Egro NEXT Top Milk User manual

NEXT

Technical Manual

ENGLISH

Egro NEXT

Technical Manual 2 Rev: AA / 09/2018

Content

1. Introduction.............................................................................................................................................. 4

2. Technical data........................................................................................................................................... 4

2.1. Type label.......................................................................................................................................... 4

2.2. Outlet................................................................................................................................................ 5

3. Installation................................................................................................................................................ 6

3.1. Electrical connections........................................................................................................................ 6

3.1.1. Change power settings............................................................................................................... 6

4. Service .......................................................................................................................................................7

4.1. Service Document ..............................................................................................................................7

4.2. Preventive Maintenance.....................................................................................................................7

4.2.1. Service interval ...........................................................................................................................7

4.2.2. Maintenance ..............................................................................................................................7

4.2.3. Lubricants...................................................................................................................................7

4.2.4. Service kits................................................................................................................................. 8

4.3. Grinder.............................................................................................................................................. 8

4.3.1. Change Grinder burrs................................................................................................................. 8

4.3.2. SAG –Self adjusting Grinder....................................................................................................... 8

4.4. Brewing unit...................................................................................................................................... 9

4.4.1. Remove the brewing unit ........................................................................................................... 9

4.4.2. Remove the spindle motor ......................................................................................................... 9

4.4.3. Brewing units............................................................................................................................. 9

4.4.4. Calibrating the brewing unit....................................................................................................... 9

4.5. Outlet............................................................................................................................................... 10

4.5.1. Manual outlet...........................................................................................................................10

4.5.2. Automatic spout AS .................................................................................................................. 10

4.6. Milk system.......................................................................................................................................11

4.6.1. Default values............................................................................................................................11

4.6.2. Milk temperature.......................................................................................................................11

4.6.3. Foam structure ..........................................................................................................................11

4.6.4. Correction time ..........................................................................................................................11

4.6.5. Change to pressure sensor ........................................................................................................ 12

4.6.6. Milk level calibration................................................................................................................. 12

4.6.7. Configurations Milk system....................................................................................................... 14

4.6.8. Cold Milk Foam CMF ................................................................................................................. 15

4.7. Fridge NEXT...................................................................................................................................... 16

4.7.1. Temperature adjustment .......................................................................................................... 16

4.7.2. Temperature offset ................................................................................................................... 16

4.7.3. Change temperature unit.......................................................................................................... 16

4.7.4. Remove milk pumps.................................................................................................................. 17

4.8. Under counter installation................................................................................................................ 17

4.9. Fridge FUM.......................................................................................................................................18

4.9.1. Temperature adjustment .......................................................................................................... 18

4.9.2. Remove milk pumps.................................................................................................................. 18

4.10. Powder Module................................................................................................................................ 19

4.10.1. Powder hopper ......................................................................................................................... 19

4.11. Diagrams, Fuses and Print Boards.................................................................................................... 20

Egro NEXT

Technical Manual 3 Rev: AA / 09/2018

5. Software .................................................................................................................................................. 21

5.1. Use of USB........................................................................................................................................ 21

5.2. Software components and versions.................................................................................................. 21

5.3. Filenames......................................................................................................................................... 21

5.4. Software update............................................................................................................................... 21

5.4.1. Control Board ........................................................................................................................... 21

5.4.2. Display /Android OS.................................................................................................................. 21

5.4.3. EgroTech and Egro UI................................................................................................................ 21

5.4.4. Recovery...................................................................................................................................22

5.4.5. Exchange of Touchscreen..........................................................................................................22

5.5. Pictures and videos ..........................................................................................................................22

5.5.1. Pictures ....................................................................................................................................22

5.5.2. Video........................................................................................................................................22

5.6. Display .............................................................................................................................................23

5.6.1. Clean the display.......................................................................................................................23

5.6.2. Lifetime ....................................................................................................................................23

5.7. Backup .............................................................................................................................................23

5.8. Technician Menu............................................................................................................................. 24

Product setup ..........................................................................................................................................25

Machine setup .........................................................................................................................................27

Date + Time............................................................................................................................................. 29

Cleanings settings ................................................................................................................................... 29

Counters ................................................................................................................................................ 30

Diagnostic ................................................................................................................................................32

6. Fault finding.............................................................................................................................................35

6.1. List of errors.....................................................................................................................................35

6.2. List of warnings ............................................................................................................................... 36

Document history

Date

Author

Revision

Changes

27.08.2018

Veith

--

First release

20.09.2019

Veith

AA

Complete rework –all chapters approved

Egro NEXT

Technical Manual 4 Rev: AA / 09/2018

1. Introduction

This manual gives additional information for the Egro NEXT.

