8

MANUGENETOP3xx - Version 2.00

© 2018 EXOR International S.p.A. - Subject to change without notice

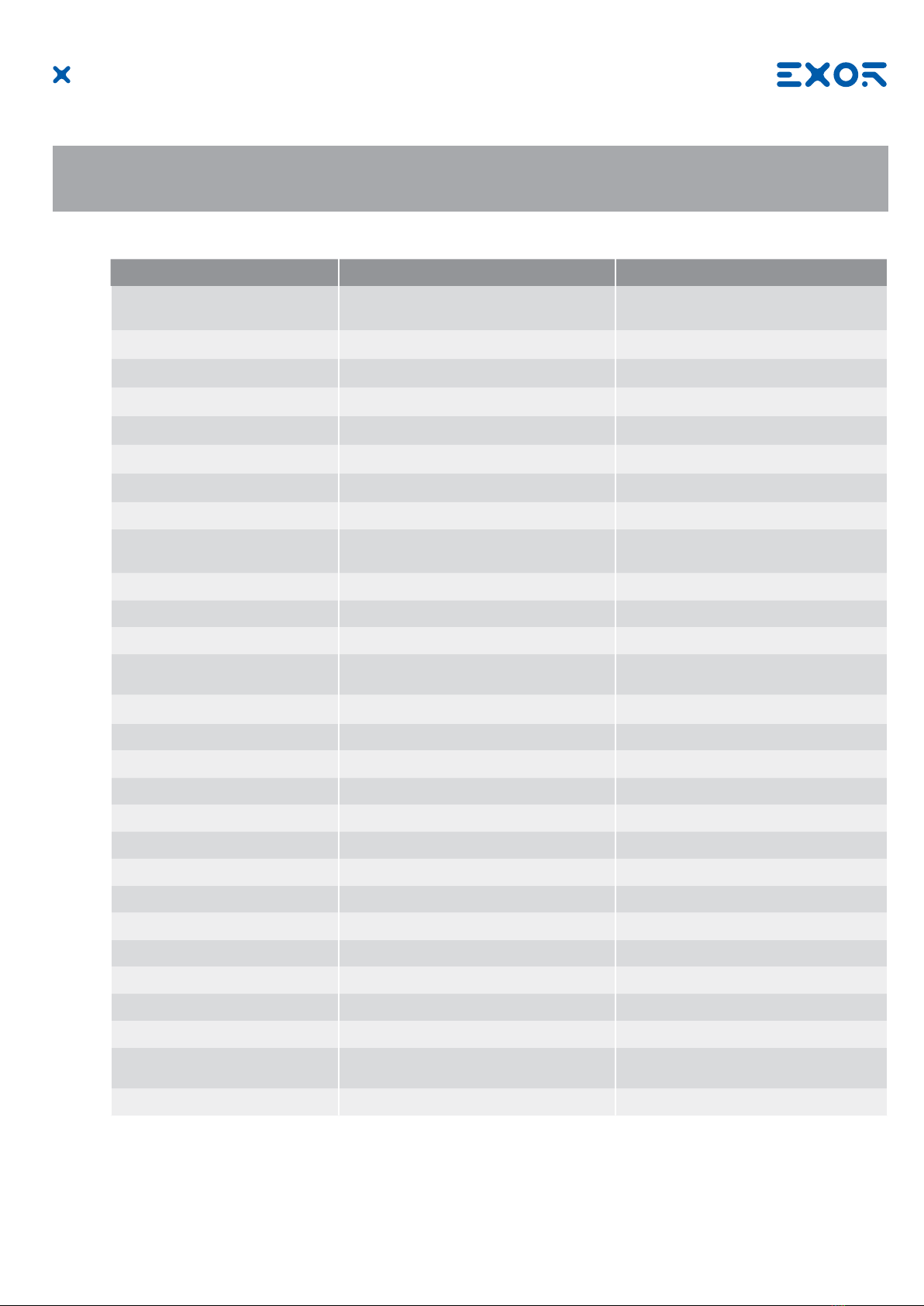

3 Technical Specications

Touch screen technology Resistive

Back-up battery 3V 50mAh Lithium, rechargeable, not user-replaceable,

model VL2330.

Fuse Automatic

PC/Printer Port RS-232, RS-485, RS-422 software congurable

300 - 38400 baud

PLC Port RS-232, RS-485, RS-422 software congurable

300 - 38400 baud

AUX Port connector D-9 pin female (functionality can be congured

with an optional communication module)

User memory 64MB

Recipe memory Flash

Hardware clock Clock/Calendar with back-up battery

Accuracy RTC (at 25°C operating) <100ppm

Alarms 1024

Historical event list last 1024 events with back-up battery

Programming software Designer version 6

Environmental conditions

Operating temperature (vertical 0 ÷ +50°C EN 60068-2-14

installation)

Storage temperature -20 ÷ +70°C EN 60068-2-14

Operating and storage humidity 5 ÷ 85 % RH not-condensing EN 60068-2-30

Vibrations 5 ÷ 9 Hz, 7 mm p-p EN 60068-2-6

9 ÷ 150 Hz, 1 g

Shock ± 50 g, 11 ms, 3 pulses per axis EN 60068-2-27

Protection class IP66 front panel * EN 60529

* The front face of the unit, installed in a solid panel, has been tested using conditions equivalent to the standards

shown in the “Environmental conditions”. Even though the level of resistance unit is equivalent to these standards, oils

that should have no effect on the panel can possibly harm the unit. This can occur in areas where either vaporized oils

are present, or where low viscosity cutting oil are allowed to adhere to the unit for long periods of time. If the front face

protection sheet on the panel becomes peeled off, these conditions can lead to the ingress of oil into the panel and

separate protection measures are suggested.

If the installation gasket is used for a long period of time, or if the unit and its gasket are removed from the panel, the

original level of the protection cannot be guaranteed.

Electromagnetic Compatibility (EMC)

Radiated disturbance test Class A EN 55011

Electrostatic discharge immunity test 8 kV (air electrostatic discharge) EN 61000-4-2

4 kV (contact electrostatic discharge)

Radiated, radio-frequency, 80 MHz ÷ 1 GHz, 10V/m EN 61000-4-3

electromagnetic eld immunity test 1,4 GHz ÷ 2 GHz, 3 V/m

2 GHz ÷ 2.7 GHz, 1 V/m