NOTICE!

Pay attention to compressed air quality.

Damage to property or loss of function from lubricated compressed air.

• Operate product only with unlubricated compressed air.

• Observe the requirements for compressed air quality èTechnical data.

7.2 Electrical installation

WARNING!

Risk of injury due to electric shock.

• For the electric power supply, use only PELV circuits that ensure a reliable

electric disconnection from the mains network.

• Observe IEC60204-1/EN60204-1.

1. Ground the shielding of the connecting cable on the cable end that is furthest

from the valve.

2. Install electrical connecting cables without squeezing, kinking or stretching.

3. Mount the earthing cable with self-tapping screw and toothed disc to the

earth connection of the valve.

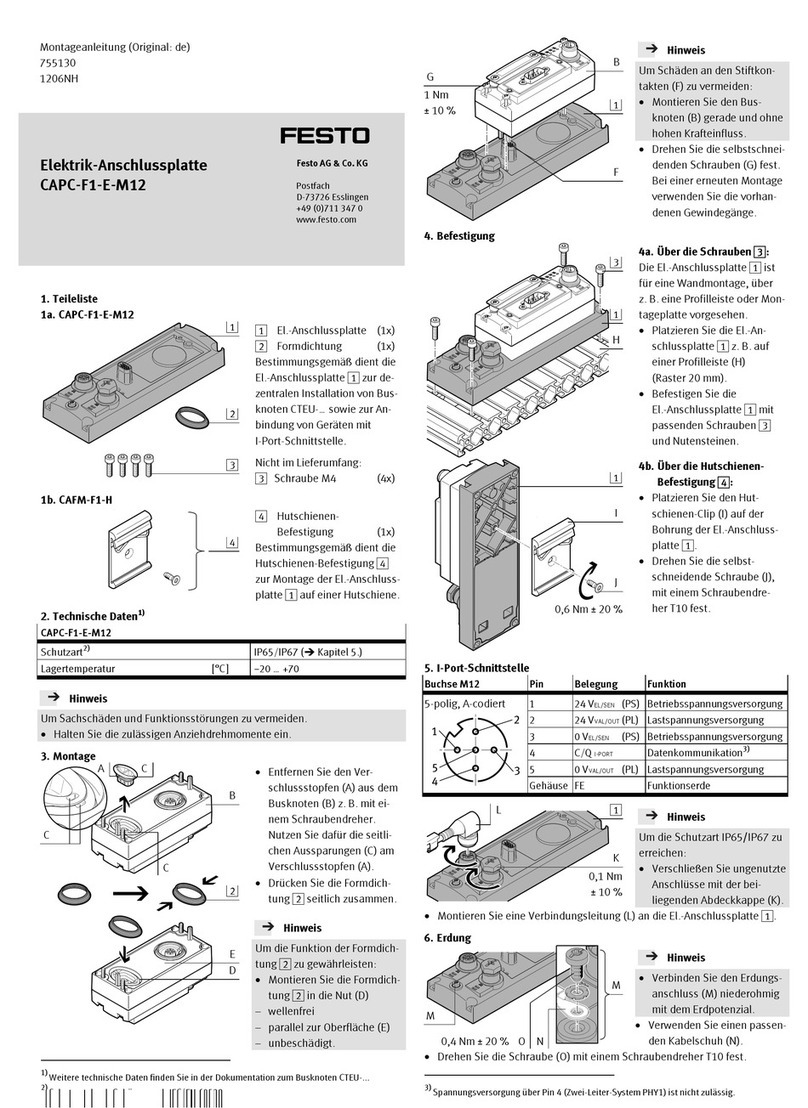

4. Screw the electrical connecting cable for CAN-BUS to the 5-pin M12 plug con-

nector. Tightening torque: £ 0.4Nm.

The maximum permitted length of the electrical connecting cable for the CAN-

BUS is 30m.

5. Remove cover cap and screw electrical connecting cable for the displacement

encoder system onto the 8-pin M12 socket. Tightening torque £ 0.4Nm.

The maximum permitted length of the electrical connecting cable for direct

connection with the displacement encoder system of the DNCI is 1.5m.

The maximum permitted length of the electrical connecting cable to the

sensor interface is 2m.

6. Connect the electrical connecting cable for non-return valve 1 and 2.

7. Connect the switching position sensing for non-return valve 1 and 2 (option-

al).

Connection Pin Function

1 Shield

2 24VDC

3 0VDC

4 CAN_H

5 CAN_L

Tab. 3 Pin allocation for plug M12, 5-pin

Connection Pin Function

1 5VDC

2 0VDC

3 Sin +

4 Sin –

5 Cos –

6 Cos +

7 Shield

8 Not connected

M12 Shield

Tab. 4 Pin allocation for socket M12, 8-pin

8 Commissioning

Requirements:

– The valve must be assembled.

– The pneumatic and electrical installation must be complete and checked.

1. Check the operating conditions and limit values èTechnical data.

2. Switch on the power supply.

3. Switch on the compressed air supply.

9 Cleaning

Clean the outside of the product with a soft cloth. Do not use aggressive cleaning

agents.

