5 / 70

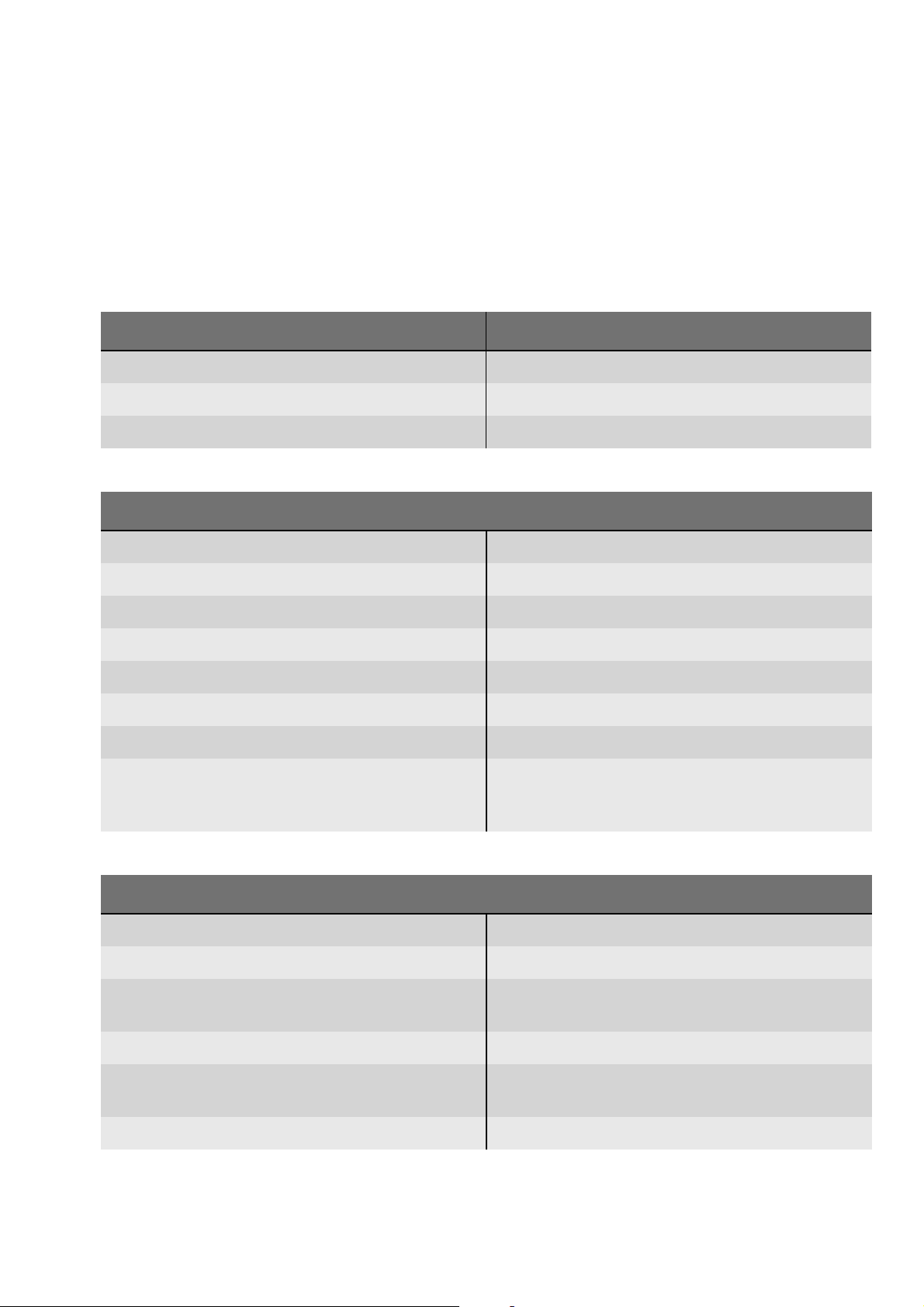

Table of Contents

80116-941_V24392

2023-03

Table of Contents

1Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Classification of the safety information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Knowledge of the User Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Protection from the risk of electric shock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Handling of argon pressure cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Electrostatically sensitive components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Liability and warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2Modifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

