GG-CSGGA 2 Rev. 08/15/03

PRIMING THE CONTINUOUS SHOT

GREASE GUN

With the gun loaded with grease and the gun hooked to

an air supply, activate the trigger until grease flows from

the hose or pipe. To relieve air pockets, operate the air vent

valve #31 while depressing the trigger. If grease does not

flow after 10-15 seconds of operation, remove the hose or

pipe and activate the trigger until grease flows from the

hose/pipe outlet. Make sure the bearing, fitting and

lubrication line are clear and free flowing before operating

the gun. If the bearing, fitting or lubrication line is blocked,

the gun can stall.

REMOVING AN EMPTY GREASE CARTRIDGE

1. Pull the T handle until the rod is fully extended. Hook

the rod into the rod notch in the end cap.

2. Unscrew the grease tube from the gun.

3. Carefully center the grease rod and eject the empty

cartridge from the grease barrel.

INSTRUCTIONS FOR CARTRIDGE LOADING

1. Pull the T handle until the rod is fully extended, lock

rod into cap notch and remove the barrel assembly from

the gun.

2. Turn T handle 1/2 turn to lock the follower rod to

the follower.

3. Remove the plastic cap from the grease cartridge and

insert the cartridge into the barrel assembly.

4. Remove the pull-tab from the grease cartridge.

5. Screw the barrel assembly on to the gun assembly.

6. Release the rod by centering the rod.

7. Push the rod by hand until the follower is inserted into

the grease cartridge. Then turn the T handle 1/2 turn to

unlock the follower rod from the follower.

8. Prime the gun and remove any air pockets per the

instructions on priming the gun.

SUCTION FILLING

1. Remove the barrel assembly from the gun.

2. Insert the open end of the barrel assembly into the

grease bucket.

3. Pull the T handle until it is fully to the rear and engage

it in the rod notch, making sure to keep the open end of

the barrel well within the grease.

4. When the barrel assembly is full of grease, screw it back

on to the gun assembly.

5. Release the rod by centering the rod.

6. Prime the gun and remove any air pockets per the

instructions on priming the gun.

USING A FILLER PUMP

1. Attach the bulk load fitting to the bulk container.

2. Operate the filler pump.

3. When the T handle and rod are fully extended (about

8-1/2"), the barrel is full.

4. Remove the gun from the bulk load container.

5. Release the rod by centering the rod.

6. Prime the gun and remove any air pockets per the

instructions on priming the gun.