It contains topics, which are not in the installation manual delivered with the machine or in the user

manual. This manual will be updated on a regularly base.

Please check yourself on www.ranciliogroup.com/Support

The manuals of Egro NEXT are available on the display and for download on our homepage

www.ranciliogroup.com

Further documentation, like document set (electric and hydraulic diagrams), software tree et al. can be

found in the restricted area of our download area.

2. Technical data

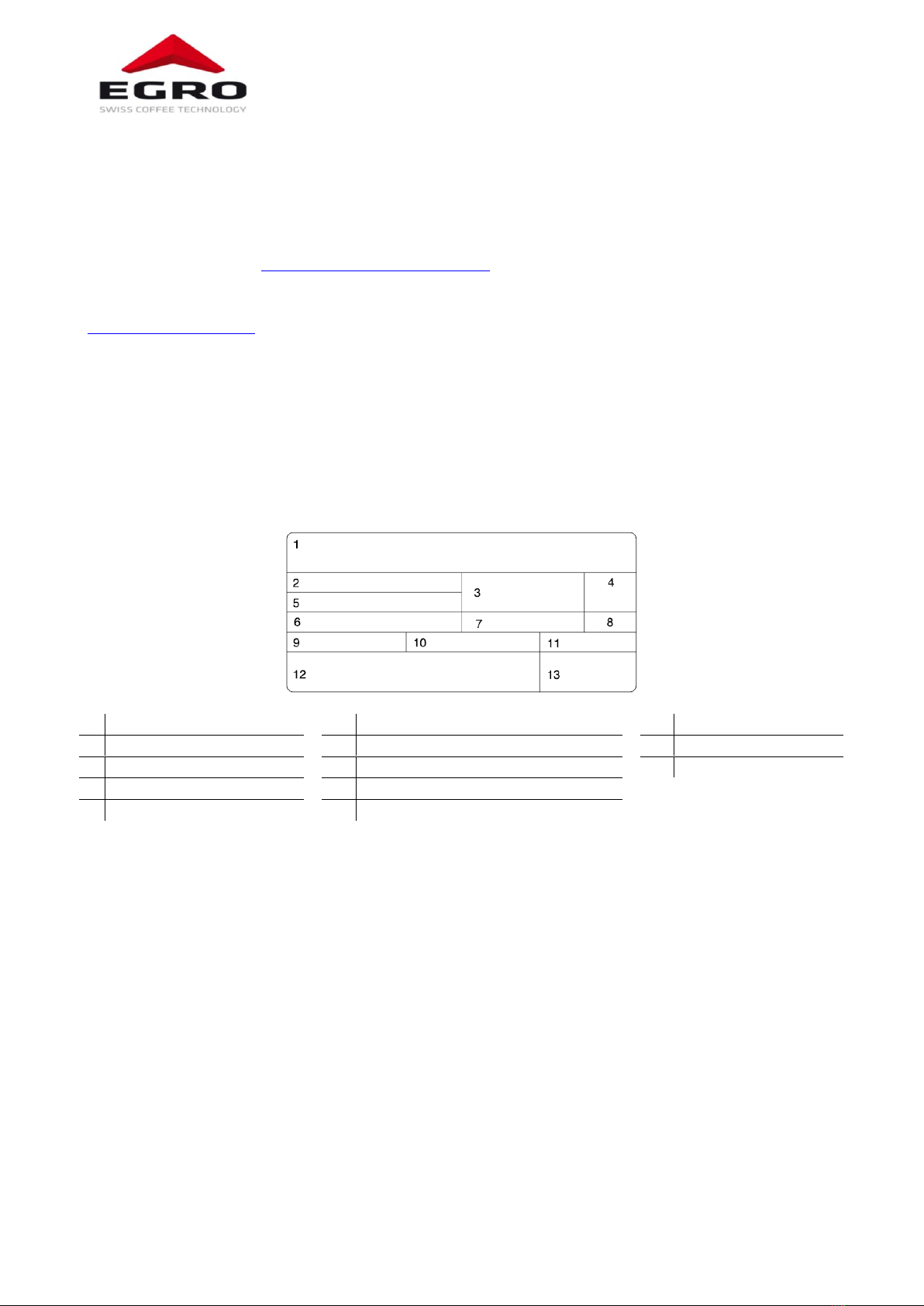

2.1. Type label

The type label is in the machine. Take out the ground drawer and it is visible on the left sidewall.