10 Malfunctions

10.1 Diagnostics via LEDs

LED Product desig-

nation

Meaning

LED1

(green)

Pwr/Err

LED2

(off)

Status

LED1 lights up green, LED2 is off:

– Supply voltage is connected

LED1

(green)

Pwr/Err

LED2

(red)

Status

LED1 lights up green, LED2 lights up red:

Error status

–Overvoltage, power supply >26.4VDC

– Coil temperature over 100°C

– Control deviation of the position controller too large

– Broken cable for displacement encoder system

LED1

(green)

Pwr/Err

LED2

(red)

Status

LED1 lights up green, LED2 flashes red:

Warning

– Supply voltage at the limit of permissible range

– Coil temperature over 80°C

LED1

(off)

Pwr/Err

LED2

(red)

Status

LED1 off, LED2 lights up red:

–Undervoltage, power supply<21.6VDC

Tab. 5 LED

10.2 Diagnostics via controller

The fault messages of the valve are sent to the higher-order controller (e.g. CECC-

D-BA).

10.3 Error status

The following valve errors lead to a switch-off in the power stage:

– Coil temperature too high

– Valve is jammed

– Hardware interface to the actuator is faulty

–Supply voltage is too low when switching on the valve (<18VDC)

When switching off the power stage, the valve has an undefined opening cross

section.

With all other errors, the valve is in the mid-position and pressure is constrained.

Communication and sensors remain active.

The pressure in the cylinder can be constrained by shutting off the two non-return

valves.

11 Conversion to direct pressure measurement on the cylinder

The mounting of the connection set for direct measurement of working pressure

on the cylinder is described in the instruction manual VABS-P15-S-B6.

12 Disassembly

1. Switch off operating voltage.

2. Switch off compressed air supply.

3. With a pin or screwdriver, press the manual ventilation and ventilate the sys-

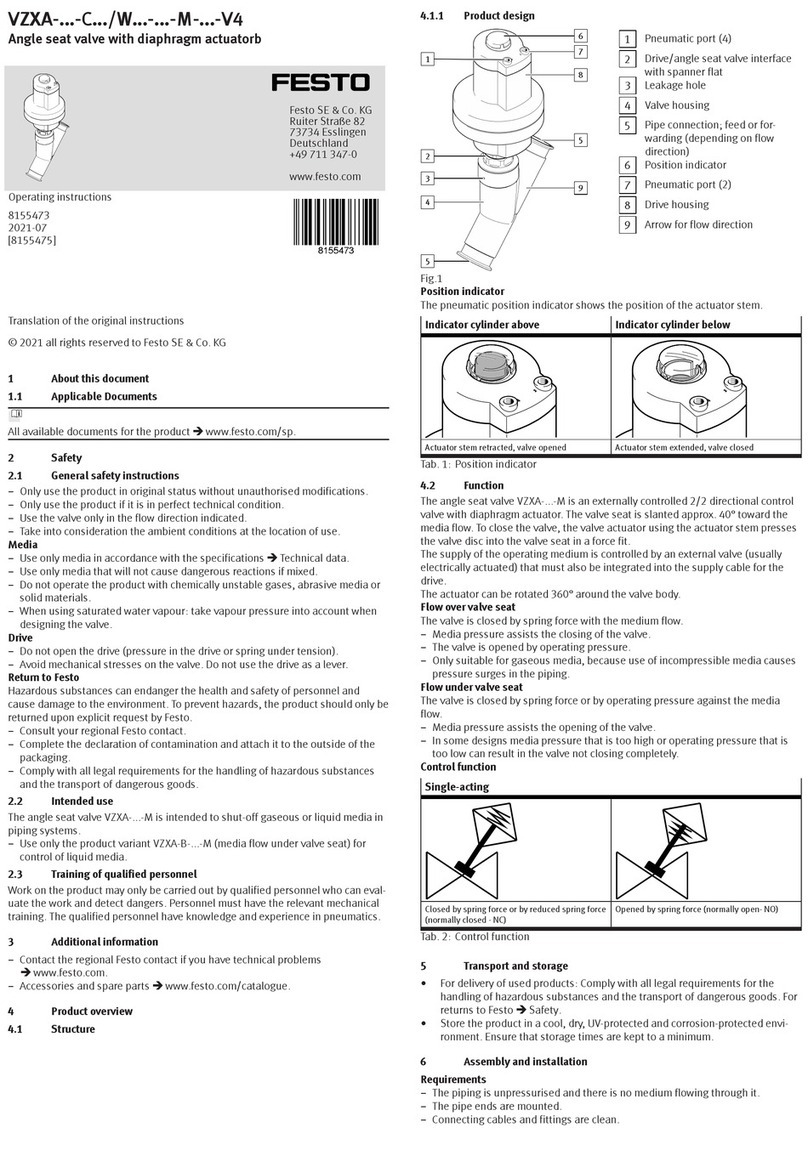

tem è Fig.1.

ÄThe air volume trapped in the cylinder and in the connecting cables is

exhausted.

4. Remove electrical connecting cables.

5. Remove compressed air lines.

6. Dismantle the product.

13 Disposal

ENVIRONMENT!

Send the packaging and product for environmentally sound recycling in accord-

ance with the current regulations èwww.festo.com/sp.

14 Technical data

Property Specification/value

Valve function 3/3-way proportional pressure regulator

Mounting position Any

Product weight [g] 1550

Dimensions

Width [mm] 78