Festo DMES User manual

Other Festo Industrial Equipment manuals

Festo

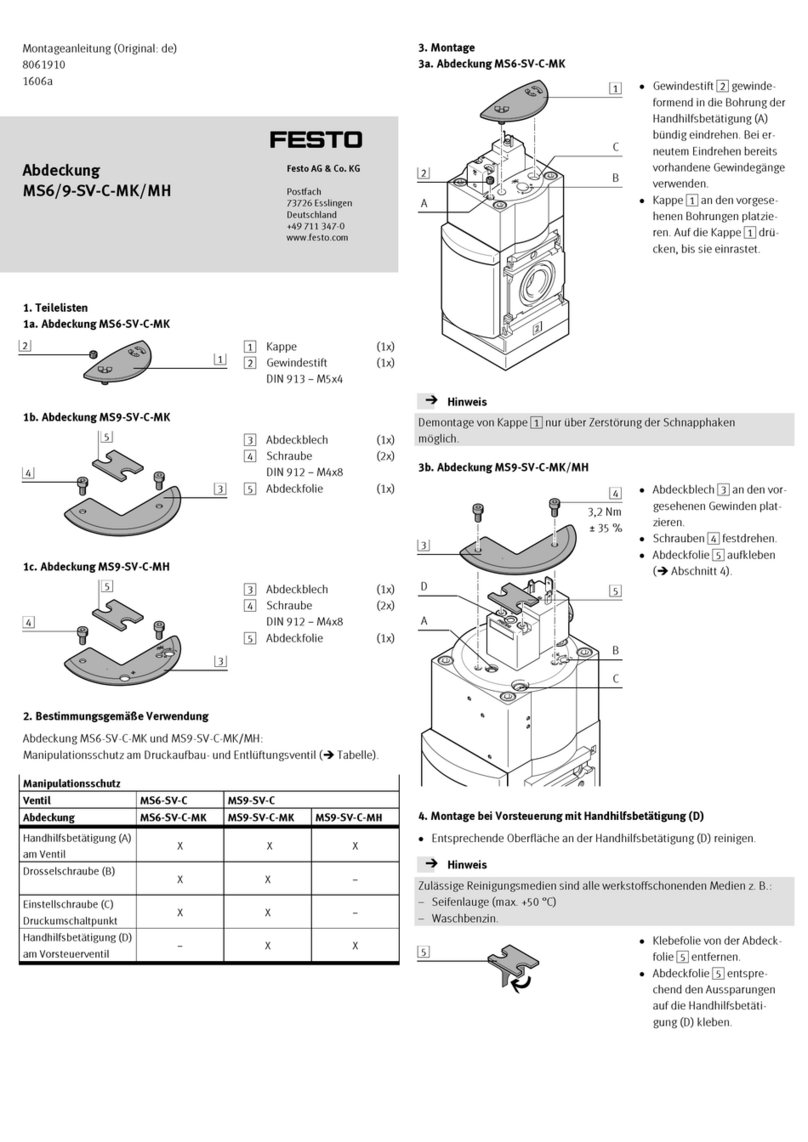

Festo MS6-SV-C-MK User manual

Festo

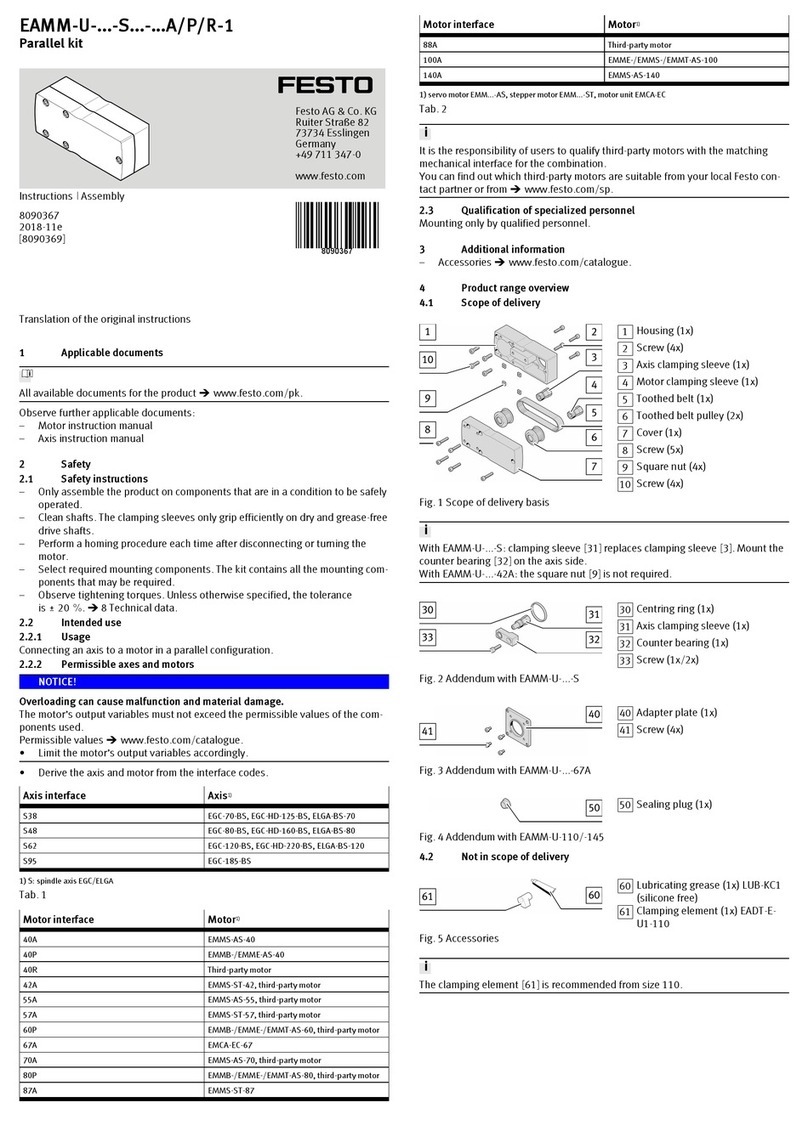

Festo EAMM-U-50-S38-40A Assembly instructions

Festo

Festo EXCM-30 -PF Series User manual

Festo

Festo ELGA-BS-KF-70 Setup guide

Festo

Festo Belt Drives 2 Instructions for use

