6

EN

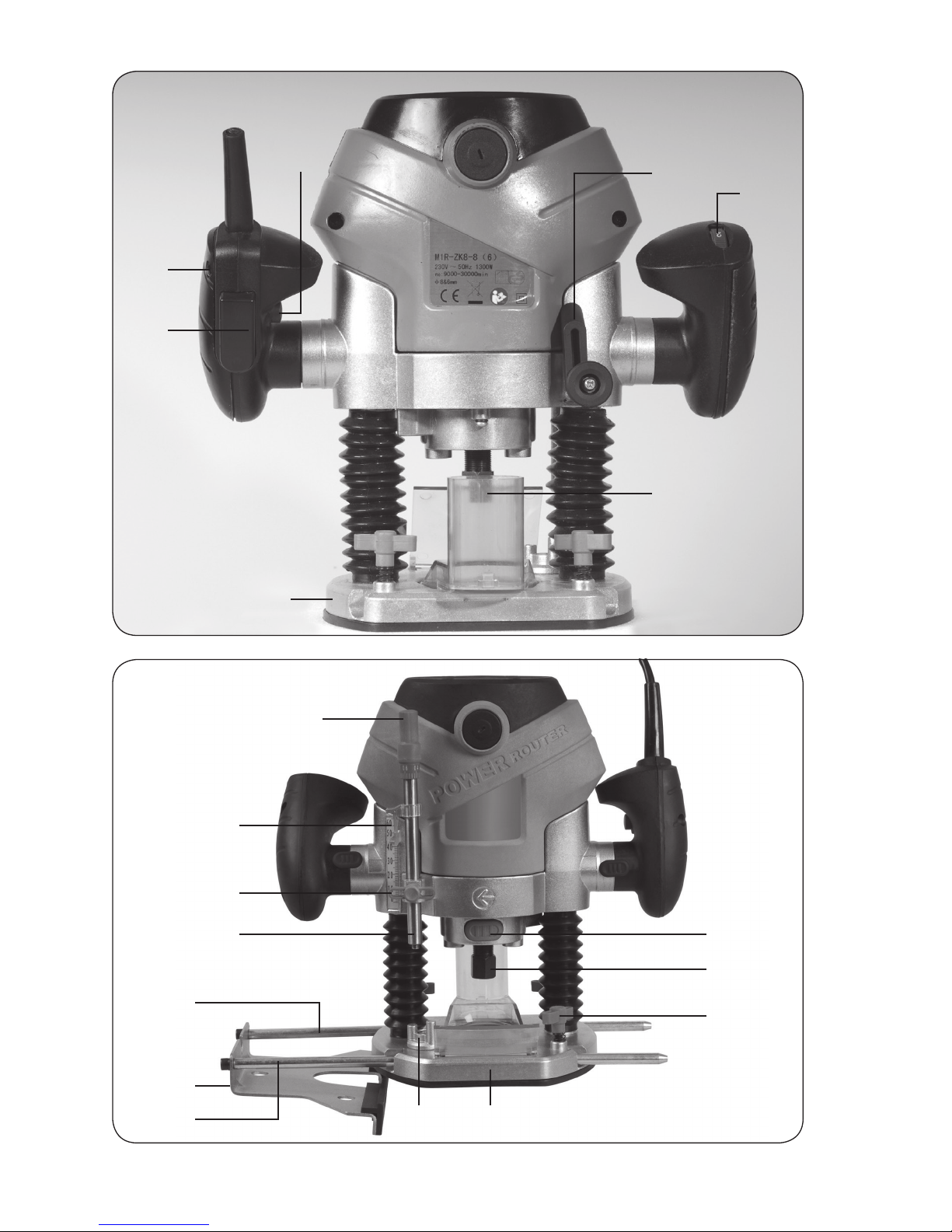

Fig. B

Only use cutters with a shaft diameter which

corresponds with the size of the collet. Only use

cutters which are suited for the maximum speed

of the machine. The cutter diameter should not

exceed the maximum diameter (see ‘Technical

specications’).

Never tighten the collet nut, if there is no router bit

in the collet; the collet may be damaged.

• Pressthespindlelock(7)andturnthecollet

nut (6) until it engages in the lock. Keep the

spindle lock pressed during this procedure.

• Openthecolletnutusingthespanner.

• Placethecuttershaftinthecollet.

• Tightenthecolletnutsothatthecutteris

locked properly.

• Openthecolletnutwhenyouwanttoreplace

a cutter.