1

Manufacturer

6

Pin

11

Frequenc

2

Model and version

7

Total absorption

12

Conformity marks

3

Voltage

8

Motor power

13

Date of manufacture

4

EC Conformity mark

9

Max. boiler/static pressure

5

Serial number

10

Heating element power

Egro NEXT

Technical Manual 5 Rev: AA / 09/2018

2.2. Outlet

1

Coffee

2

Hot Water

3

Milk/Milk foam

4

Powder product

5

Cold Milk Foam (CMF)

1

4

4

3

3

2

1

3

2

5

5

5

Egro NEXT

Technical Manual 6 Rev: AA / 09/2018

3. Installation

3.1. Electrical connections

The machines are delivered according to the information on the type label, but they offer different

electrical connections.

Power supply

Power rating

Identification

“Reduced Power”

220-240V 3~, 50/60Hz

5.5 kW

2P

OFF

220-240V 3~, 50/60Hz

6.0 kW

2P

OFF

380-415V 2N~, 50/60Hz

5.5 kW

2P

OFF

380-415V 2N~, 50/60Hz

6.0 kW

2P

OFF

220-240V 1N~ 50/60Hz

5.5 kW

1P

OFF

220-240V 1N~ 50/60Hz

6.0 kW

1P

OFF

220-240V 1N~ 50/60Hz

3.1 kW

LP

ON

220-240V 1N~ 50/60Hz

3.6 kW

LP

ON

208/240 V2ph~, 60Hz

5/6 kW

-

OFF

3.1.1. Change power settings

The power settings can be changed depending on the available power supply. The electrical diagram and

the installation manual show the different ways to connect the machine.

When connecting the machine to 220-240V 1N~ 50/60Hz with 16A fuse the parameter “Machine

setup/Boiler/Reduced Power” in the EgroTech App has to be set to “ON”.

Egro NEXT

Technical Manual 7 Rev: AA / 09/2018

4. Service

4.1. Service Document

The service document for information of maintenance done, will be delivered with every machine. It has

space for breakdowns, which should be noted down by the service technician.

4.2. Preventive Maintenance

Preventive maintenance ensures a continuous quality of products and reduces unscheduled breakdowns.

During preventive maintenance service will be done and necessary spare parts will be exchanged.

The base for preventing maintenance are “Service kits”with all necessary parts.

The preventive maintenance is driven by the number of brewing cycles and/or the predefined time.

Reaching the number of cycles or the time, the coffee machine indicates the message "Perform the

preventive maintenance".

We recommend adjusting the maximum brewing cycles to 40’000 cycles and the time to 1 year.

The brewing cycles depend on various criteria as regularity of brewing and cleanings, composition of water,

cleaning product, climatic conditions, etc.

In case of unfavorable conditions adjust the number of brewing cycles.

4.2.1. Service interval

Cycles

40'000

80'000

120'000

160'000

200'000

Time

1 Year

2 Years

3 Years

4 Years

5 Years

Service kit

Service kit &

Service kit iSteam

Service kit

Service kit &

Service kit iSteam

Service kit

4.2.2. Maintenance

Tables with maintenance tasks for each machine model are available in our download area. They list the

tasks and the parts and are given with the necessary drawings.

4.2.3. Lubricants

The lubricant table informs which lubricant has to be used according the application. The use of not

specified lubricants can shorten the lifetime extremely.

Description

Type

ID

Thermal Range

Area of Application

High performance

lubricant

Berulub

FG-H 2 SL

059246

-45 - +160°C

All connections:

Boiler fittings, tea- and steam wand,

piston motors

Used for connections and mechanical

moving parts

High performance

lubricant

Berulub

SIHAF 2

059247

-45 -+160°C

For all rubber seals like:

NBR, EPDM, Viton

Not applicable for Silicon O-Ring!

Synth. Assembly

Grease

Klübersynth

UH1 64-2403

054567

-30 - +140°C

Piston O-Rings

Do not use with EPDM rubbers!