Festo

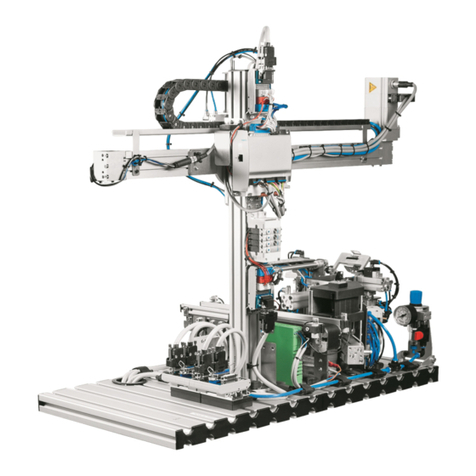

Festo MPS 8049013 Service manual

Festo

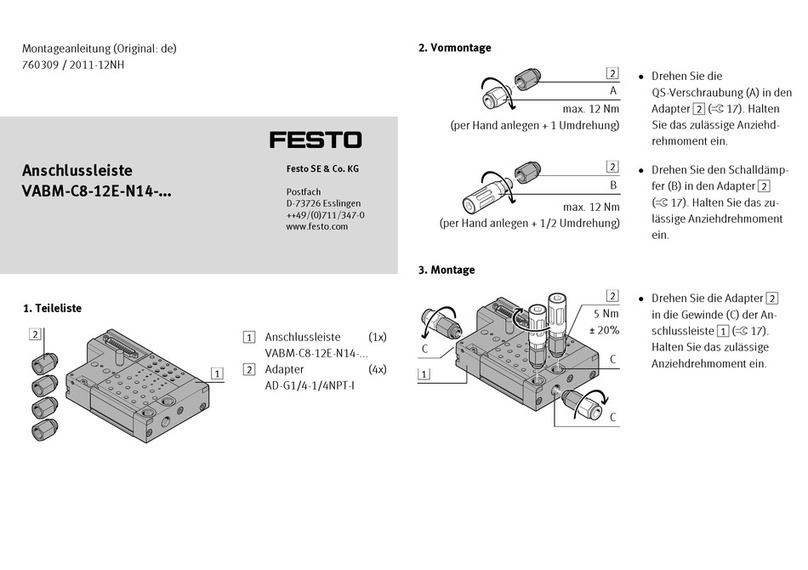

Festo VABM-C8-12E-N14 Series User manual

Festo

Festo MPS 8046521 User manual

Festo

Festo YJKP User manual

Festo

Festo Checkbox Compact CHB-C Series User manual

Festo

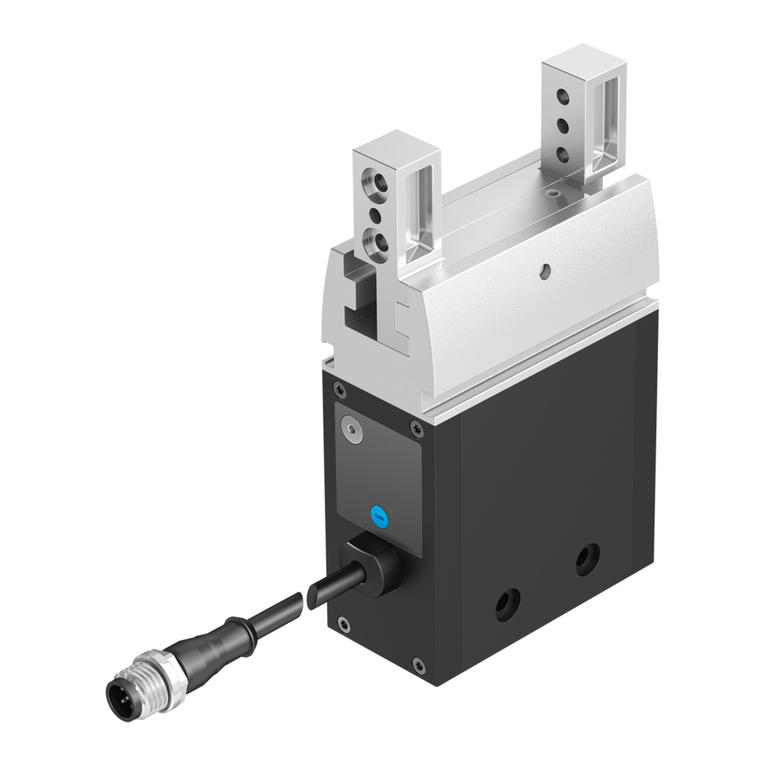

Festo EHPS User manual

Festo