From Version 1.1.x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

From Version 1.2.x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

From version 1.3.x. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

From version 1.4.x. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

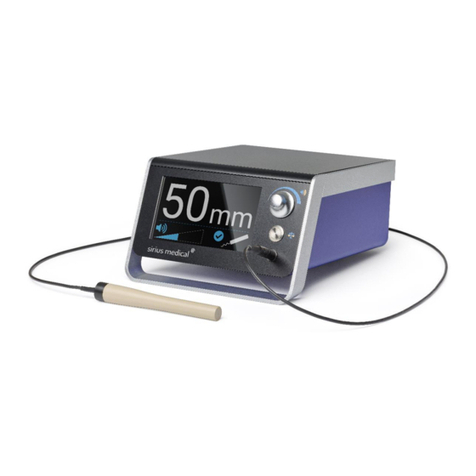

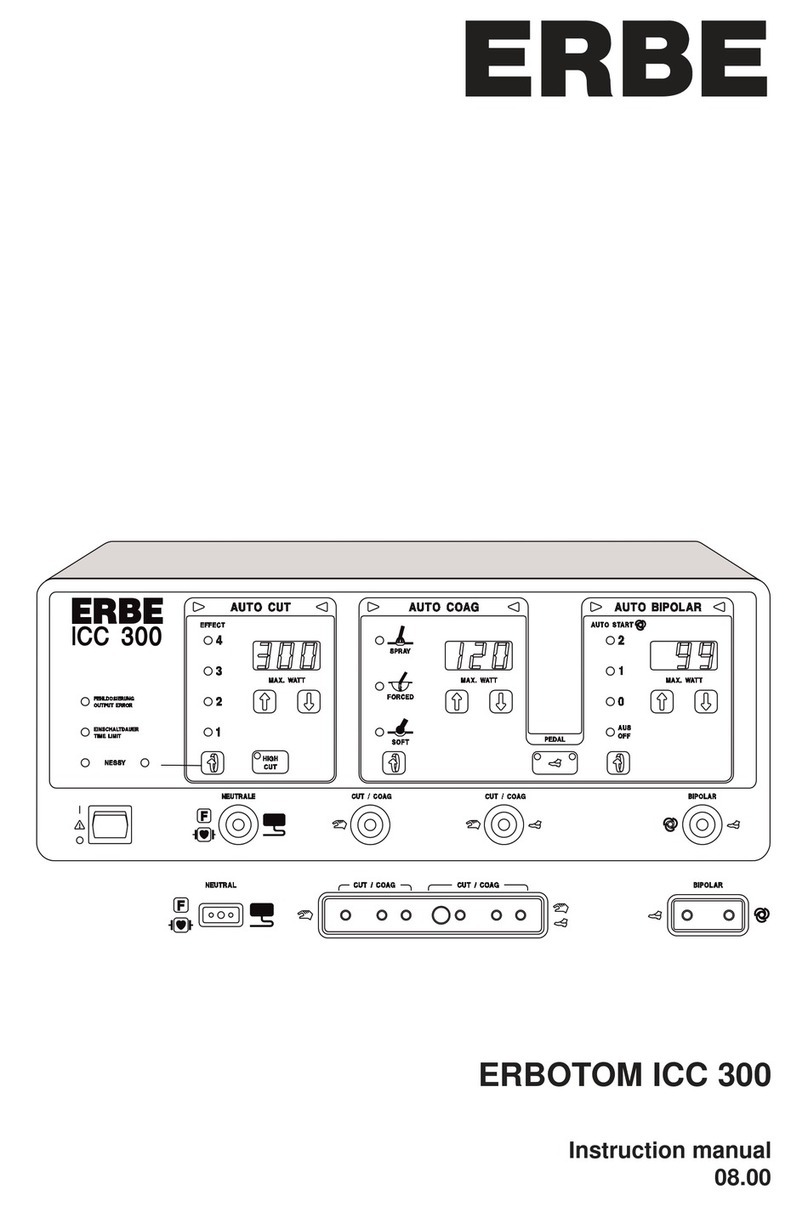

3Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Controls at the front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Controls at the rear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