Egro NEXT

Technical Manual 8 Rev: AA / 09/2018

4.2.4. Service kits

The service kits are listed below with their ID-number. As the content can change based on technical

improvements, we do not list the content. The parts of the sets can be seen in our WEB-shop.

Description

ID-Number

Service kit ONE/NEXT Pure Coffee

10701515

Service kit ONE/NEXT Milk

10701514

4.3. Grinder

4.3.1. Change Grinder burrs

A counter for the ground coffee is integrated in the software. We recommend to set to the counter in the

EgroTech App <Counter/Grinder/Ma. Value left> and <…/Max. Value right> to 1000 kg. As soon as the

amount is reached, a message will inform to replace the burrs.

-Close the bean hopper and grind the beans still in the grinder

-Switch off the machine

-Remove the bean hopper and the top plate

-Empty the grinder completely with a vacuum cleaner

-Remove the grinder adjustment from the grinder

-Turn the upper burr-holder counter-clockwise until the head emerges completely;

-Unscrew the screws and remove the burrs from the burr-holder:

-Carefully clean the burr supports, the burr-holder thread and its housing;

-Position the new burrs in their holders and block them firmly in place;

-Reassemble the machine, performing the previous steps in reverse.

-Switch on the machine

-Calibrate the new burrs.

If the grinding process takes an unusually long time, the grinder should be recalibrated. If the grinder during

the calibration takes more than 5 seconds to grind 10 grams of coffee, the burrs must be replaced.

If the grinding result is irregular, the burrs must also be checked and replaced if necessary.

4.3.2. SAG –Self adjusting Grinder

The grinder setting will be managed according the brewing time of the coffee. This is done with a motor

with worm gear mounted to the grinder.

All machines of Egro NEXT have SAG by default

SAG is working with a reference product for each grinder. Most time it is Espresso for the left grinder and

coffee for the right one. The parameters which have to be considered for the reference product are:

grams

pulses

pre-infusion

pressure

If for the left grinder the product “Espresso” is selected, not only this product will be taken in account, but

all products, which have the same values for the above mentioned parameters, e.g. “Cappuccino”.

Egro NEXT

Technical Manual 9 Rev: AA / 09/2018

4.4. Brewing unit

4.4.1. Remove the brewing unit

Unlock the frame, remove left sheet metal, and

disconnect the tubes from the pistons and the cables

from the control board. Unscrew fastening screws

and disassemble brewing unit.

4.4.2. Remove the spindle motor

To remove the spindle motors, the screws at the top

or at the bottom must be removed. Subsequently,

the motor with the piston are pulled out up or down

and can be taken apart.

4.4.3. Brewing units

Egro NEXT can be equipped with two different

brewing chambers –BC18 or BC22.

BC18 is the default brewing unit. It has the smaller

diameter of the brewing chamber and can work with

up to 18 gram of grind coffee.

4.4.4. Calibrating the brewing unit

When replacing the brewing unit or after the

exchange of spindle motors, the brewing unit must be

recalibrated.

The auto calibration can be found in <Machine setup>

under <Factory settings> of the EgroTech App. The

password can be found in the menu of EgroTech App.

BC18

Egro NEXT

Technical Manual 10 Rev: AA / 09/2018

4.5. Outlet

4.5.1. Manual outlet

This force, which is needed to adjust the outlet, is controlled

by a spring. To adjust the spring use an allen key on the two

screws on the backside of the outlet.

Move clockwise for stronger movement and to the opposite

direction for easier movement.

4.5.2. Automatic spout AS

The Automatic Spout (AS) is driven by a motor and offer the possibility to define five different cup heights

in the EgroTech app, which will be assigned to the products in the Egro UI.

The parameter cup height is also used for hot water products if the machine has a central outlet and should

be set up according to the cup used.

If the machine has the hot water outlet on the side, the cup height must be defined to “top” so that no

movement of the outlet takes place.

Machines with AS have no handle on the outlet. Anyhow it is possible, when needed, to move the outlet

slowly by hand.

This should only be done, if the outlet does not move anymore with the motor.

Egro NEXT

Technical Manual 11 Rev: AA / 09/2018

4.6. Milk system

4.6.1. Default values

The default values are considered as recommendations. As not all systems work the same, they might be

adjusted. The values are set for a milk temperature of 5°C.

The temperature setting “Medium” is to be used for foam products.

The higher the value of the milk temperature (low/medium/high) the more milk will be delivered. As the

steam delivery is constant the milk product will be cooler.