PROPER GREASE GUN USE

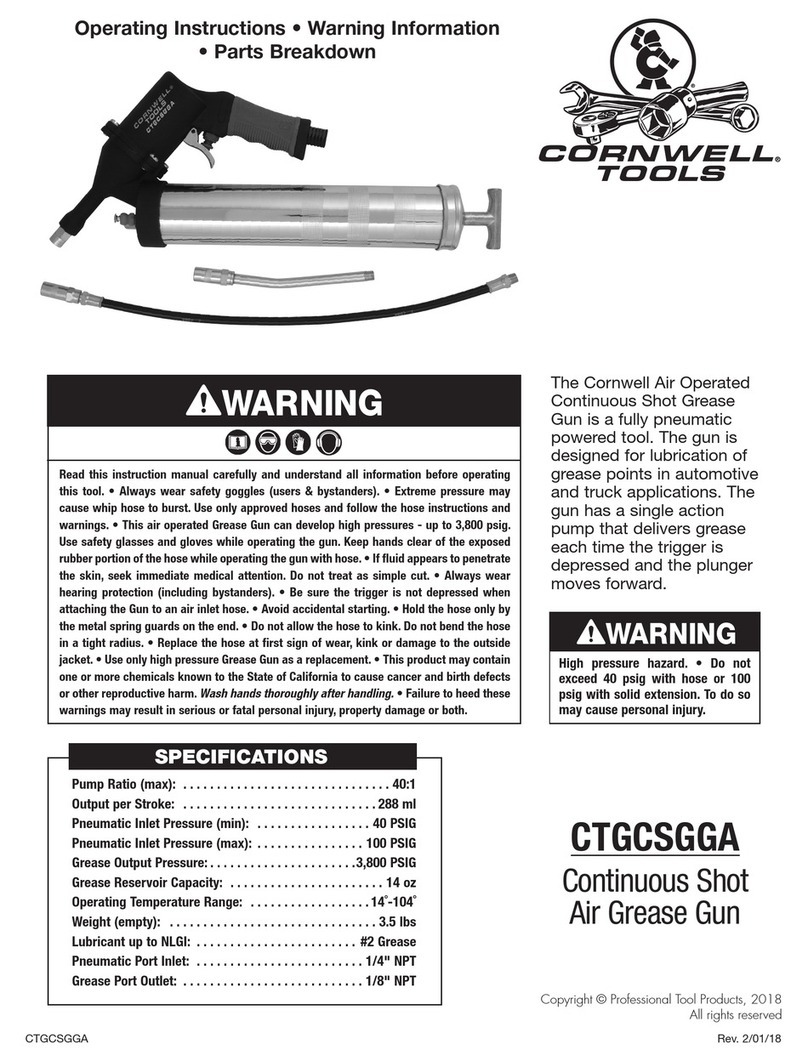

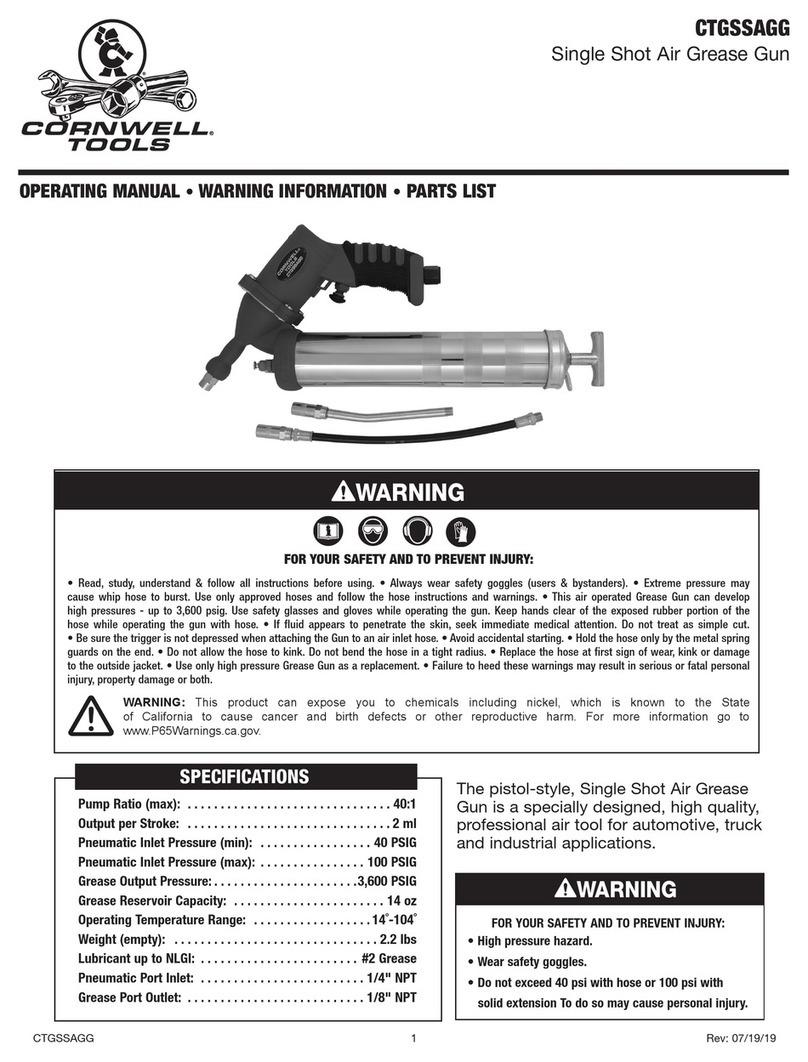

This Air Powered Continuous Shot Grease Gun was

developed for the specific purpose of dispensing grease

by using pneumatic power.

The maximum rating listed below should not be

exceeded.

This tool should only be used for its designed purpose

and according to the instructions in this manual.

SPECIFICATIONS

Pump ratio (max)...........................................................40:1

Output per stroke ..................................... .038 in (cubed)

Pneumatic inlet pressure (min)................................40 Psig

Pneumatic inlet pressure (max) .............................150 Psig

Grease output pressure .......................................6,000 Psig

Grease reservoir capacity ........................................14.5 oz.

Operating temperature range ..........................0 to 120° F

Weight (empty)........................................................4.74 lbs

Weight (full).............................................................4.84 lbs

Lubricant up to NLGI ...........................................#2 Grease

Pneumatic port inlet ........................................1/4 - 18 NPT

Grease port outlet .........................................1/8 - 27 UNPT

GENERAL CAUTIONARY NOTES

Do not allow bystanders, children or other on-lookers in

the work area as they can cause distractions, which may

lead to mistakes and accidents.

Carefully inspect the equipment for damaged, loose or

missing parts. If the unit is worn or damaged, do not use

it and contact an authorized service center for evaluation

or repair.

The Continuous Shot Grease Gun must be primed after

each refill or grease cartridge change. You should also

check the priming of the gun before each use.

For best performance and to extend product life, add a

few drops of air tool oil through the air fitting at the

bottom of the handle if gun begins to cycle slowly or

erratically.

CAUTION!

Air pockets in the cartridge will cause the gun to lose

prime.