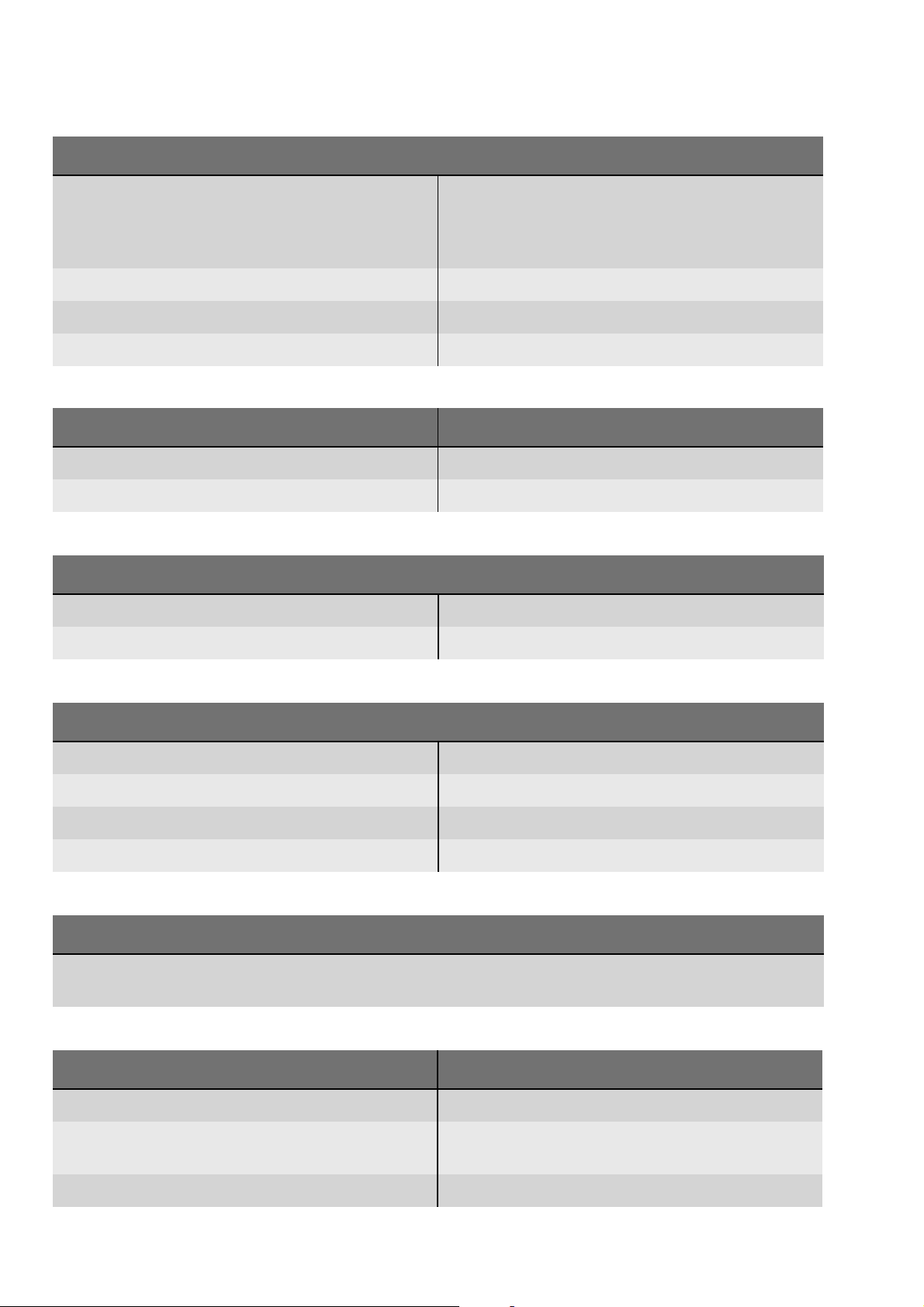

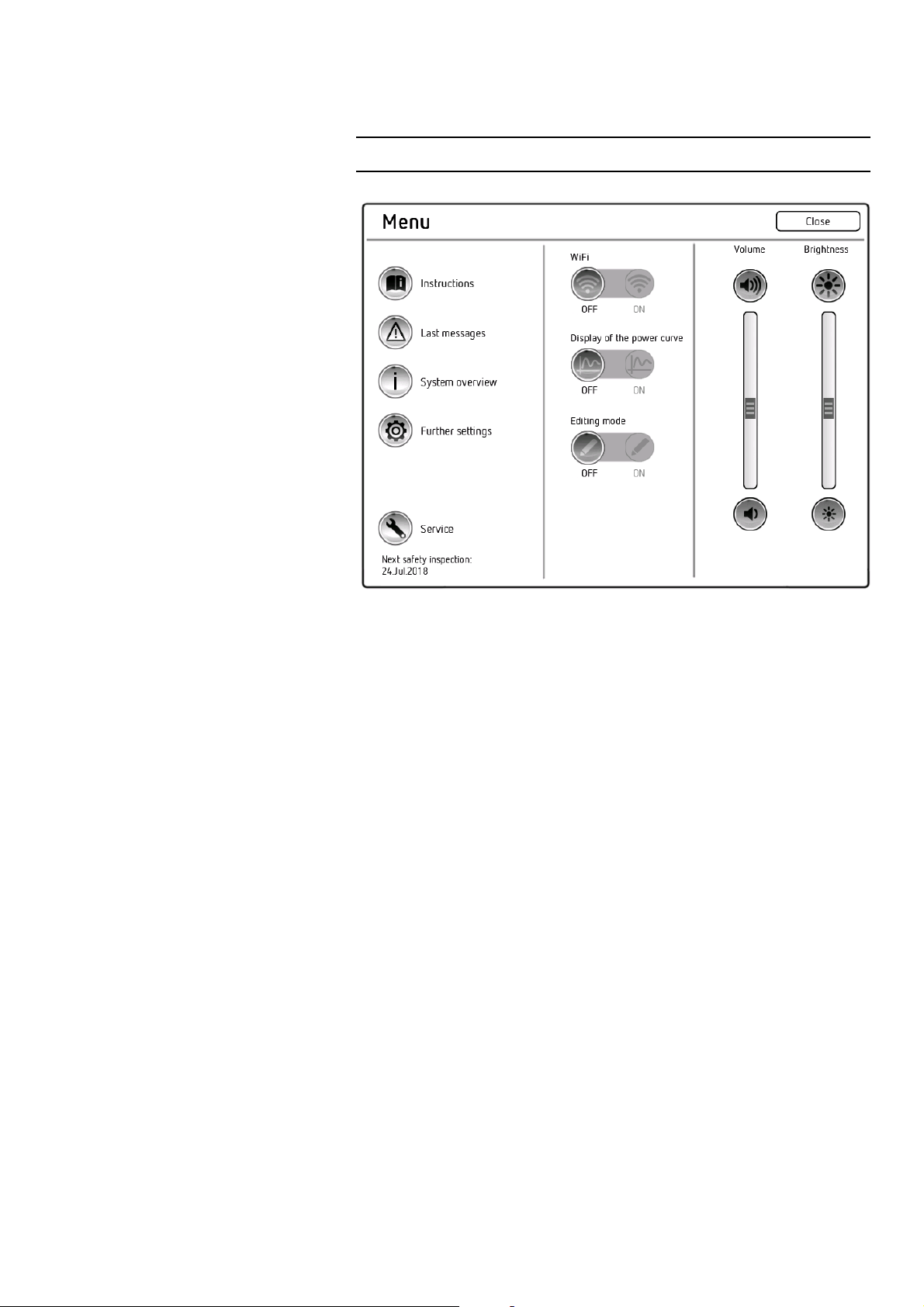

5System settings and "Service" menu. . . . . . . . . . . . . . . . . . . . . . . . 15

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Overview of system settings 1: Further settings . . . . . . . . . . . . . . . . . . . . . . . . 15

Overview of system settings 2:

Protected settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Overview: "Service" menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Calling up system settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Calling up the "Service" menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