The higher the value of the foam structure (fine/medium/big) the more air will be pumped. By adding air,

the temperature of the milk products will increase.

4.6.2. Milk temperature

First, the milk temperature has to be adjusted. This is done in percentage of the power of the milk pump on

the Egro NEXT TopMilk and with restrictors on the Egro NEXT QuickMilk.

Please take care, that foam products always have a higher temperature than milk products with the same

settings.

TopMilk

Milk temperature

High speed (Low milk temp.)

95

Medium speed (Medium milk temp.)

70

Low speed (High milk temp.)

57

4.6.3. Foam structure

We recommend using only one temperature setting for foam products. This simplifies the setting of the

foam structure (in %). When changing the temperature setting the foam structure has to be adjusted.

TopMilk & QuickMilk

Foam structure

Fine

33

Medium

38

Big

42

4.6.4. Correction time

The correction time enlarges the milk delivery time for the the first product after the rinsing. This is

necessary as the milk pipes are empty. It should be adjusted in a way that the milk reaches the frother head

when the steam will be switched on. This can be seen by a seriously increase of steam or by the switching

of the steam valves.

If the correction time is too short, it could happen that after a rinsing no milk will be charged.

Next to machine

Under counter

Correction time

1.0 s

2.0 s

Rinsing time

0.0 s

0.5 s

Blowout time

0.0 s

1.5 s

The adjustement of these values is particulary necessary, when the refrigerator is placed under the

counter.

Egro NEXT

Technical Manual 12 Rev: AA / 09/2018

4.6.5. Change to pressure sensor

All TopMilk configurations of the milk system can work with a level measurement based on a pressure

sensor.

For a retrofit the the pressure sensor level measurement, select in the Web Shop according to the single or

double milk configuration of your system and follow the instruction given here for each sensor.

For the sensor(s), an auto calibration is available and the technician can adjust it for the milk container in use at

the customer.

-Remove the milk pump unit from the fridge

-Remove the tube from the white plastic part and take out the milk tube

-Remove the circlip and move the plastic part through the opening

-Insert the new plastic part with the mounted pressure sensor. The sensor with the red point on it is

the standard /left sensor, the blue point shows the right one, which is only used with two kind of

milk.

Attention: Take care not to damage the cables and the sensor

-Secure the plastic part with the circlip and install the pump unit in the right place

-Plug in the milk tubes

-Connect the wires of each sensor together with the other sensor.

-Connect them to the mainboard of the coffee machine (connector J3)

-Perform the auto calibration for each sensor.

When ordering the machine with KS9, the cable is in the fridge and has to be connected to J4 on the

extension board.

When ordering the machine for FUM (Fridge Under Machine) or SMPU (Standanlone Milk Pump Unit) the

cable in the coffee machine is already mounted.

