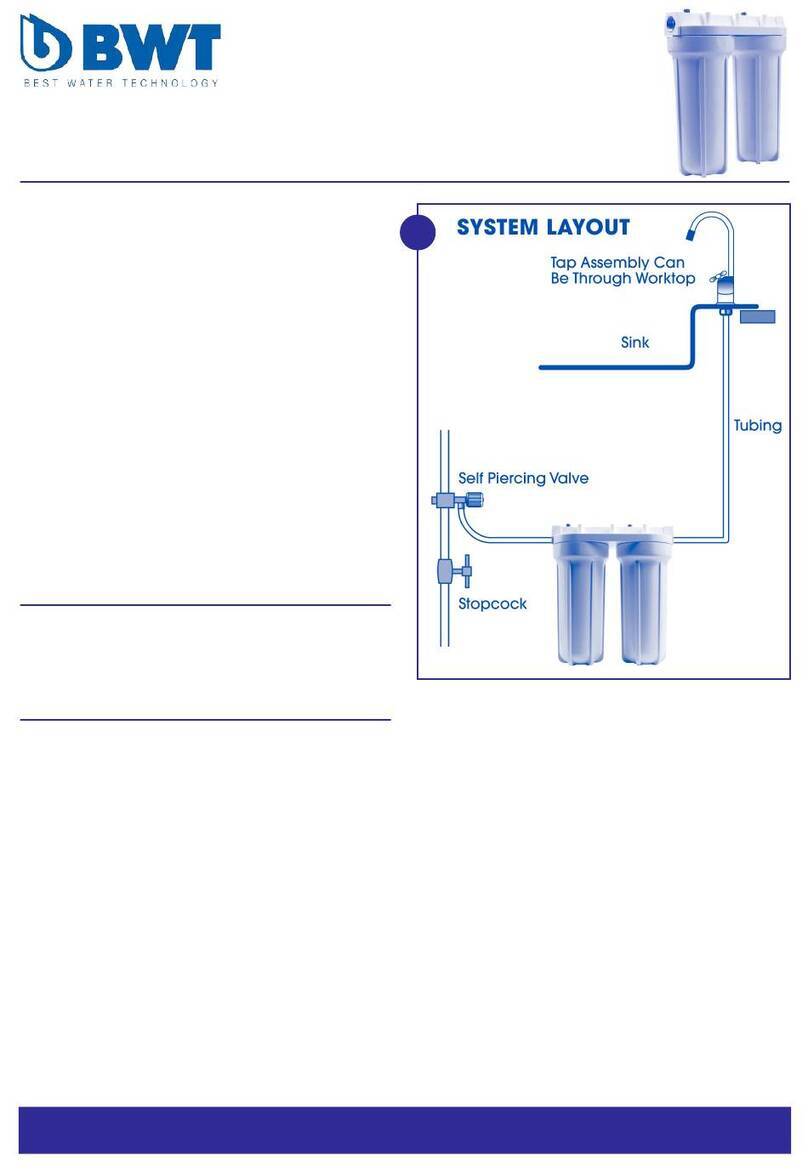

6. Mounting the Filter System

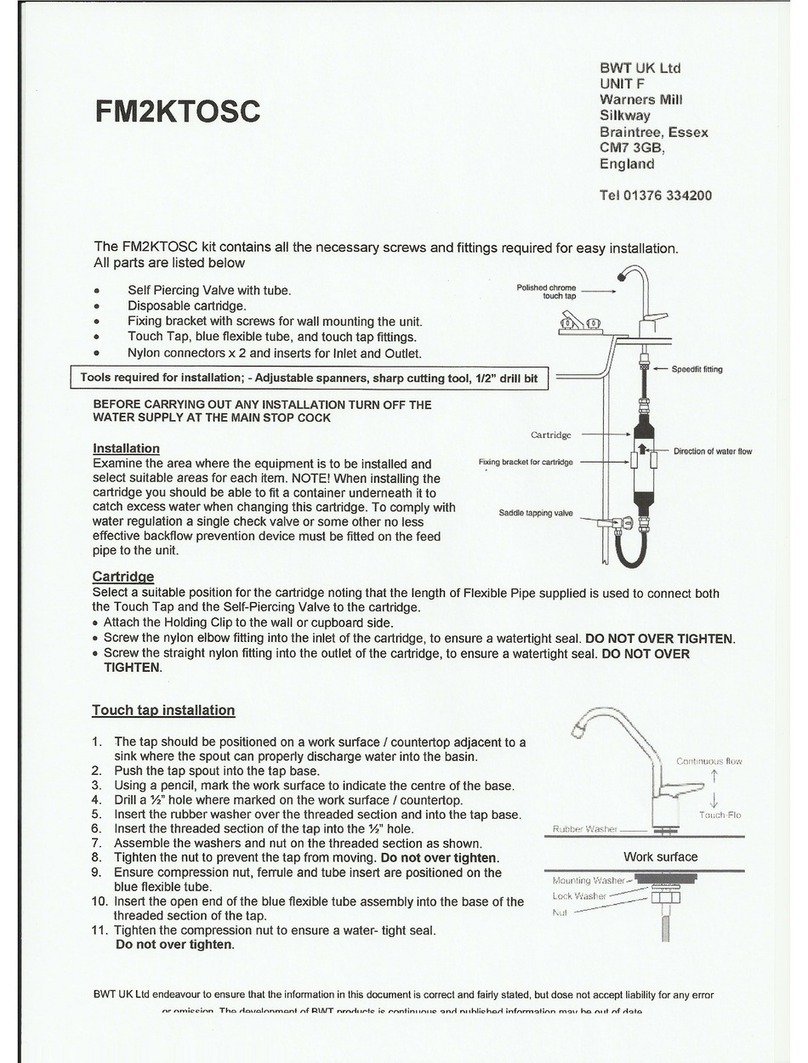

A) Taking note of the length of connecting tube available select a suitable position for the

filter (normally on the side of the cupboard underneath the sink)

B) Allow enough space below the head to facilitate filter changes (100mm).

C) Using the template supplied as a guide, mark the position of the fixing holes with a pencil.

D) Drill small pilot holes for the screws.

E) Fix the bracket supplied to the side of the cupboard using suitable screws (screws not

supplied)

7.

A) To fit the tubing to the filter, remove the filter housing from the fixing. The red tube

connects to the inlet, the blue tube to the outlet. Please see Fig 6

B) Using a sharp hobby knife or similar to cut the flexible red tube from the self-cutting tap

to a length suitable for it to reach the inlet side of the filter housing (marked ‘IN’).

Remember to allow a sufficient length, so that it can be routed without kinks and be

kept clear of any sharp edges or obstacles.

C) With the tube cut ‘squarely’ and to the right length, ensure the end is clean, remove the

locking clip Z, (Fig 7) before firmly pushing it into the push fit connector on the inlet side

of the filter cartridge, pull back slightly to affect a water tight seal, replace the locking

clip Z.(You may nd this easier on Trio models if you rst remove the lters)

D) Repeat process for the blue tube from the touch flow tap.

E) Attach the tube to the outlet side of the cartridge head. (Ret cartridges if removed)