Festo ELGT-BS User manual

Festo

Festo Checkbox Series User manual

Festo

Festo DG Series Parts list manual

Festo

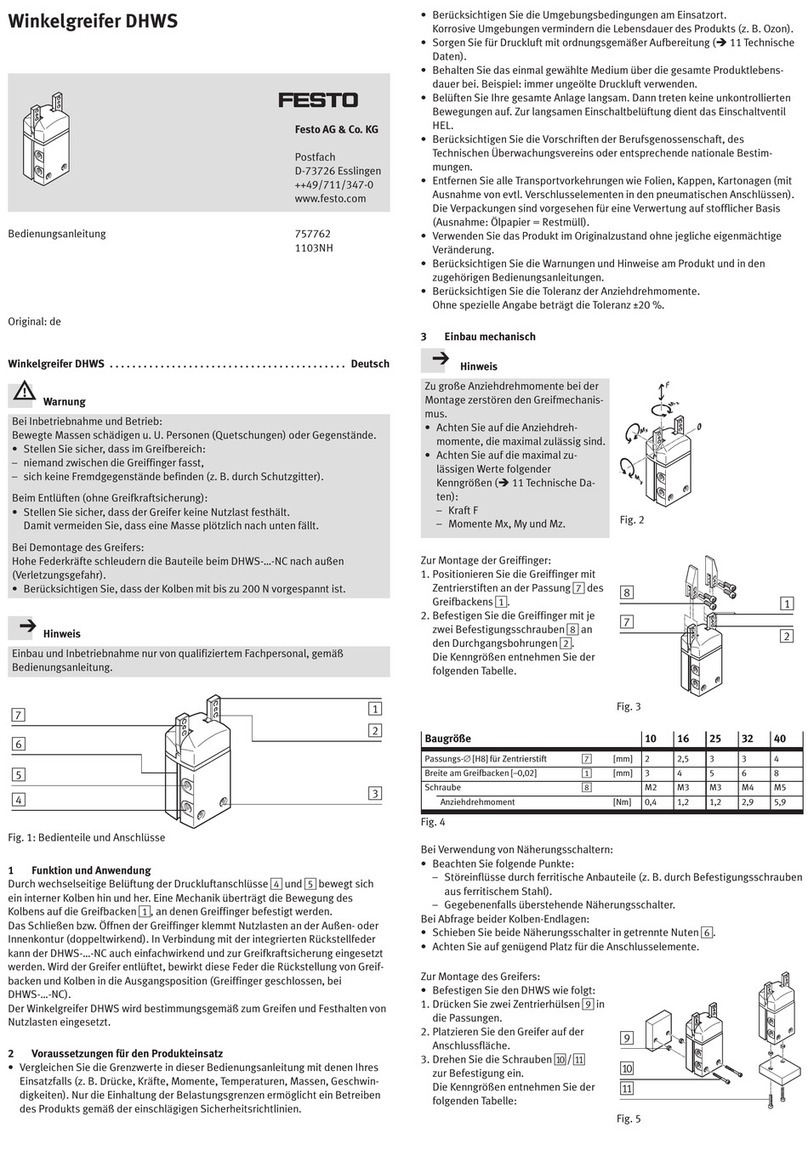

Festo DHWS User manual

Festo

Festo DHTG-***-P4 User manual

Festo

Festo CPX-F8DE-P User manual

Festo

Festo 586849 User manual

Festo

Festo DGEA Series User manual

Festo

Festo VABM-B10 EEE Series User manual