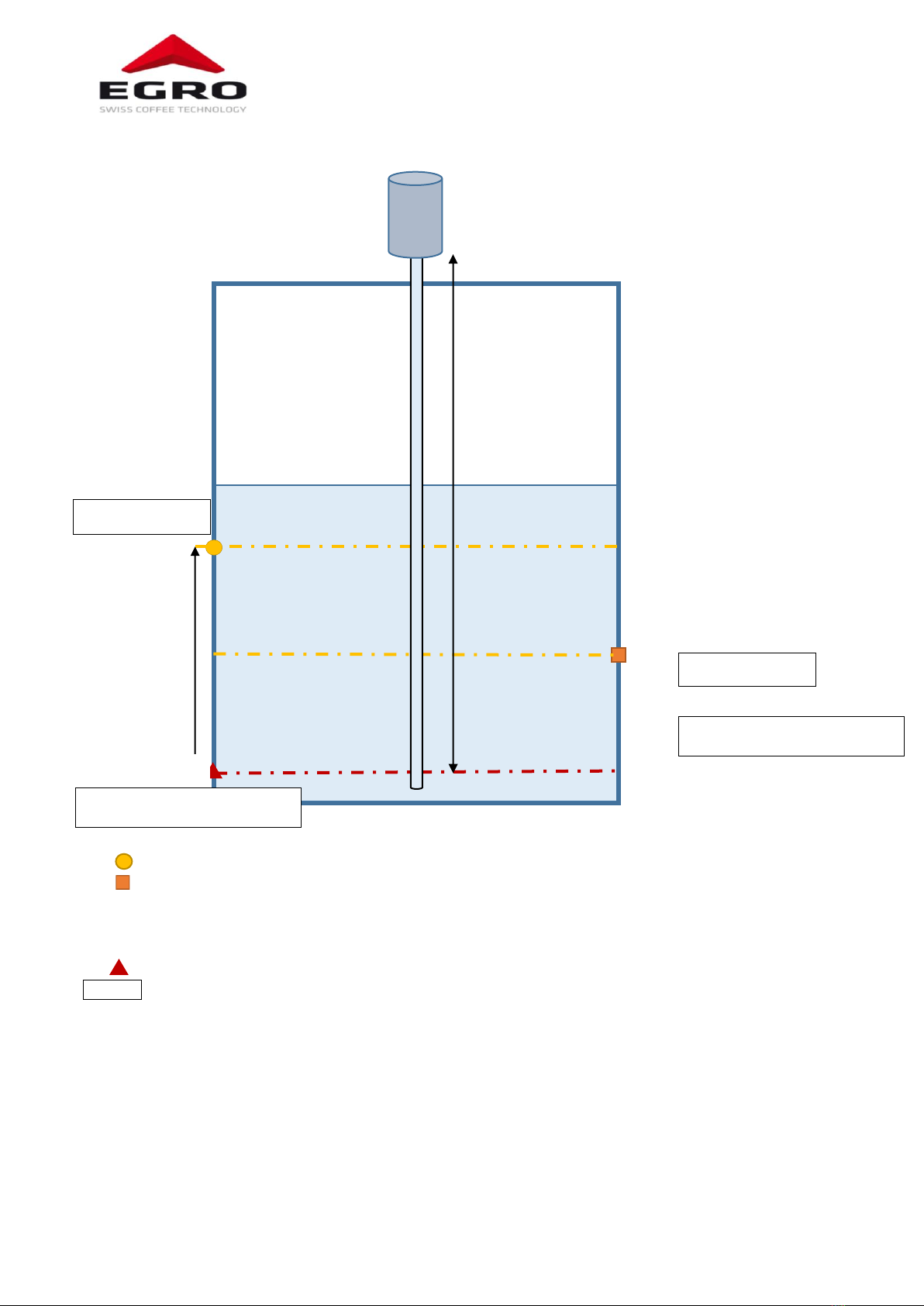

4.6.6. Milk level calibration

ATTENTION! Set <Product Setup/Milk/Module Type> first to “TopMilk”or “TopMilk CMF”.

The menu for the level measurement is in the software under <Product Setup/Milk>.

The system with the pressure sensor must be correctly configured in order to be able to calculate the

available milk in the fridge.

The machine has an automatic calibration, which allows the technician to adjust the system to the milk

container in use.

The calibration should be done, when the machine is correctly positioned on a stable, leveled surface.

The auto calibration for the milk level guides with a sequence of steps through the procedure. It takes some

minutes depending on the capacity of the milk container. When the “Fill”-button appears, press it at least

up to the point that the metallic restrictor holder is completely in the water.

Attention, water is coming out of the outlet of the coffee machine!

As preparation take care that the milk tube is hanging free in the container and almost touch the bottom of

it.

When having two machines, which take the milk out of the same container(s), take care to set the Zero

level a little bit higher to avoid that the products cannot be finished as both machine can take out milk at

the same time.

Perform the auto calibration for both machines independently (not together).

Egro NEXT

Technical Manual 13 Rev: AA / 09/2018

Milk level Alarm concept

Level= X cm (Warning level parameter)

At least one milk product is not possible.

Milk qty. Product > Milk qty. in container

Products with a higher milk quantity than in the container are disabled.

Zero Level

Message

►Action

Zero level

parameter [cm]

X cm

Warning level

parameter [cm]

Low milk level

Residual Milk parameter:

ON

OFF ►All Milk products blocked

Zero Level

Low milk level

Milk missing, refill container

Milk missing, refill container

Egro NEXT

Technical Manual 14 Rev: AA / 09/2018

4.6.7. Configurations Milk system

The configurations shown below are available for the fridge KS9 or as standalone milk pump unit (SMPU).

1L –1M

2L –1M

1 milk –1 machine

2 milk –1 machine

1L –2M

2L –2M

1 milk –2 machines

2 milk –2 machines

Milk pump unit:

1 Milk pumps

2 Milk valves

Egro NEXT

Technical Manual 15 Rev: AA / 09/2018

4.6.8. Cold Milk Foam CMF

Cold Milk Foam (CMF) is an option of the milk system, which should be ordered with the machine/fridge.