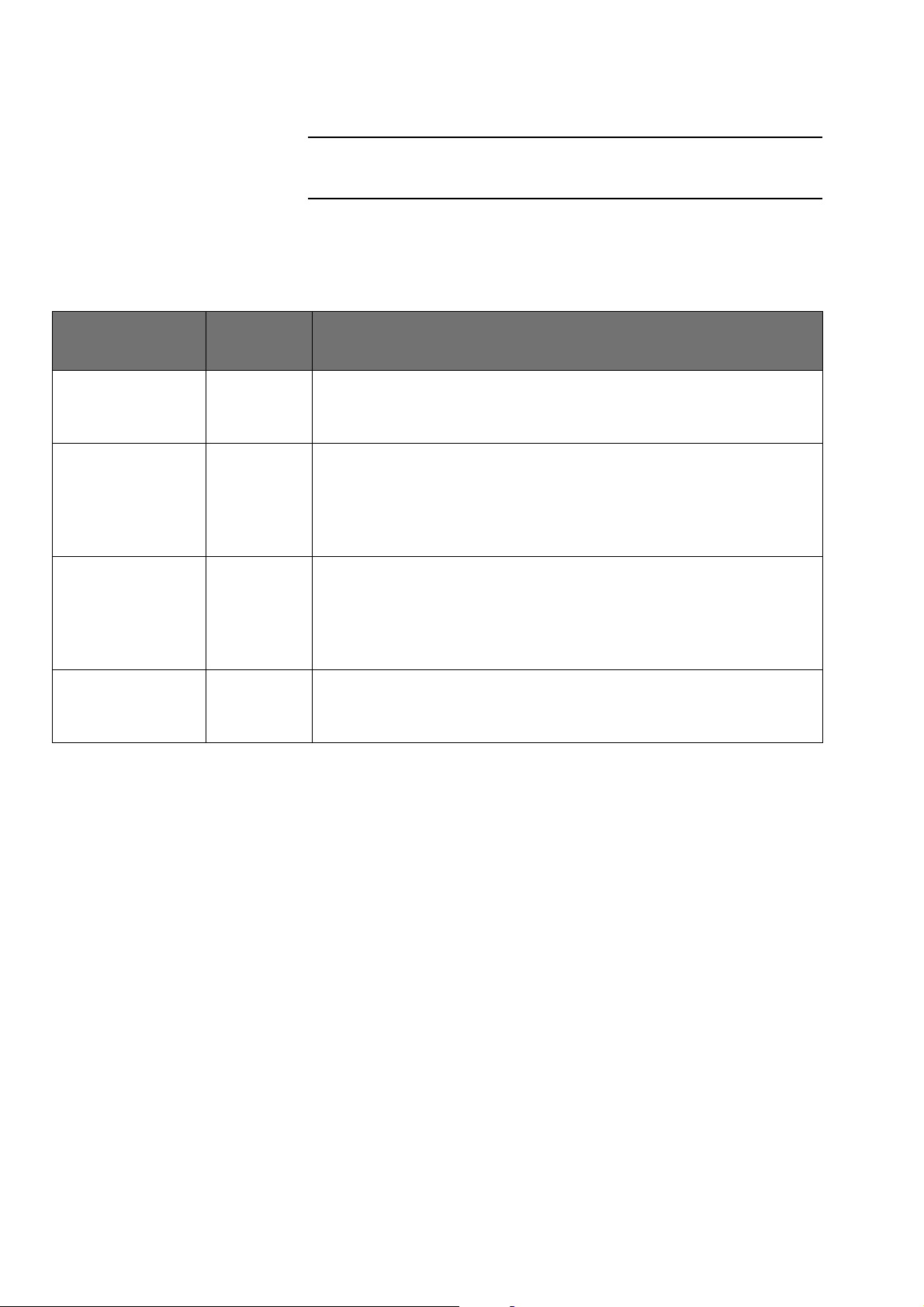

6Remedying malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

ERROR list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Abbreviations of Error displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