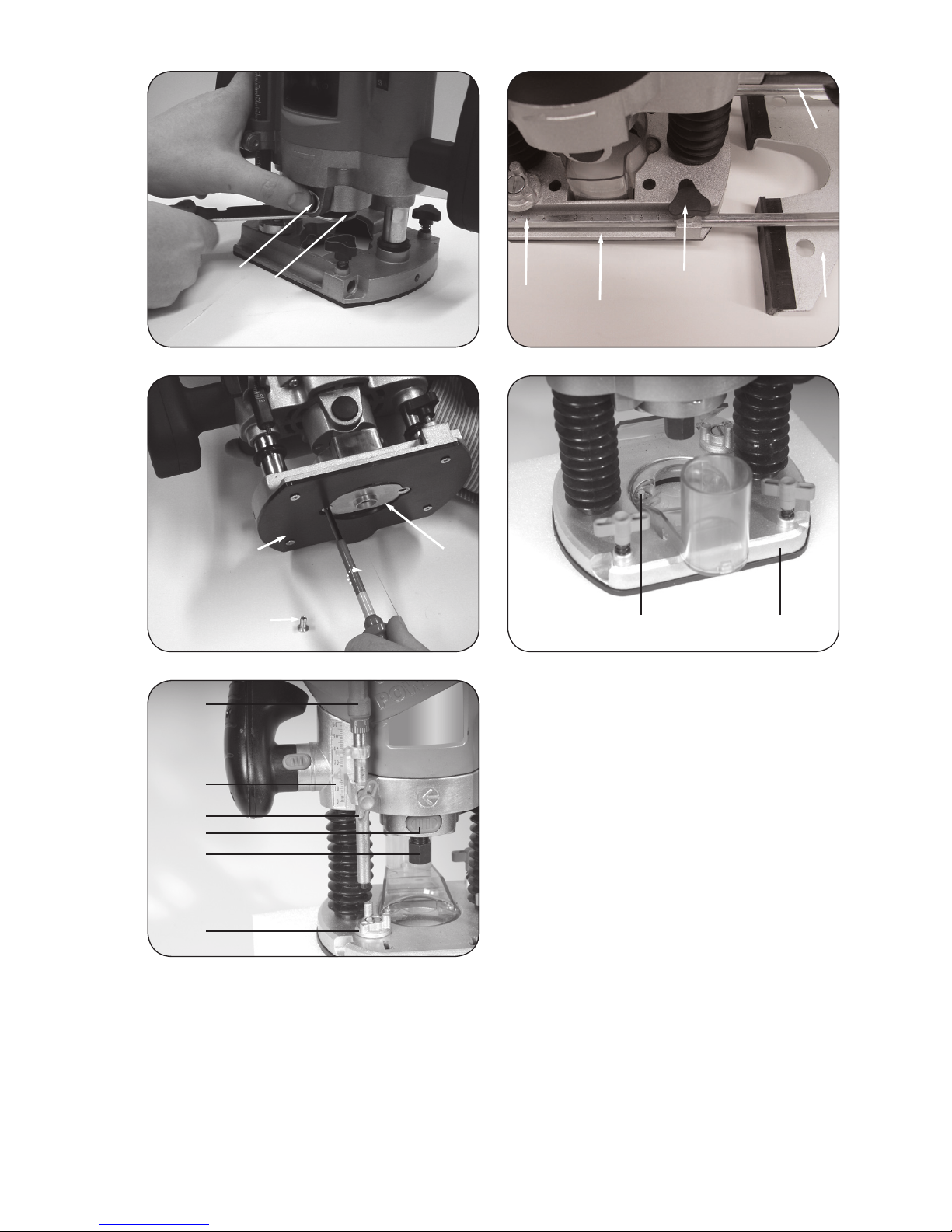

The parallel fence is a useful tool for precision

routingataxeddistancefromtheedgeofthe

workpiece.

• Placethedesiredcutterinthetool.

• Slidetheparallelguidewiththeguiderodsinto

the baseplate and tighten at the required

measure with the wing bolts

Fig. D

The template guide is a handy aid for cutting a

pattern.

• Mountthetemplateguide(23)ontherouter

base (3) using the screws (22).