CMF is only available for Egro NEXT TopMilk with one milk and one machine! All other versions cannot be

equipped with it.

Special maintenance work is not necessary for the CMF-module. For the rinsing and cleaning of the milk

system the way through the CMF-module will be considered automatically, when a CMF-product was

delivered before.

Cold milk foam can have different stiffness. We integrated three levels with the following parameters:

Liquid

Creamy

Stiff

Milk pump

46%

44%

42%

Air pump

50%

50%

50%

Mixer

100%

100%

100%

The stiffness will be done mainly with the milk pump. Mixer and air-pump should not be adjusted. The

values listed above are considered as guiding value and have to be adjusted, if necessary

Egro NEXT

Technical Manual 16 Rev: AA / 09/2018

4.7. Fridge NEXT

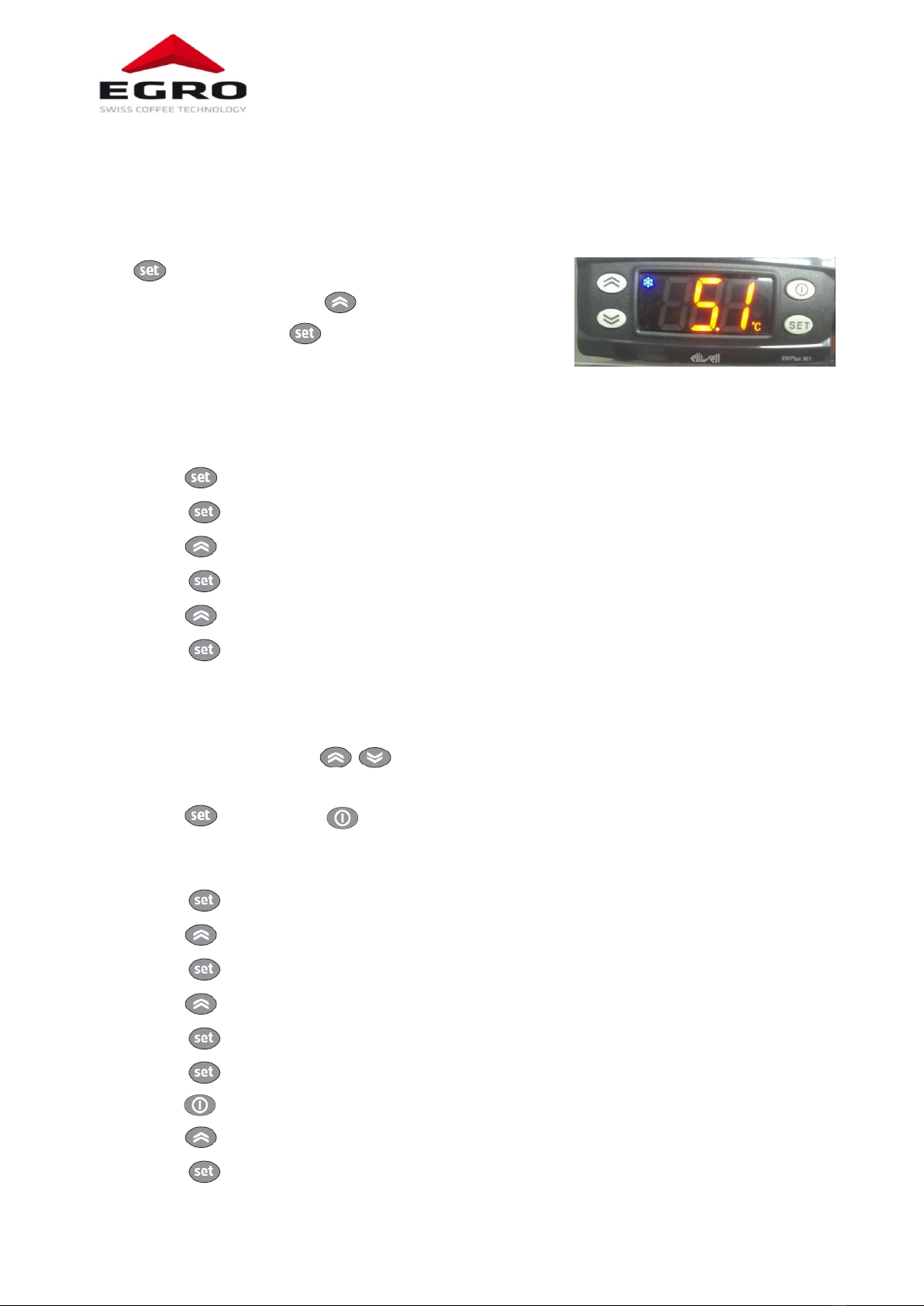

The temperature controller is on the left side inside the housing of the fridge. After removing the left side

panel, adjustment, unit change and calibration of the temperature can be done.