APC/APC-A error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

I/I-A error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

S/S-A error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

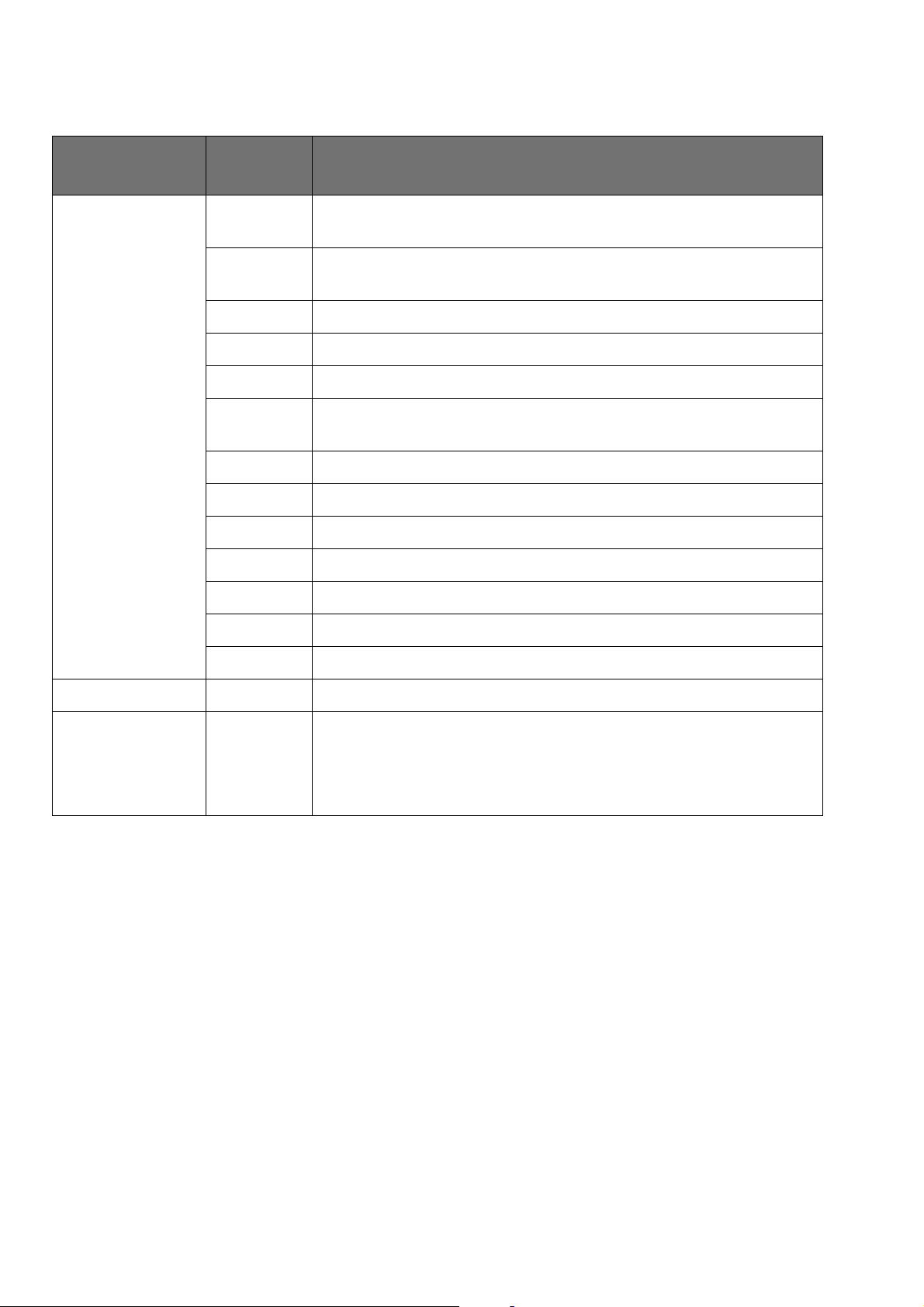

7Maintenance and servicing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Who is allowed to perform servicing and maintenance work? . . . . . . . . . . . . . 33

What is a technical safety check? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

How often does a technical safety check have to be performed?. . . . . . . . . . . 33

Technical safety check – step by step. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Testing and measuring equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35