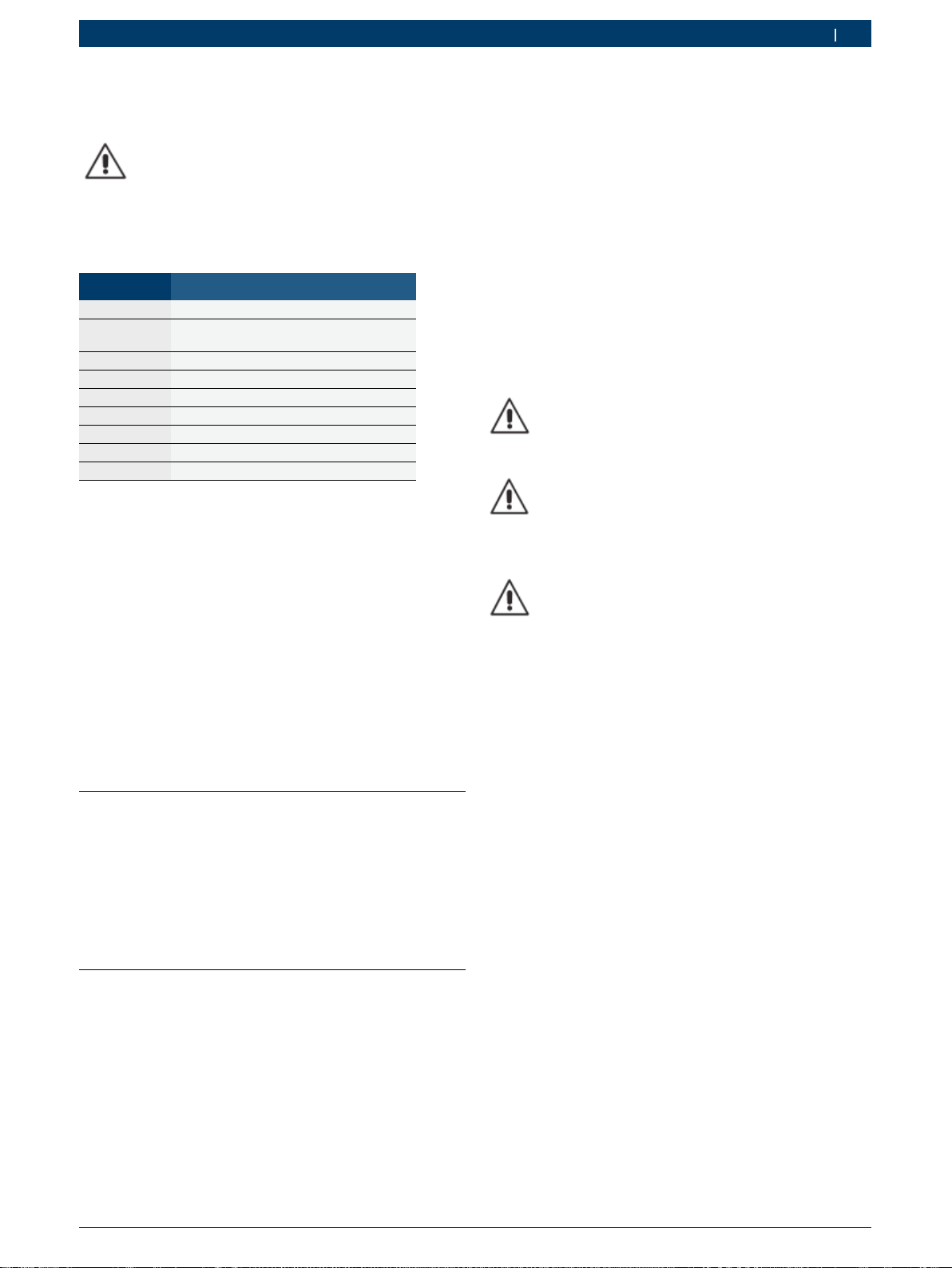

Symbol Meaning

V Voltage supplied to the machine

A Rated current when the ma-

chine is running

Kw Power

Hz Frequency

Ph Phase of power supply

bar Operating air supply pressure

Serial N. Machine’s serial number

ISO 9001 Certified management system

CE CE safety marks

RThe completed information of machine model and

serial number will be helpful for our technical per-

sonnel to provide you with the service and technical

support and also make it more accurate and easier

to change the parts. If there is difference between

the data in the manual and the data on the name-

plate, the one on the nameplate should be conside-

red to be correct.