4.7.1. Temperature adjustment

Press twice.

Modify the temperature with the buttons.

Confirm the new value with .

The temperature must be set to the highest temperature in the

fridge. We recommend to set it to 5 °C/41°F

4.7.2. Temperature offset

Press until <PA1> appears on the display, approx. 5 sec.

Press and <0> will appears on the display

Press until <15> appears on the display

Press once; <dF1> appears on the display

Press until <CA1> appears on the display

Press once; the shown temperature is the offset-temperature, which mean the correction

between the measured and the displayed temperature.

Measure the milk temperature in the fridge. The milk should be cold and for at least three hours

there was no refill.

Adjust temperature with until the value in the display corresponds with the measured

value

Press once and then to leave programming

4.7.3. Change temperature unit

Press until <PA1> appears on the display, approx. 5 sec.

Press once; <PA2> appears on the display

Press and <0> will appear on the display

Press until display shows <15>

Press once; <CP>appears on the display

Press once and on the display appears <dF1>

Press once; <CP>appears again on the display

Press until display shows <di 5>

Press once and on the display appears <LOC>

Egro NEXT

Technical Manual 17 Rev: AA / 09/2018

Press until display shows <dro>

Press once and select the temperature unit with the button:

o<0> = °C <1> =°F

Press twice, to leave programming

4.7.4. Remove milk pumps

Switch off the fridge!

Remove the two screws (a) on the front of the

plastic cover inside the fridge!

Take out milk pump unit.

4.8. Under counter installation

When installing the refrigerator under the counter, some parameters must be adjusted. Please note

chapter 4.6.4.

Egro NEXT

Technical Manual 18 Rev: AA / 09/2018

4.9. Fridge FUM

4.9.1. Temperature adjustment

The temperature adjustment is on the back side of the fridge.

Turn the thermostat to the left to lower the temperature.

Do not turn to the maximum power, as the milk might freeze.

We recommend to mark the ideal temperature on the scale. The ideal

temperature is in the area, where the controller is palced in the picture.

4.9.2. Remove milk pumps

Switch off the fridge!

Remove the two screws

(a) on the upper end of

the milk pump unit inside

the fridge.

Take out milk pump unit.

Egro NEXT

Technical Manual 19 Rev: AA / 09/2018

4.10. Powder Module

The preparation of a powder product is handled with a number of parameters described with the diagram

below. The parameters are split in the one, which are necessary to adjust for each product and the ones

which are handled as a machine parameter.

Make sure to make the water calibration, in the <Product Setup/Powder/Water test> of the EgroTech

app!

Parameters of the EgroTech app are makred with “ET”. All other parameters are configured in the Egro UI

Preparation

time

Start

Stop

Water

Mixer

running

Powder

Powder 1

Powder 2

1

2

3

4

5

6

7

1

Product configuration/ Powder delay

5

Product configuration/ Left powder amount

or Right powder amount

2

Product configuration/ Water delivery

6

“ET” Product set up/ Stop Mixer

3

“ET” Product set up/ Mixer delay

7

Fix values (not configurable)

4

“ET” Product set up/Hopper delay

4.10.1. Powder hopper

The powder hoppers should be cleaned completely once a week.

When reassembling, it is important to have the right order and placements of the parts to secure a proper

function. Some parts are similar and can easily be mixed up.

Front components

Back components

Take care on the knobs!

They are available on the front and on the back of

the powder hopper

Egro NEXT

Technical Manual 20 Rev: AA / 09/2018

4.11. Diagrams, Fuses and Print Boards

The diagram set with the electric and hydraulic diagrams and their legend are delivered with the coffee

machine.

For the detailed description of the print boards with the values of the fuses and the description of the LEDs

we offer a separate document in our download area.

This manual suits for next models

1

Table of contents

Other Egro Coffee Maker manuals