F) Turn on water supply and open the saddle valve, then check all connections for leaks.

G) Turn on the quarter turn tap to remove any airlocks. Run water for several minutes

until water runs clear to flush and prime cartridge.

H) Mount the filter back onto the fixing screws.

NOTE: For optimum performance, flow rate should not exceed 2 Lpm.

8. Filter Cartridge Replacement (Figs 8-11)

A) Turn off the water supply to the filter and dispense water from

drinking water tap until water flow stops to relieve pressure.

B) Place a small bowl and towel under the filters to catch any water drips.

C) Hold the filter cartridge, twist anti clockwise, the filter should pull out

easily.

D) Repeat for all cartridges.

E) Remove and dispose of the cartridge, recycling where facilities exist.

F) Fit the new cartridges, Remove cartridges from packaging, locate cartridge into head,

push in when lugs line up, and twist clockwise until locked in. Make sure cartridges are

in the correct order.

G) Turn on water and check for leaks.

H) Flush water through drinking water tap for up to 5 minutes to remove air, and any

excess filter media.

9. Filter Cartridge Replacement Packs

DUO Pack Contains:

1 X Slim C-101 High Efficiency Activated Carbon Filter

1 X Slim Mg-103 BWT Mg+ Filter

TRIO Pack Contains:

1 X Slim C-101 High Efficiency Activated Carbon Filter

1 X Slim Mg-103 BWT Mg+ Filter

1 X Slim UF-104 Membrane Filter 0.1 -0.01 micron

Fig 7

Fig 8

Fig 9

Fig 10

Fig 11

IN

OUT

Fig 6

Duo Model Shown

IN

OUT

IN

OUT

IN

OUT

IN

OUT