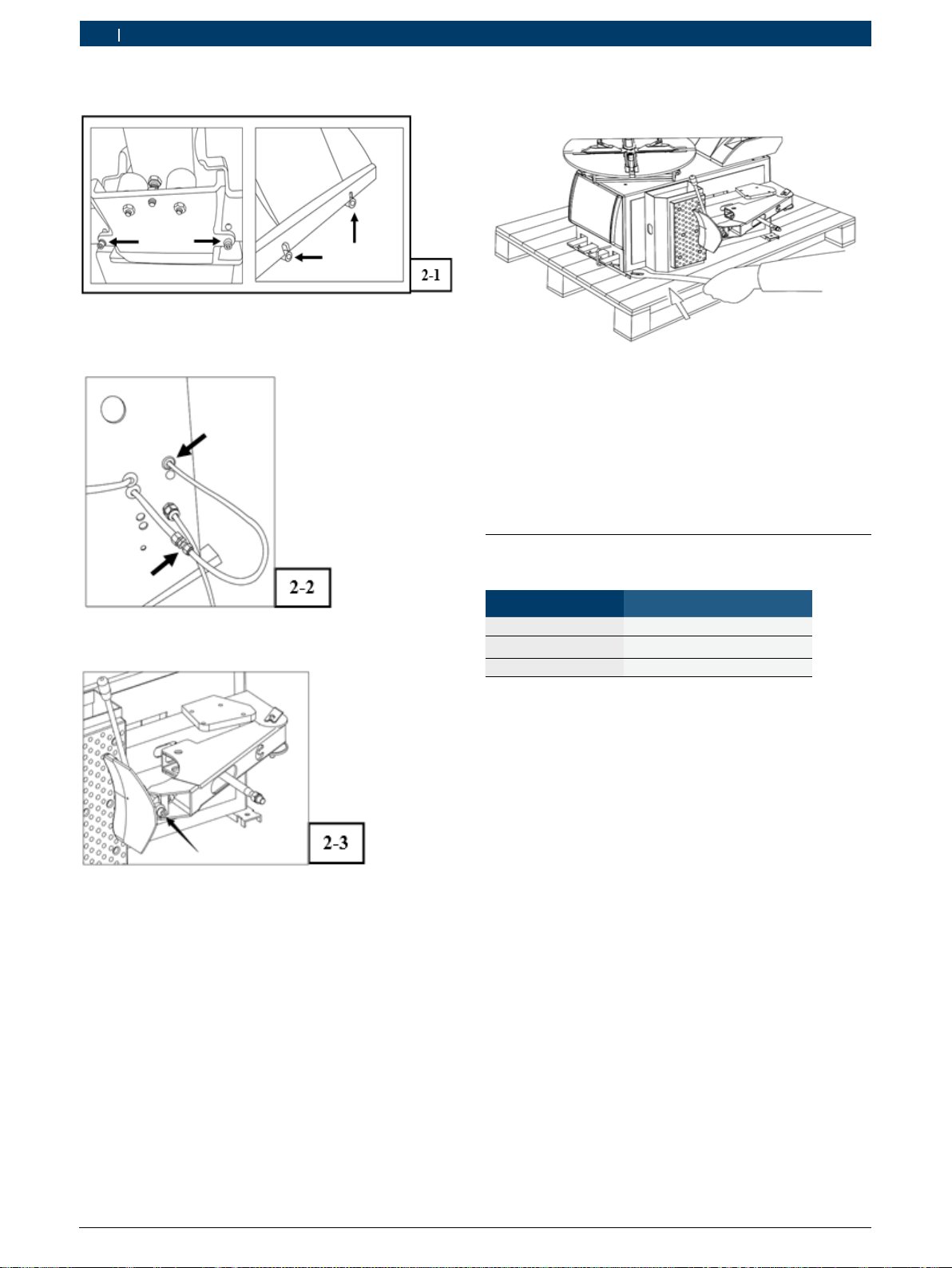

2. Safety requirements and

notes

2.1 Usage

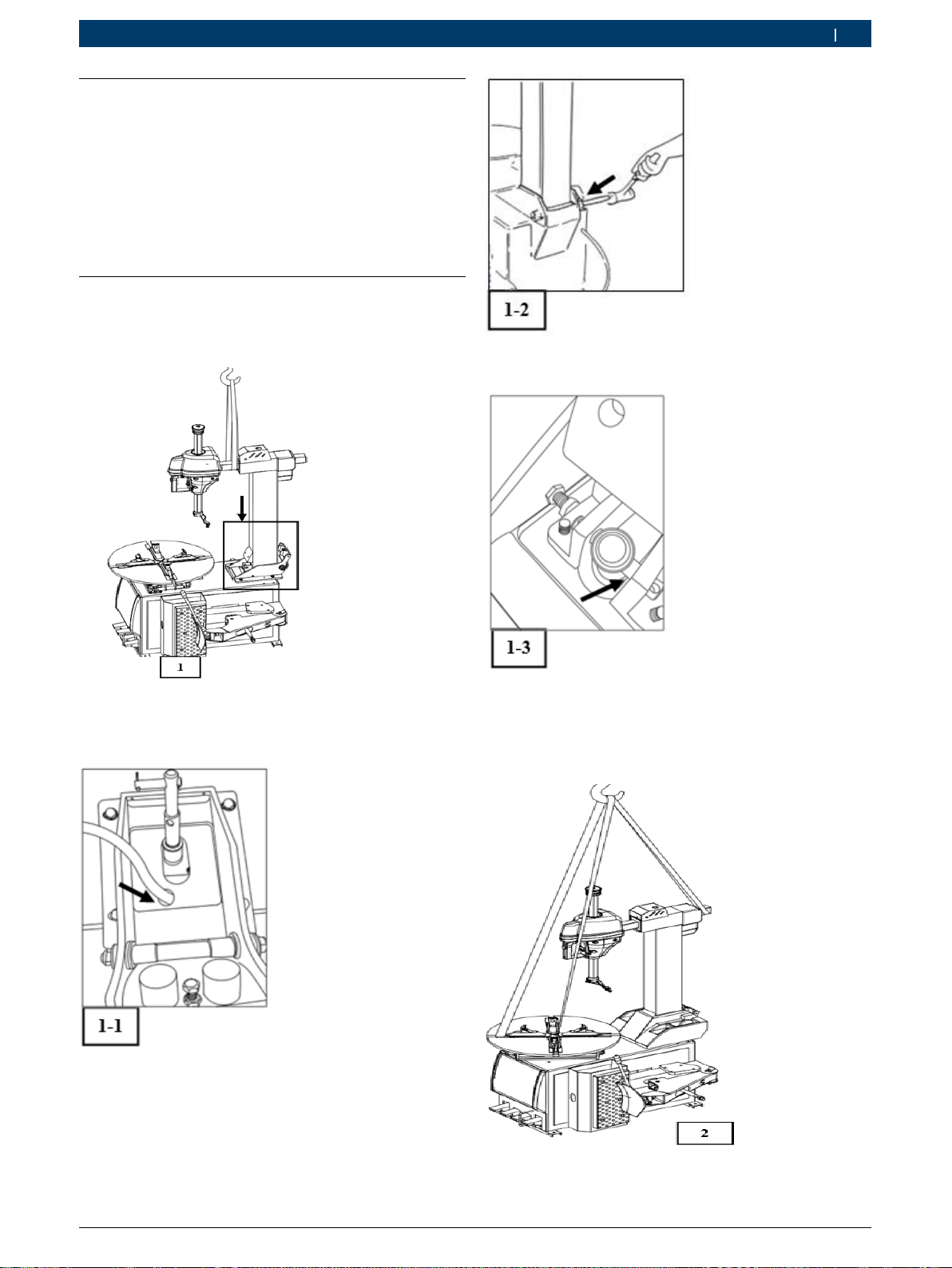

1. This machine is used to demount/ mount the car

tire. The dimension of the rim is 10”-26”. The max

diameter of the wheel can reach 1050mm.

2. Any other usage will be incorrect.

3. Special statement: the manufacturer will not bear

any responsibility to any damage arising from the

operation not specified in the manual.

2.2 General safety precautions

1. This machine can only be operated by the authorized

personnel who have received special training.

2. The manufacturer will not bear any responsibility

to any direct or indirect damage arising from the

modification to the machine without the permission

of the manufacturer.

3. When the machine is delivered out of the factory,

which is equipped with the complete instruction

manual and warning signs. If they are damaged or

ruined for some reasons, please ask the manufactu-

rer to change.

4. The machine should be kept away from the inflam-

mable and explosive materials. It should also be kept

from sun and glare. The place to place the machine

should be good ventilation.

5. Make sure to use the original parts and accessories.

6. The machine should be installed by the authorized

personnel as per the manual.

7. During operation, you should pay attention whether

there is any danger. Once you find the danger, stop

the machine at once and contact the dealers.

8. When the machine is running, the unauthorized per-

sonnel should be kept away from the machine.

9. The operator should wear the protective equipments

such as gloves, goggle and overalls to prevent the

accidental injury.

Warning

Secure that the grounding of the machine is perfect.

Warning

When operate the machine, the unauthorized personnel

should be kept away from the machine.

Warning

Non-compliance to the operation requirement or the

warning requirements related to the danger specified

in the manual will cause the injuries to the operators

or personnel nearby. Before connect the machine to

the power supply, please carefully read the manual and

warning notes. The machine must be operated by the

profession personnel. The operator must have received

special training and understood the requirement in the

manual. He or she should also understand related safe-

ty requirement and detailed requirement in the process

of operation. The operator must not operate the machi-

ne after drinking.

RThe operator must pay attention to:

$Understand all the requirements specified in the

manual;

$Understand the function of the machine;

$Unauthorized personnel should be kept away from

the machine;

$Secure the installation of the machine should

comply with the related local law and regulation;

$Secure that the operators have received the trai-

ning and have the skill to operate the machin, and

they must be monitored;