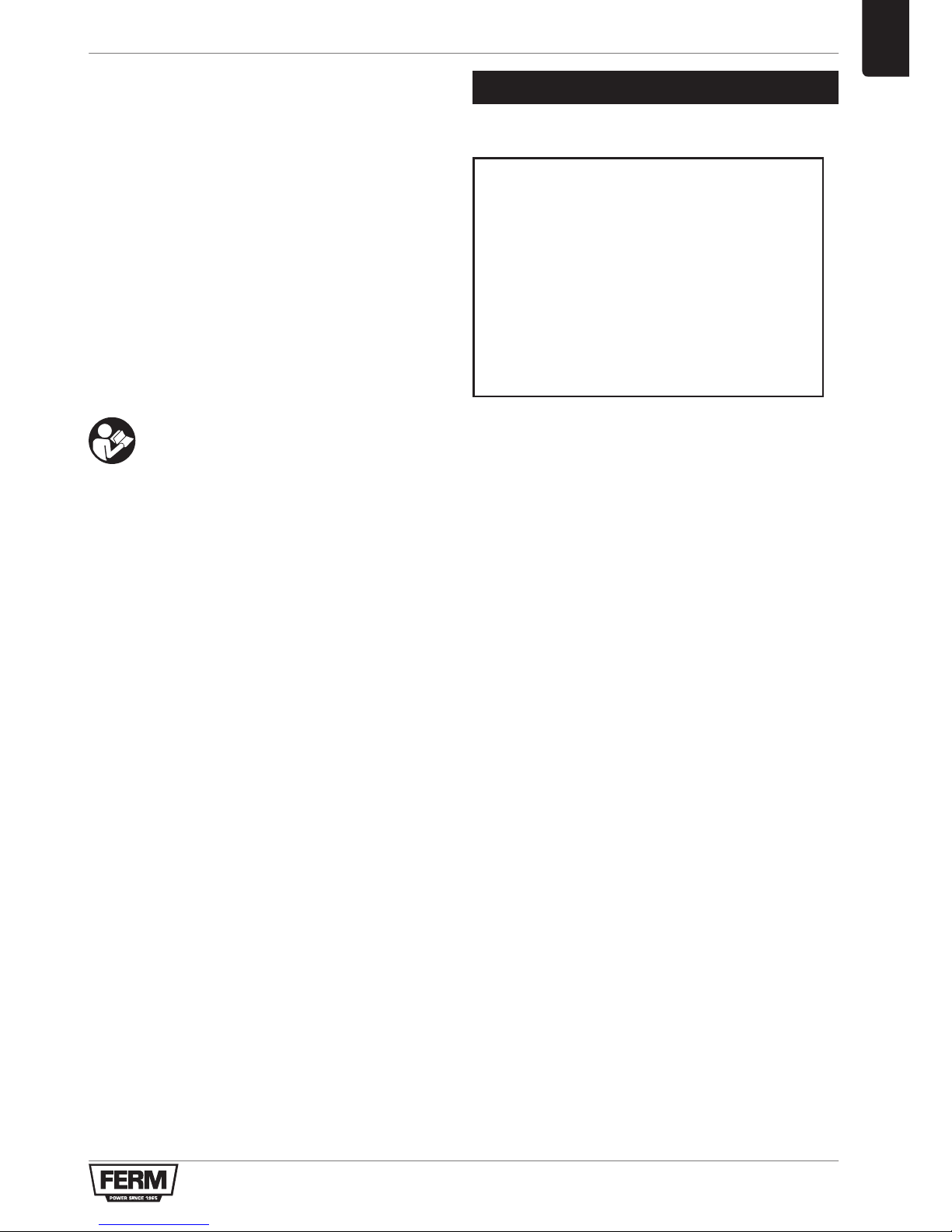

Fig. E & F

Usethedustadapterfortheextractionofdust.In

case the adapter is not mounted on the machine,

follow these instructions.

• Mountthedustadapter(24,Fig.E)withthe

screws (22) on the cutter sole (3).

• Placethedusttube(25)inthedustoutput(16

Fig. F).

• Placethetubeofyourvacuumcleaneronthe

dust tube (25, Fig. F).

Keep the outlet of the machine behind

the machine for a good view on the

workpiece.

• Toswitchonthetool,pressandholdtheon/off

switch (1, Fig. A1, page 2).

• Ifyoureleasetheon/offswitch(1,Fig.A1,

page 2), the tool will be switched off.

• Youcanlocktheon/offswitchbypressingthe

on/off switch (1, Fig. A1, page 2) and then

button (5, Fig. A1, page 2). The switch lock

canbereleasedbybrieypressingtheon/off

switch (1, Fig. A1, page 2).

• Donotputthemachinedownwhenthemotor

is still running. Do not place the machine on a

dusty surface. Dust particles may enter the

mechanism.

• Afterswitchingthemachineon,makesurethe

machine reaches full speed before using it on

the workpiece.

• Clamptheworkpieceandmakesurethatthe

workpiece cannot slide from under the

machine during the cutting activities.

• Holdthemachinermlyandmoveitevenly

over the workpiece. Do not force the machine.

• Onlyusecutterswhichdonotshowanysigns

of wear. Worn cutters have a negative effect

ontheefciencyofthemachine.

• Alwaysswitchoffthemachinerstbefore

removing the plug from the wall socket.

The required speed can be preselected with the

thumbwheel. Also during running the rotational

speed can be adjusted.

1 – 2 = low speed

3 – 4 = medium speed

5 – 6 = high speed

Max = maximum speed

The required speeds depends on the material and

can be determined by practical testing.

Furthermore router bits with a large diameter

need a lower rotational speed.